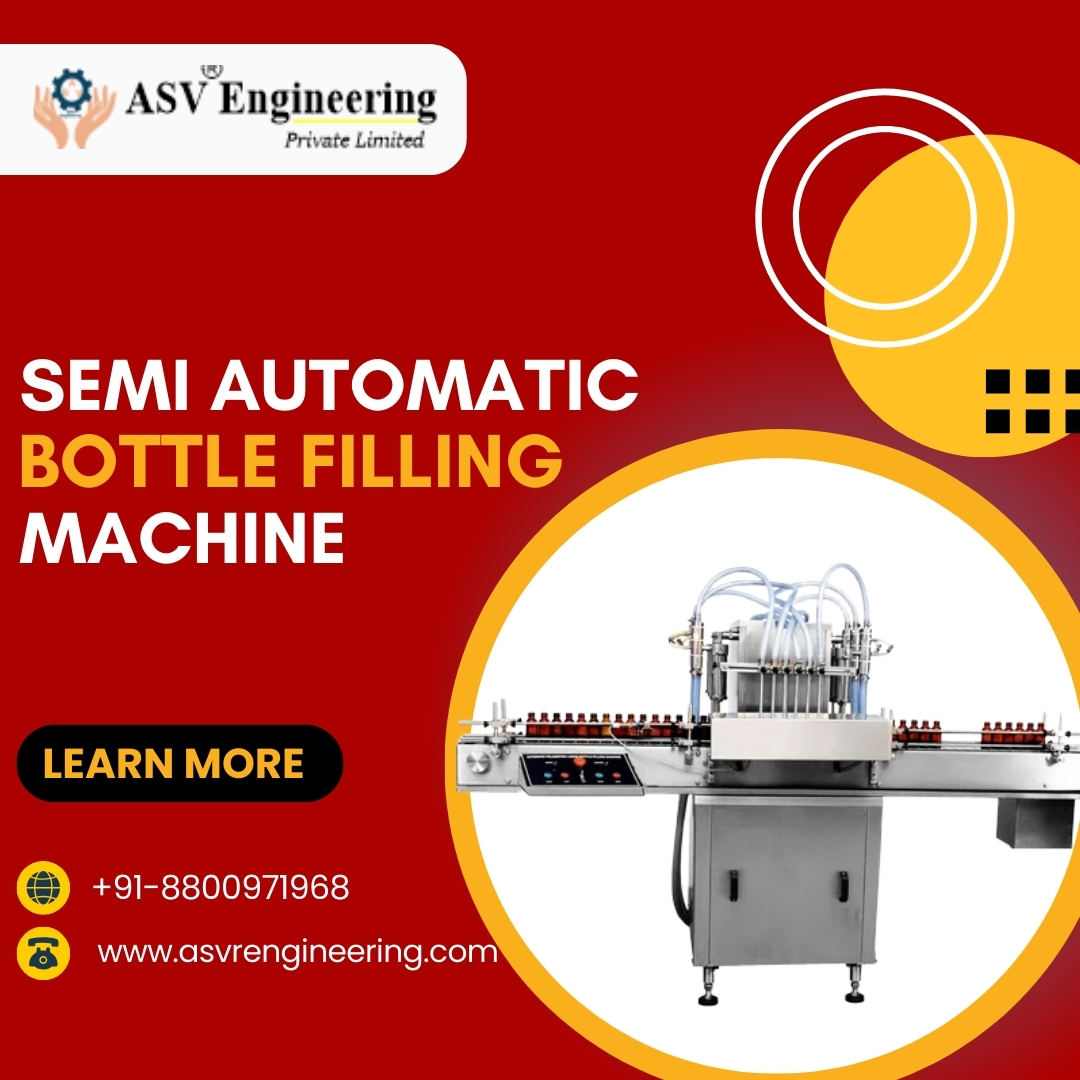

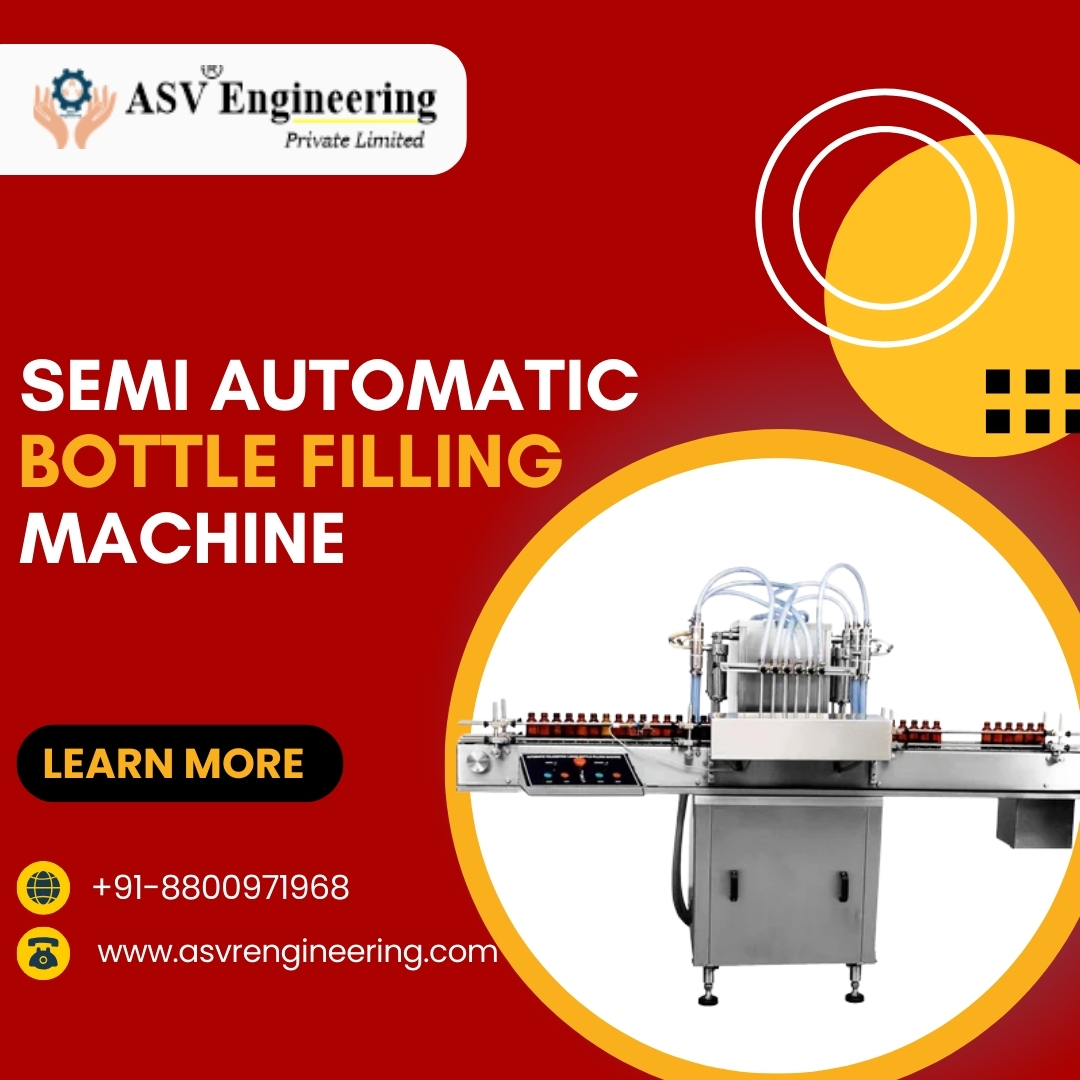

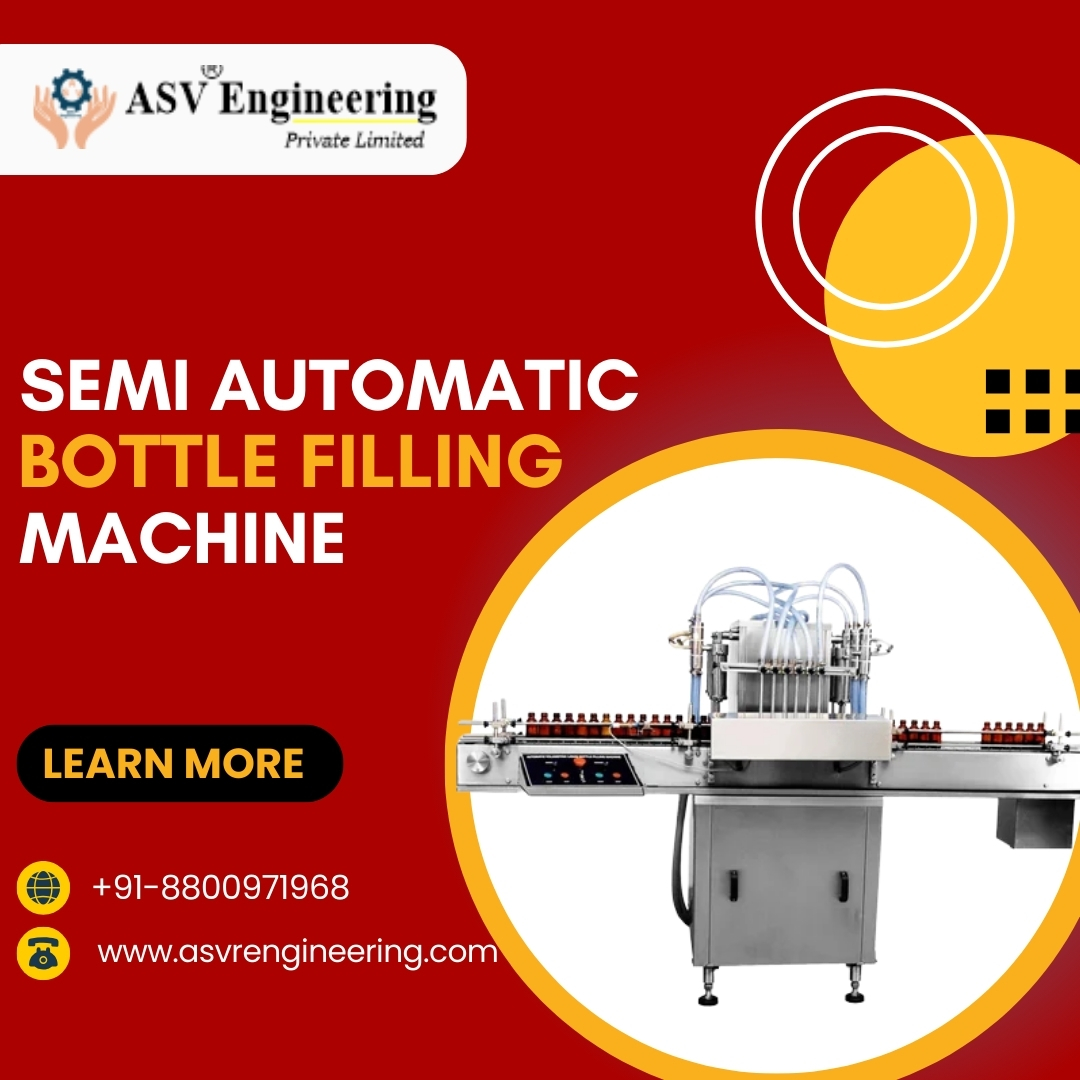

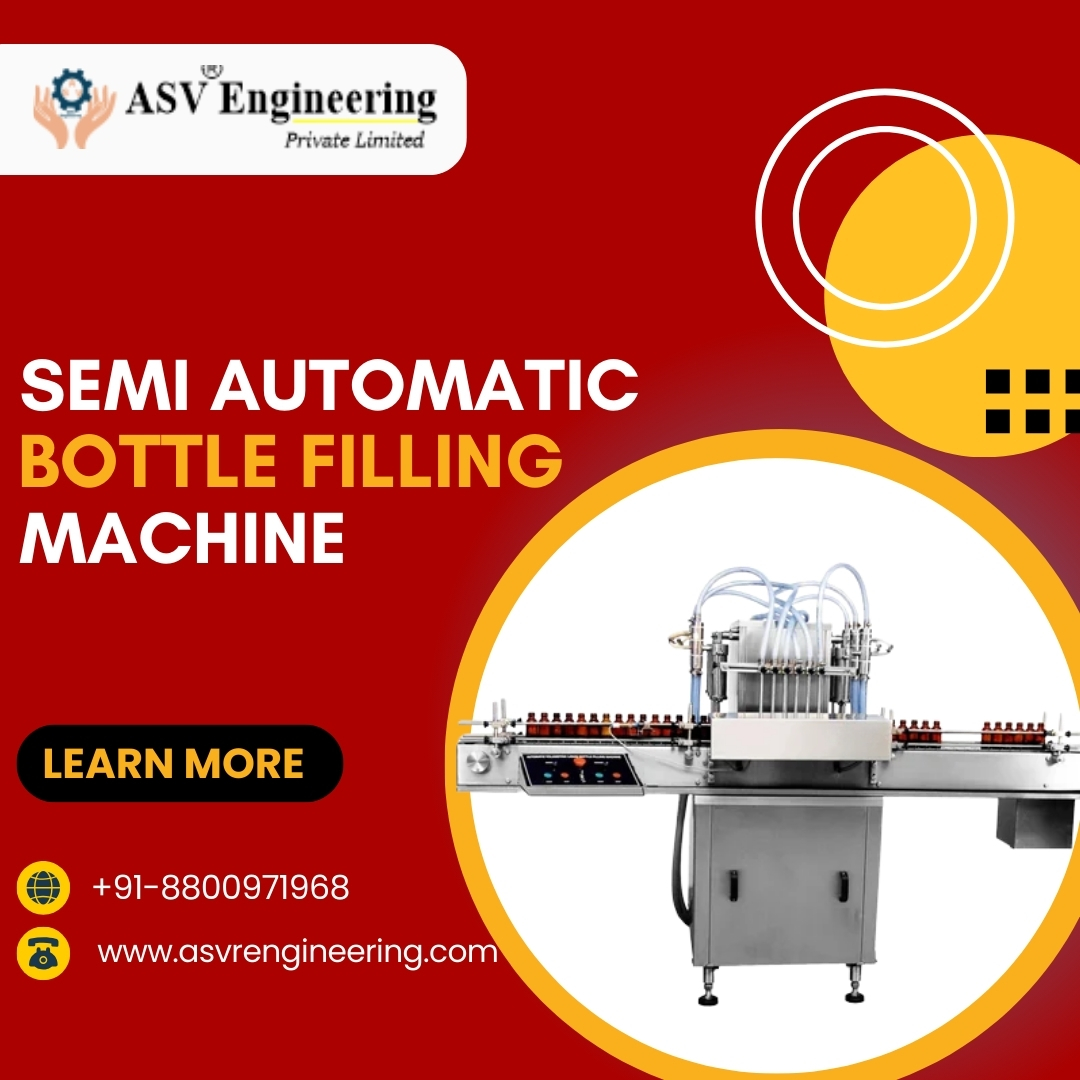

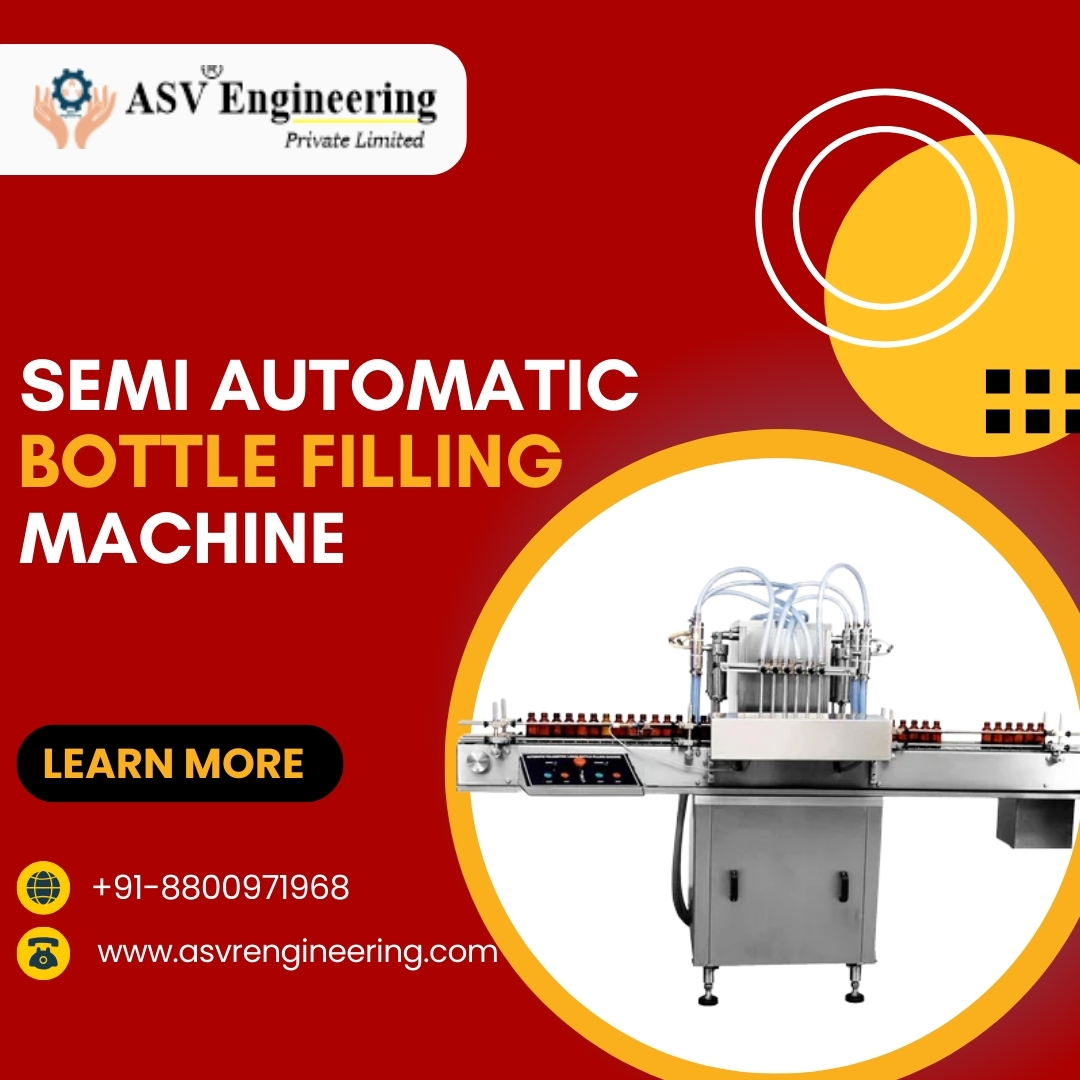

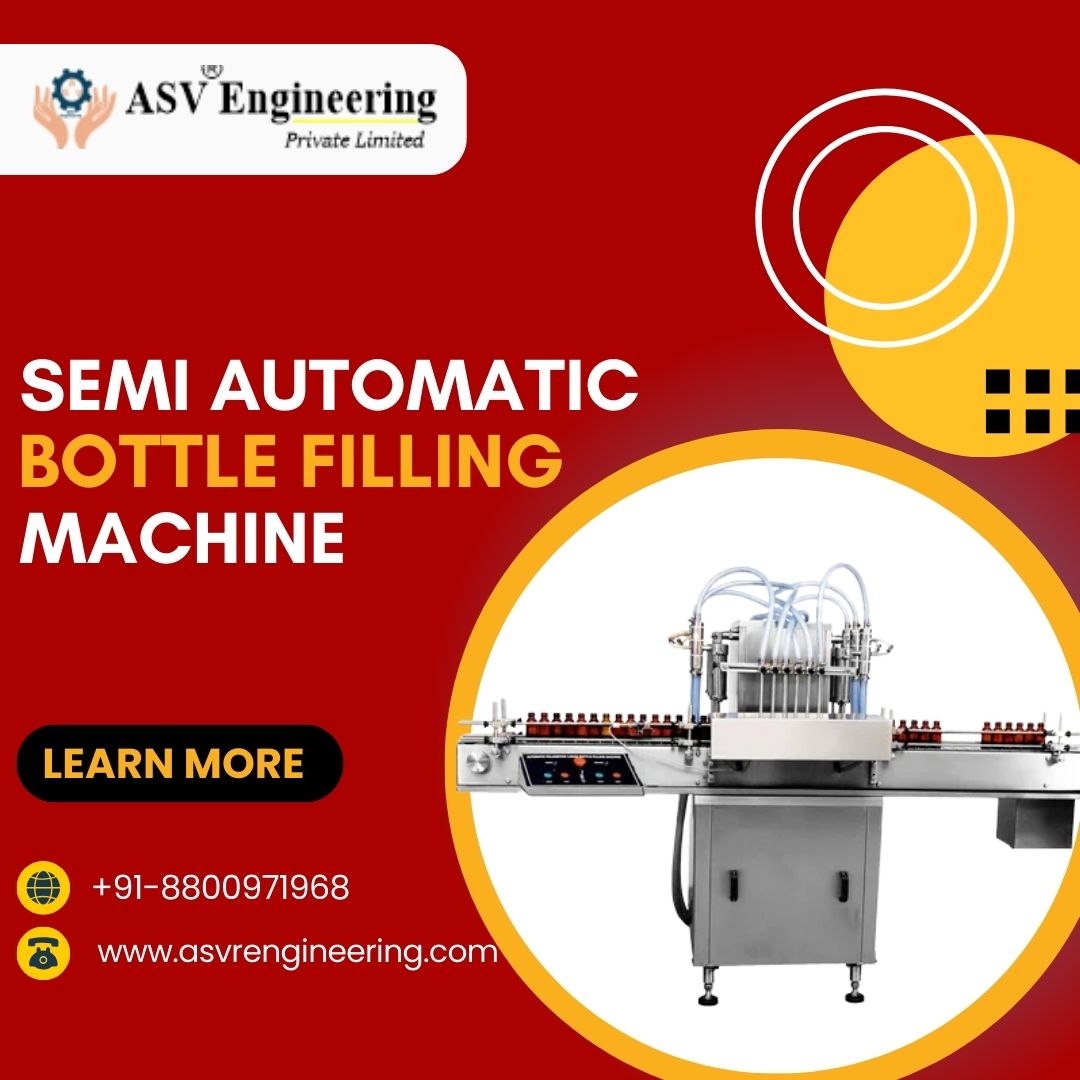

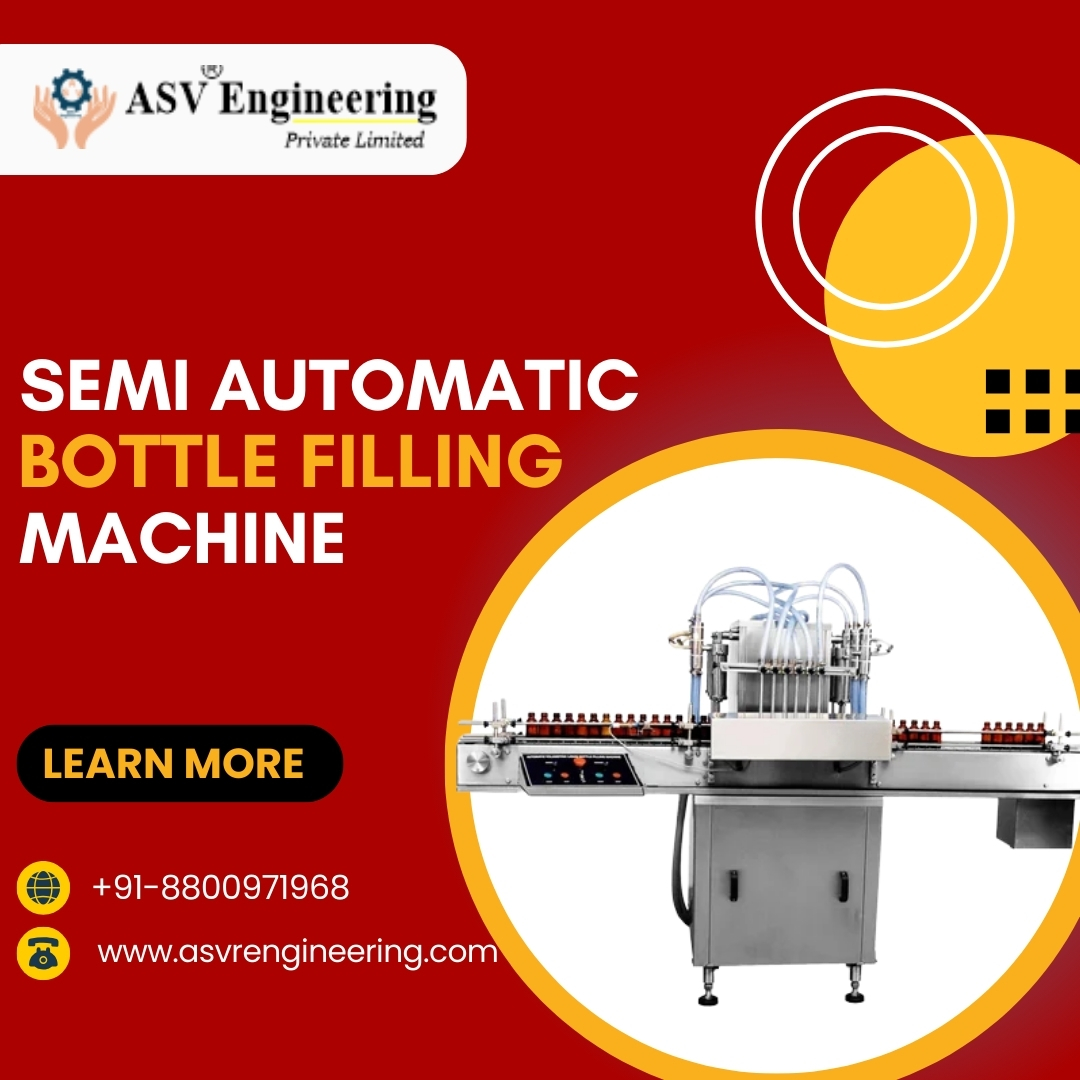

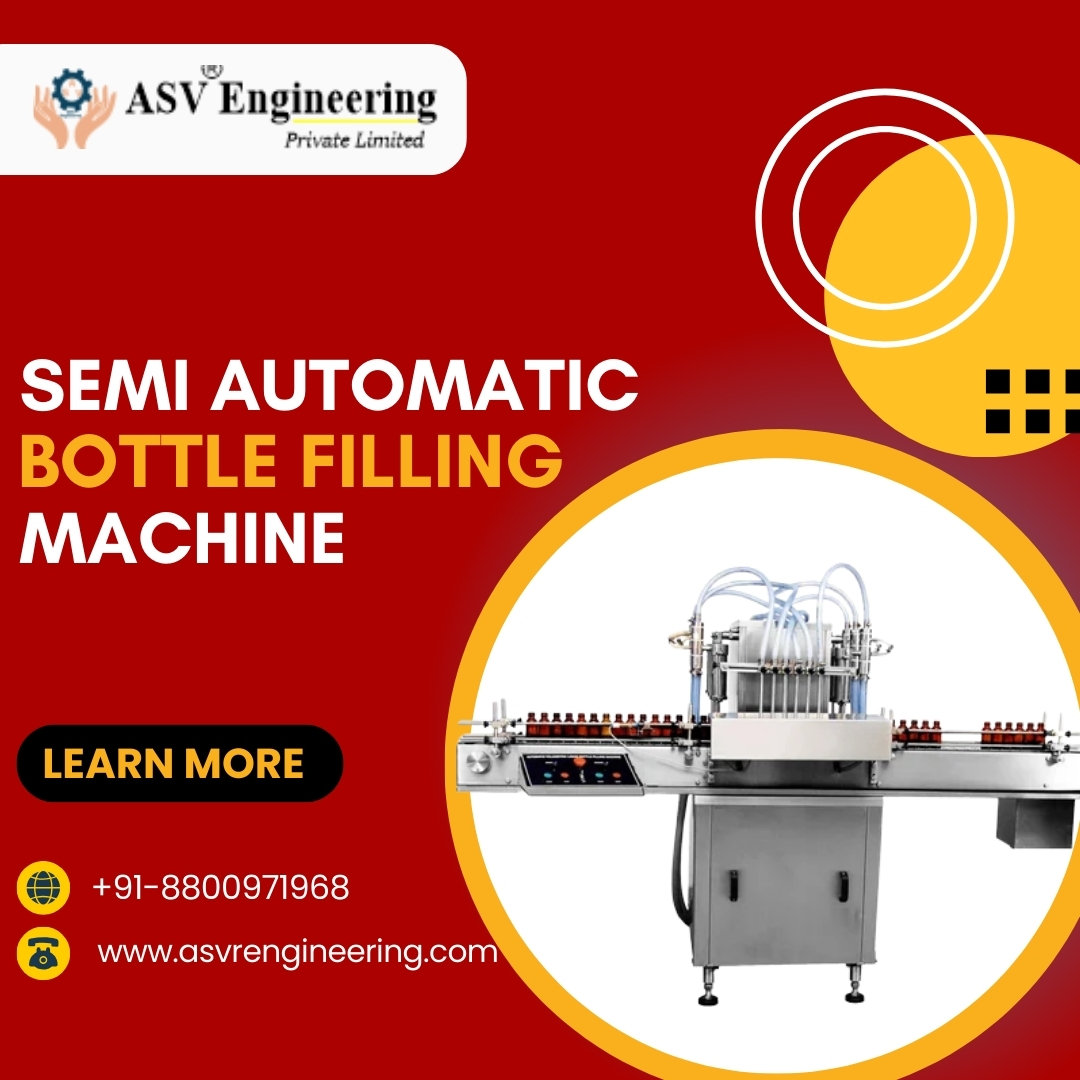

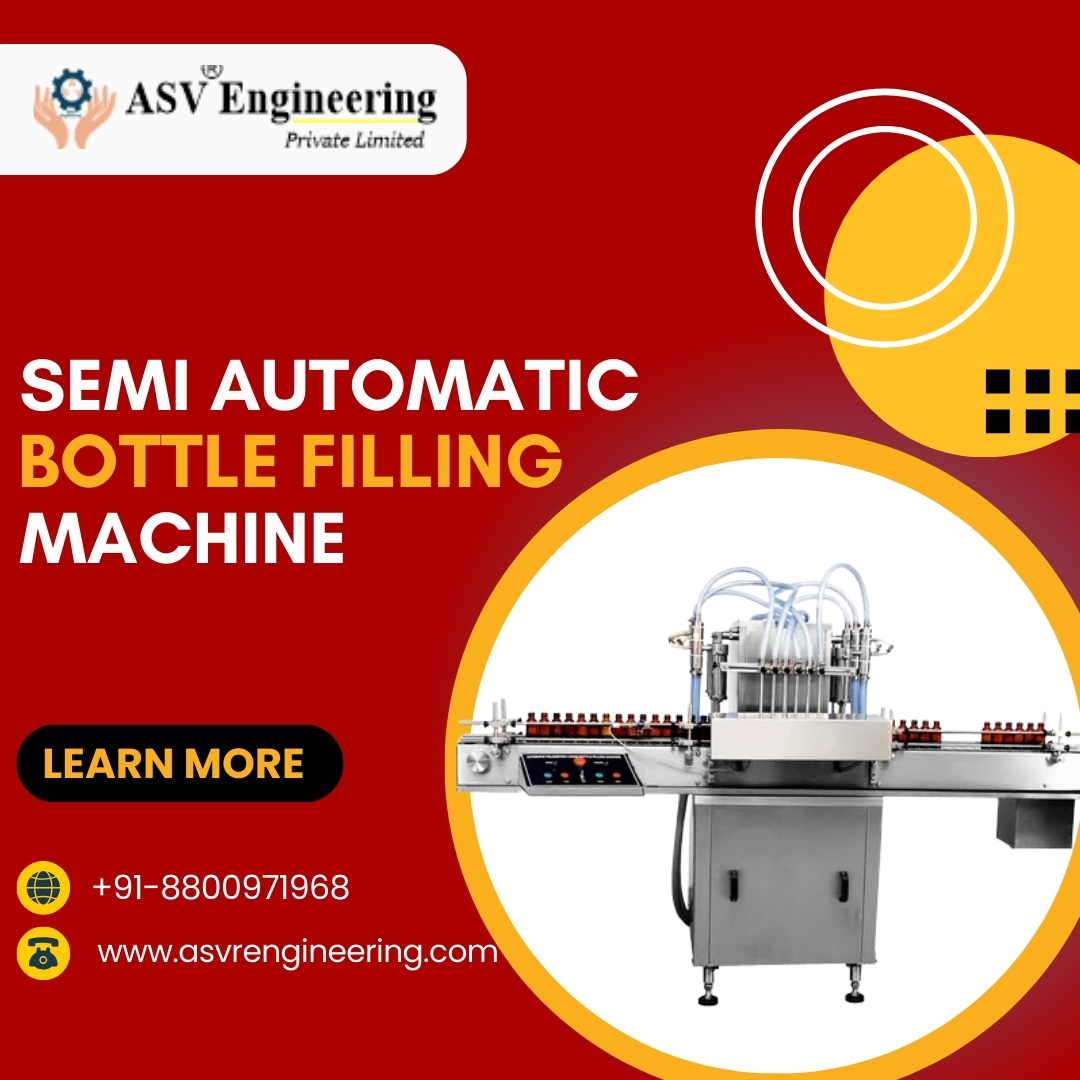

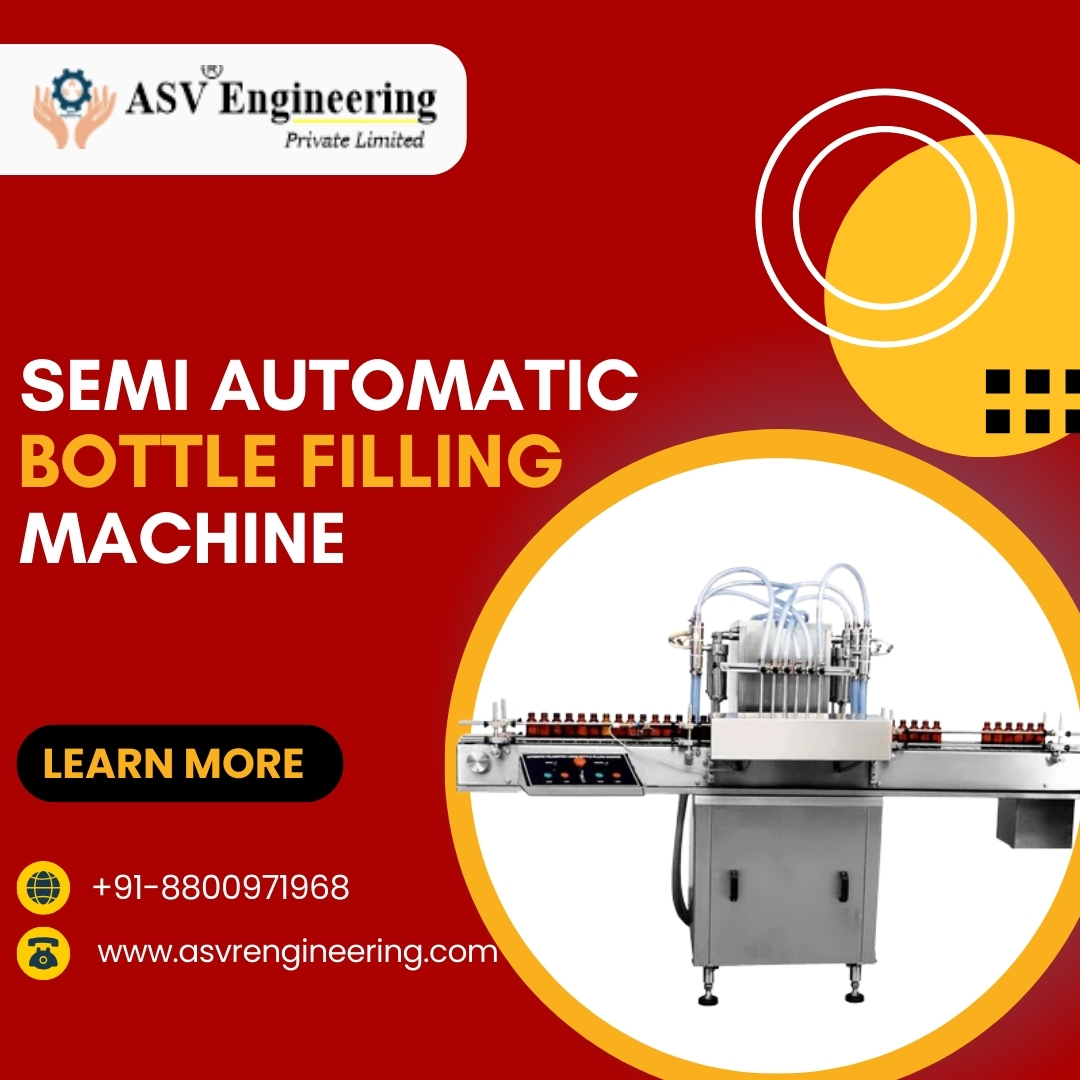

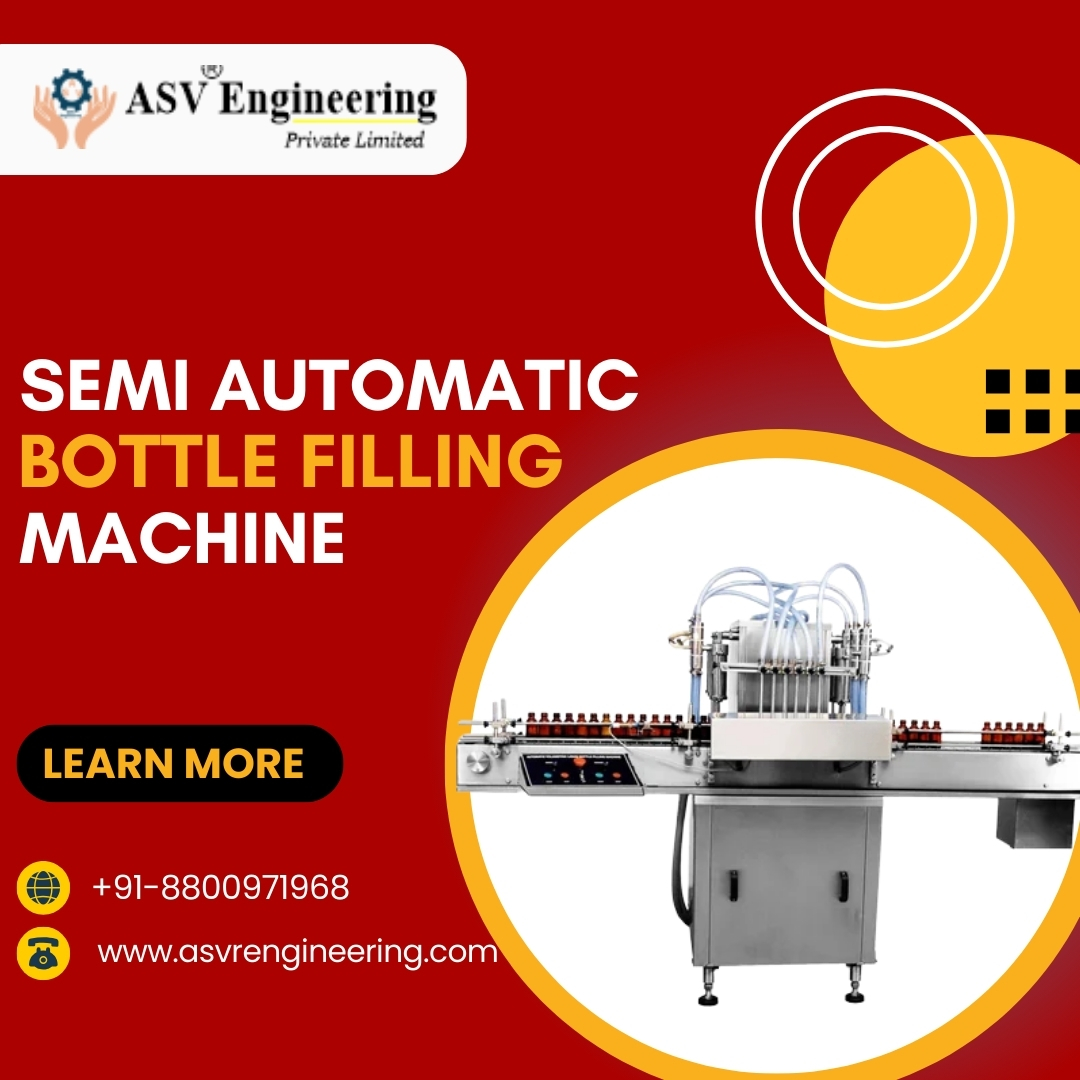

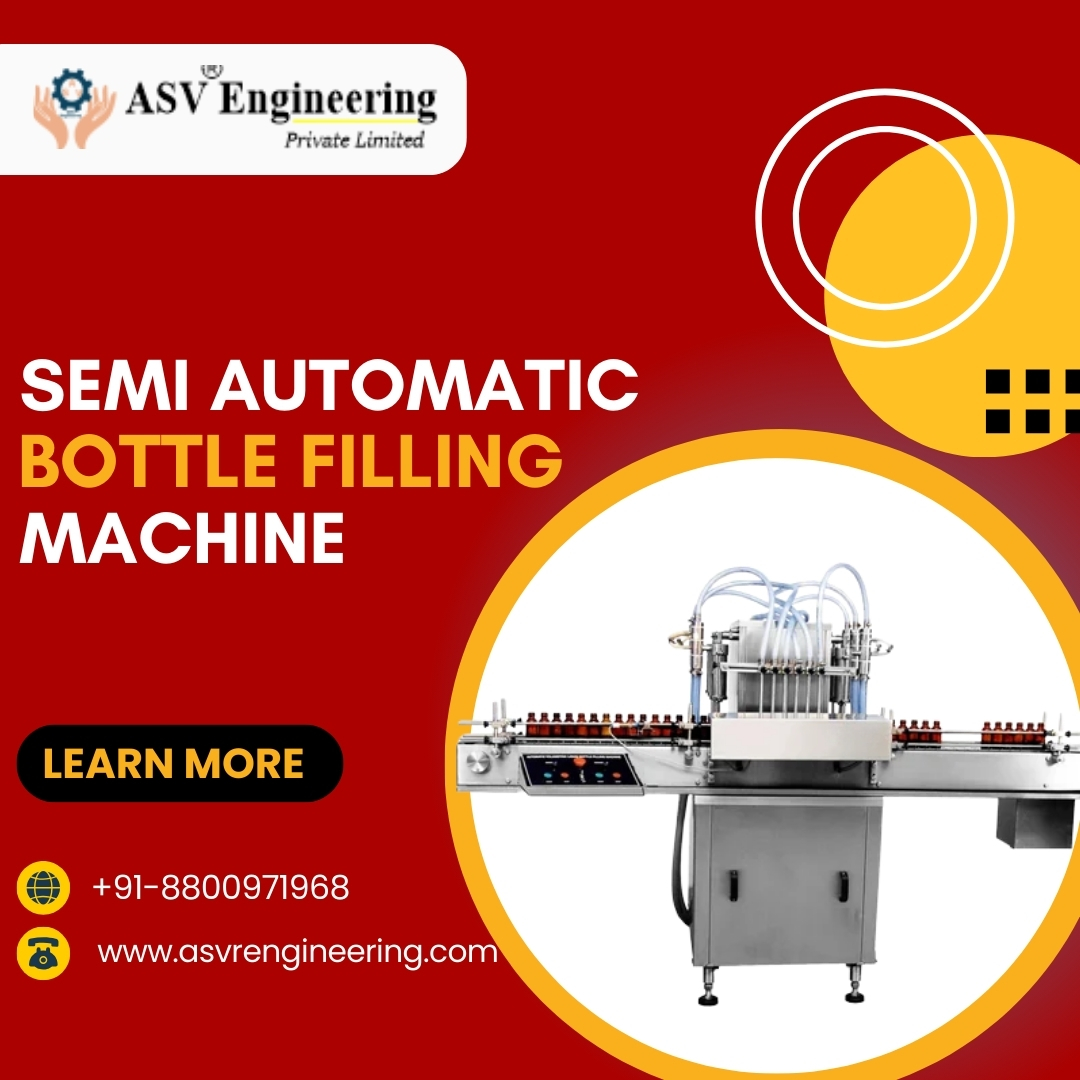

Semi Automatic Bottle Filling Machine

Price: ₹125000

In today’s competitive manufacturing and packaging environment, accuracy, consistency, and efficiency are not optional—they are essential. A Semi Automatic Bottle Filling Machine is one of the most practical and widely used solutions for industries that require precise liquid filling without the high investment of fully automatic systems. Designed to strike the perfect balance between productivity and affordability, this machine is ideal for small to medium-scale manufacturers who want reliable output with minimal wastage.

At ASVR Engineering, we understand the real challenges faced by manufacturers in sectors such as pharmaceuticals, food & beverages, cosmetics, chemicals, and edible oils. Our semi automatic bottle filling machines are engineered with a focus on durability, user-friendly operation, and long-term performance, ensuring you get maximum value from your investment.

What is a Semi Automatic Bottle Filling Machine?

A semi automatic bottle filling machine is a packaging solution where the operator manually places bottles under the filling nozzles, while the machine controls the filling process. The filling quantity is preset, ensuring consistent volume in every bottle. This combination of manual handling and automated filling makes it an excellent choice for businesses that want precision without the complexity and cost of a fully automatic line.

These machines are especially suitable for liquid products such as water, juices, oils, syrups, shampoos, liquid soaps, chemicals, and pharmaceutical formulations.

How the Semi Automatic Bottle Filling Machine Works

The working process is simple, efficient, and operator-friendly:

-

Empty bottles are manually placed on the platform under the filling nozzles.

-

The operator initiates the filling cycle using a foot switch or control button.

-

The machine dispenses a pre-set quantity of liquid into each bottle.

-

Once filling is complete, the operator removes the filled bottles and replaces them with empty ones.

This straightforward process reduces training time, minimizes errors, and allows even small teams to achieve professional packaging results.

Key Features of Semi Automatic Bottle Filling Machine

1. High Filling Accuracy

Our machines are designed to deliver uniform filling volumes, reducing product wastage and ensuring compliance with packaging standards.

2. Robust Construction

Manufactured using high-grade stainless steel and quality components, the machine is resistant to corrosion, chemicals, and wear, making it suitable for long-term industrial use.

3. Versatile Application

The same machine can be used for multiple liquid types by adjusting settings, making it a flexible solution for diverse industries.

4. Easy Operation & Maintenance

Simple controls, minimal moving parts, and easy cleaning ensure smooth daily operation and low maintenance costs.

5. Cost-Effective Investment

Compared to fully automatic systems, semi automatic bottle filling machines offer excellent productivity at a much lower price point.

Applications of Semi Automatic Bottle Filling Machine

The semi automatic bottle filling machine is widely used across multiple industries due to its adaptability and efficiency:

Pharmaceutical Industry

Ideal for filling syrups, suspensions, tonics, and other liquid medicines with high accuracy and hygiene.

Food & Beverage Industry

Used for filling water, fruit juices, flavored drinks, sauces, edible oils, and other food-grade liquids.

Cosmetic & Personal Care Industry

Perfect for shampoos, lotions, creams, hair oils, hand washes, and liquid soaps.

Chemical Industry

Suitable for filling non-corrosive and mildly corrosive chemicals, cleaning liquids, and industrial solutions.

Ayurvedic & Herbal Products

Commonly used for herbal juices, oils, and liquid extracts where consistency is crucial.

Advantages of Choosing a Semi Automatic Bottle Filling Machine

Better Control Over Production

Manual bottle placement allows operators to monitor quality closely, reducing the chances of defects.

Reduced Labor Costs

One or two operators can efficiently manage the filling process, cutting down on manpower requirements.

Compact Design

The machine occupies minimal floor space, making it suitable for small manufacturing units.

Scalable Solution

As production grows, businesses can easily integrate additional machines or upgrade to automated systems.

Why Choose ASVR Engineering?

When you invest in a semi automatic bottle filling machine from ASVR Engineering, you are not just buying a machine—you are partnering with a company committed to quality and customer satisfaction.

Proven Engineering Expertise

We design and manufacture machines that meet industrial standards and deliver consistent performance.

Customization Options

Our machines can be customized based on bottle size, filling volume, liquid type, and production capacity.

Quality Assurance

Each machine undergoes strict quality checks before delivery to ensure reliability and safety.

Competitive Pricing

We offer cost-effective solutions without compromising on build quality or performance.

After-Sales Support

Our dedicated support team ensures quick assistance, spare parts availability, and technical guidance whenever needed.

Technical Specifications (Typical)

While specifications may vary depending on customization, a standard semi automatic bottle filling machine generally includes:

-

Filling range: Customizable as per requirement

-

Number of nozzles: Single or multi-nozzle options

-

Material: Stainless steel contact parts

-

Power consumption: Low and energy-efficient

-

Operation: Pneumatic / electrical (as per model)

For exact specifications, we recommend contacting our technical team.

Ideal for Small & Medium Scale Businesses

If you are a startup, MSME, or expanding manufacturer, a semi automatic bottle filling machine is an ideal starting point. It allows you to maintain professional packaging quality while keeping capital expenditure under control. Many of our clients begin with semi automatic machines and later expand their production lines with confidence, knowing they have a reliable foundation.

Safety and Hygiene Standards

Our machines are designed keeping operator safety and product hygiene in mind. Smooth surfaces, food-grade materials, and easy cleaning mechanisms ensure compliance with industry hygiene requirements, especially in pharmaceutical and food sectors.

Long-Term Value & ROI

A semi automatic bottle filling machine from ASVR Engineering offers excellent return on investment. With low maintenance costs, minimal downtime, and consistent output, the machine pays for itself over time while supporting business growth.

Contact ASVR Engineering

If you are looking for a reliable, accurate, and affordable semi automatic bottle filling machine, ASVR Engineering is your trusted partner.

📞 Contact Numbers:

+91-8076004849

+91-8800971968

🌐 Website: https://www.asvrengineering.com

Our team will be happy to understand your requirements and suggest the most suitable bottle filling solution for your business.

Buy Now

Related Posts

Leading Automatic Bottle Filling Machine Manufacturers for High-Speed Industrial Packaging Solutions

Trusted Automatic Milk Bag Packaging Machine Distributors for Dairy Plants, Milk Booths & FMCG Units

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

(6).jpg)

.png)

.png)

.png)

.png)

(6).jpg)

.png)

(6).jpg)