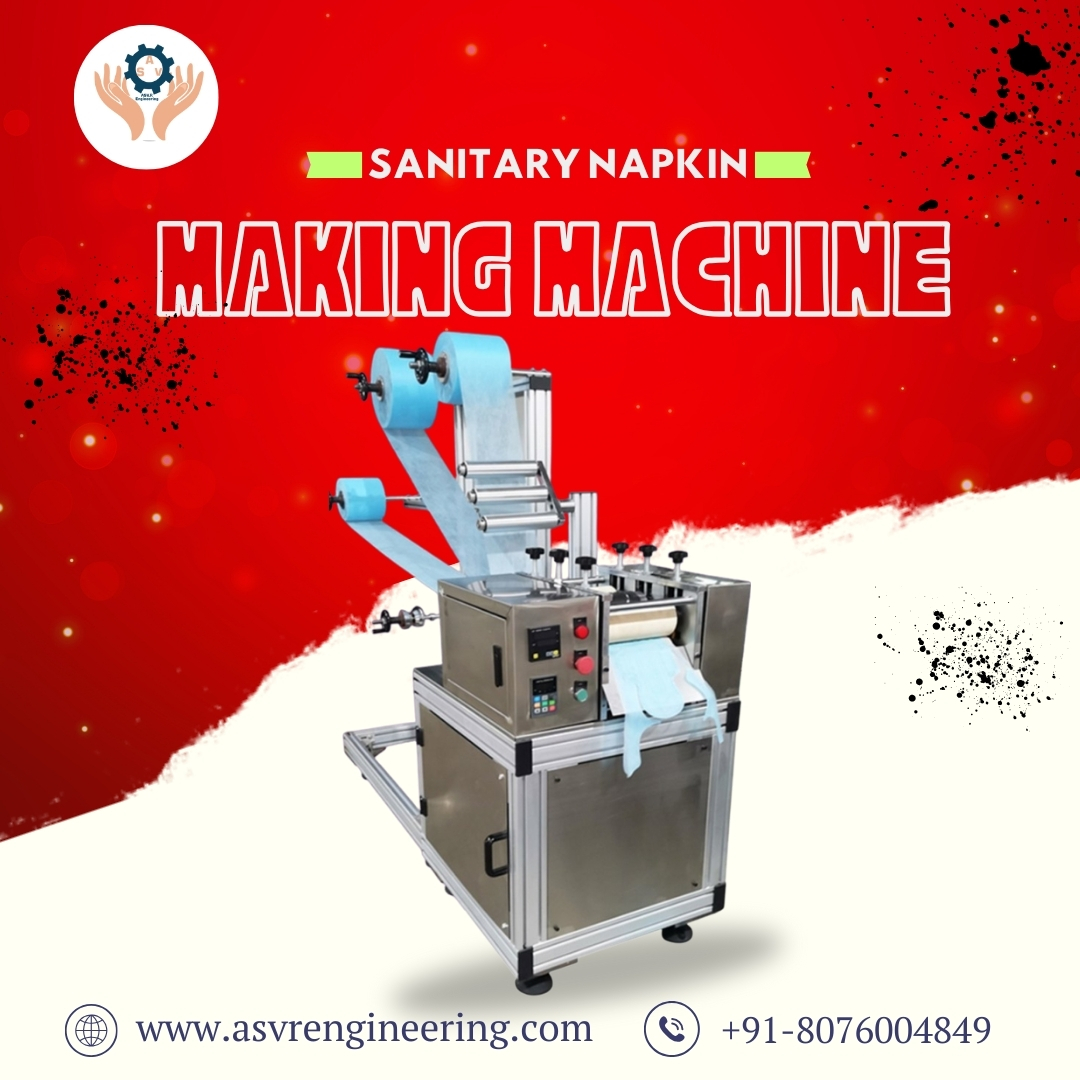

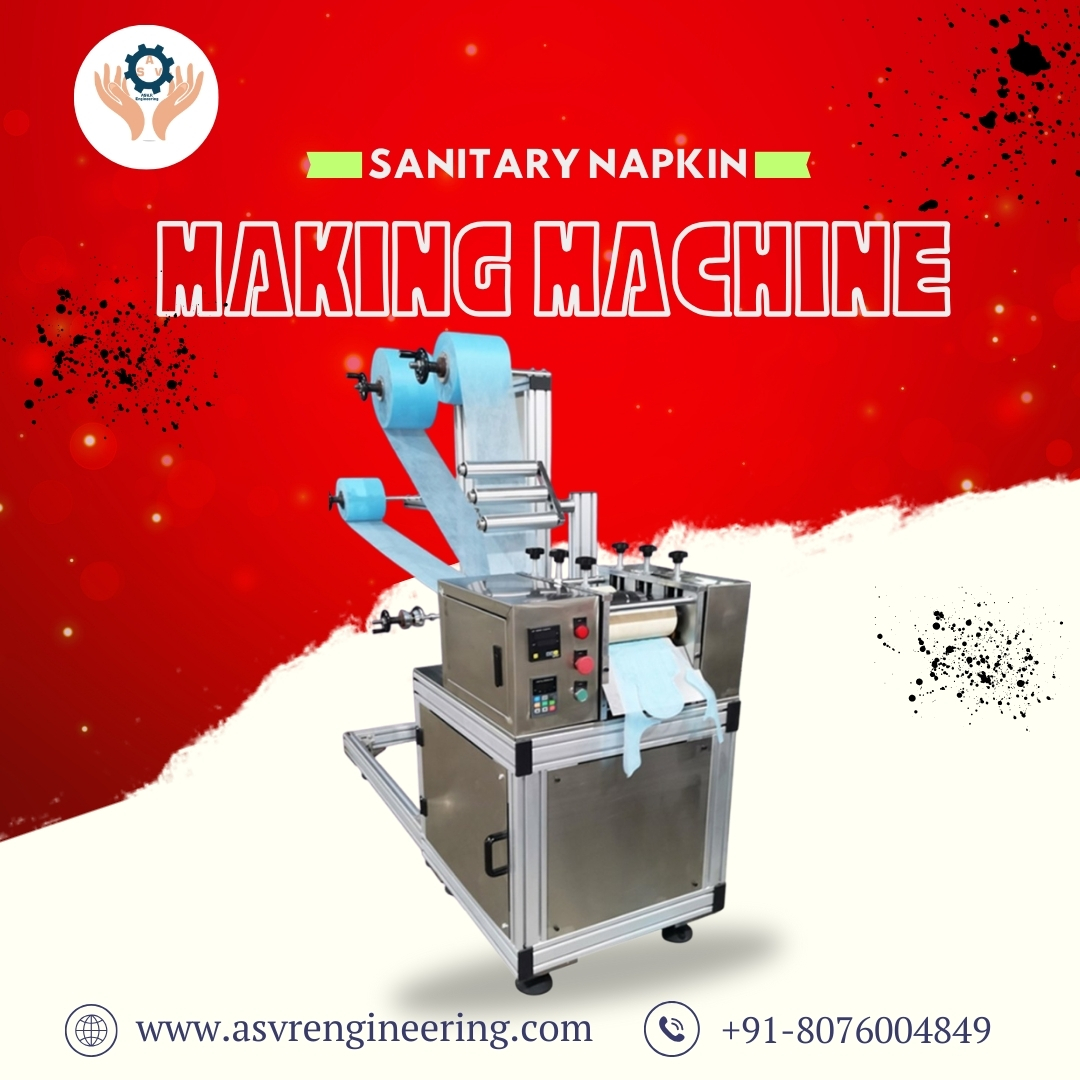

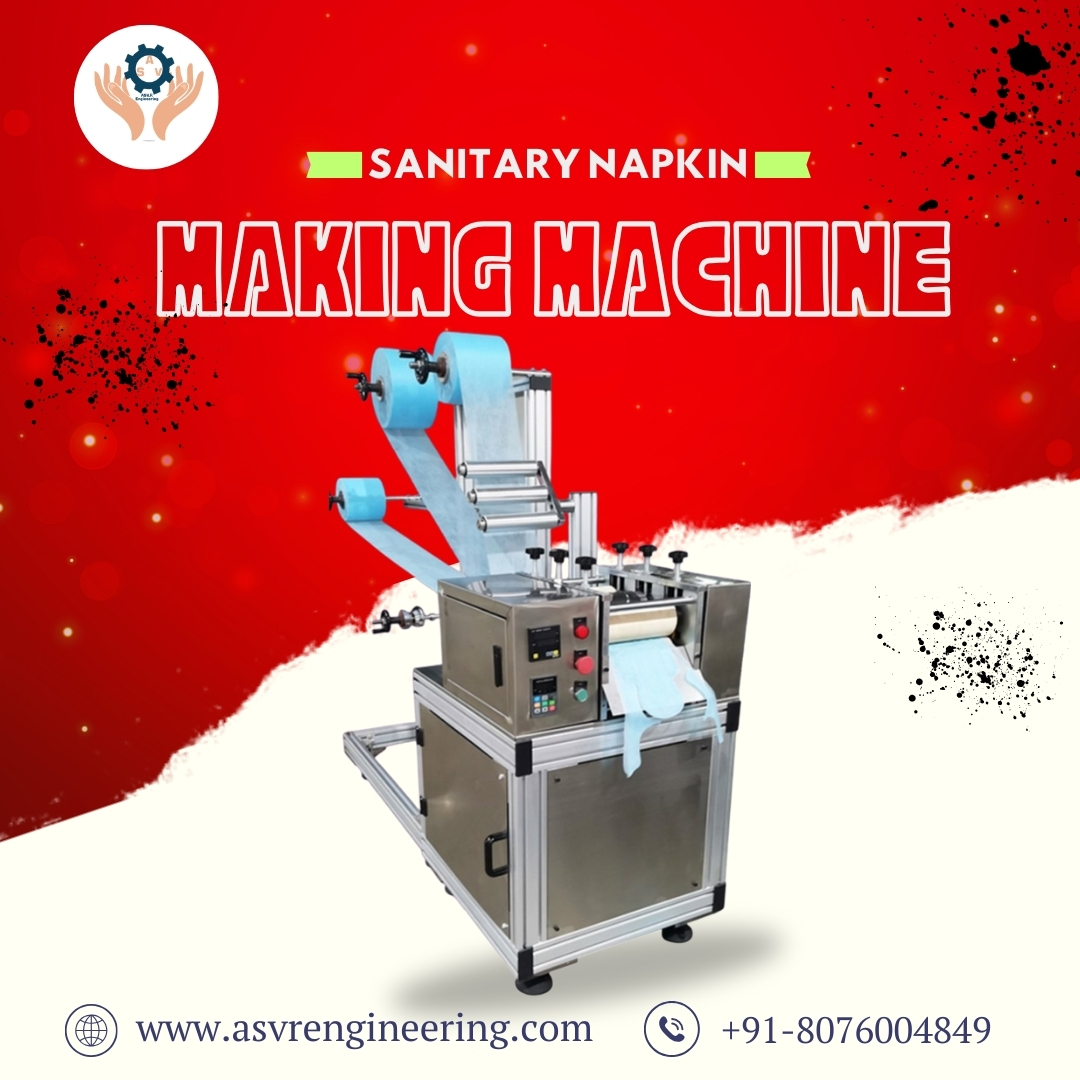

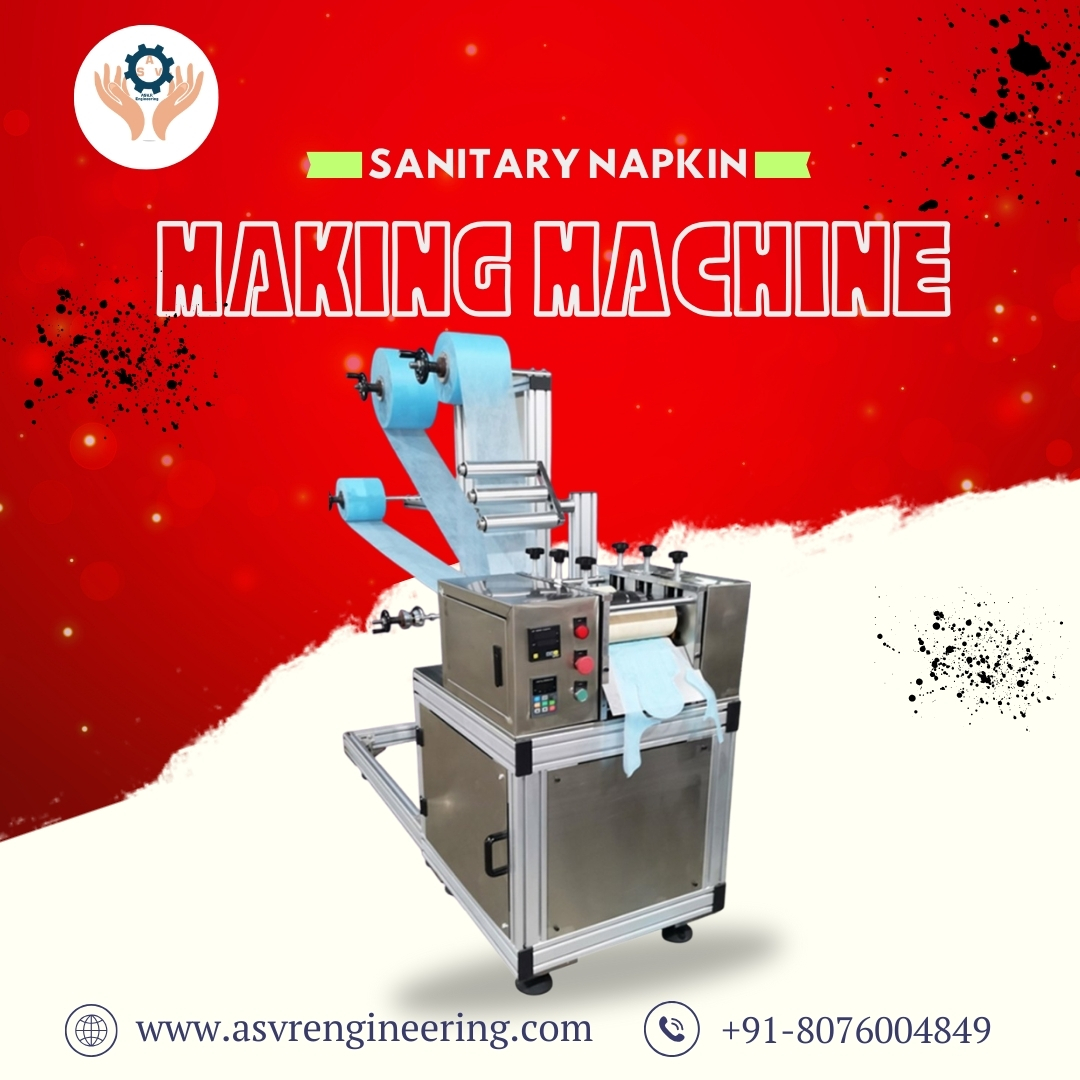

Fully & Semi Automatic Sanitary Napkin Making Machine Manufacturers | High-Efficiency Production Systems

Price: ₹425000

In today’s rapidly growing hygiene and personal care industry, sanitary napkins have become an essential product with consistent year-round demand. Rising awareness of menstrual health, increasing urbanization, and government-backed hygiene initiatives have created strong opportunities for entrepreneurs and established manufacturers alike. Choosing the right machinery partner plays a critical role in ensuring product quality, production efficiency, and long-term profitability.

ASVR Engineering stands among the most reliable fully and semi automatic sanitary napkin making machine manufacturers, delivering advanced, durable, and high-efficiency production systems designed for Indian and global markets. With a focus on engineering precision, user-friendly operation, and cost optimization, the company supports businesses at every stage—from startup units to large-scale manufacturing plants.

Understanding Fully & Semi Automatic Sanitary Napkin Manufacturing Systems

Sanitary napkin production requires accuracy, hygiene control, and consistent output. Modern machines integrate multiple processes into a streamlined production line, reducing manual dependency while maintaining strict quality standards.

Fully Automatic Sanitary Napkin Making Machines

Fully automatic systems are designed for high-volume production with minimal human intervention. These machines handle the entire process—from raw material feeding to finished napkin output—at high speed and uniform quality.

Key Features:

-

Automatic raw material feeding and layering

-

Precise cutting, sealing, and shaping

-

High production speed with consistent thickness

-

Reduced labor cost and material wastage

-

Ideal for large-scale and export-oriented units

Semi Automatic Sanitary Napkin Making Machines

Semi automatic machines offer flexibility and affordability, making them suitable for startups, small manufacturers, NGOs, and self-help groups.

Key Features:

-

Partial automation with manual assistance

-

Lower initial investment

-

Easy operation and maintenance

-

Suitable for controlled batch production

-

Gradual scalability toward full automation

Both systems are engineered to meet hygiene standards while delivering reliable daily output.

High-Efficiency Production Systems for Maximum Output

Efficiency in sanitary napkin manufacturing is not only about speed but also about material utilization, consistency, and machine uptime. Advanced production systems are built with optimized layouts and high-grade components to ensure long service life.

Optimized Material Usage

Modern machines are designed to minimize wastage of absorbent cores, non-woven fabric, and release paper. Precision cutting and alignment ensure each napkin meets uniform quality benchmarks.

Consistent Quality Control

Uniform weight distribution, secure sealing, and smooth finishing are essential for user comfort and brand credibility. High-efficiency systems maintain consistency across thousands of units per shift.

Energy-Efficient Operation

Low power consumption motors and optimized drive mechanisms help reduce operational costs without compromising output.

Applications Across Multiple Business Segments

Sanitary napkin manufacturing machines are widely used across various sectors:

-

Commercial Manufacturing Units – Large-scale branded production

-

Small & Medium Enterprises (SMEs) – Regional and private-label brands

-

NGOs & Self-Help Groups – Affordable hygiene initiatives

-

Government-Supported Projects – Rural and semi-urban hygiene programs

-

Export-Focused Manufacturers – International supply chains

Each segment benefits from tailored machine configurations and production capacities.

Why Choose a Reliable Sanitary Napkin Machine Manufacturer

Selecting the right manufacturer ensures long-term success and peace of mind. A reliable partner offers more than just machinery—they provide technical support, customization, and after-sales service.

Engineering Expertise

Machines built with precision-engineered components deliver consistent performance even under continuous operation.

Customization Options

Production capacity, napkin size, thickness, and packaging compatibility can be customized to meet specific market needs.

After-Sales Support

Timely service, spare parts availability, and operator training are crucial for uninterrupted production.

Compliance & Safety

Well-designed machines adhere to hygiene and safety norms, protecting both operators and end users.

Growth Opportunities in the Sanitary Napkin Manufacturing Business

The sanitary napkin market continues to expand due to increasing awareness and demand for affordable hygiene products. Manufacturers who invest in high-efficiency machinery gain a competitive advantage through:

-

Faster production turnaround

-

Lower per-unit manufacturing cost

-

Consistent product quality

-

Scalable production capacity

With the right machinery setup, businesses can cater to local, national, and international markets effectively.

Commitment to Quality, Innovation & Reliability

High-performance sanitary napkin manufacturing systems are developed with a commitment to quality materials, robust fabrication, and continuous innovation. From machine design to final installation, every stage focuses on reliability and customer satisfaction.

Manufacturers offering both fully and semi automatic sanitary napkin making machines ensure flexibility for businesses at different growth stages. Whether starting small or scaling up to industrial-level production, the right system lays a strong foundation for long-term success.

Contact Details

📞 Phone: +91-8076004849, +91-8800971968

🌐 Website: https://www.asvrengineering.com

For detailed specifications, pricing, and customized solutions, connect with the experts today and take a confident step toward building a profitable sanitary napkin manufacturing business.

Buy Now

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)