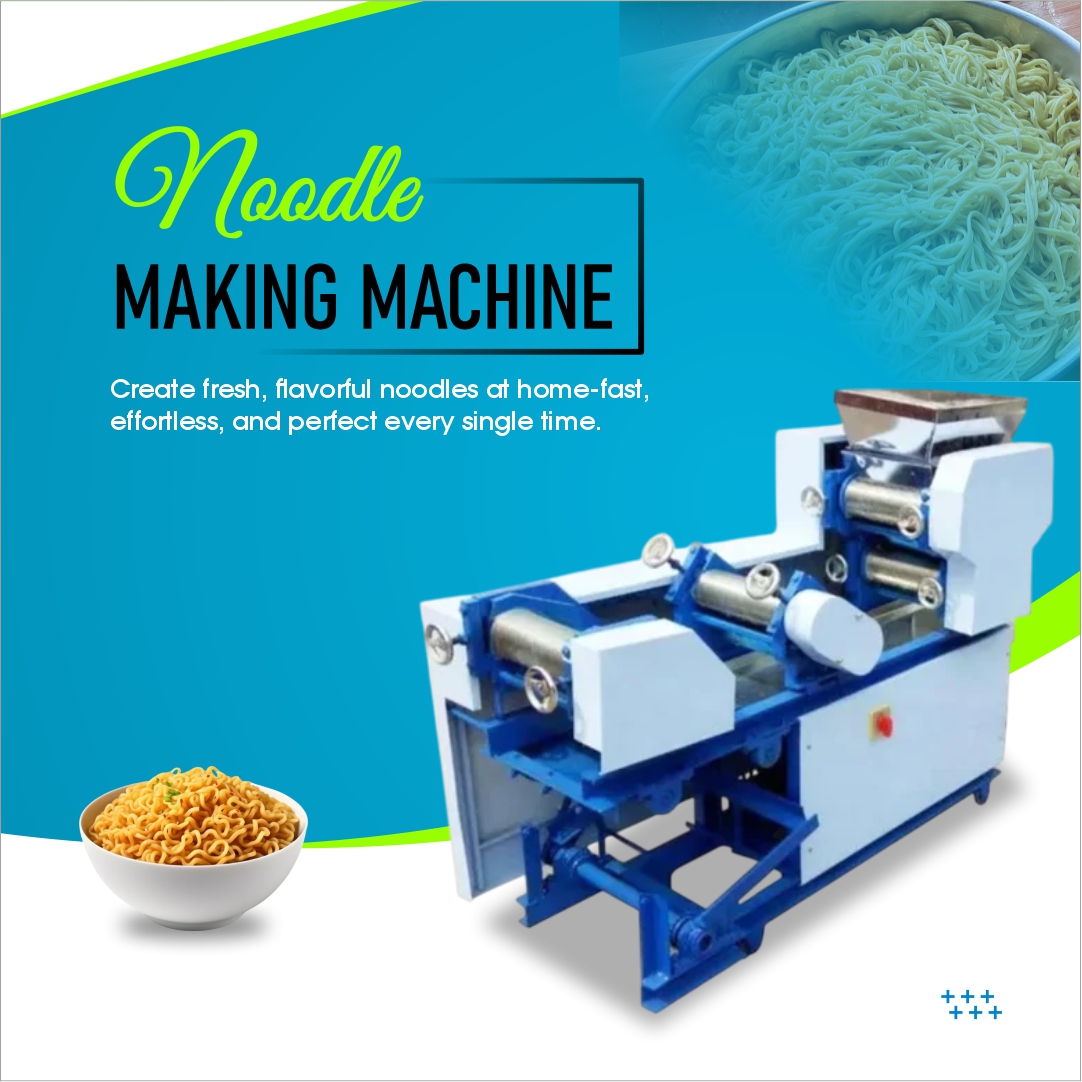

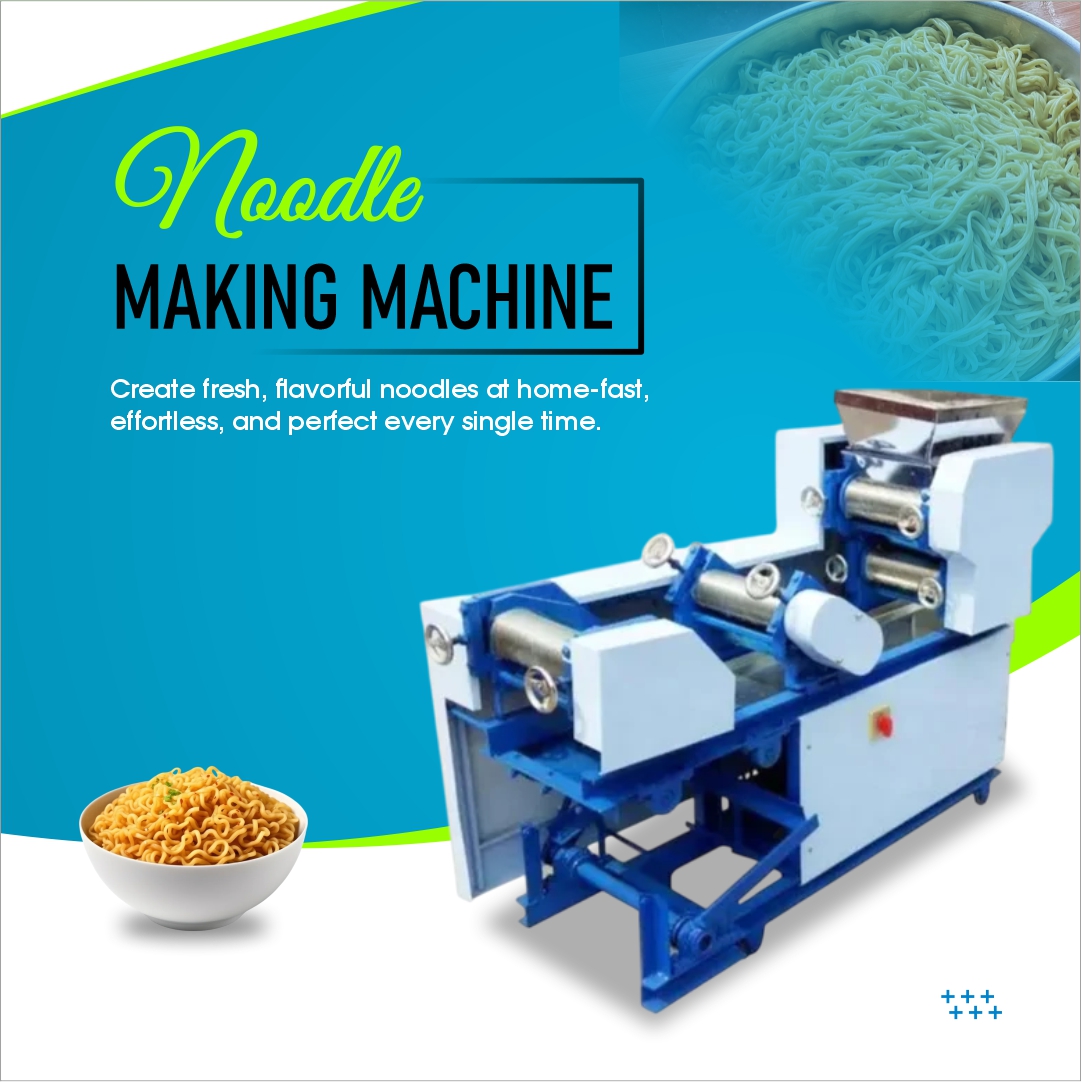

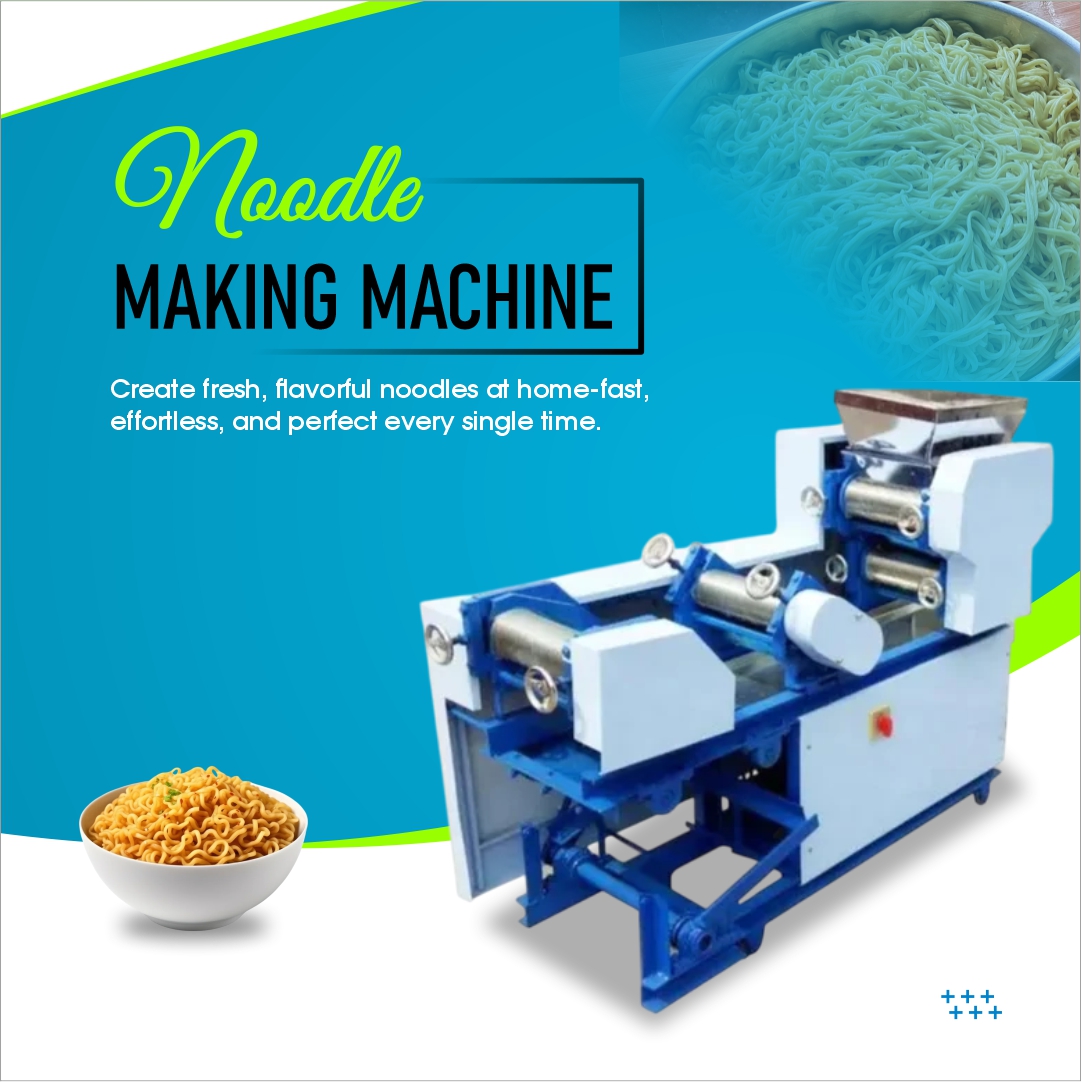

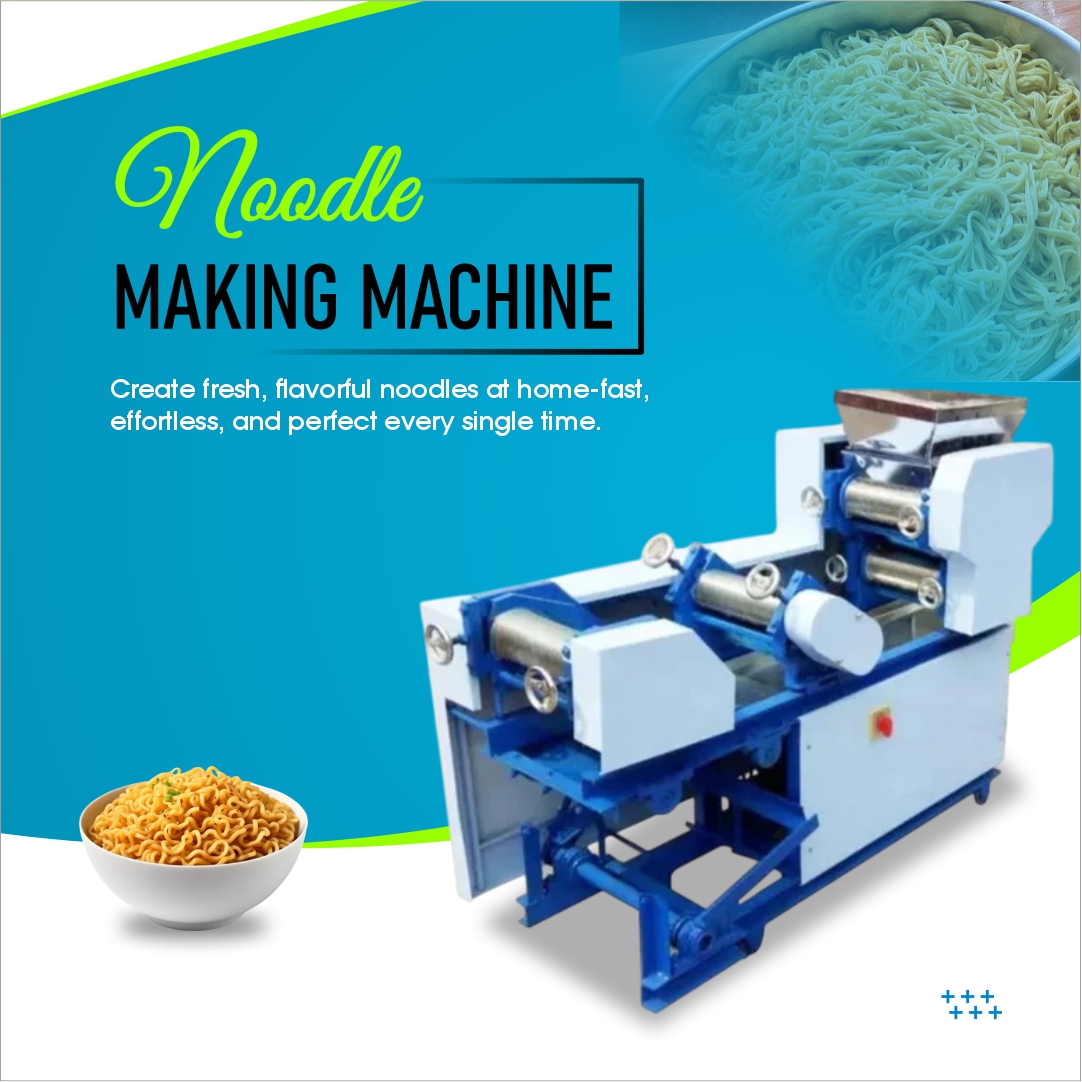

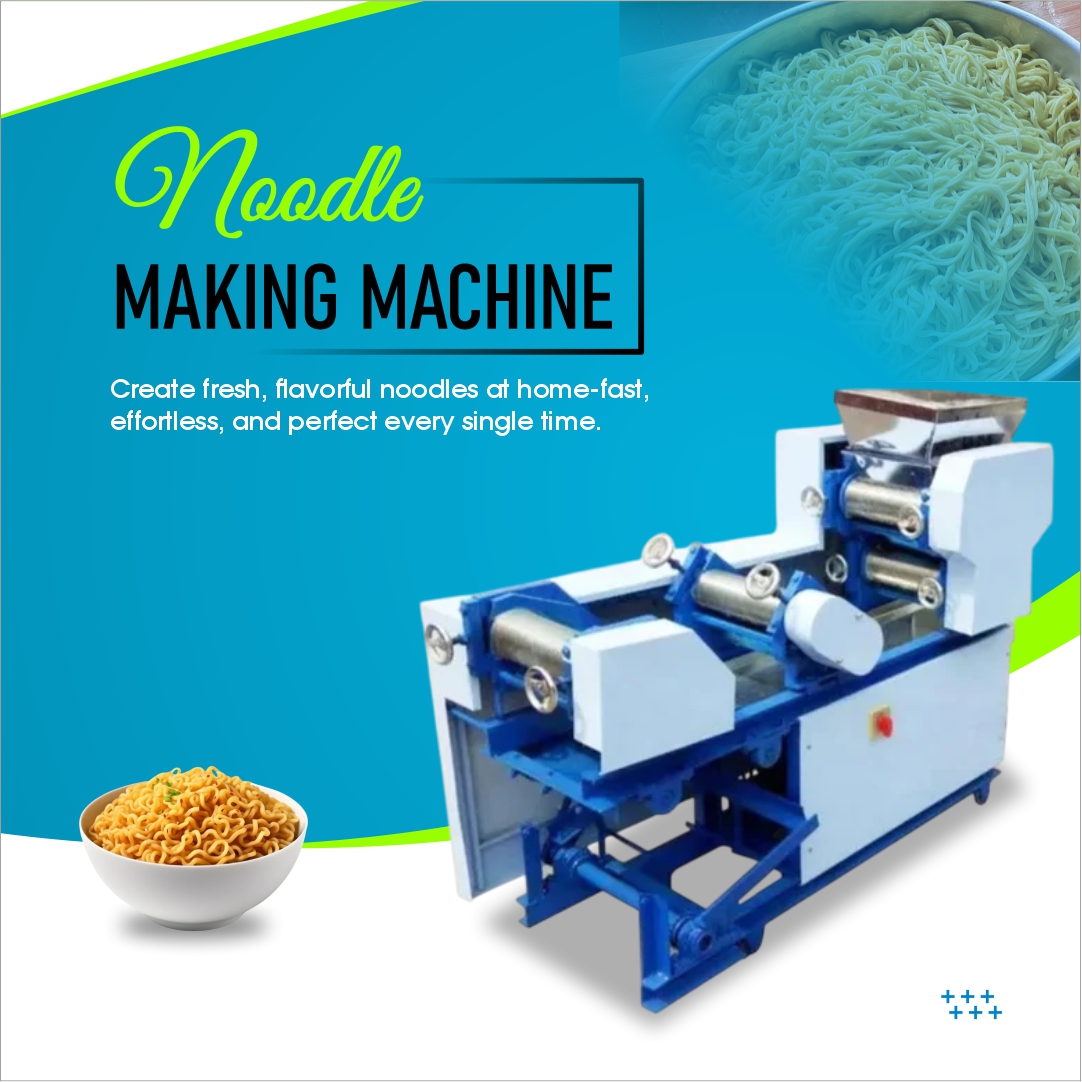

Leading Noodle Making Machine Wholesalers Offering High-Speed & Fully Automatic Plants

Price: ₹80000

In today’s fast-evolving food processing industry, noodles have emerged as one of the most consumed staple foods across India and global markets. From instant noodles and wheat noodles to rice noodles and specialty variants, consumer demand continues to rise rapidly. To meet this demand with consistency, hygiene, and efficiency, food manufacturers increasingly rely on advanced automation. This is where leading noodle making machine wholesalers play a critical role by supplying high-speed, fully automatic noodle making plants that combine precision engineering with scalable production capacity.

Growing Demand for Automated Noodle Manufacturing

The noodle market has expanded far beyond traditional boundaries. Urban lifestyles, quick-service restaurants, retail chains, and export demand have driven manufacturers to adopt automated solutions that ensure uniform quality and higher output. Manual or semi-automatic methods can no longer keep pace with modern requirements such as:

-

Consistent dough preparation

-

Uniform noodle thickness and texture

-

High hourly production capacity

-

Compliance with food safety and hygiene standards

-

Reduced labor dependency

Fully automatic noodle making machines address all these challenges efficiently, making them the backbone of modern noodle production facilities.

Why Choose High-Speed & Fully Automatic Noodle Making Plants?

High-speed noodle making plants are designed to streamline the entire manufacturing process—from raw material feeding to final cutting and shaping—under a single automated system. As trusted wholesalers, companies like ASVR Engineering supply machines that are engineered for durability, accuracy, and long-term performance.

Key Advantages

1. Superior Production Speed

High-speed plants can produce large volumes of noodles per hour without compromising on quality. This enables manufacturers to fulfill bulk orders, expand distribution, and maximize profitability.

2. Fully Automated Operations

Automation ensures precise control over mixing, kneading, rolling, slitting, steaming, and cutting. This eliminates human error and delivers consistent results batch after batch.

3. Uniform Quality & Texture

Advanced rollers, cutters, and calibration systems ensure noodles of uniform width, thickness, and length—essential for brand consistency and customer satisfaction.

4. Hygienic & Food-Grade Design

Machines are manufactured using food-grade stainless steel, ensuring compliance with hygiene norms and easy cleaning for long-term safety.

5. Energy & Cost Efficiency

Modern noodle plants are optimized for lower power consumption and minimal wastage, helping manufacturers reduce operational costs.

Complete Process of a Fully Automatic Noodle Making Plant

A fully automatic noodle production line integrates multiple stages into a seamless workflow:

Raw Material Feeding & Mixing

High-quality flour is fed into the mixing system where precise quantities of water and additives are blended to form a uniform dough. Automated dosing systems maintain consistency.

Dough Kneading & Resting

The kneaded dough is allowed to rest, improving elasticity and texture. This stage is crucial for achieving smooth and flexible noodles.

Rolling & Sheet Formation

The dough passes through a series of rollers that gradually reduce thickness and form smooth dough sheets.

Slitting & Cutting

Specially designed cutters slice the sheets into noodles of required width—flat, round, or wave-style—depending on production needs.

Steaming / Pre-Cooking (Optional)

For instant noodle production, noodles are steamed to partially cook them before drying or frying.

Final Cutting & Collection

Noodles are cut to desired lengths and transferred for further processing, drying, or packaging.

Types of Noodle Making Machines Offered by Leading Wholesalers

Top wholesalers supply a wide range of machines to meet diverse business requirements:

-

Fully Automatic Noodle Making Plants – Ideal for large-scale industrial production

-

High-Speed Instant Noodle Lines – Designed for FMCG and export-oriented units

-

Semi-Automatic Noodle Machines – Suitable for medium-scale manufacturers

-

Customized Noodle Plants – Tailored for wheat, rice, millet, or specialty noodles

This flexibility allows manufacturers to scale operations according to market demand and budget.

Importance of Choosing the Right Noodle Making Machine Wholesaler

Investing in a noodle making plant is a long-term decision. Choosing the right wholesaler ensures not only superior machinery but also dependable after-sales support. Reputed wholesalers focus on:

-

Proven engineering expertise

-

Customization as per production requirements

-

Installation & commissioning support

-

Operator training

-

Easy availability of spare parts

-

Reliable technical assistance

These factors collectively ensure smooth plant operations and long machine life.

Applications Across Multiple Market Segments

High-speed noodle making machines are widely used across:

-

Instant noodle manufacturing units

-

Restaurants and QSR chains

-

Large food processing factories

-

Export-oriented food brands

-

Private label FMCG manufacturers

With automation, manufacturers can diversify product lines while maintaining quality and efficiency.

Why ASVR Engineering Is a Preferred Choice

As one of the trusted names among noodle making machine wholesalers in India, ASVR Engineering focuses on delivering robust, efficient, and future-ready solutions. Their machines are designed keeping Indian and international market requirements in mind, ensuring performance, safety, and compliance.

Whether you are planning to set up a new noodle manufacturing unit or upgrade an existing facility, partnering with an experienced wholesaler ensures faster ROI and consistent output.

Future of Noodle Manufacturing with Automation

The future of the noodle industry lies in smart automation, digital controls, and scalable systems. High-speed, fully automatic plants enable manufacturers to adapt quickly to changing consumer preferences, introduce new variants, and expand into new markets with confidence.

With rising competition, automation is no longer optional—it is essential for survival and growth.

Contact Information

For high-quality, high-speed, and fully automatic noodle making machines, get in touch with:

Company: ASVR Engineering

Phone: +91-8076004849, +91-8800971968

Website: https://www.asvrengineering.com

Buy Now