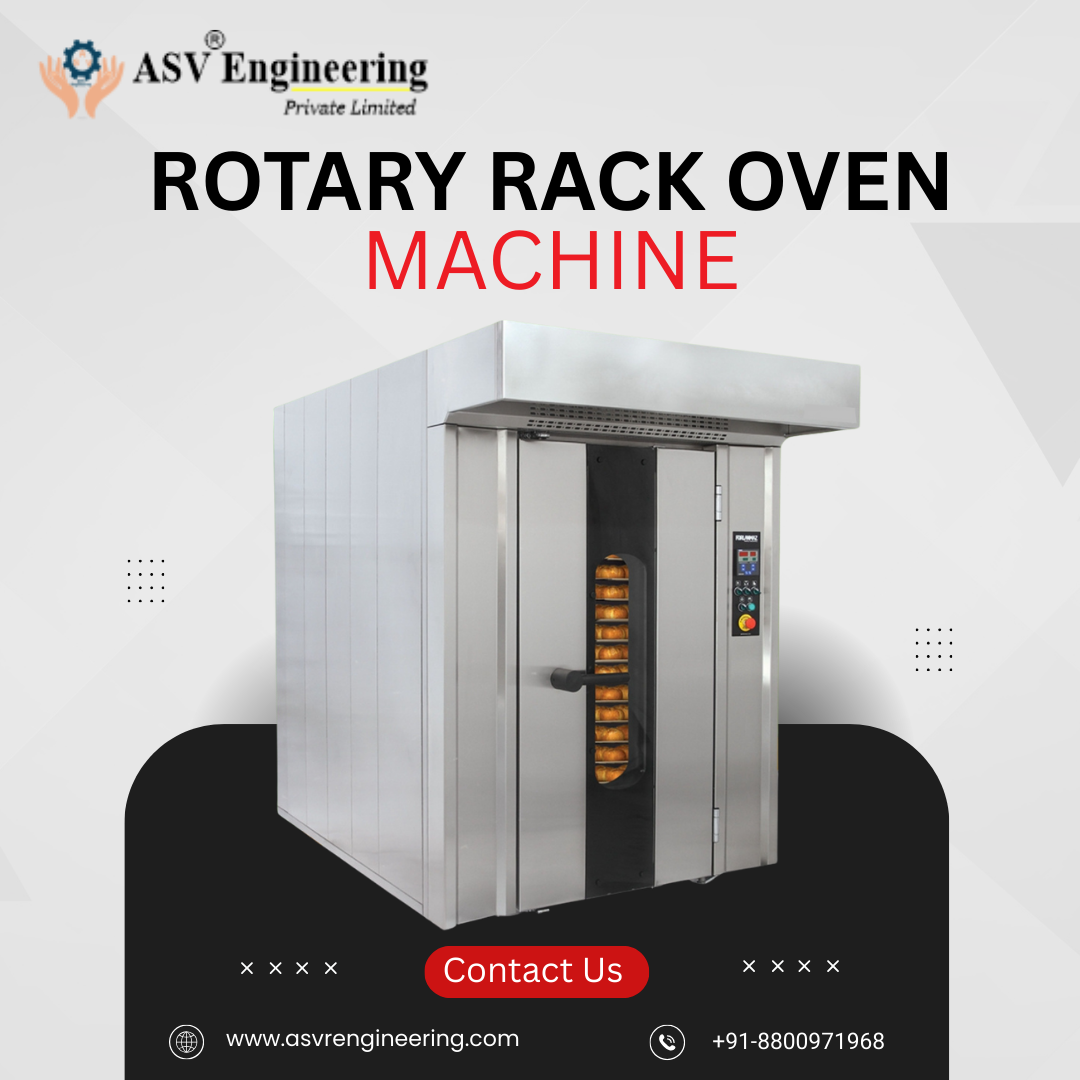

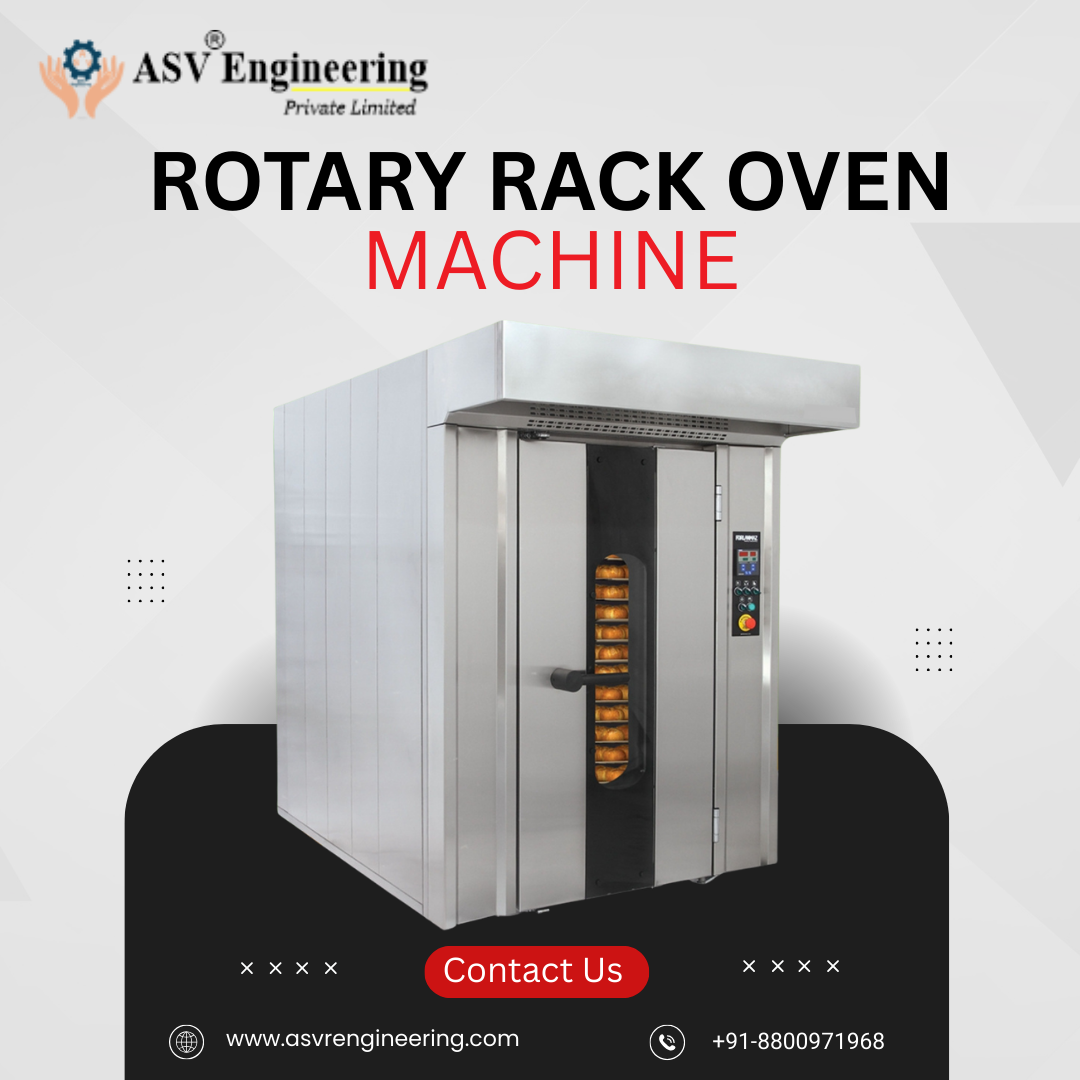

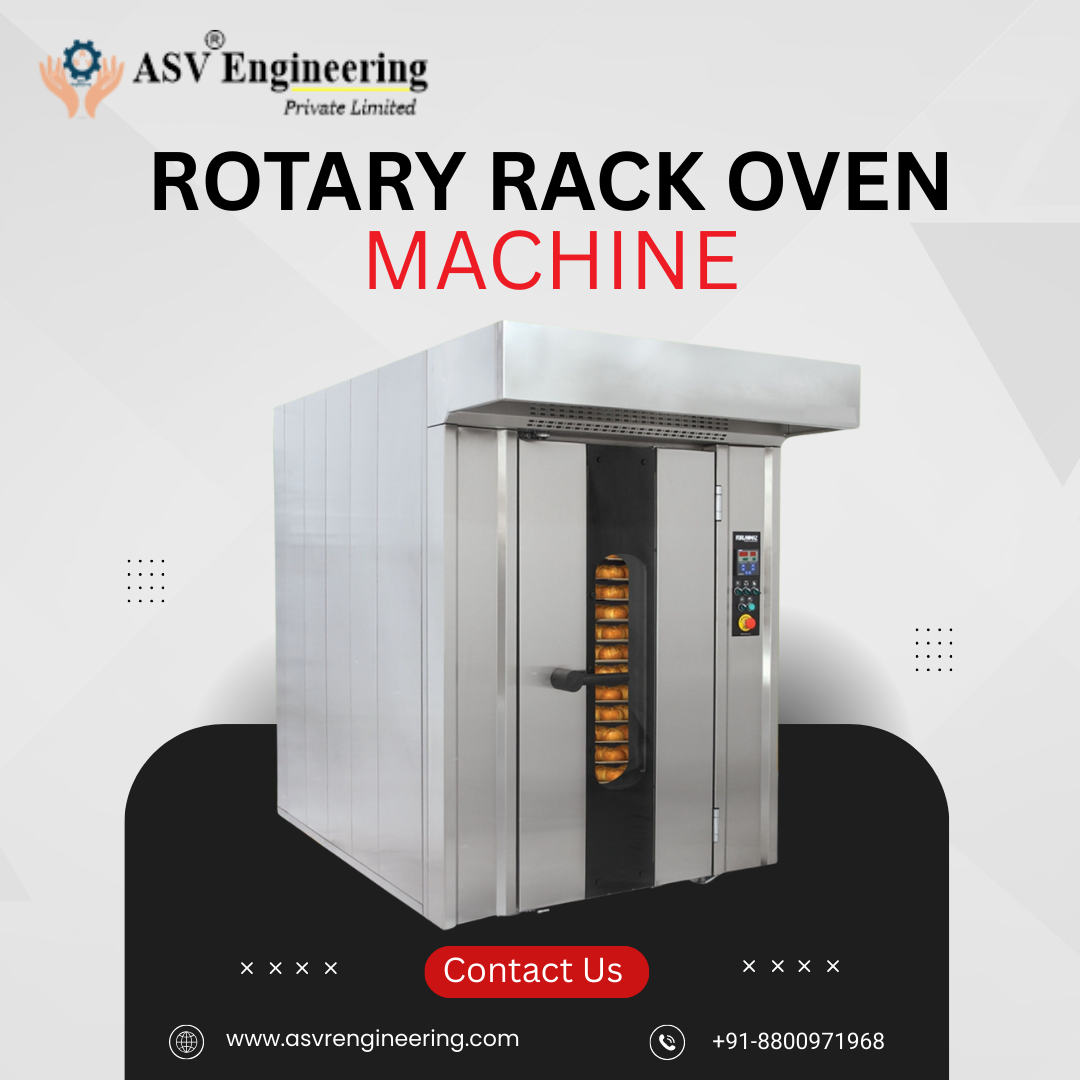

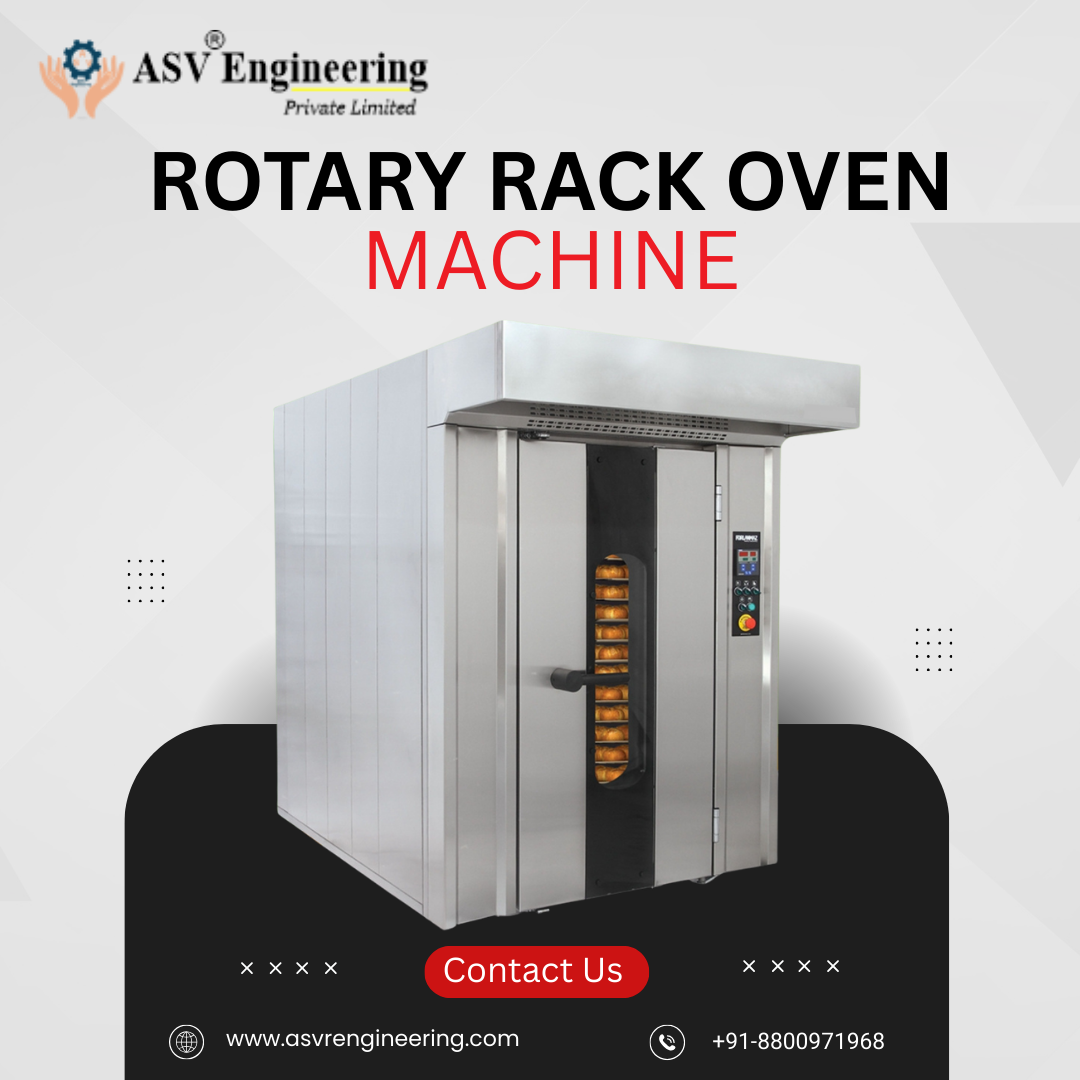

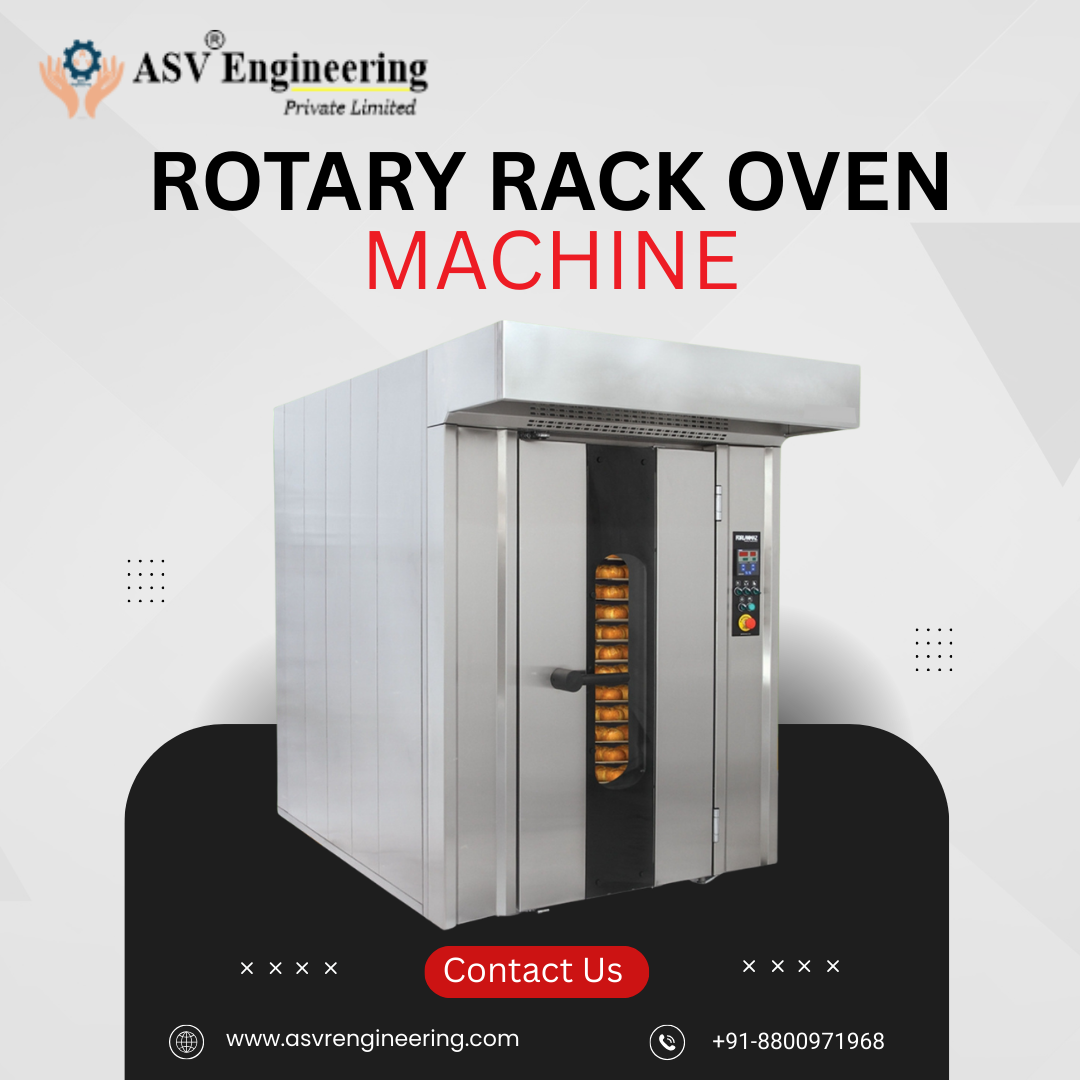

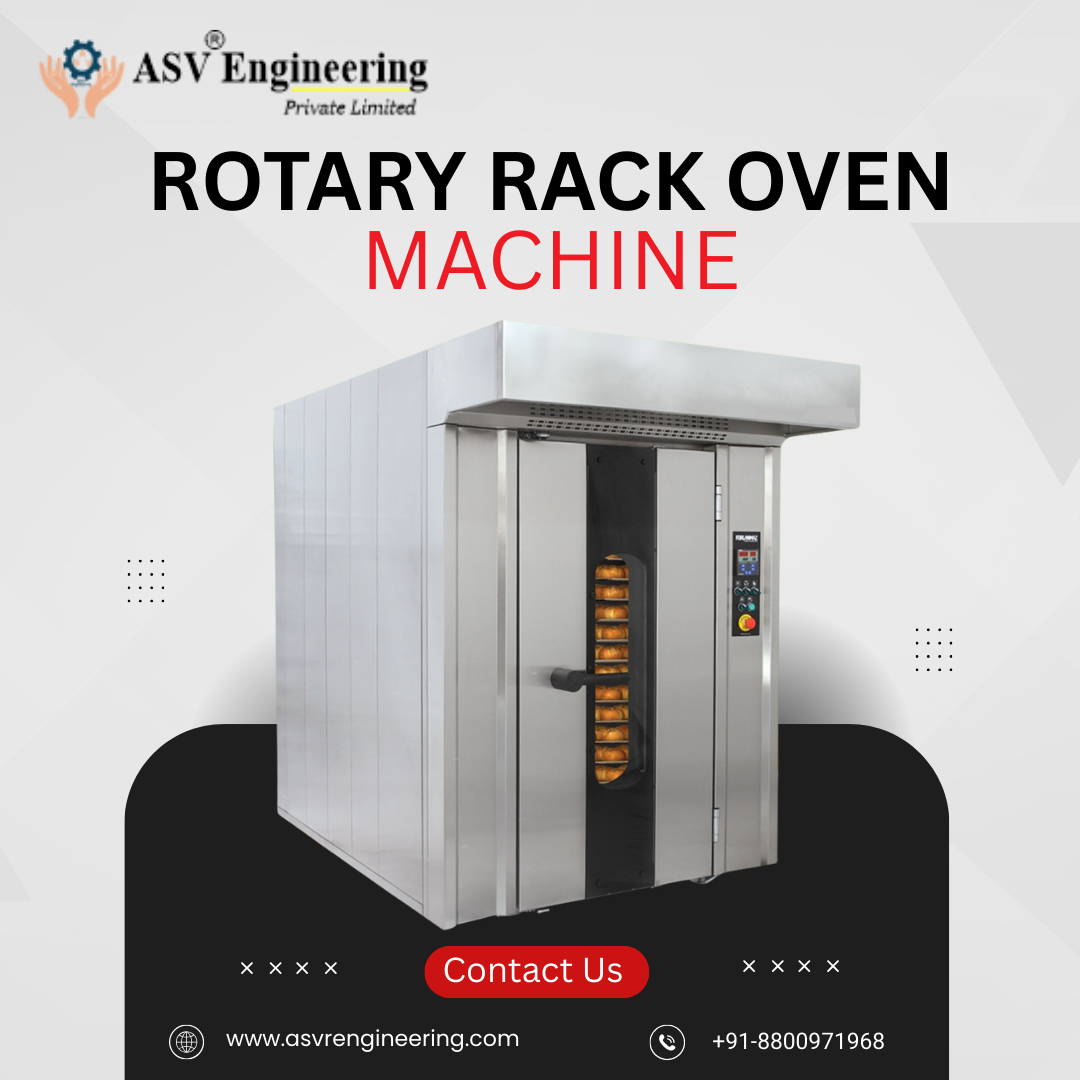

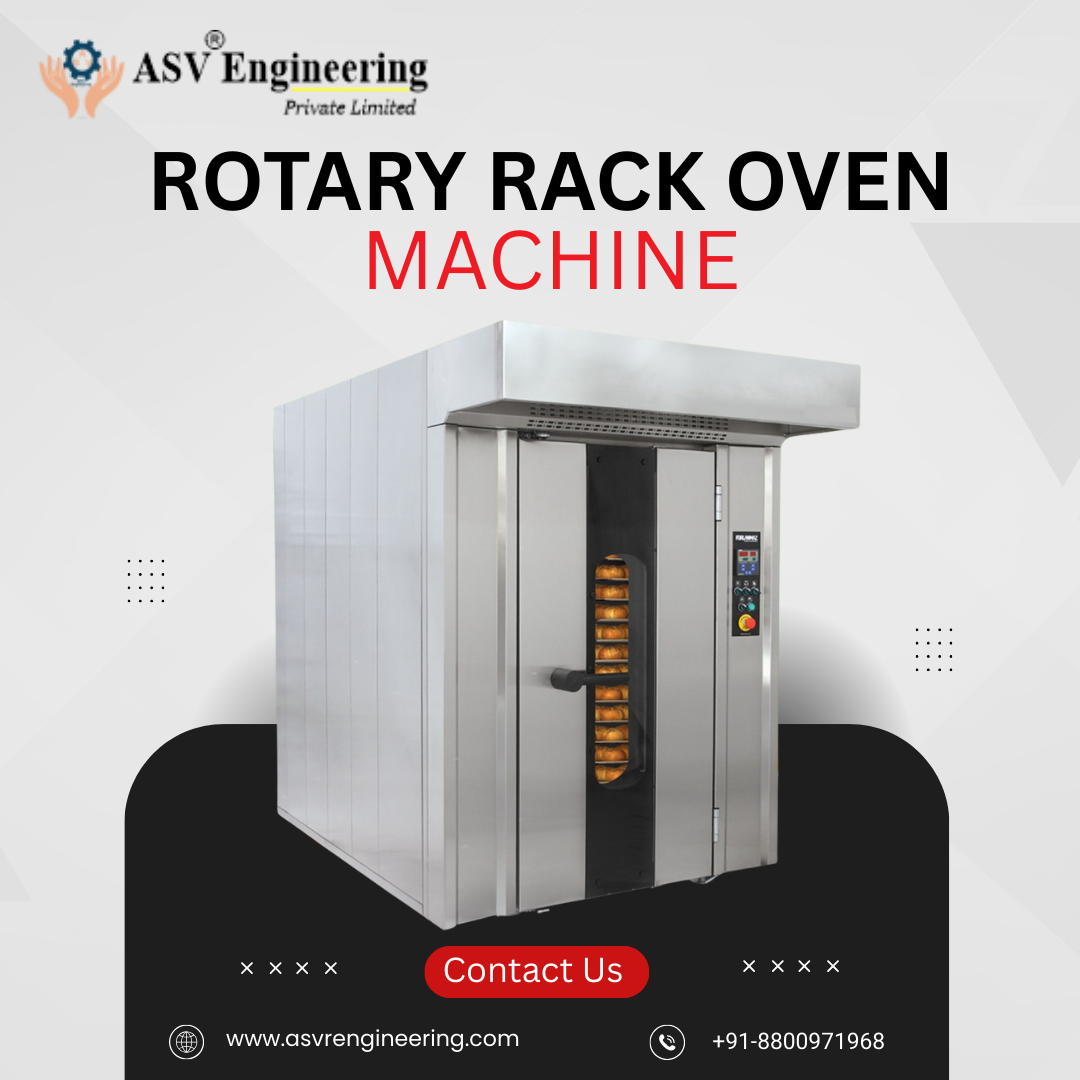

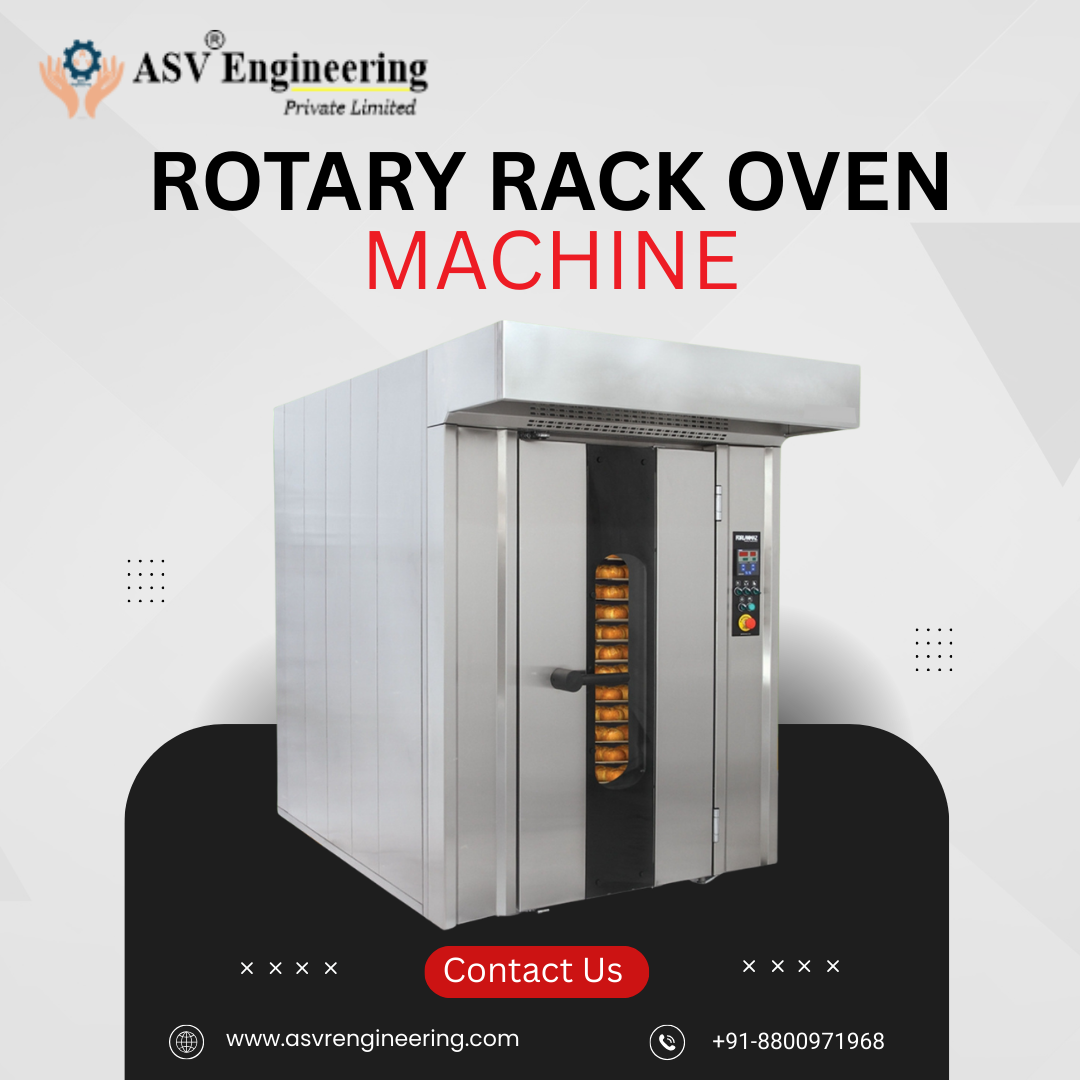

Rotary Rack Oven Machine

Price: ₹306000

In today’s fast-growing food and bakery industry, consistency, speed, and quality are the key pillars of success. Whether it is a medium-scale bakery, a large industrial unit, or a hotel kitchen catering to hundreds of customers daily, the baking equipment used plays a critical role in defining the final product. Among all commercial baking solutions, the Rotary Rack Oven Machine stands out as one of the most efficient, reliable, and versatile ovens available in the market.

A rotary rack oven is specially designed to deliver uniform baking results, even at high production volumes. Its advanced rotation mechanism ensures that every tray receives equal heat exposure, eliminating uneven baking, undercooked corners, or over-browned surfaces. This makes it a preferred choice for bakers who aim to maintain product quality batch after batch.

What is a Rotary Rack Oven Machine?

A rotary rack oven machine is a heavy-duty commercial baking oven where the entire rack rotates slowly inside the baking chamber. Unlike traditional deck ovens where trays remain stationary, this rotation allows hot air to circulate evenly around the products. As a result, bread, biscuits, cookies, cakes, buns, and other baked items are baked uniformly from all sides.

These ovens are engineered to handle large loads, making them ideal for high-output bakeries and food production units. With robust construction, precise temperature control, and efficient fuel usage, rotary rack ovens have become a backbone of modern baking operations.

Why Rotary Rack Ovens are Essential for Commercial Bakeries

1. Uniform Baking Quality

One of the biggest challenges in commercial baking is maintaining consistency. A rotary rack oven solves this problem effectively. The rotating rack combined with controlled airflow ensures that every tray receives the same amount of heat, resulting in perfectly baked products every time.

2. High Production Capacity

Rotary rack ovens are built for volume. They can accommodate multiple trays in a single batch, significantly increasing production capacity without compromising quality. This makes them ideal for bakeries supplying to retailers, hotels, and distributors.

3. Energy Efficiency

Modern rotary rack oven machines are designed to minimize heat loss and optimize fuel consumption. Whether operated on electricity, diesel, or gas, these ovens ensure maximum output with reduced operating costs, making them economical in the long run.

4. Versatility in Baking

From soft bread loaves and crispy biscuits to cakes and savory items, rotary rack ovens can handle a wide range of bakery products. Adjustable temperature and baking time settings allow bakers to switch between products with ease.

5. Durable and Hygienic Design

Manufactured using high-grade stainless steel, rotary rack ovens are resistant to corrosion, easy to clean, and suitable for food-grade environments. Their strong structure ensures long service life even under continuous operation.

Working Principle of a Rotary Rack Oven

The working mechanism of a rotary rack oven is both simple and highly effective. Once the loaded rack is placed inside the oven chamber, it is connected to a rotating mechanism. When the oven starts, hot air is generated through electric heaters or burners. This hot air circulates evenly inside the chamber while the rack rotates slowly.

The combination of airflow and rotation ensures that heat is distributed uniformly across all trays. Temperature and humidity can be controlled precisely, allowing bakers to achieve the desired crust, texture, and color for different products.

Types of Rotary Rack Oven Machines

Electric Rotary Rack Oven

Electric rotary rack ovens are preferred in locations where electricity is stable and easily available. They provide precise temperature control, low emissions, and clean operation, making them suitable for urban bakeries and food labs.

Gas-Fired Rotary Rack Oven

Gas rotary rack ovens are known for faster heating and lower running costs in areas where gas supply is economical. They are widely used in large bakeries due to their efficiency and high output.

Diesel-Based Rotary Rack Oven

Diesel rotary rack ovens are commonly used in regions with limited gas availability. They offer reliable performance and are cost-effective for continuous baking operations.

Applications of Rotary Rack Oven Machine

Rotary rack ovens are used across a wide range of food processing and baking applications, including:

-

Commercial bakeries

-

Industrial bread manufacturing units

-

Biscuit and cookie production

-

Cake and pastry shops

-

Hotel and restaurant kitchens

-

Food processing industries

-

Institutional kitchens and catering units

Their adaptability makes them suitable for both small-scale and large-scale operations.

Advantages Over Conventional Baking Ovens

Compared to conventional deck ovens or trolley ovens, rotary rack ovens offer several advantages:

-

Faster baking cycles

-

Consistent product quality

-

Reduced manpower requirement

-

Lower fuel and energy consumption

-

Ability to handle bulk production

-

Easy operation and maintenance

These benefits directly translate into higher productivity and better profitability for bakery owners.

Factors to Consider Before Buying a Rotary Rack Oven

When investing in a rotary rack oven machine, it is important to consider the following factors:

-

Production capacity requirement

-

Available space in the bakery

-

Type of fuel preferred (electric, gas, diesel)

-

Power consumption and operating cost

-

Ease of maintenance and service support

-

Quality of materials and safety features

Choosing the right oven based on your production needs ensures long-term efficiency and smooth operations.

Why Choose ASVR Engineering for Rotary Rack Oven Machines?

ASVR Engineering is committed to delivering high-quality bakery machinery that meets the evolving demands of the food industry. Their rotary rack oven machines are designed with precision engineering, robust construction, and user-friendly controls to support both growing and established bakeries.

With a focus on performance, durability, and customer satisfaction, ASVR Engineering ensures that every machine undergoes strict quality checks before delivery. Their solutions are trusted by bakery owners who value reliability and consistent output.

Maintenance and Long-Term Performance

Proper maintenance is essential to ensure the long life of a rotary rack oven. Regular cleaning of the baking chamber, timely inspection of burners or heating elements, and proper lubrication of moving parts help maintain peak performance. With basic care, a well-built rotary rack oven can serve efficiently for many years.

Conclusion

The Rotary Rack Oven Machine is an indispensable asset for any commercial bakery aiming for high production, consistent quality, and operational efficiency. Its advanced baking mechanism, energy-efficient design, and versatility make it a smart investment for modern food businesses.

If you are planning to upgrade your bakery or start a new venture, choosing a reliable rotary rack oven can set the foundation for long-term success.

📞 Contact Numbers: +91-8076004849, +91-8800971968

🌐 Website: https://www.asvrengineering.com

Buy Now