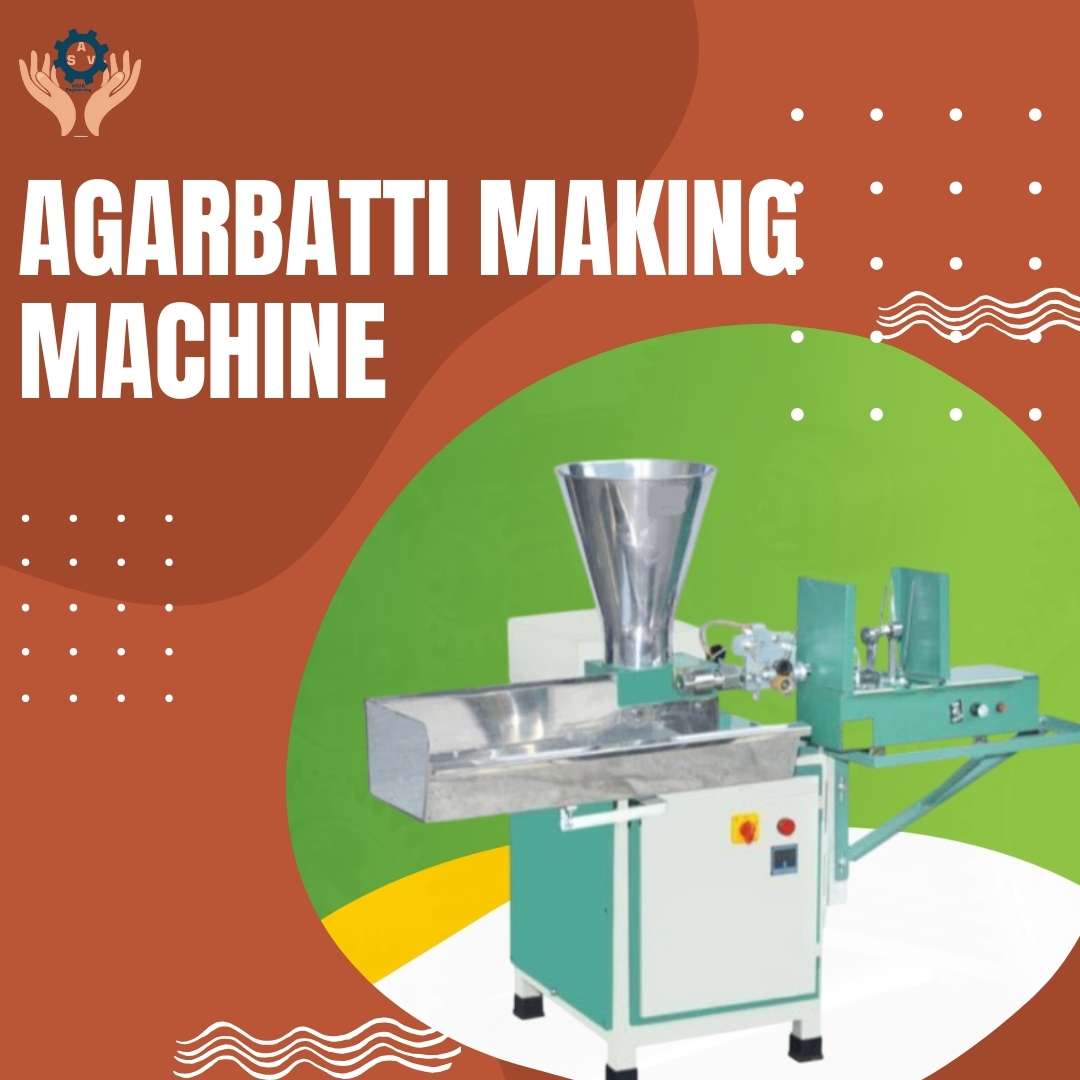

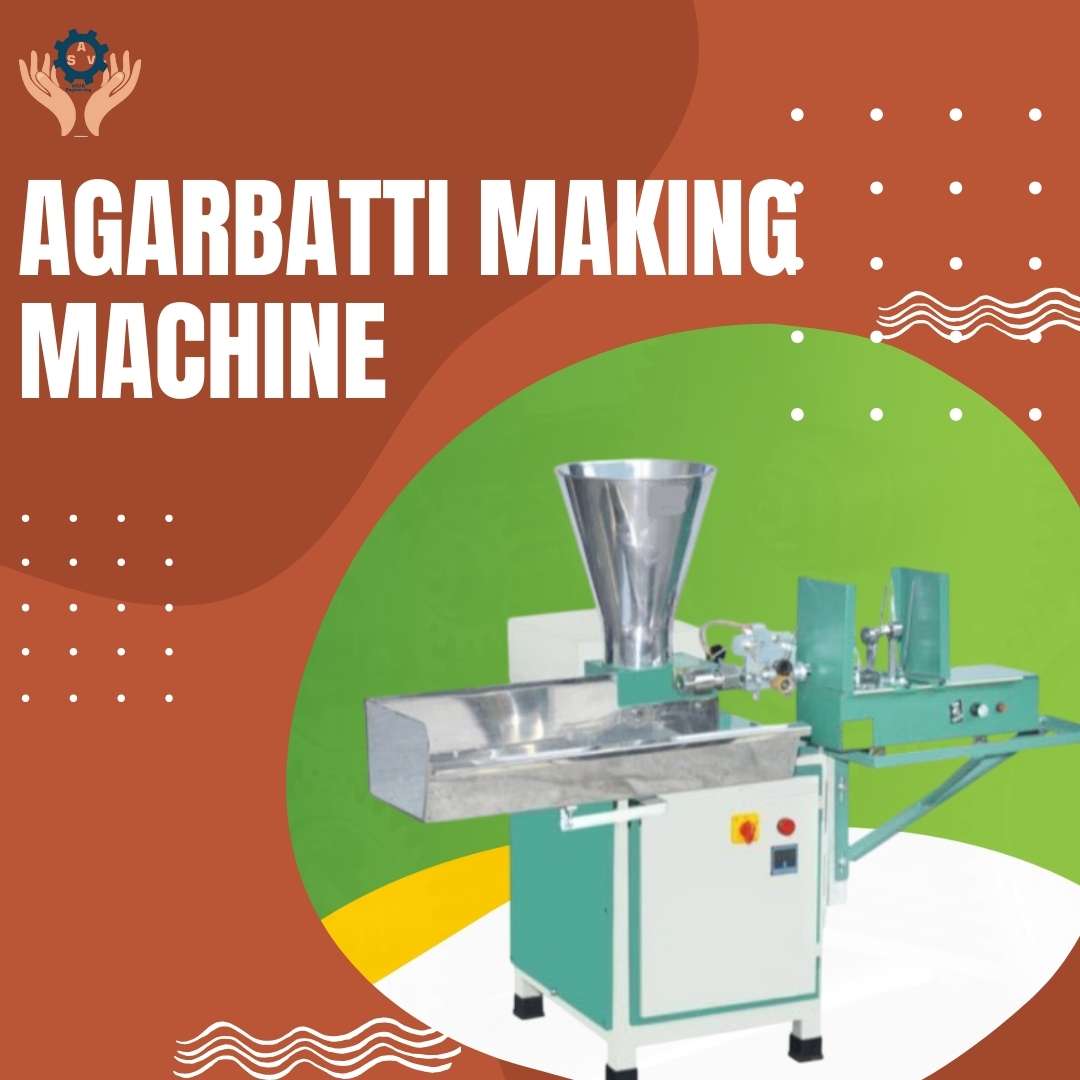

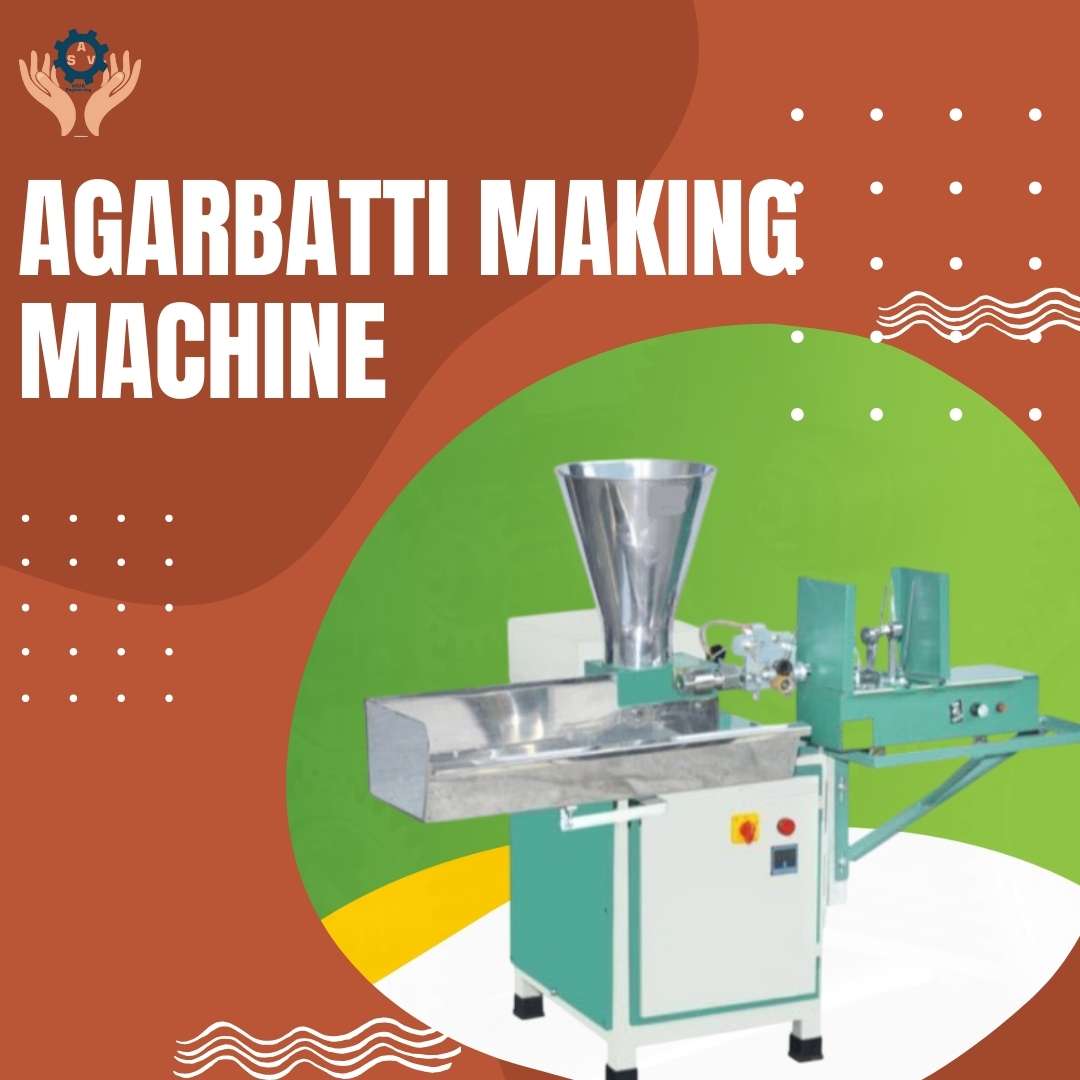

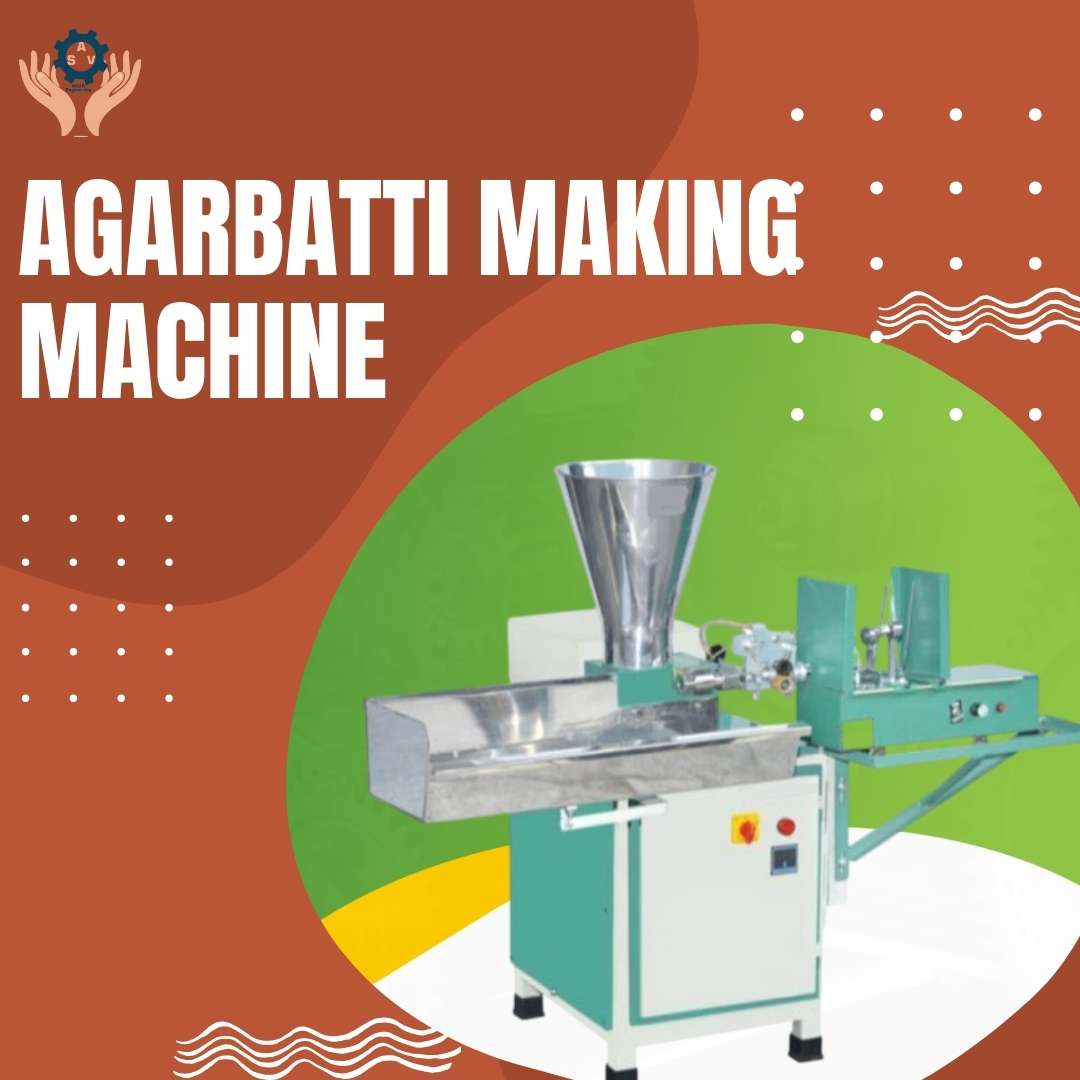

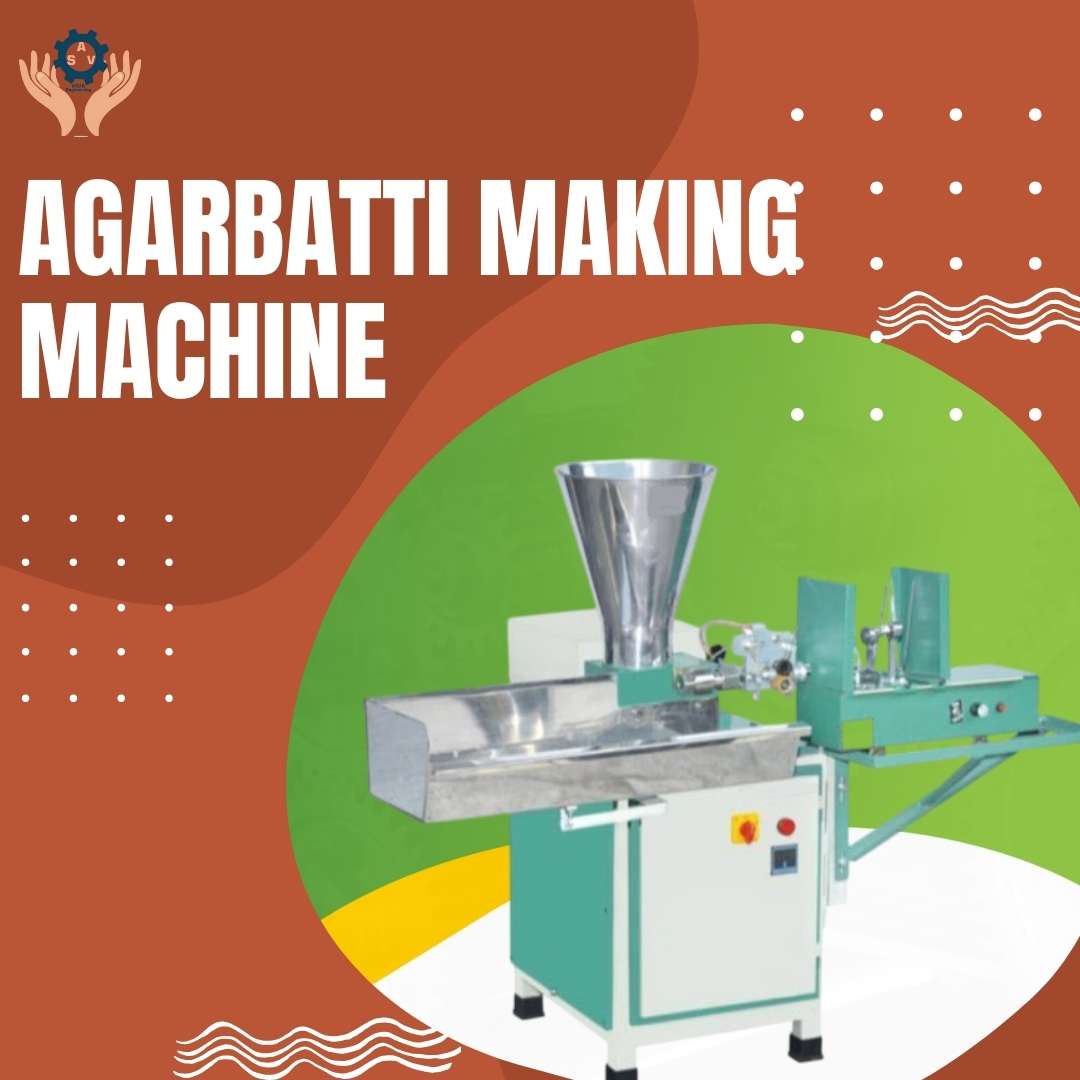

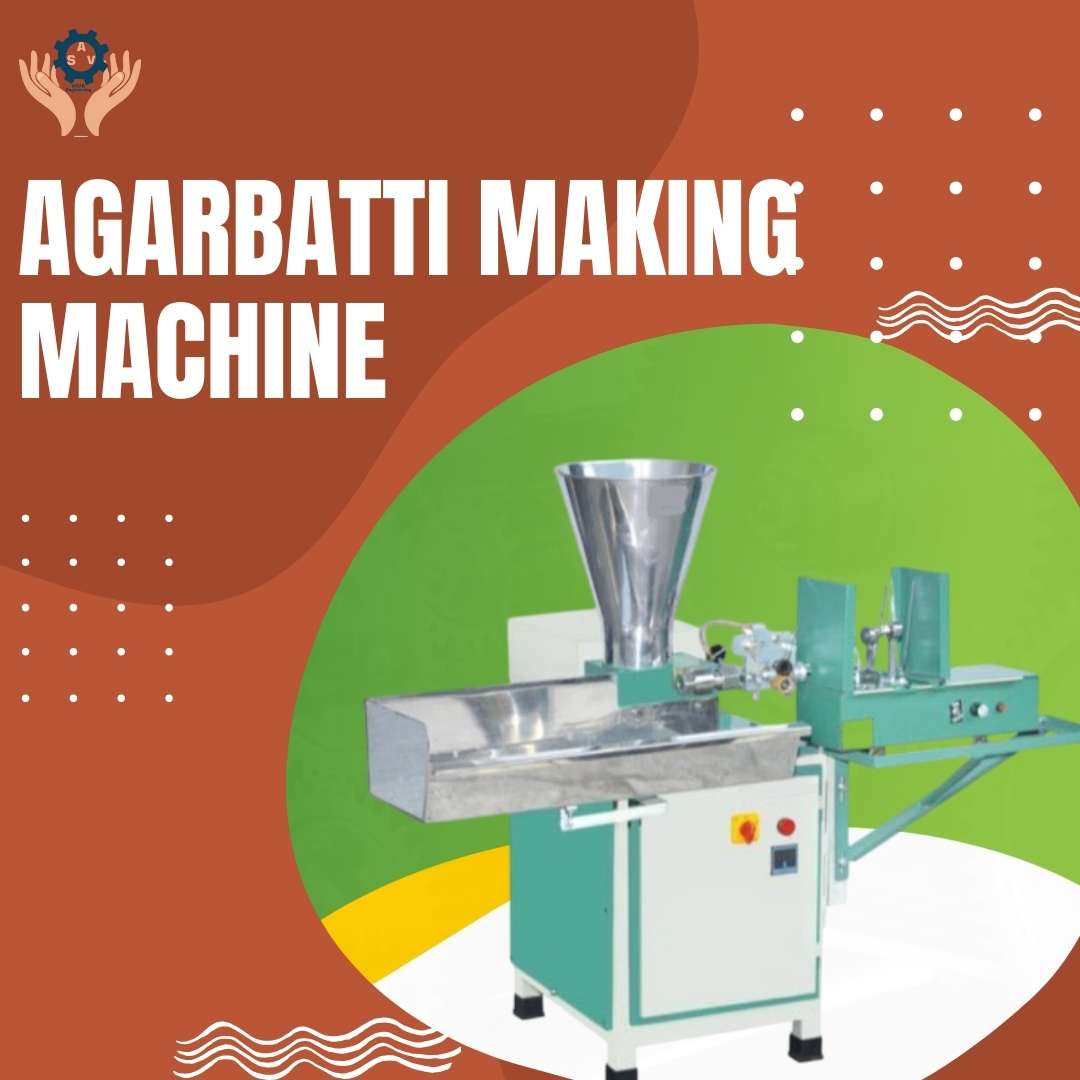

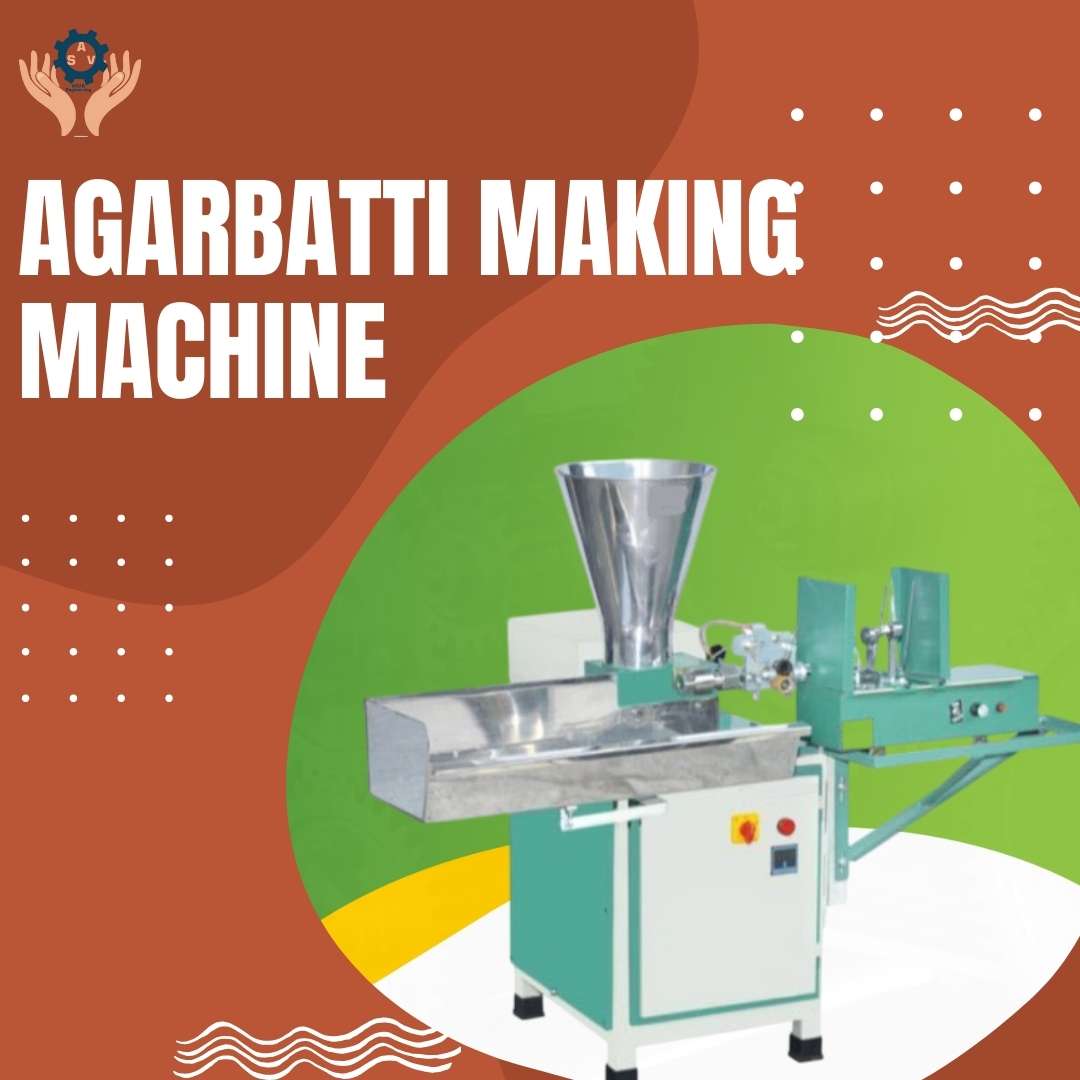

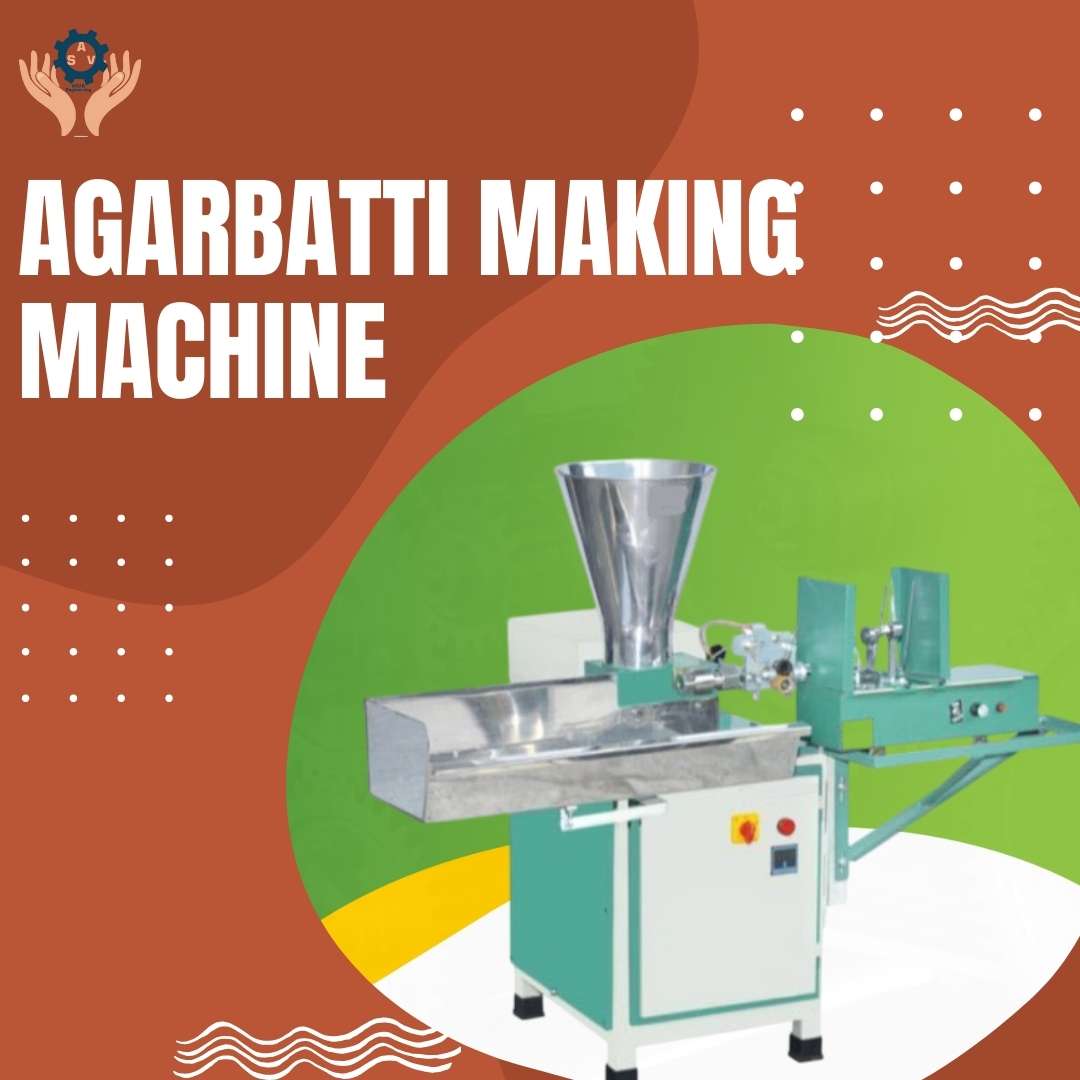

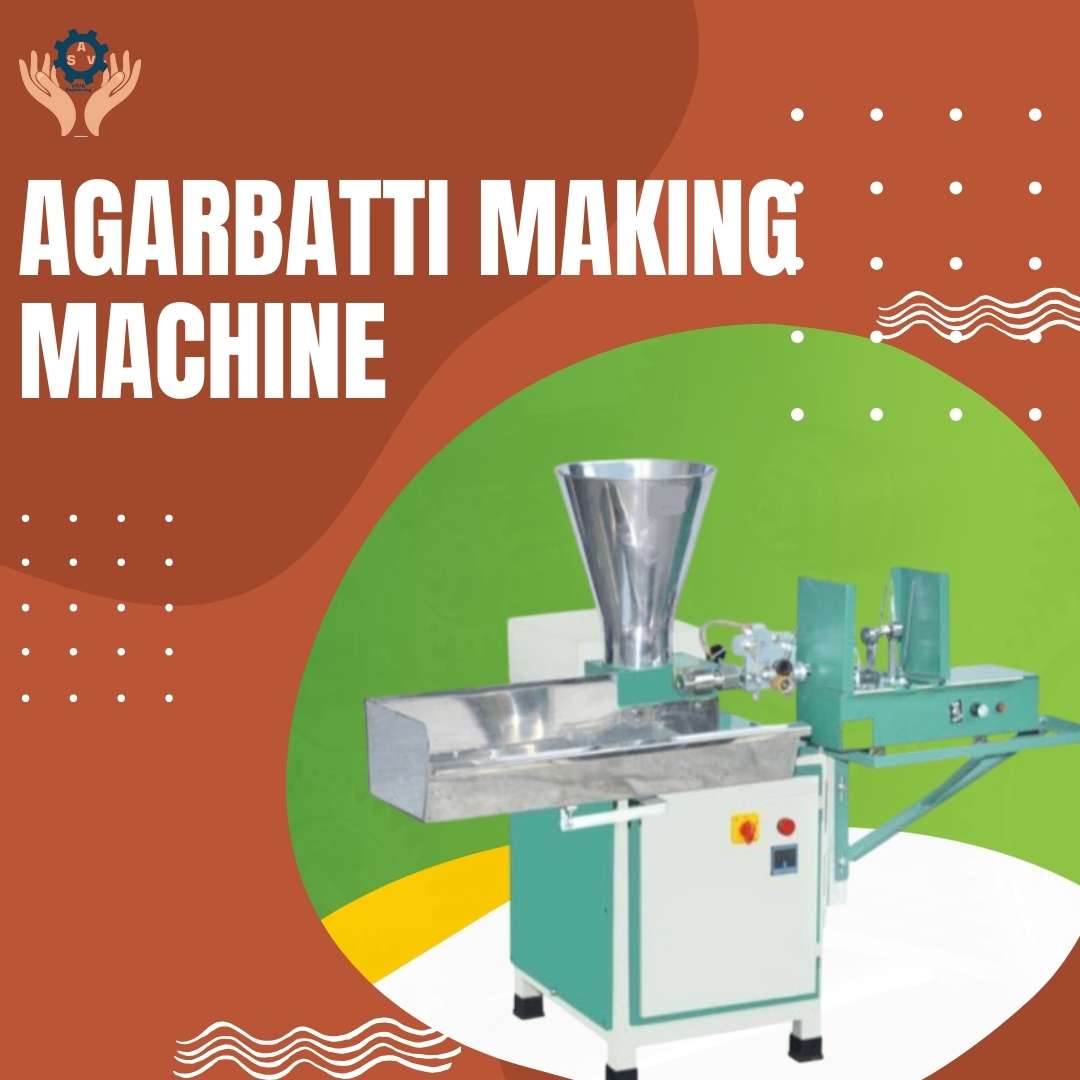

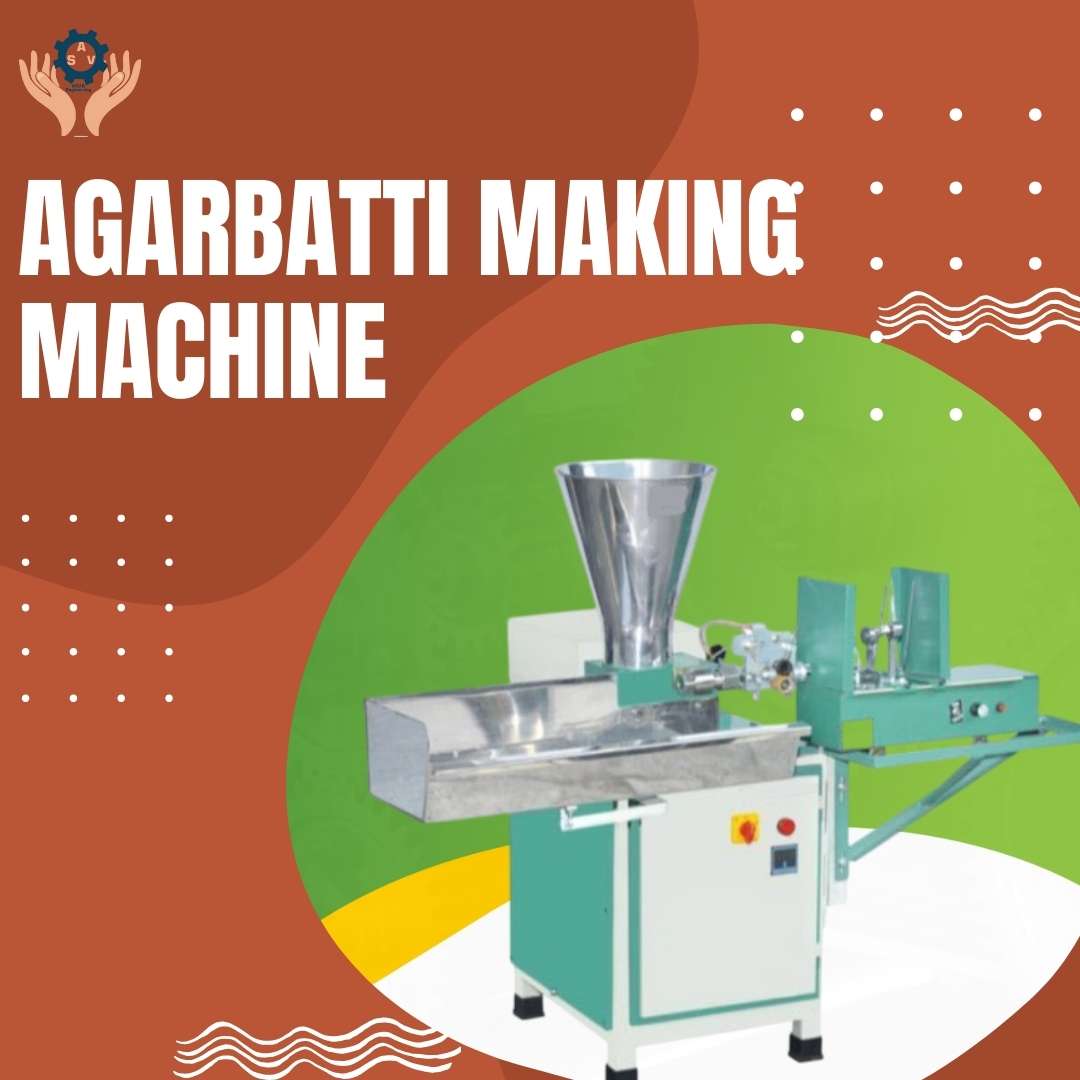

Agarbatti Making Machine

Price: ₹65000

The agarbatti industry in India is deeply rooted in culture, spirituality, and daily rituals. From homes and temples to offices and meditation centers, agarbatti (incense sticks) are used every single day. With increasing domestic demand and strong export potential, starting or upgrading an agarbatti manufacturing unit has become a highly profitable business idea. At the heart of this business lies one crucial component – a reliable and efficient Agarbatti Making Machine.

An agarbatti making machine simplifies the manufacturing process, increases production capacity, maintains consistent quality, and reduces dependency on manual labor. Whether you are a first-time entrepreneur or an established manufacturer looking to scale up, investing in the right machine can define your long-term success.

What Is an Agarbatti Making Machine?

An agarbatti making machine is a specialized mechanical or automatic device used to produce incense sticks by coating a uniform mixture of charcoal powder, jiggat powder, wood powder, and fragrance binders over bamboo sticks. These machines ensure that each stick has consistent thickness, smooth finishing, and uniform burning quality.

Depending on production needs, machines are available in manual, semi-automatic, and fully automatic variants. Each type caters to different business scales, budgets, and operational capacities.

Importance of Using an Agarbatti Making Machine

Using an agarbatti making machine is no longer a luxury—it is a necessity for anyone serious about quality production and market competitiveness.

Higher Productivity

Machines can produce thousands of incense sticks per hour, which is impossible to achieve consistently with manual hand-rolling methods.

Uniform Quality

Consistency in thickness, length, and coating directly affects burning time and fragrance diffusion. Machines ensure standardized output in every batch.

Reduced Labor Cost

Automation significantly cuts down labor dependency, reducing recurring operational expenses and human errors.

Faster ROI

With higher output and lower costs, businesses can recover their investment faster and start generating steady profits.

Scalability

As demand grows, machine-based production allows easy scaling without major workflow disruptions.

Types of Agarbatti Making Machines

Understanding different machine types helps you choose the right one for your business.

Manual Agarbatti Making Machine

This is suitable for small-scale or home-based businesses. It requires more human effort but has a low initial cost. Ideal for beginners testing the market.

Semi-Automatic Agarbatti Making Machine

A balanced option for growing businesses. It automates part of the process, improves speed, and maintains good quality while still being cost-effective.

Fully Automatic Agarbatti Making Machine

Designed for large-scale commercial production. These machines offer high output, minimal labor involvement, consistent quality, and long-term durability.

Key Components and Working Process

An agarbatti making machine works through a systematic and controlled process:

-

Raw Material Preparation – A well-mixed blend of charcoal powder, jiggat powder, and binding agents.

-

Feeding System – The mixture is fed into the machine chamber.

-

Stick Insertion – Bamboo sticks are aligned and inserted automatically or manually depending on machine type.

-

Coating & Rolling – The machine evenly coats the mixture around the stick.

-

Cutting & Output – Finished raw agarbatti sticks are collected for drying and fragrance application.

This process ensures minimal wastage and maximum efficiency.

Raw Materials Used in Agarbatti Production

A good machine performs best when combined with quality raw materials:

-

Bamboo sticks

-

Charcoal powder

-

Jiggat powder

-

Wood powder

-

Fragrance oils

-

Binding agents

Proper proportion and mixing are essential for smooth machine operation and high-quality incense sticks.

Applications of Agarbatti Making Machine

Agarbatti making machines are widely used by:

-

Small home-based entrepreneurs

-

Medium incense manufacturers

-

Large commercial agarbatti factories

-

Export-oriented incense producers

-

Self-help groups and MSMEs

They are suitable for producing various incense types such as masala agarbatti, perfumed agarbatti, herbal incense, and dhoop sticks.

Why the Agarbatti Business Is Profitable in India

India is one of the largest producers and consumers of incense sticks globally. Factors contributing to profitability include:

-

Daily religious usage

-

Strong domestic demand

-

Growing export markets

-

Low raw material cost

-

Government support for MSMEs

With the right agarbatti making machine, manufacturers can tap into this ever-growing market efficiently.

Choosing the Right Agarbatti Making Machine

Before purchasing, consider these important factors:

-

Production capacity per hour

-

Power consumption

-

Machine durability and build quality

-

Ease of operation and maintenance

-

Availability of spare parts

-

After-sales support

Selecting a reliable supplier is just as important as selecting the machine itself.

Maintenance and Longevity

Proper maintenance ensures long machine life and uninterrupted production:

-

Regular cleaning of rollers and chambers

-

Timely lubrication of moving parts

-

Using properly mixed raw materials

-

Periodic inspection for wear and tear

A well-maintained agarbatti making machine can operate efficiently for years.

Why Choose ASVR Engineering for Agarbatti Making Machines?

ASVR Engineering is a trusted name in industrial and food processing machinery, offering high-quality agarbatti making machines designed for Indian manufacturing conditions. Their machines are known for robust construction, smooth operation, and consistent output.

With a strong focus on customer satisfaction, ASVR Engineering provides technical guidance, reliable service support, and cost-effective solutions suitable for startups as well as large manufacturers.

Business Growth with the Right Machinery

Investing in a high-performance agarbatti making machine is not just about production—it’s about building a sustainable and scalable business. With consistent quality, faster output, and reduced costs, manufacturers can strengthen their brand presence, meet bulk orders, and explore export opportunities confidently.

Contact Details

For detailed specifications, pricing, and expert guidance on selecting the best agarbatti making machine for your business, get in touch today:

📞 Contact Numbers:

+91-8076004849

+91-8800971968

🌐 Website:

https://www.asvrengineering.com

Buy Now