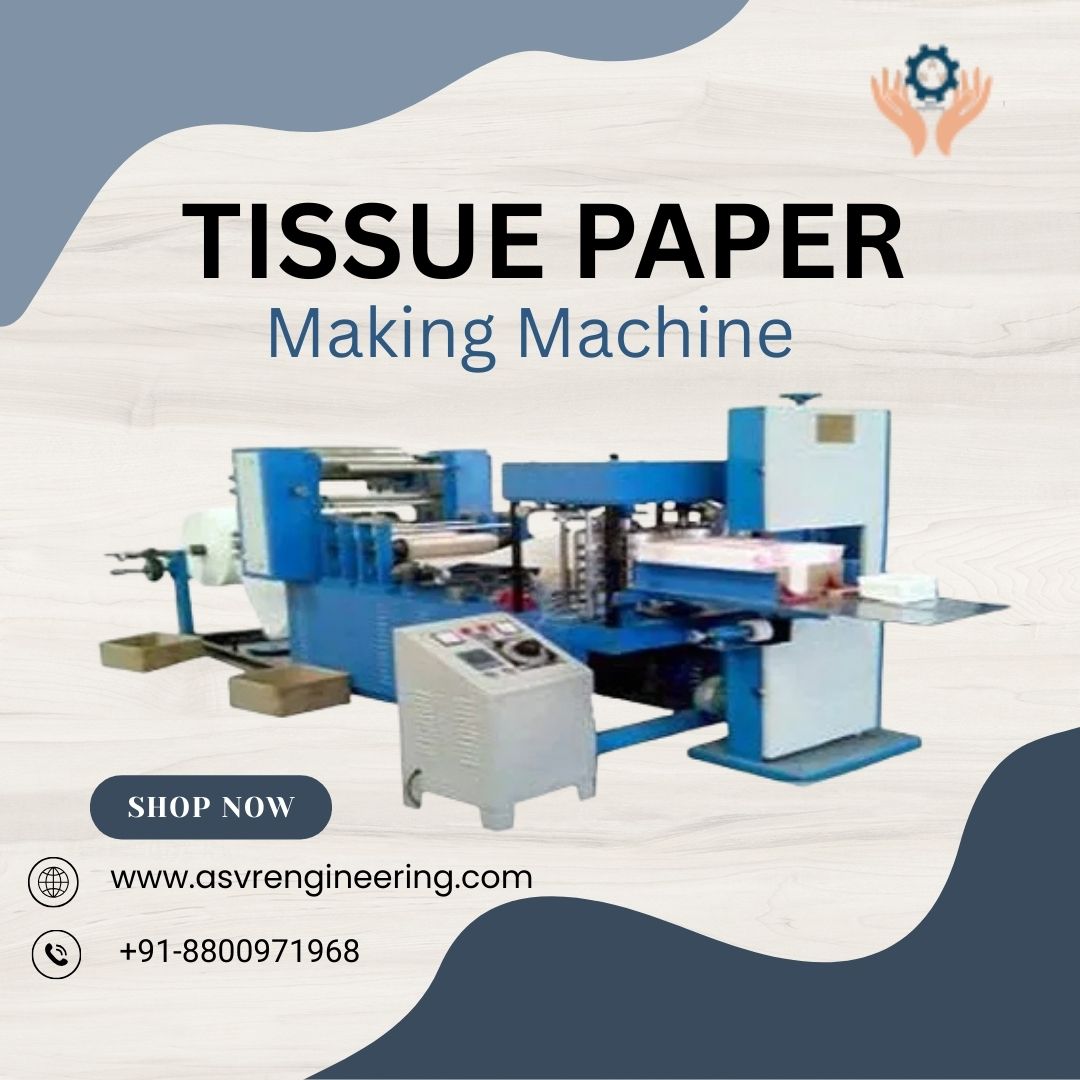

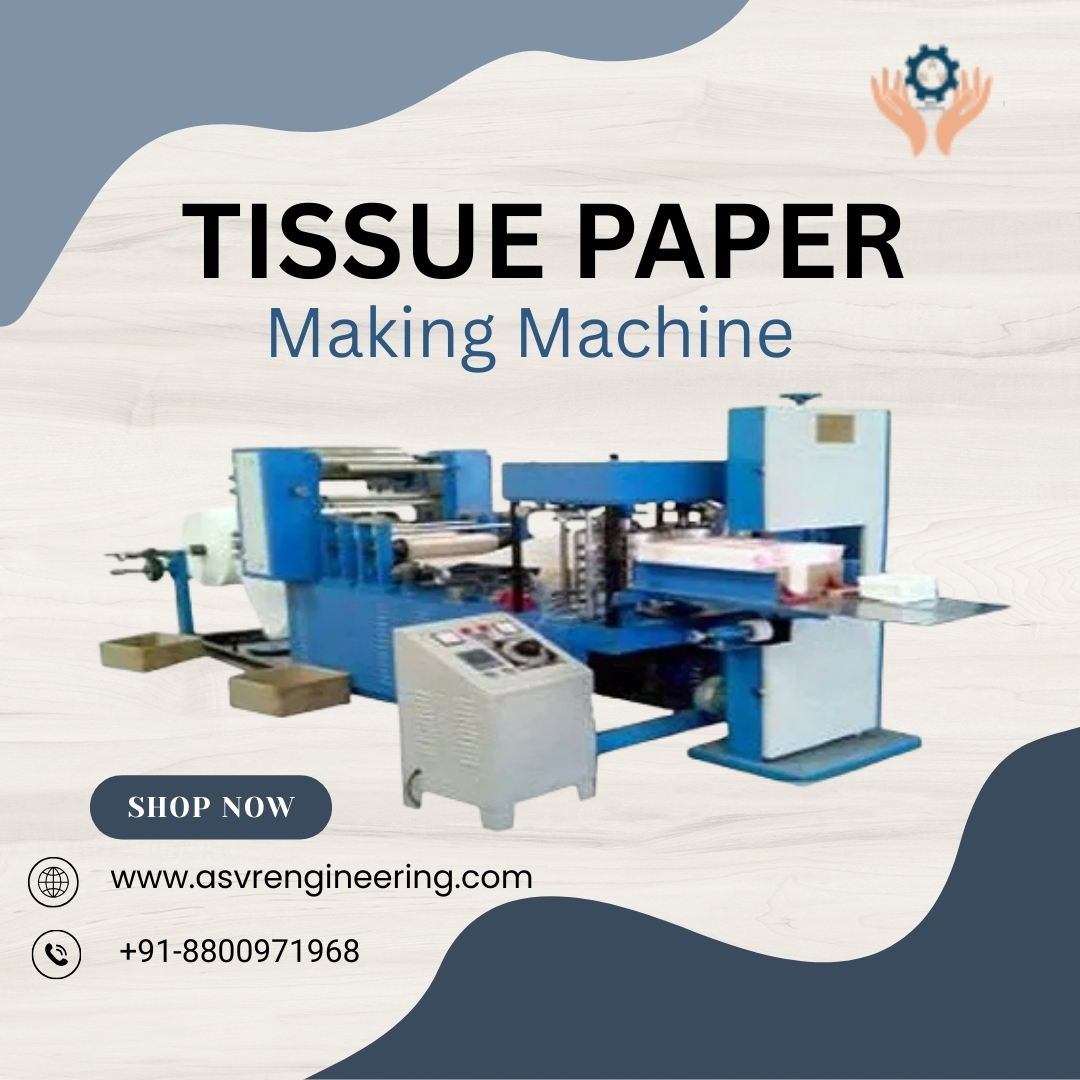

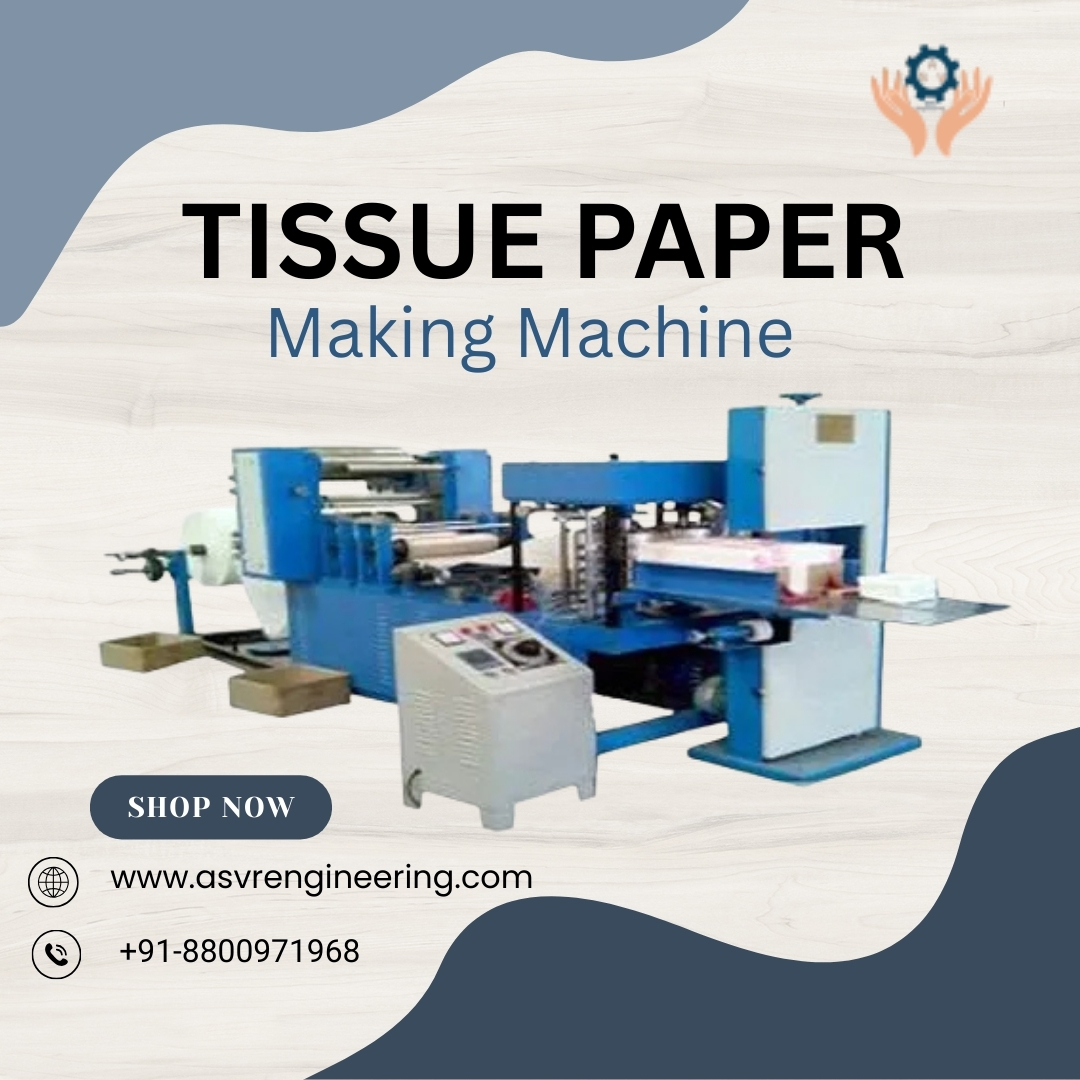

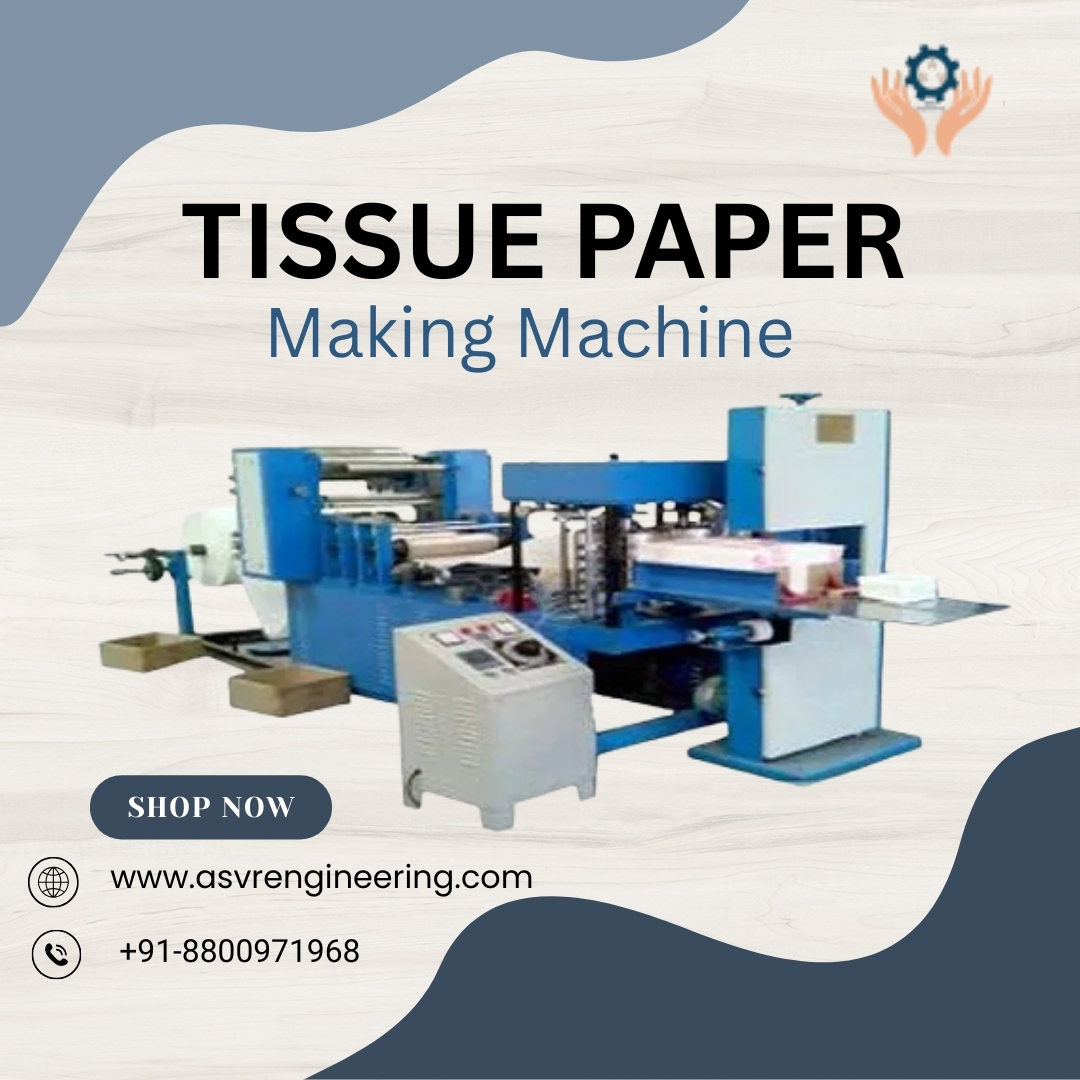

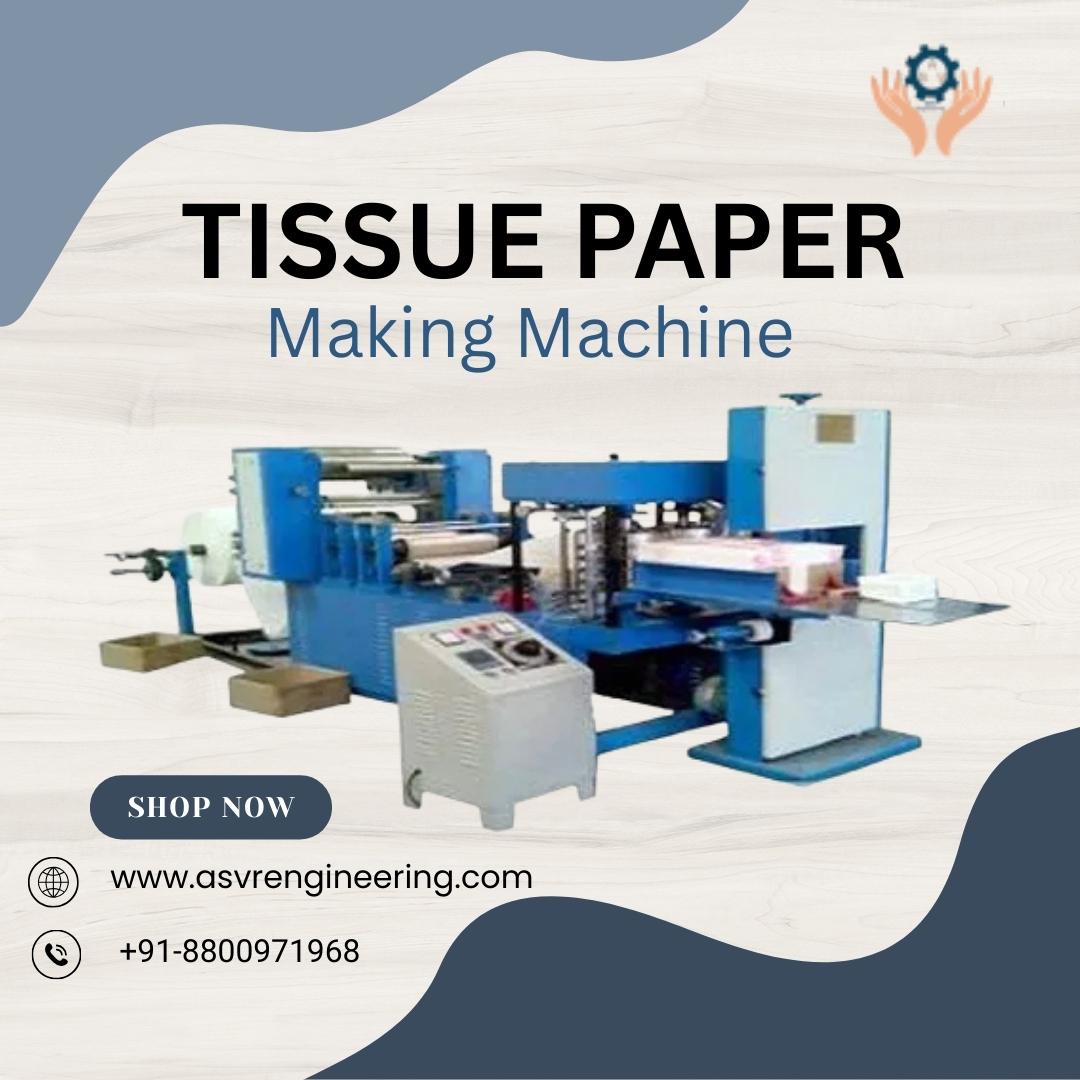

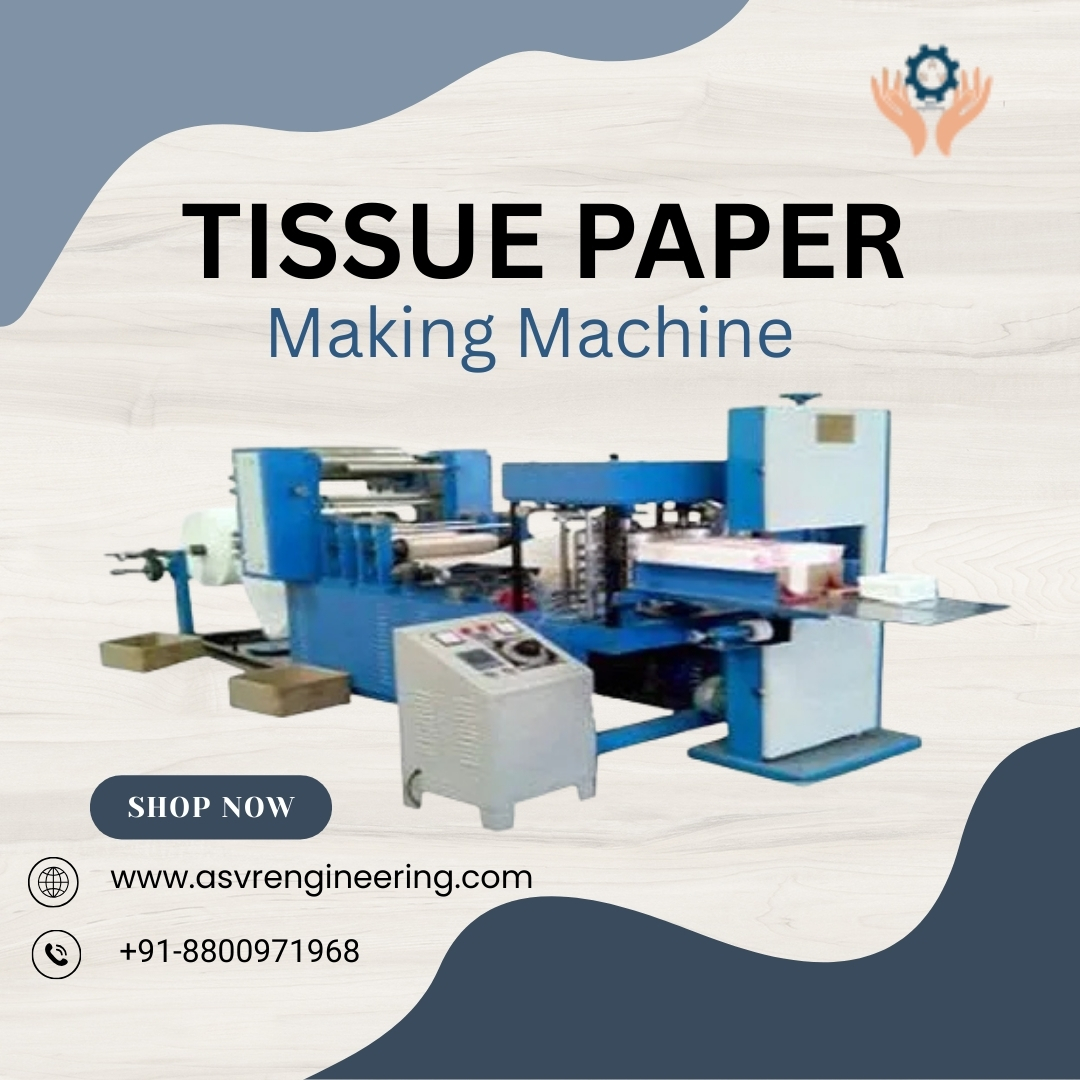

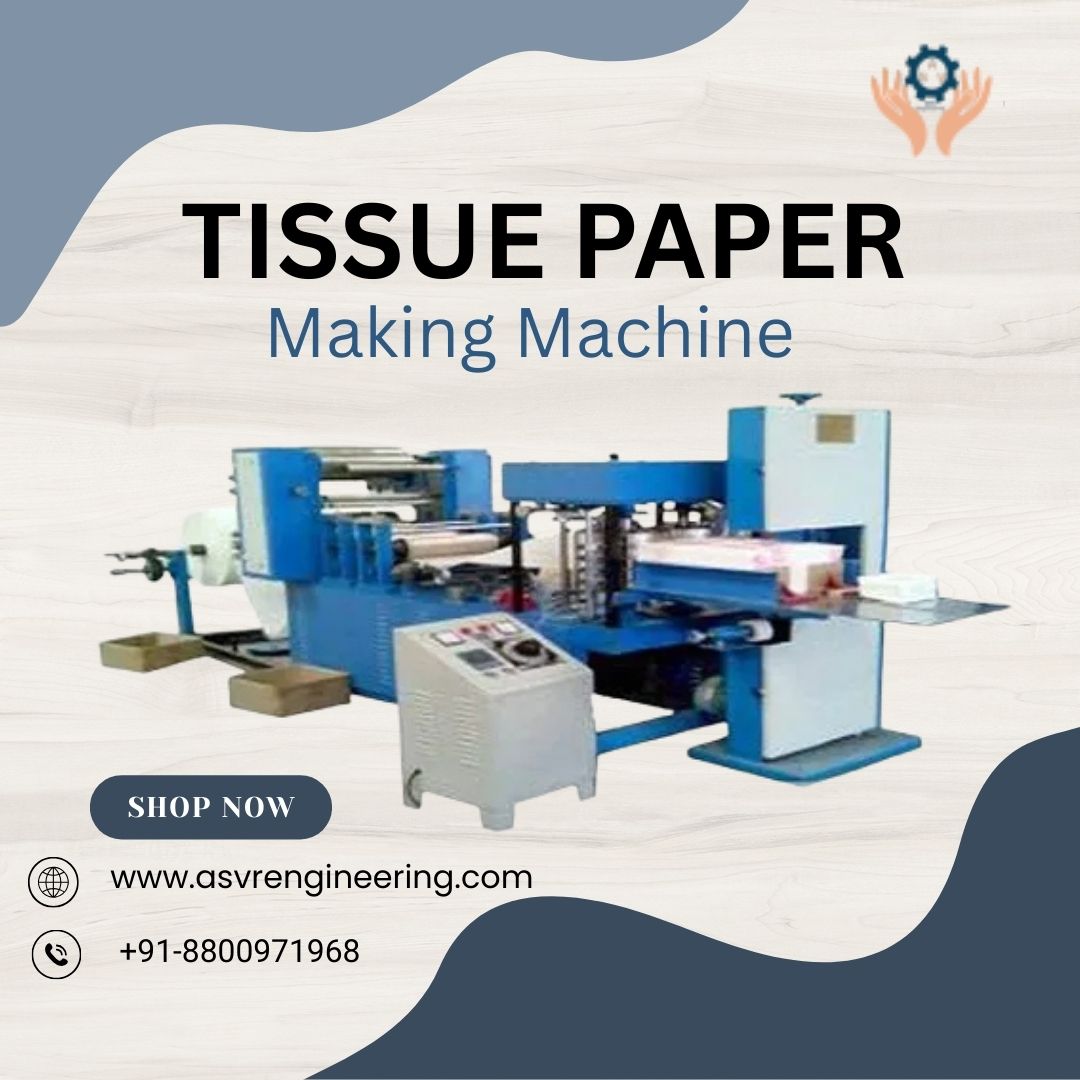

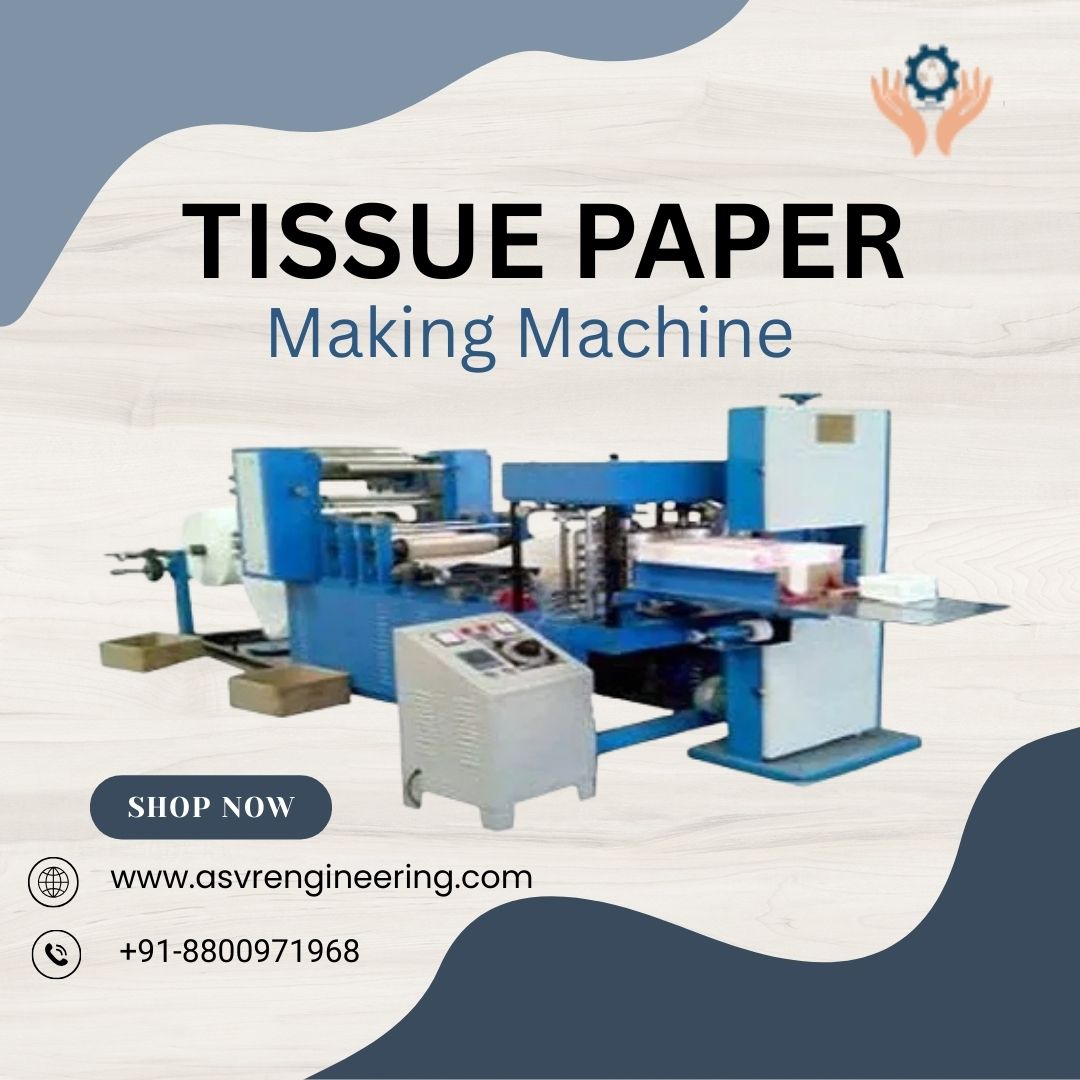

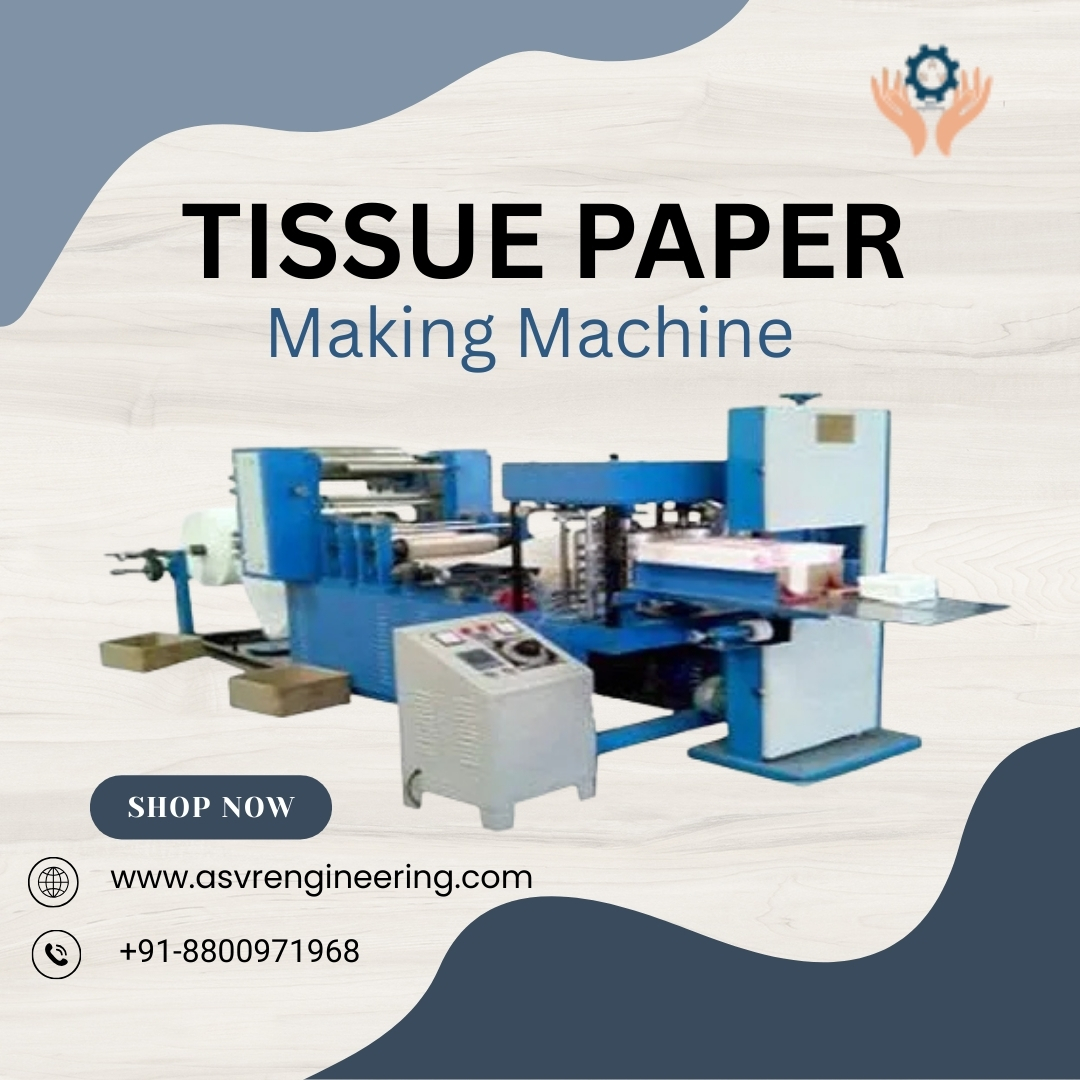

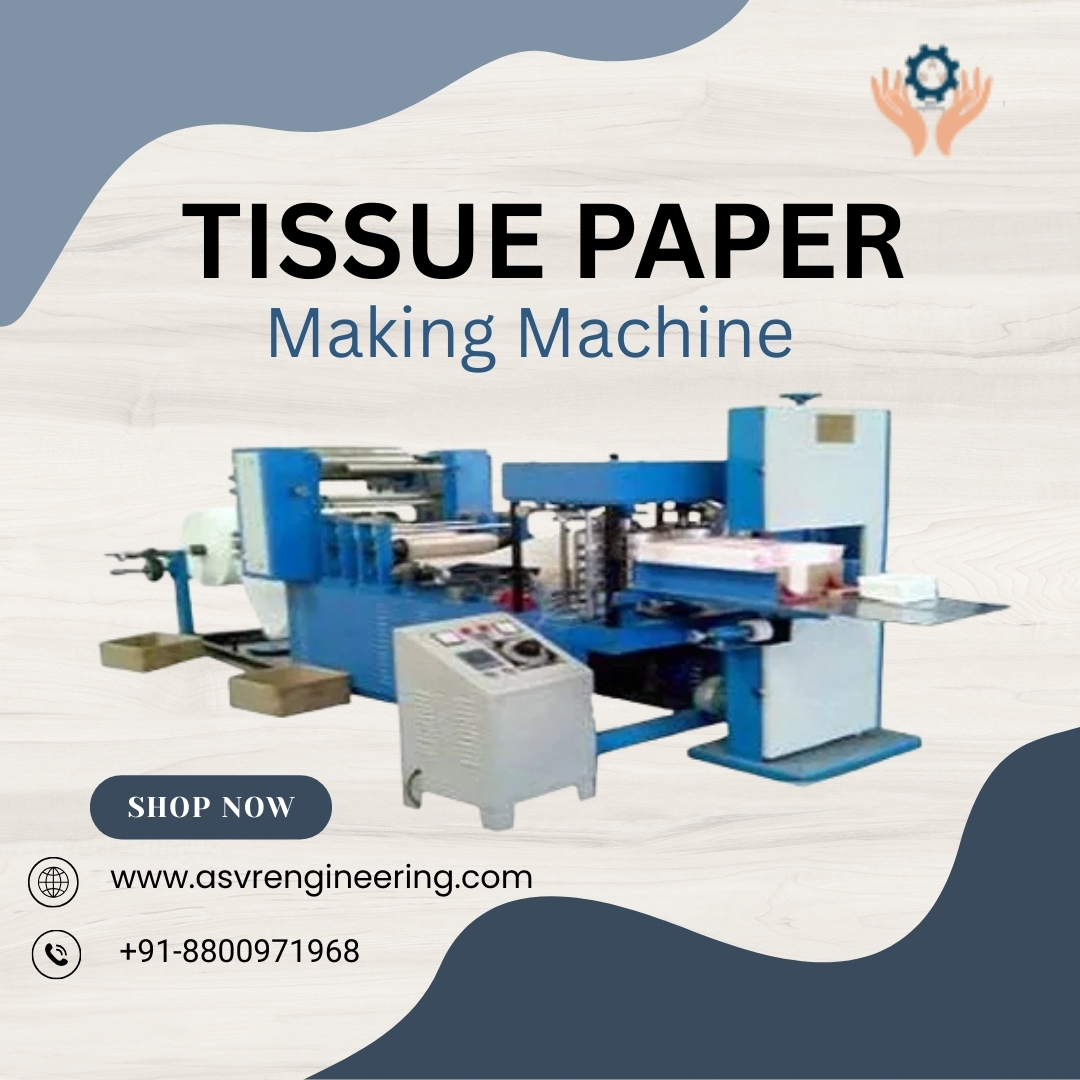

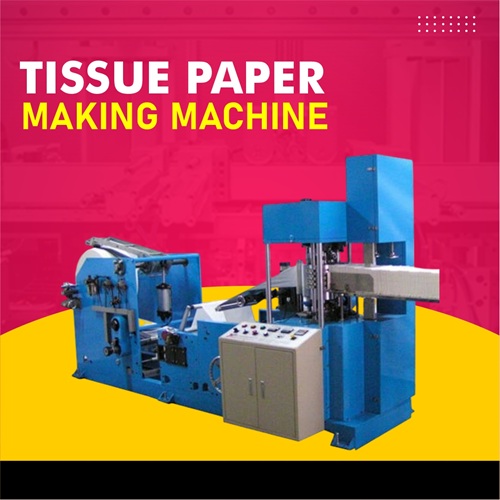

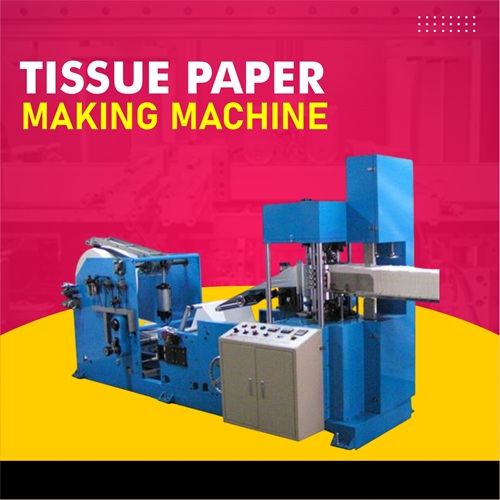

Leading Tissue Paper Machine Exporters Delivering High-Speed & Energy-Efficient Production Lines Worldwide

Price: ₹450000

The global demand for tissue paper products has grown steadily over the last decade, driven by rising hygiene awareness, urbanization, hospitality expansion, healthcare needs, and increased consumption in both residential and commercial sectors. From facial tissues and toilet paper to paper napkins, kitchen towels, and industrial wipes, tissue paper has become an essential daily-use product across the world. To meet this growing demand efficiently, manufacturers require advanced, reliable, and energy-efficient tissue paper production lines that can deliver consistent quality at high output rates.

This is where leading tissue paper machine exporters play a critical role. They bridge the gap between innovation and manufacturing by supplying modern, high-speed, and energy-efficient tissue paper machines to businesses worldwide. With robust engineering, precision manufacturing, and global service capabilities, exporters like ASVR Engineering help tissue manufacturers scale operations, reduce production costs, and maintain international quality standards.

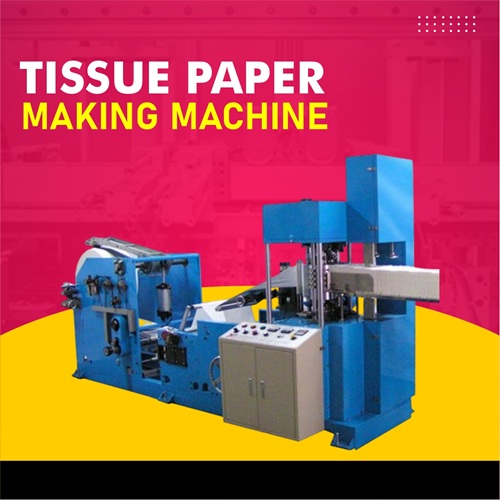

Understanding Tissue Paper Manufacturing Technology

Tissue paper manufacturing is a highly specialized process that involves converting raw pulp into lightweight, absorbent, and soft paper products. Modern tissue paper production lines are designed to ensure speed, efficiency, and minimal wastage while maintaining superior product quality.

A standard tissue paper production line typically includes:

-

Stock preparation system for pulp processing

-

Headbox and forming section for uniform sheet formation

-

Press and drying sections for moisture removal

-

Yankee dryer for creping and softness

-

Rewinder and slitting units for converting jumbo rolls into finished sizes

Advanced tissue paper machines integrate automation, PLC controls, and energy-saving components that ensure consistent output, reduced downtime, and lower operational costs.

High-Speed Tissue Paper Machines for Global Markets

One of the defining features of modern tissue paper machinery is high-speed operation. Export-grade tissue paper machines are engineered to operate at significantly higher speeds without compromising paper softness, strength, or absorbency.

High-speed tissue paper machines offer multiple advantages:

-

Increased production capacity to meet bulk demand

-

Uniform paper quality across large volumes

-

Reduced cost per unit through optimized performance

-

Faster return on investment for manufacturers

For exporters, delivering high-speed machines means ensuring structural stability, precision balancing, and durable components that can handle continuous operations in diverse climates and working conditions worldwide.

Energy-Efficient Production Lines: A Sustainable Advantage

Energy efficiency has become a top priority for tissue paper manufacturers due to rising power costs and environmental regulations. Leading tissue paper machine exporters now focus on supplying energy-efficient production lines that reduce power consumption, water usage, and steam requirements.

Energy-efficient tissue paper machines typically include:

-

Optimized drying systems with improved heat recovery

-

Advanced Yankee dryer technology for faster moisture removal

-

Variable frequency drives (VFDs) to control motor speed

-

Automated process control systems to minimize wastage

By adopting energy-efficient machinery, tissue manufacturers not only lower operational costs but also contribute to sustainable manufacturing practices, making their products more acceptable in international markets.

Why Choose Experienced Tissue Paper Machine Exporters

Exporting industrial machinery is far more complex than domestic supply. It involves compliance with international standards, logistics coordination, documentation, and after-sales support across borders. Choosing an experienced tissue paper machine exporter ensures smooth project execution and long-term operational success.

Key benefits of working with established exporters include:

1. Global Quality Standards

Export-grade tissue paper machines are manufactured in compliance with international norms such as ISO standards, ensuring safety, reliability, and performance consistency.

2. Customization for Regional Needs

Different countries have varying power standards, raw material availability, and market requirements. Leading exporters provide customized solutions tailored to local conditions.

3. Turnkey Project Capability

From plant layout design and machine installation to operator training and commissioning, exporters often deliver complete turnkey tissue paper manufacturing solutions.

4. Worldwide Installation & Support

Reliable exporters provide on-site installation, technical training, and after-sales support, ensuring uninterrupted production regardless of location.

Complete Tissue Paper Production Line Solutions

Top tissue paper machine exporters do not just sell individual machines—they deliver complete production line solutions. These integrated systems ensure seamless coordination between each stage of the manufacturing process, resulting in higher productivity and reduced operational complexity.

A complete tissue paper production line may include:

-

Pulping and stock preparation units

-

Tissue paper machine with high-speed forming section

-

Efficient drying and creping system

-

Automatic rewinding and slitting machines

-

Optional embossing, perforation, and packaging units

Such comprehensive solutions are ideal for both new entrepreneurs entering the tissue paper industry and established manufacturers looking to upgrade or expand capacity.

Applications of Tissue Paper Machines Supplied Worldwide

Tissue paper machines exported globally cater to a wide range of applications, including:

-

Toilet paper rolls for residential and commercial use

-

Facial tissues for personal hygiene

-

Paper napkins for hotels, restaurants, and events

-

Kitchen towels for household and industrial cleaning

-

Medical and industrial wipes for specialized sectors

The versatility of modern tissue paper machines allows manufacturers to diversify product offerings and adapt quickly to changing market demands.

Technology, Automation, and Precision Engineering

Automation plays a crucial role in modern tissue paper production. Exporters now focus on delivering machines equipped with advanced PLC systems, touch-screen interfaces, and real-time monitoring features.

Key technological advantages include:

-

Automated thickness and grammage control

-

Real-time fault detection and diagnostics

-

Reduced dependence on manual labor

-

Consistent product quality across long runs

Precision engineering ensures that each component of the tissue paper machine works in perfect synchronization, reducing wear and tear while extending machine life.

Global Export Experience and Market Reach

Leading tissue paper machine exporters serve clients across Asia, the Middle East, Africa, Europe, and South America. Their global experience enables them to understand diverse regulatory frameworks, shipping requirements, and operational challenges.

Strong export capabilities include:

-

Secure packaging for international shipping

-

Efficient logistics and documentation handling

-

Compliance with import/export regulations

-

Timely delivery and installation support

Such expertise ensures that tissue paper manufacturers worldwide receive machines that are ready for immediate production upon commissioning.

Investment Value and Long-Term Benefits

Investing in a high-speed, energy-efficient tissue paper production line is a strategic decision that delivers long-term value. With reliable exporters, manufacturers benefit from:

-

Lower production and maintenance costs

-

Improved product consistency and brand reputation

-

Scalability for future expansion

-

Competitive advantage in domestic and export markets

A well-designed tissue paper machine not only enhances productivity but also strengthens the manufacturer’s position in a highly competitive industry.

Partner with a Trusted Tissue Paper Machine Exporter

Choosing the right exporter is crucial for the success of any tissue paper manufacturing project. A trusted exporter combines engineering excellence, global experience, and customer-focused service to deliver solutions that perform reliably for years.

With a strong commitment to quality, innovation, and customer satisfaction, ASVR Engineering stands out as a dependable partner for tissue paper manufacturers seeking advanced, high-speed, and energy-efficient production lines worldwide.

Contact Information

For inquiries, technical details, or customized tissue paper machine solutions, contact:

Phone: +91-8076004849, +91-8800971968

Website: https://www.asvrengineering.com

Buy Now