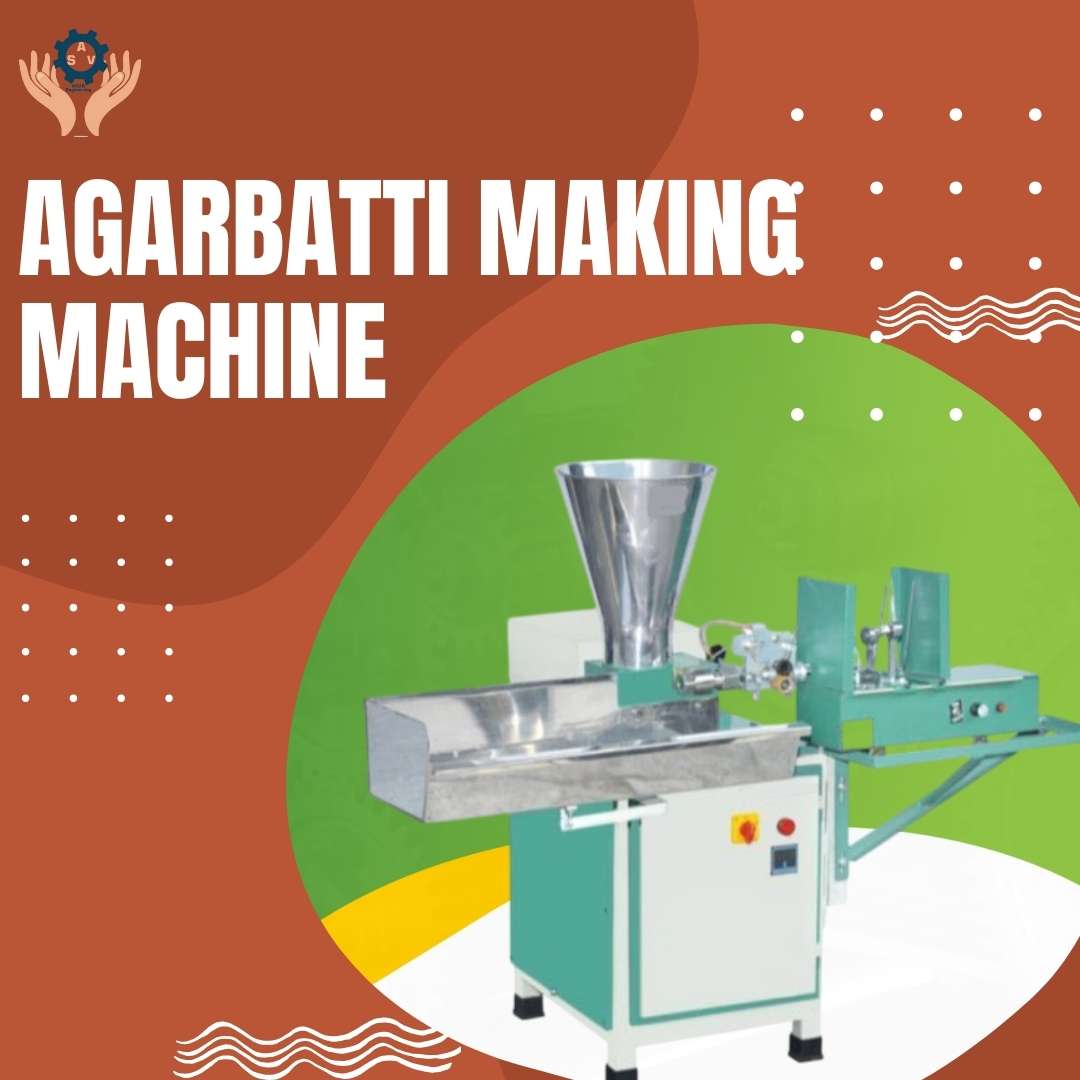

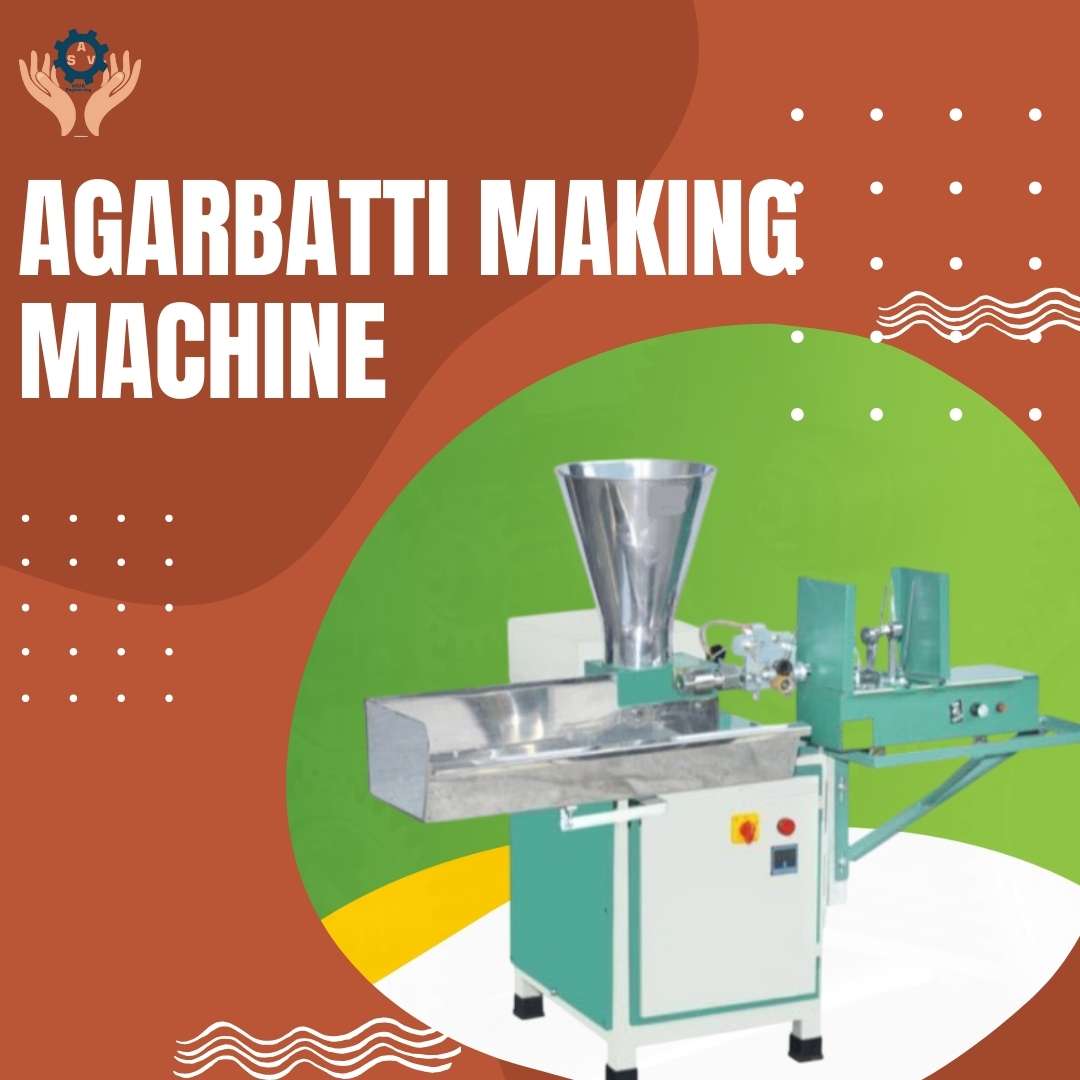

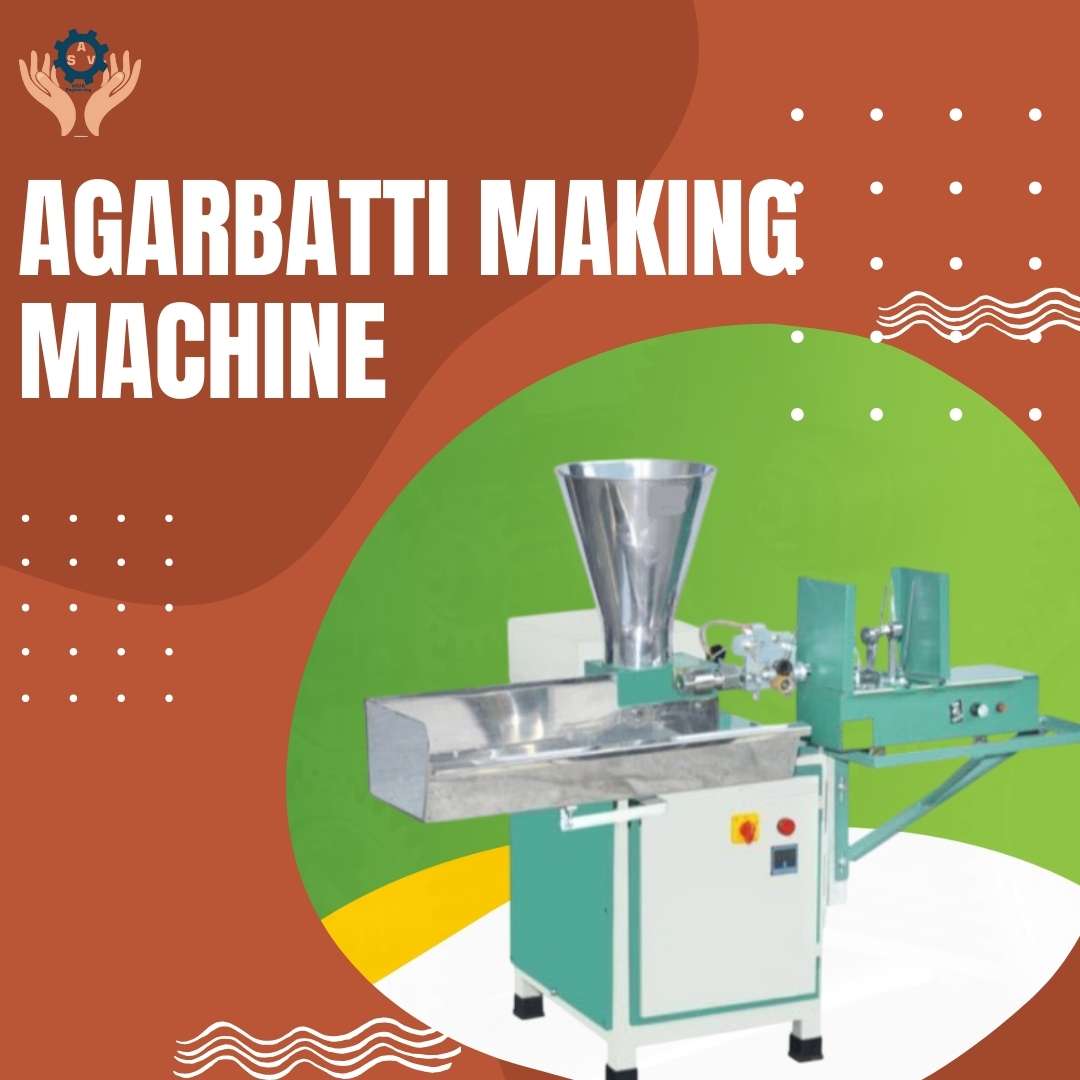

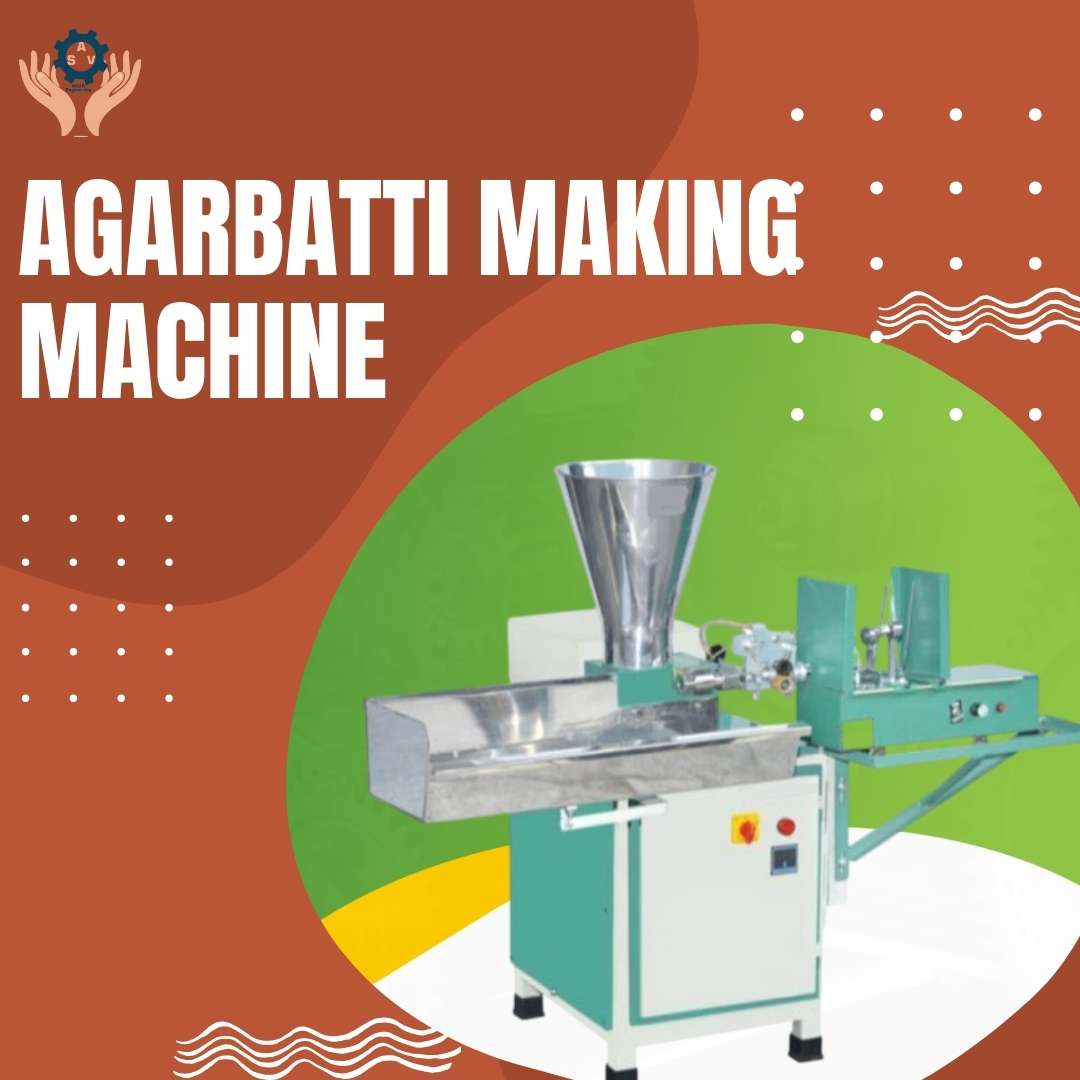

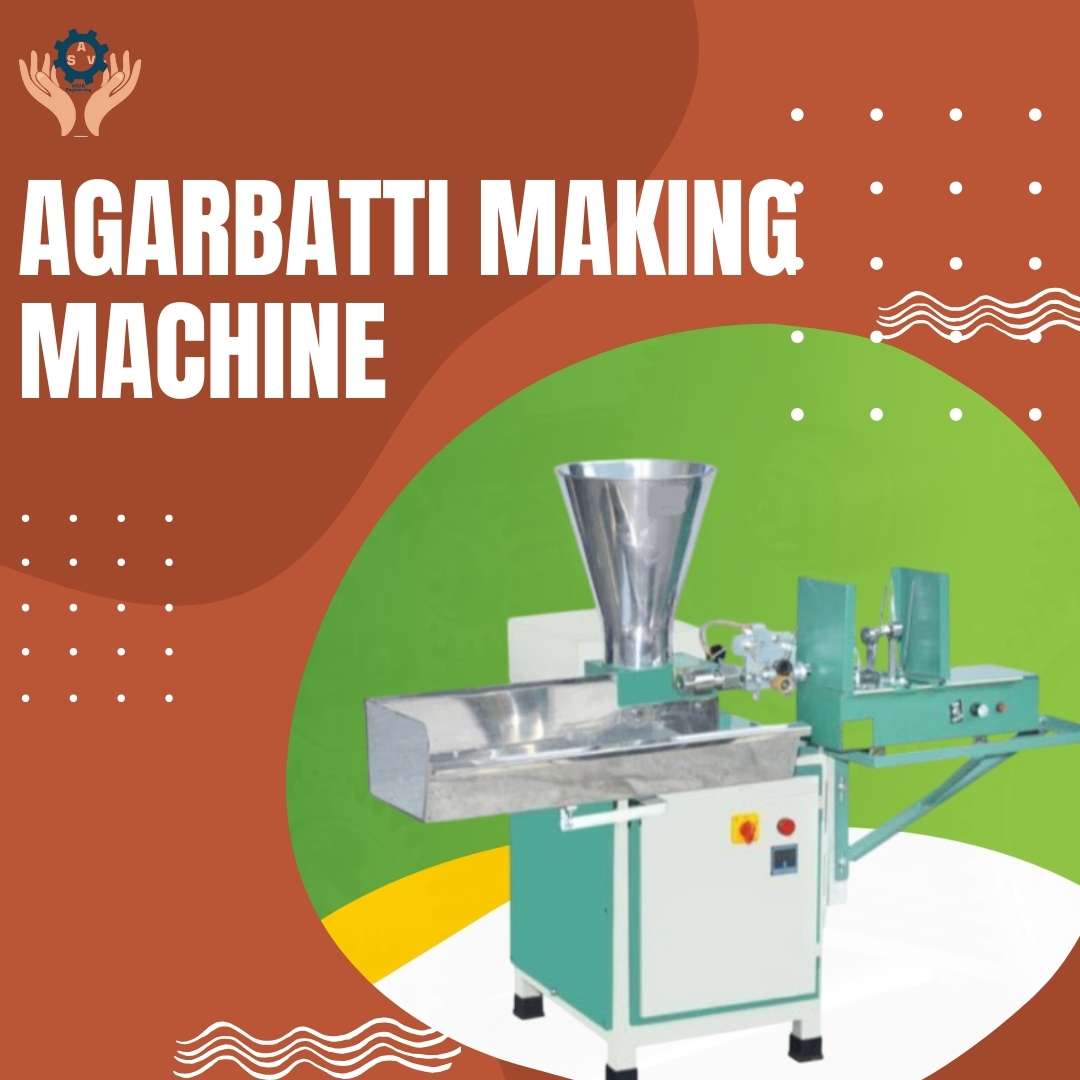

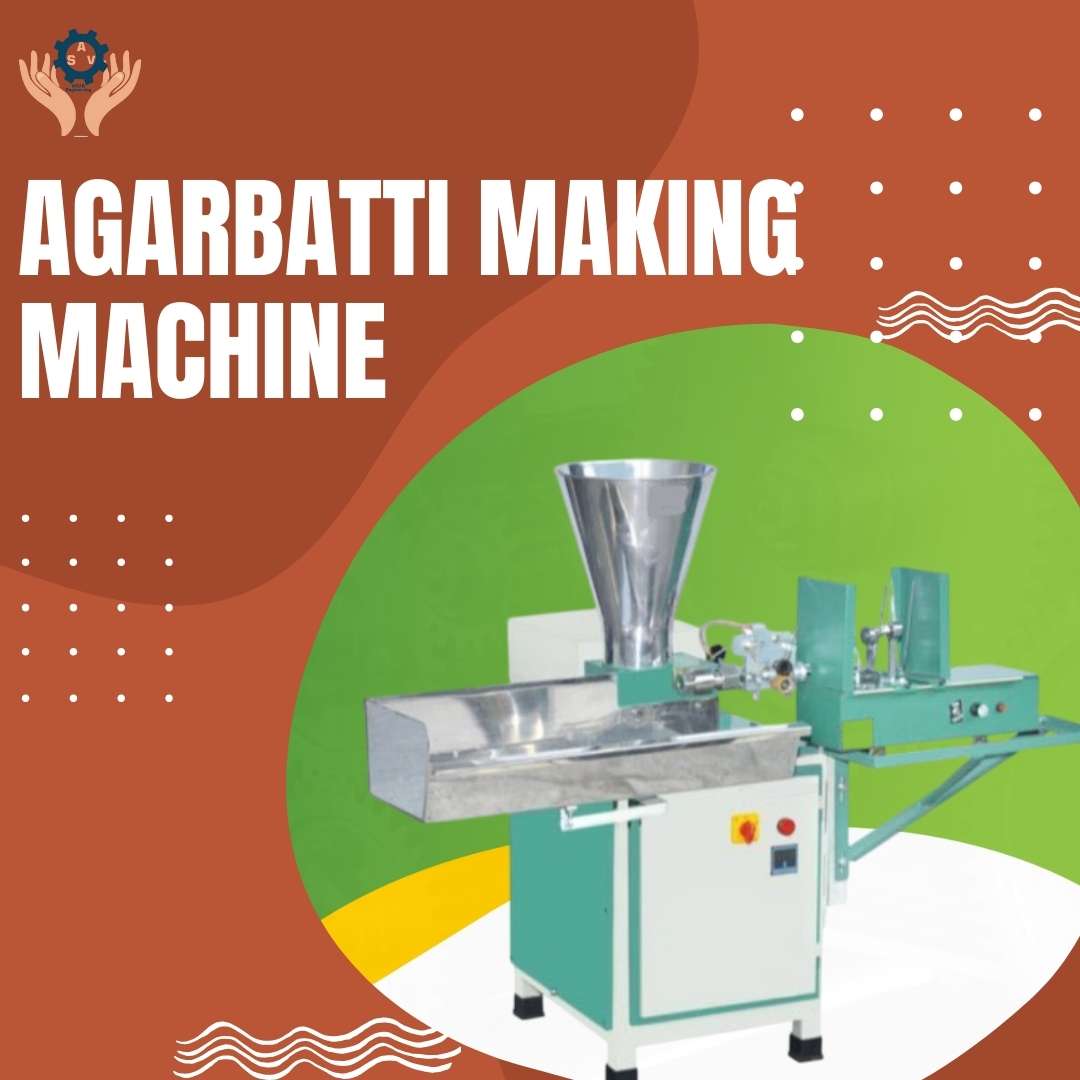

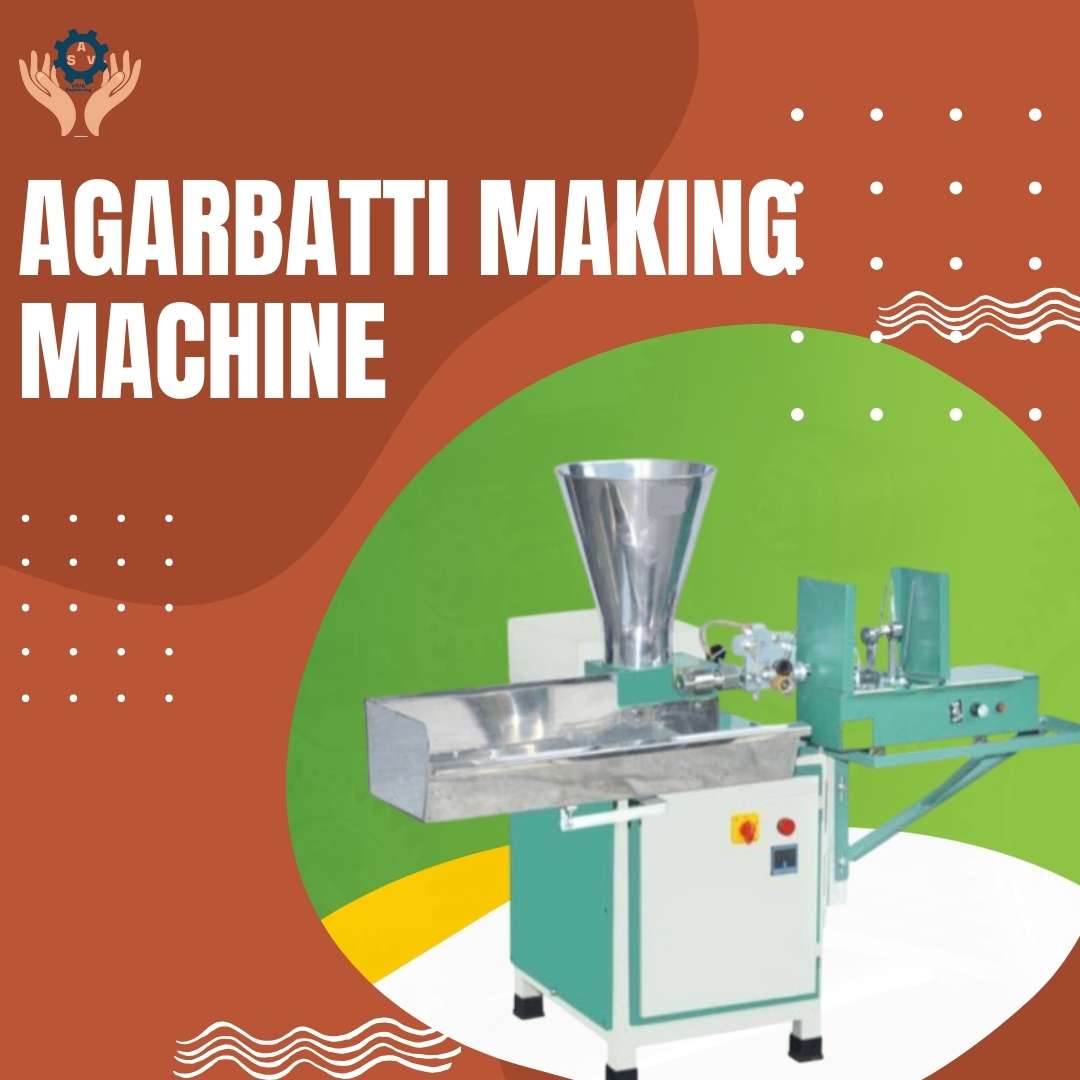

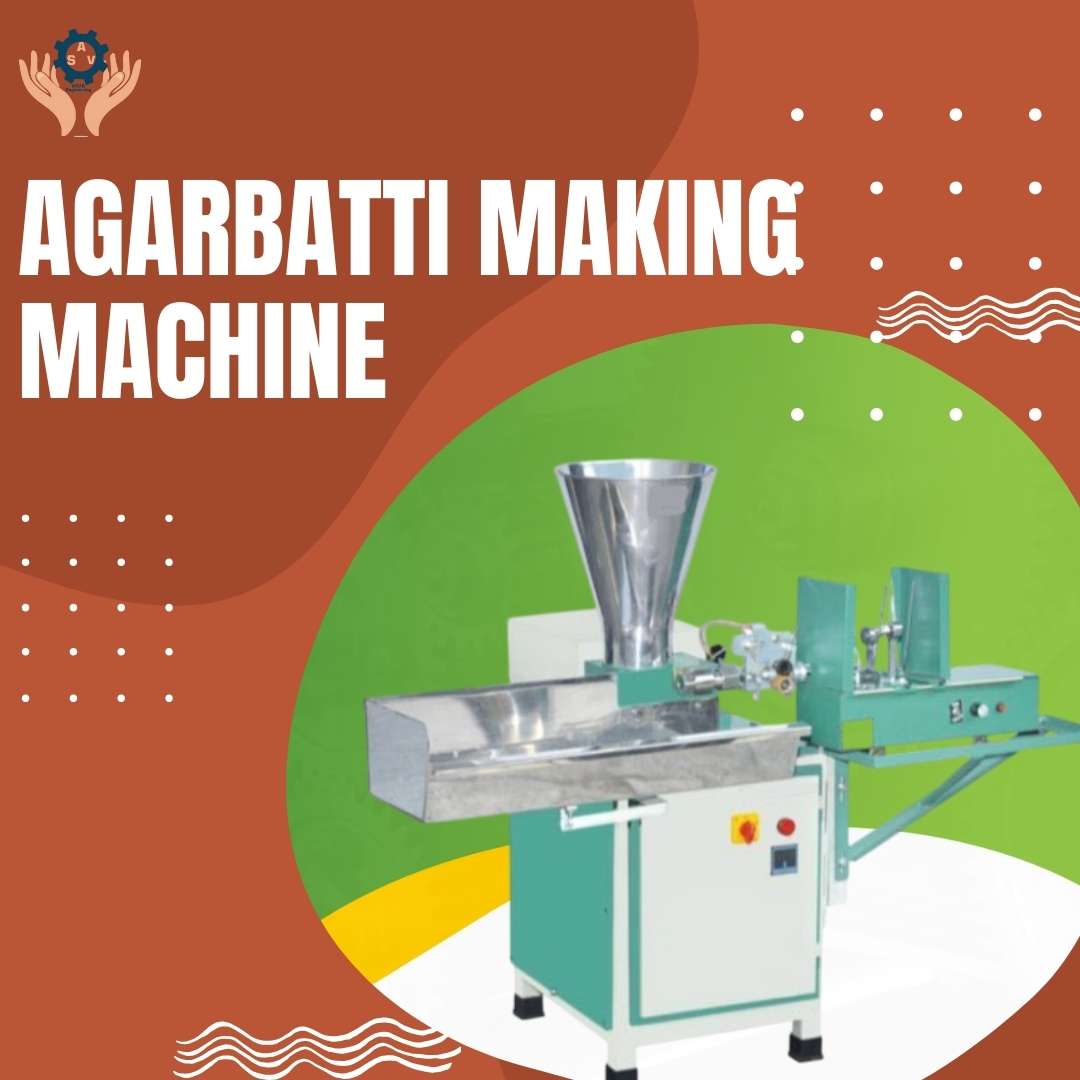

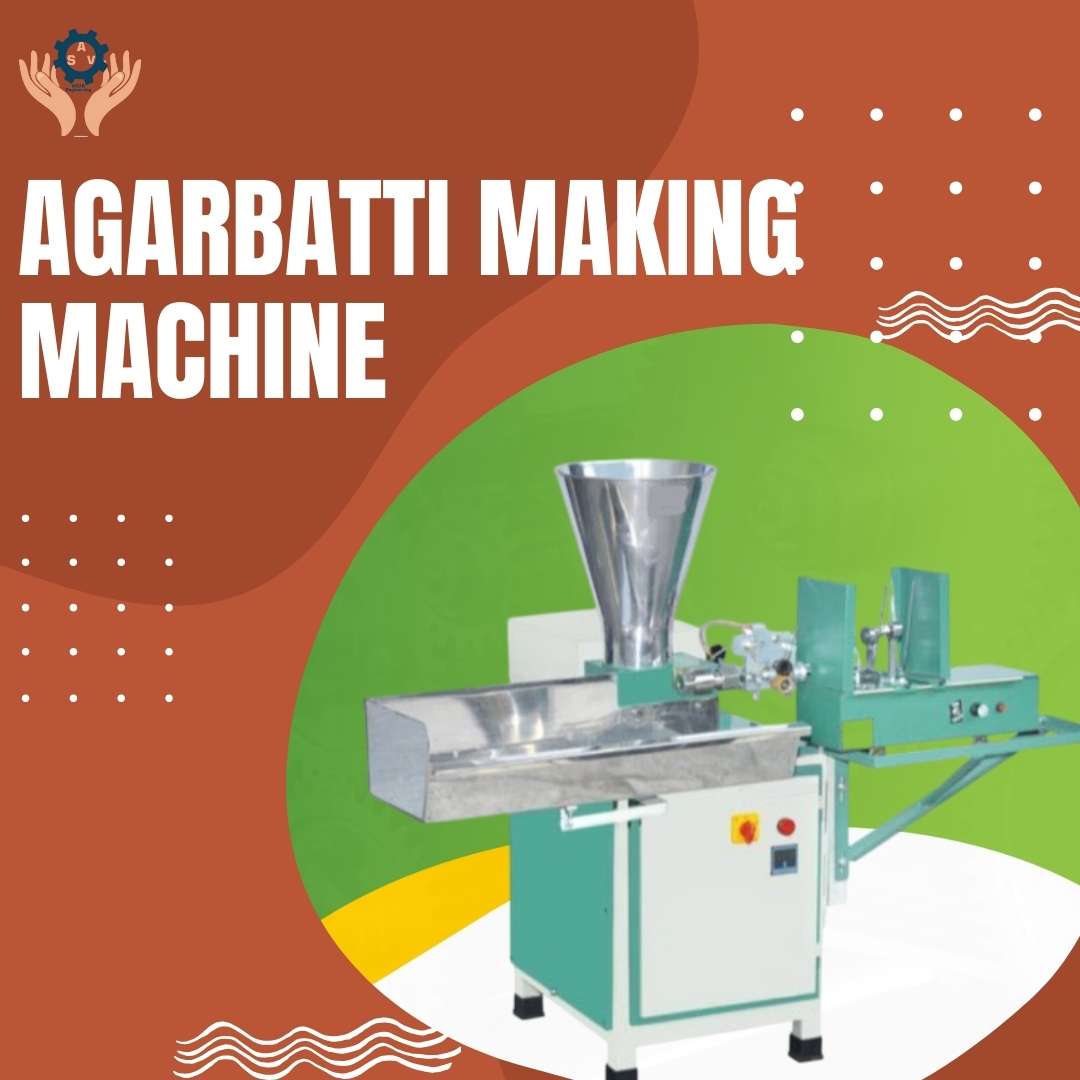

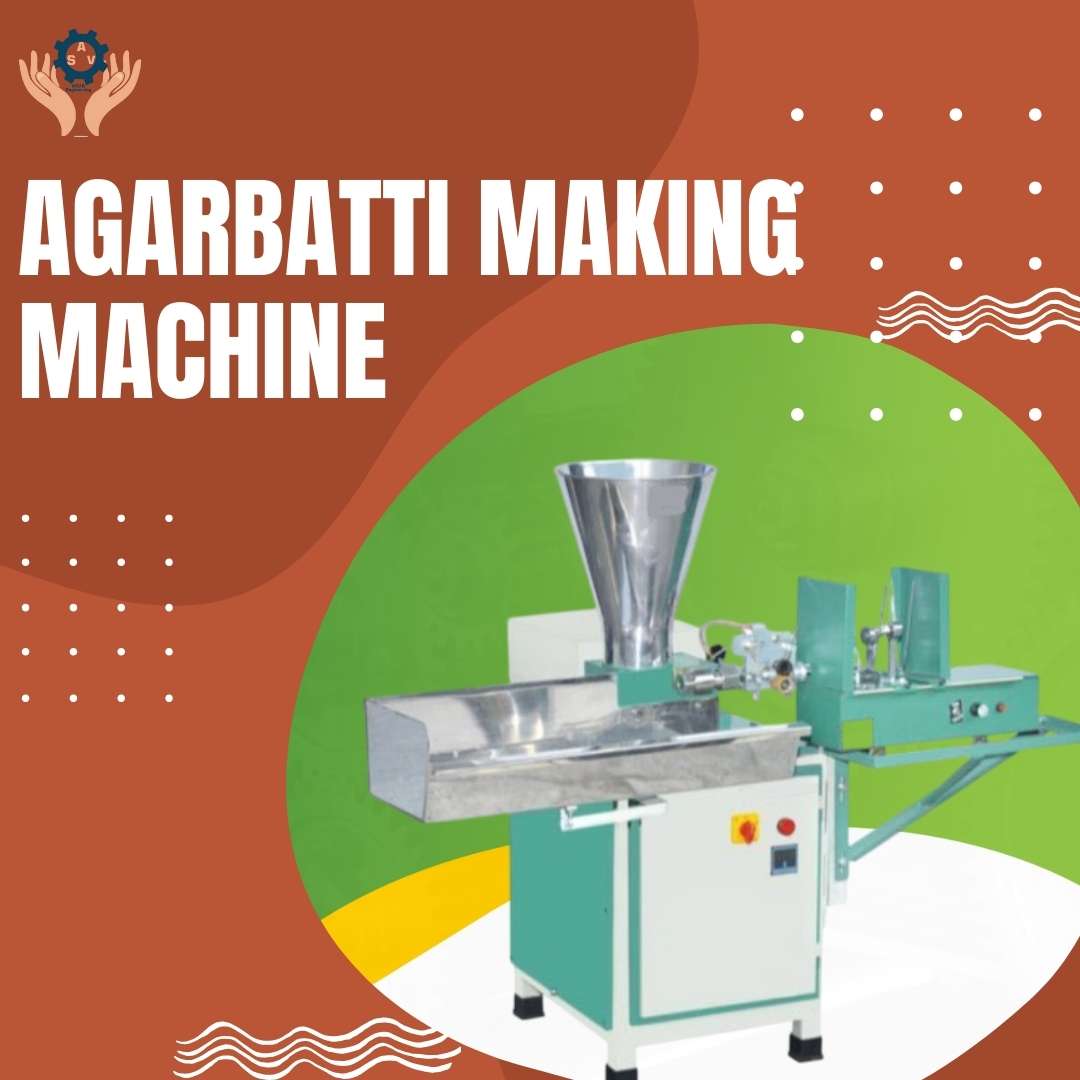

Trusted Automatic Agarbatti Making Machine Exporters Providing Advanced, Cost-Effective Manufacturing Solutions

Price: ₹63000

In the global incense industry, quality, consistency, and production efficiency are the key factors that determine long-term success. As demand for agarbatti continues to grow across Asia, the Middle East, Africa, Europe, and the Americas, manufacturers are increasingly shifting toward automation to meet large-scale requirements while maintaining uniform standards. In this evolving scenario, trusted automatic agarbatti making machine exporters play a critical role by supplying reliable, advanced, and cost-effective manufacturing solutions to businesses worldwide.

Understanding the Growing Global Demand for Agarbatti

Agarbatti, also known as incense sticks, holds cultural, religious, and aromatic significance across many countries. From daily prayers in Indian households to meditation practices, wellness centers, and spiritual spaces worldwide, agarbatti consumption is consistently rising. With expanding export markets and increasing consumer awareness about fragrance quality and eco-friendly production, manufacturers need modern machinery that can deliver high output without compromising product integrity.

Manual or semi-automatic methods are no longer sufficient to handle bulk orders or maintain consistent stick thickness, fragrance binding, and burn time. This has led to a rapid increase in demand for automatic agarbatti making machines that ensure precision, speed, and reduced labor dependency.

Why Automation Is Essential in Agarbatti Manufacturing

Automation in agarbatti production offers several advantages that directly impact profitability and scalability. Automatic machines are designed to handle continuous production cycles with minimal downtime. They ensure uniform paste application, consistent stick length, smooth finishing, and controlled drying compatibility.

By adopting advanced automatic agarbatti machines, manufacturers can significantly reduce material wastage, improve workforce efficiency, and maintain consistent product quality. Export-grade machines are engineered to perform reliably under extended operational hours, making them ideal for businesses targeting domestic as well as international markets.

Role of Trusted Automatic Agarbatti Making Machine Exporters

Choosing the right exporter is as important as choosing the right machine. Trusted exporters do more than just supply equipment—they provide complete manufacturing solutions. This includes technical guidance, machine customization, installation support, operator training, and long-term after-sales service.

Reliable exporters understand global compliance standards, export packaging norms, and logistics requirements. Their machines are designed to meet international quality benchmarks, ensuring smooth operations for buyers across different regions. A trusted exporter also focuses on durability, ensuring that machines perform efficiently even in challenging industrial environments.

Advanced Technology for Superior Performance

Modern automatic agarbatti making machines integrate advanced engineering and robust components to deliver superior performance. Features such as adjustable speed control, precision die systems, consistent paste extrusion, and smooth stick rolling mechanisms ensure uniform output across every batch.

Advanced machines are also designed for easy maintenance and quick troubleshooting. Modular components allow for fast replacements, minimizing downtime and ensuring uninterrupted production. For exporters, offering such technologically advanced machines enhances customer confidence and builds long-term business relationships.

Cost-Effective Manufacturing Solutions for Global Buyers

Cost efficiency is a major consideration for both small-scale entrepreneurs and large manufacturing units. Trusted exporters focus on optimizing machine design to balance performance and affordability. Automatic agarbatti machines help reduce recurring labor costs, lower raw material wastage, and improve production speed, resulting in faster return on investment.

Exporters offering cost-effective solutions ensure that buyers receive maximum value without compromising on quality. Energy-efficient motors, durable frames, and optimized production mechanisms help reduce operational expenses over the machine’s lifespan.

Customization to Match Diverse Market Needs

Different markets have different requirements in terms of stick length, thickness, fragrance binding, and production capacity. Leading exporters offer customized automatic agarbatti making machines to suit specific business needs. Whether a buyer requires high-speed production for bulk exports or flexible settings for multiple product variants, customization plays a crucial role.

By understanding regional preferences and end-use applications, exporters can recommend suitable configurations that align with market demand. This approach not only improves production efficiency but also helps manufacturers expand their product portfolio.

Quality Standards and Export Compliance

Exporting industrial machinery requires strict adherence to quality standards and safety norms. Trusted automatic agarbatti making machine exporters follow rigorous quality control processes at every stage of manufacturing. From raw material selection to final machine testing, each unit is inspected for performance, durability, and safety.

Compliance with international standards ensures that machines can be seamlessly imported and operated in foreign markets. Proper documentation, export-grade packaging, and secure logistics further enhance the reliability of the exporter.

Supporting Small and Large-Scale Manufacturers Alike

Automatic agarbatti machines are no longer limited to large factories. With compact designs and scalable configurations, exporters now cater to startups, small enterprises, and large industrial units alike. Entry-level automatic machines help new entrepreneurs establish their manufacturing operations, while high-capacity production lines support established exporters and wholesalers.

By offering a wide range of models, trusted exporters ensure that businesses at every stage of growth can access reliable manufacturing technology.

After-Sales Support and Technical Assistance

One of the most important aspects of choosing a trusted exporter is after-sales support. Reliable exporters provide technical assistance, spare parts availability, and maintenance guidance to ensure smooth long-term operation. Prompt support minimizes downtime and protects the buyer’s investment.

Training programs for machine operators and supervisors further enhance productivity and safety. Exporters who prioritize customer satisfaction build long-term partnerships and strong brand credibility in the global market.

Why Choose ASVR Engineering

When it comes to trusted automatic agarbatti making machine exporters, ASVR Engineering stands out for its commitment to quality, innovation, and customer-centric solutions. The company specializes in delivering advanced and cost-effective agarbatti manufacturing machinery designed to meet international standards.

With a strong focus on performance, durability, and efficiency, ASVR Engineering serves clients across domestic and international markets. Each machine is engineered to ensure consistent output, minimal maintenance, and long operational life. The company’s expertise, combined with reliable after-sales support, makes it a preferred choice for businesses looking to scale their agarbatti production.

Building Long-Term Success in the Incense Industry

The incense industry is highly competitive, and success depends on consistent quality, timely delivery, and efficient production processes. Investing in advanced automatic agarbatti making machines from trusted exporters provides manufacturers with a strong foundation for sustainable growth.

By partnering with experienced exporters, businesses gain access to technical expertise, innovative machinery, and reliable support systems. This enables them to focus on product development, market expansion, and brand building while maintaining efficient manufacturing operations.

Conclusion

As global demand for agarbatti continues to rise, the need for reliable, advanced, and cost-effective manufacturing solutions becomes more critical than ever. Trusted automatic agarbatti making machine exporters bridge the gap between traditional practices and modern industrial requirements by delivering machines that enhance productivity, quality, and profitability.

For manufacturers aiming to compete in domestic and international markets, choosing the right exporter is a strategic decision. With advanced technology, customization options, strict quality control, and dependable after-sales support, exporters like ASVR Engineering empower businesses to achieve long-term success in the agarbatti manufacturing industry.

Contact Details

📞 Phone: +91-8076004849, +91-8800971968

🌐 Website: https://www.asvrengineering.com

Buy Now