Starting a manufacturing company can yield a lot of money when you take the correct actions. The market for tissues has been growing consistently because of its wide use within offices, homes, and businesses. To start, you must research the market to find prospective customers and assess the demand. It is also essential to select the kind of tissue paper you'd like to create, like facial tissues, toilet paper, or napkins. After the market research has been completed, sign up your business, choose the right location, and then purchase the equipment you need, for example, a tissue paper machine. Work with suppliers of raw materials andand ensure that you adhere to the laws governing the paper business, including licensing and environmental regulations. Finally, it would help if you focused on marketing strategies that connect with your customers.

Tissue Paper Making: A Profitable Business Opportunity

Tissue paper making is one of the highest-paying possibilities for business in paper. Since it requires a low cost of entry and a huge demand, it's obtainable for many business owners. Its operating expenses are pretty low after manufacturing is set up. Tissue paper products are vital to our daily lives, and companies in this industry can expect constant expansion.

Understanding Tissue Paper Manufacturing: A Step-by-Step Guide

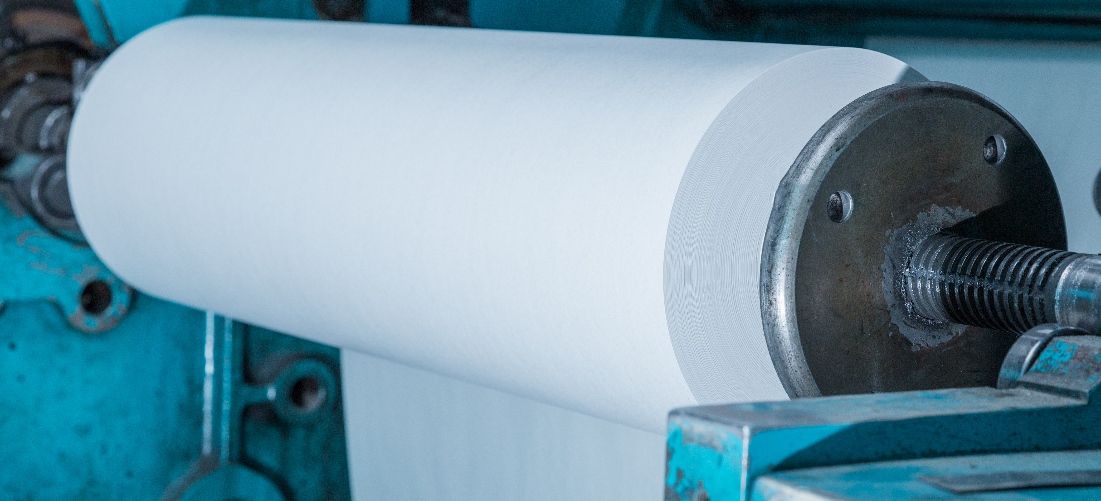

Tissue paper manufacturing involves several crucial stages:

- Pulping Raw materials like wood pulp are processed to create a fibrous substance.

- Pressing Pulp: The pulp is pressurized to eliminate excess water and shaped into thin sheets.

- Drying: The tissues are dried with massive drying equipment.

- Cutting and rolling: The dry tissue is cut into sheets or rolls according to the product's specifications.

- Packaging: The finished tissue paper is packed to ensure distribution.

Effective production is essential for maximizing profits, and having a high-quality machine will make a difference.

How to Find Tissue Manufacturers Near Me for Business Partnerships

Establishing relationships with local tissue producers can benefit particularly for sourcing supplies, distribution, or collaborations with businesses. Searching directories online or attending local business fairs and networking with professionals in the industry is possibley. Entrepreneurs located in India, specifically in Delhi firms such as ASVR Engineering, provide extensive solutions to the production of tissue papers. This includes equipment supply as well as ongoing assistance.

Tissue Paper Making Machine Price: What You Need to Know

The cost of manufacturing machines may vary according to the model and the capacity. The most straightforward machines could cost from Rs3 lakhs up to 10 lakhs for ,small-scale production, and advanced high-output models can range between Rs15 lakhs up to Rs50 lakhs. Some of the factors that influence price are the speed of production, levels of automation, and the efficiency of energy.

ASVR Engineering, based in Delhi, is a supplier of low-cost, high-quality manufacturing machines that can be adapted to businesses of different budgets and sizes.

Comparing Tissue Paper Making Machine Prices in India

In India, the tissue paper production machine costs differ depending on location, manufacturer as well as features of the machine. The northern regions, such as Delhi and its surrounding ,areas typically have competitive prices because of abundant manufacturing. It is recommended that the prices of several suppliers be evaluated and the machine's specifications examined. ASVR Engineering provides transparent and competitive pricing, providing equipment tailored explicitly to Indian manufacturing.

Exploring Tissue Paper Wholesale Price Trends

The wholesale prices of tissue paper can be affected by factors such as the cost of raw materials and demand and shipping. Prices generally drop when bulk orders are more significant. In India, the wholesale pricef tissue paper could range between Rs40 and Rs100 per kilogram. Knowing the trends in wholesale will help you design your sales and production strategies.

Starting a Tissue Paper Business: Key Considerations

If you are considering starting an enterprise in the field of tissue paper, be aware of these essential aspects:

- Market Demand: Define your market of choice (e.g., Hotels, retail, offices, etc.).

- Capital Investment: Calculate the amount of money needed to purchase machinery, raw materials, and labor.

- The location should be easily accessible to transport facilities and raw materials.

- Machinery Supplier: Work with a reliable company like ASVR Engineering for high-quality tissue maker machines.

- Marketing: Design an effective marketing strategy to reach the market effectively.

Tissue Paper Price Per Kg: How It Affects Your Profit Margins

The cost per kilogram of paper used for tissue is an essential element in determining your profits. In general, the price of making tissue paper can range from Rs30-R50 per kg, and the price at which it is sold ranges from Rs50 up to Rs120 based on the type and quality. Effectively managing your production costs, which, including machinery and expenses, can allow you profitable margins.

Tissue Paper Production: The Manufacturing Process

Making tissue paper transforms pulp into thin, soft pieces of paper. It is simple but demands accuracy. It begins with making the pulp by making thin layering, then drying it before cutting it into the size you want. The high-end machinery ensures the paper is flexible, absorbent, and long-lasting.

ASVR Engineering provides state-of-the-art machines that simplify the entire manufacturing process to ensure high quality and efficiency.

Tissue Paper Making Machine Price in Delhi: A Comprehensive Guide

In Delhi, the, prices of machines for making tissue paper range between Rs5 lakhs and 40 lakhs, based on the machine's capabilities,,, speed, and other attributes. ASVR Engineering, a Delhi-based producer, has a wide range of equipment designed to satisfy the demands of different paper companies, offering the best prices and quality control.

Tissue Paper Manufacturing Plant Cost Breakdown

The price to establish the tissue paper production plant is comprised of:

- Machinery: Rs5 lakhs to 40 lakhs

- Raw Materials: The initial cost between Rs2 lakhs and ten lakhs

- Utilities and Labor Cost: Between Rs50,000 and Rs1 Lakh each month

- Other overheads include rent packaging, rent, and marketing expenses

Tissue Paper Factory Cost: Initial Investment and Expenses

The establishment of a tissue paper production facility will require an initial capital investment of:

- Machinery

- Raw materials (wood pulp or recycled paper)

- Equipment and space for the factory

- Labor

- Materials for packaging

Small-scale factories can begin with a capital investment of 10 lakhs up to Rs20 lakhs; however, more extensive facilities could need at least Rs50 lakhs.Small-scale factories can begin with a capital investment of 10 lakhs up to Rs20 lakhs; however, more extensive facilities could need at least Rs50 lakhs.

The Complete Tissue Paper Production Process Explained

The manufacturing process consists of:

- The preparation of basic materials

- Refining and pulping

- Then, drying and pressing the paper

- Cutting or rolling into sheets

- Packaging for distribution

Every step is essential to keeping the high standard of the item.

How to Make Tissue Paper: A DIY Guide for Beginners

If you're interested in making tissue paper in a smaller size, it could be made with the help of simple methods. The materials you'll require are wood pulp water and essential tools to dry, press, and then cut the sheets. To produce large quantities of industrial equipment, it is needed to meet the quantity and requirements for quality

Tissue Paper Manufacturing Unit Cost: Calculating Your Expenses

The expense of setting up a paper production unit is contingent upon elements like the type of machinery, raw materials, labor,, and the cost of utilities. A moderate-sized business requires between around Rs20 to 40 lakhs as capital. A reliable equipment company such as ASVR Engineering can help keep the costs in check and increase your production's effectiveness.

Paper Manufacturing Business: How Tissue Paper Fits In

The manufacturing of paper is vast, with tissue paper being one of the niches that will continue to expand because of the increasing consumer demand for hygienic products. Business owners can venture into this sector with a relatively small investment compared with other products made of paper, and demand for the product ensures constant business expansion.

Tissue Paper Making Machine Price: What to Look For in Your Purchase

When you purchase a tissue paper maker, be sure to look at:

Capacity: Be sure that the machine can goalscan meet your production goals.

Durability: Premium materials cut the cost of maintenance.

Efficiency: Energy-efficient machines lower operating expenses.

After-Sales Service: Join forces with a provider such as ASVR Engineering that offers reliable support throughout India.

How to Start a Tissue Paper Manufacturing Business

Starting a manufacturing company can yield a lot of money when you take the correct actions. The market for tissues has been growing consistently because of its wide use within offices, homes, and businesses. To start, you must research the market to find prospective customers and assess the demand. It is also essential to select the kind of tissue paper you'd like to create, like facial tissues, toilet paper, or napkins. After the market research has been completed, sign up your business, choose the right location, and then purchase the equipment you need, for example, a tissue paper machine. Work with suppliers of raw materials andand ensure that you adhere to the laws governing the paper business, including licensing and environmental regulations. Finally, it would help if you focused on marketing strategies that connect with your customers.

Tissue Paper Making: A Profitable Business Opportunity

Tissue paper making is one of the highest-paying possibilities for business in paper. Since it requires a low cost of entry and a huge demand, it's obtainable for many business owners. Its operating expenses are pretty low after manufacturing is set up. Tissue paper products are vital to our daily lives, and companies in this industry can expect constant expansion.

Understanding Tissue Paper Manufacturing: A Step-by-Step Guide

Tissue paper manufacturing involves several crucial stages:

- Pulping Raw materials like wood pulp are processed to create a fibrous substance.

- Pressing Pulp: The pulp is pressurized to eliminate excess water and shaped into thin sheets.

- Drying: The tissues are dried with massive drying equipment.

- Cutting and rolling: The dry tissue is cut into sheets or rolls according to the product's specifications.

- Packaging: The finished tissue paper is packed to ensure distribution.

Effective production is essential for maximizing profits, and having a high-quality machine will make a difference.

How to Find Tissue Manufacturers Near Me for Business Partnerships

Establishing relationships with local tissue producers can benefit particularly for sourcing supplies, distribution, or collaborations with businesses. Searching directories online or attending local business fairs and networking with professionals in the industry is possibley. Entrepreneurs located in India, specifically in Delhi firms such as ASVR Engineering, provide extensive solutions to the production of tissue papers. This includes equipment supply as well as ongoing assistance.

Tissue Paper Making Machine Price: What You Need to Know

The cost of manufacturing machines may vary according to the model and the capacity. The most straightforward machines could cost from Rs3 lakhs up to 10 lakhs for ,small-scale production, and advanced high-output models can range between Rs15 lakhs up to Rs50 lakhs. Some of the factors that influence price are the speed of production, levels of automation, and the efficiency of energy.

ASVR Engineering, based in Delhi, is a supplier of low-cost, high-quality manufacturing machines that can be adapted to businesses of different budgets and sizes.

Comparing Tissue Paper Making Machine Prices in India

In India, the tissue paper production machine costs differ depending on location, manufacturer as well as features of the machine. The northern regions, such as Delhi and its surrounding ,areas typically have competitive prices because of abundant manufacturing. It is recommended that the prices of several suppliers be evaluated and the machine's specifications examined. ASVR Engineering provides transparent and competitive pricing, providing equipment tailored explicitly to Indian manufacturing.

Exploring Tissue Paper Wholesale Price Trends

The wholesale prices of tissue paper can be affected by factors such as the cost of raw materials and demand and shipping. Prices generally drop when bulk orders are more significant. In India, the wholesale pricef tissue paper could range between Rs40 and Rs100 per kilogram. Knowing the trends in wholesale will help you design your sales and production strategies.

Starting a Tissue Paper Business: Key Considerations

If you are considering starting an enterprise in the field of tissue paper, be aware of these essential aspects:

Market Demand: Define your market of choice (e.g., Hotels, retail, offices, etc.).

Capital Investment: Calculate the amount of money needed to purchase machinery, raw materials, and labor.

The location should be easily accessible to transport facilities and raw materials.

Machinery Supplier: Work with a reliable company like ASVR Engineering for high-quality tissue maker machines

Marketing: Design an effective marketing strategy to reach the market effectively.

Tissue Paper Price Per Kg: How It Affects Your Profit Margins

The cost per kilogram of paper used for tissue is an essential element in determining your profits. In general, the price of making tissue paper can range from Rs30-R50 per kg, and the price at which it is sold ranges from Rs50 up to Rs120 based on the type and quality. Effectively managing your production costs, which, including machinery and expenses, can allow you profitable margins.

Tissue Paper Production: The Manufacturing Process

Making tissue paper transforms pulp into thin, soft pieces of paper. It is simple but demands accuracy. It begins with making the pulp by making thin layering, then drying it before cutting it into the size you want. The high-end machinery ensures the paper is flexible, absorbent, and long-lasting.

ASVR Engineering provides state-of-the-art machines that simplify the entire manufacturing process to ensure high quality and efficiency.

Tissue Paper Making Machine Price in Delhi: A Comprehensive Guide

In Delhi, the, prices of machines for making tissue paper range between Rs5 lakhs and 40 lakhs, based on the machine's capabilities,,, speed, and other attributes. ASVR Engineering, a Delhi-based producer, has a wide range of equipment designed to satisfy the demands of different paper companies, offering the best prices and quality control.

Tissue Paper Manufacturing Plant Cost Breakdown

The price to establish the tissue paper production plant is comprised of:

Machinery: Rs5 lakhs to 40 lakhs

Raw Materials: The initial cost between Rs2 lakhs and ten lakhs

Utilities and Labor Cost: Between Rs50,000 and Rs1 Lakh each month

Other overheads include rent packaging, rent, and marketing expenses

Tissue Paper Factory Cost: Initial Investment and Expenses

The establishment of a tissue paper production facility will require an initial capital investment of:

- Machinery

- Raw materials (wood pulp or recycled paper)

- Equipment and space for the factory

- Labor

- Materials for packaging

Small-scale factories can begin with a capital investment of between 10 lakhs up to Rs20 lakhs; however, more extensive facilities could need at least Rs50 lakhs.

The Complete Tissue Paper Production Process Explained

The manufacturing process consists of:

- The preparation of basic materials

- Refining and pulping

- Then, drying and pressing the paper

- Cutting or rolling into sheets

- Packaging for distribution

Every step is essential to keeping the high standard of the item.

How to Make Tissue Paper: A DIY Guide for Beginners

If you're interested in making tissue paper in a smaller size, it could be made with the help of simple methods. The materials you'll require are wood pulp water and essential tools to dry, press, and then cut the sheets. To produce large quantities of industrial equipment, it is needed to meet the quantity and requirements for quality.

Tissue Paper Manufacturing Unit Cost: Calculating Your Expenses

The expense of setting up a paper production unit is contingent upon elements like the type of machinery, raw materials, labor,, and the cost of utilities. A moderate-sized business requires between around Rs20 to 40 lakhs as capital. A reliable equipment company such as ASVR Engineering can help keep the costs in check and increase your production's effectiveness.

Paper Manufacturing Business: How Tissue Paper Fits In

The manufacturing of paper is vast, with tissue paper being one of the niches that will continue to expand because of the increasing consumer demand for hygienic products. Business owners can venture into this sector with a relatively small investment compared with other products made of paper, and demand for the product ensures constant business expansion.

Tissue Paper Making Machine Price: What to Look For in Your Purchase

When you purchase a tissue paper maker, be sure to look at:

Capacity: Be sure that the machine goalscan meet your production goals.

Durability: Premium materials cut the cost of maintenance.

Efficiency: Energy-efficient machines lower operating expenses.

After-Sales Service: Join forces with a provider such as ASVR Engineering that offers reliable support throughout India.

How To Start Agarbatti Making Business

Agarbatti, also known as incense sticks, is widely used for religious and spiritual purposes, as well as for creating a pleasant aroma in homes and offices. With the increasing demand for agarbatti, starting a business in this industry can be a lucrative venture.

Continue Reading

Paper Plate Making Business Cost

Starting a paper plate making business can be a rewarding entrepreneurial journey. With the growing demand for eco-friendly alternatives and the simplicity of the manufacturing process, this business offers an excellent opportunity for success.

Continue Reading