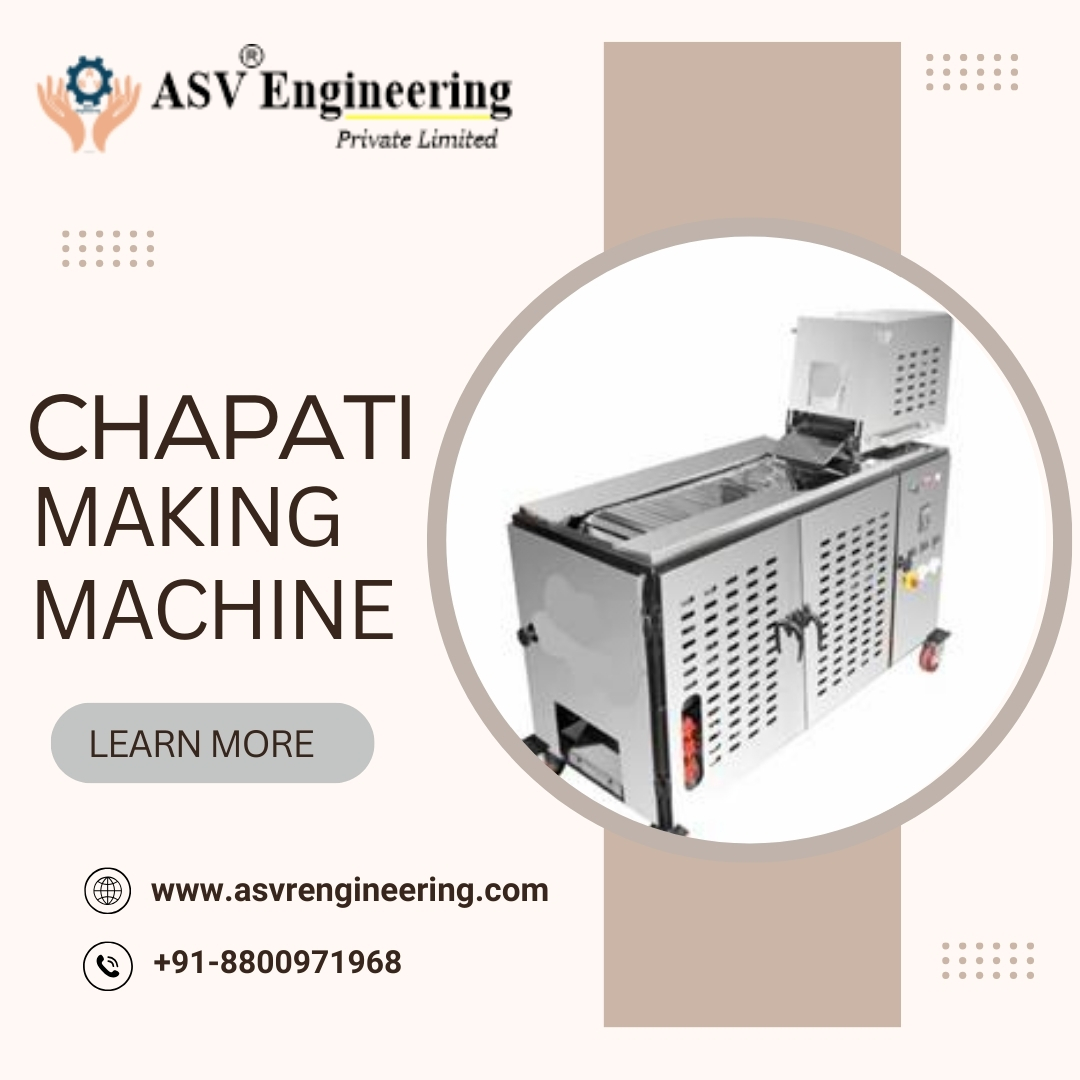

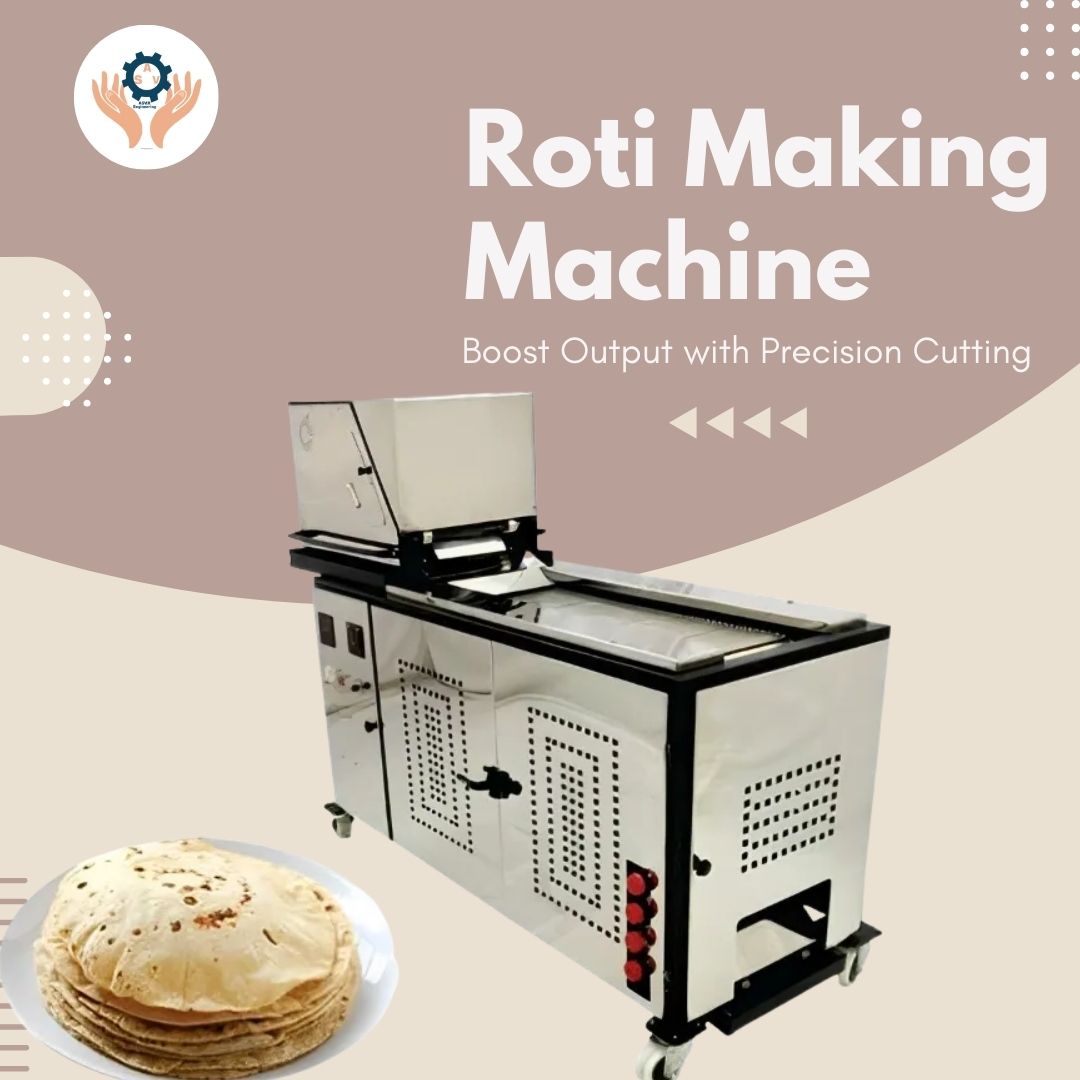

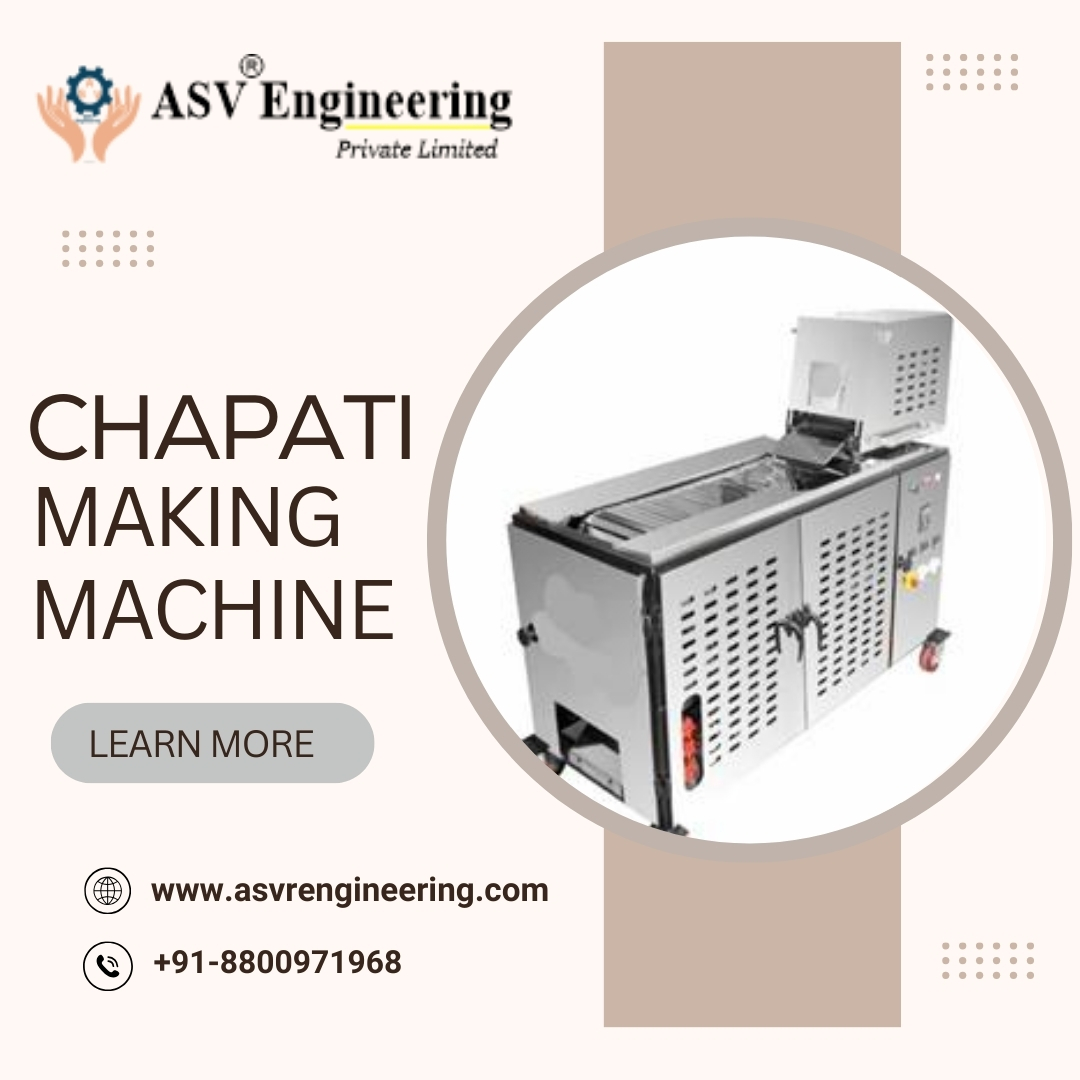

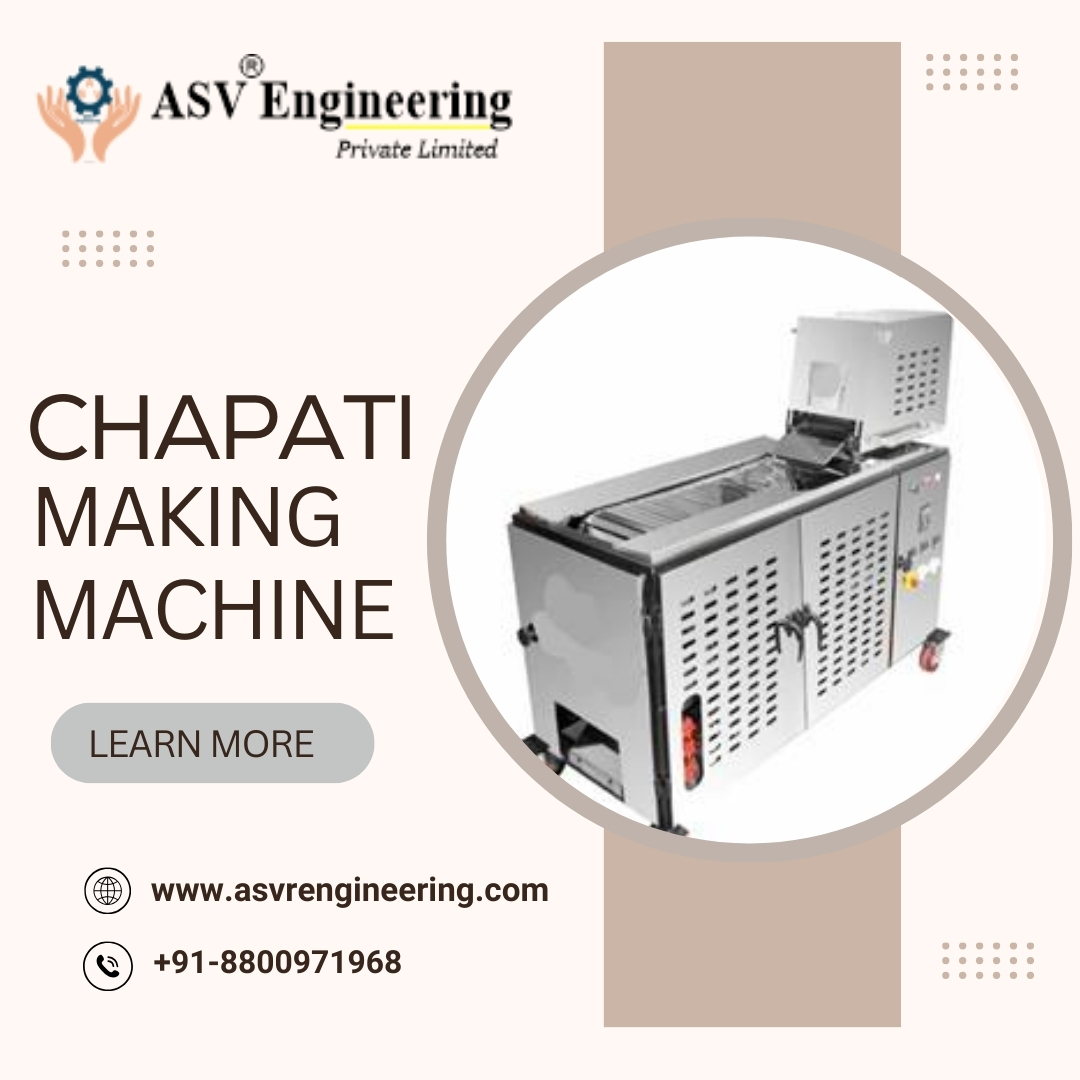

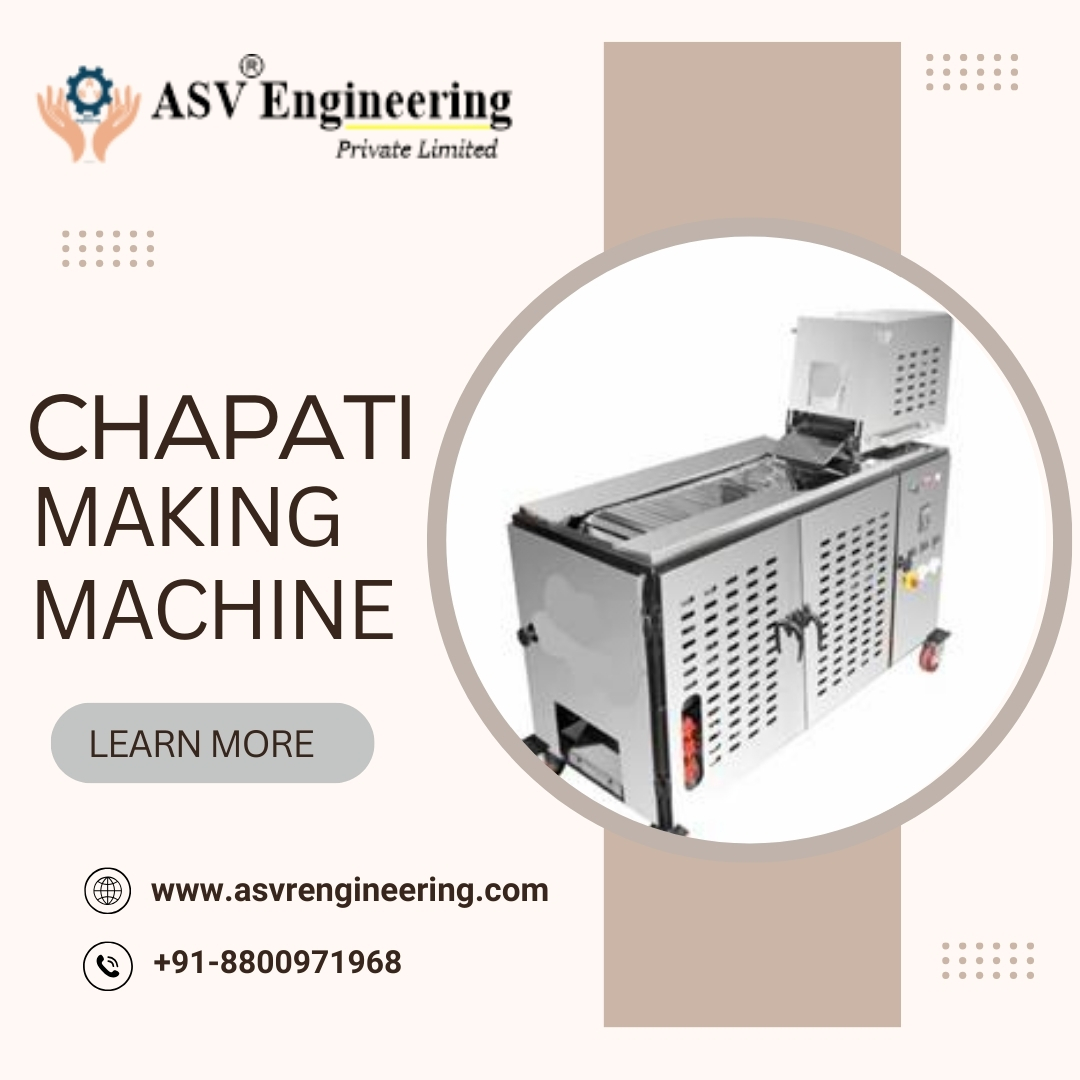

Automatic Chapati Making Machine

Price: ₹225000

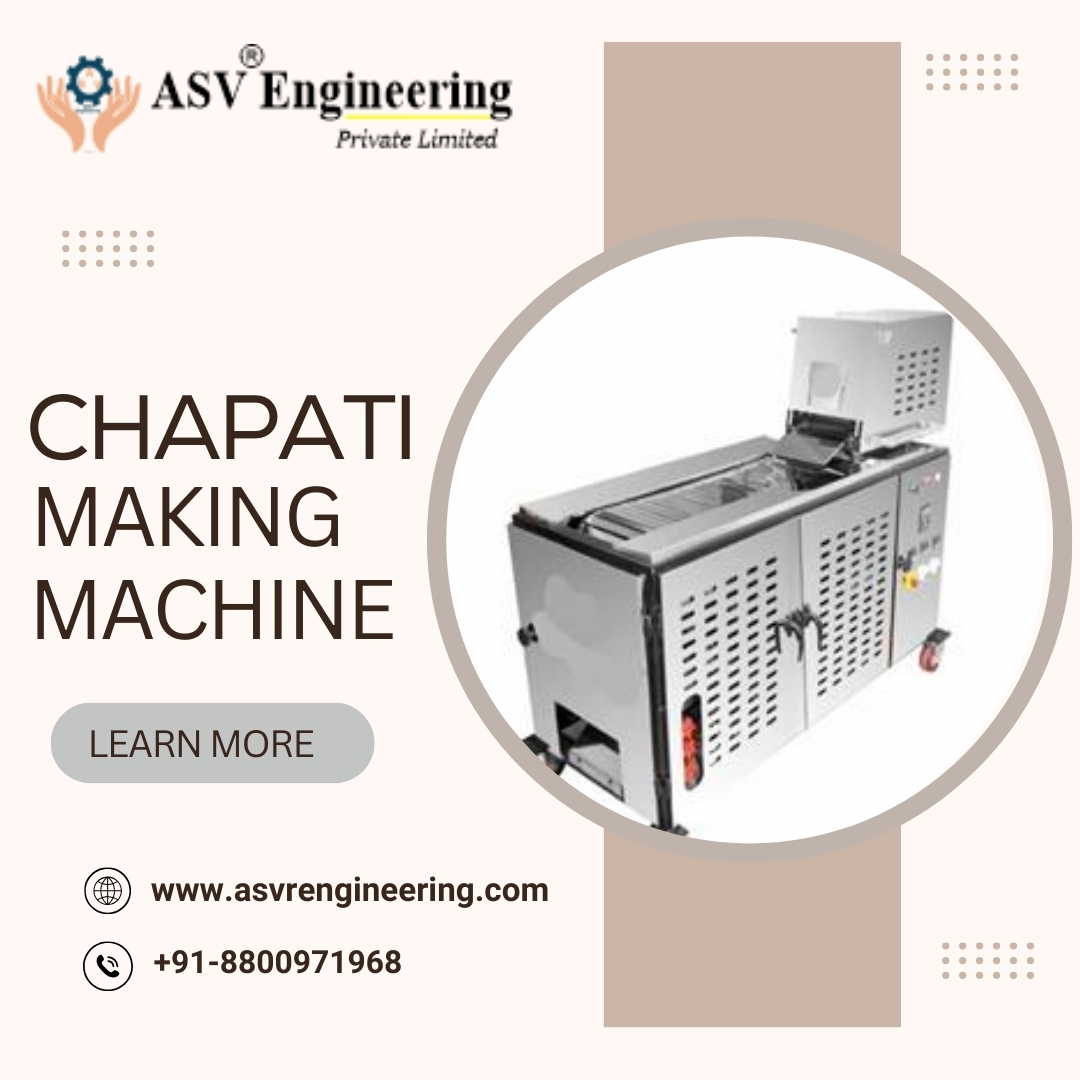

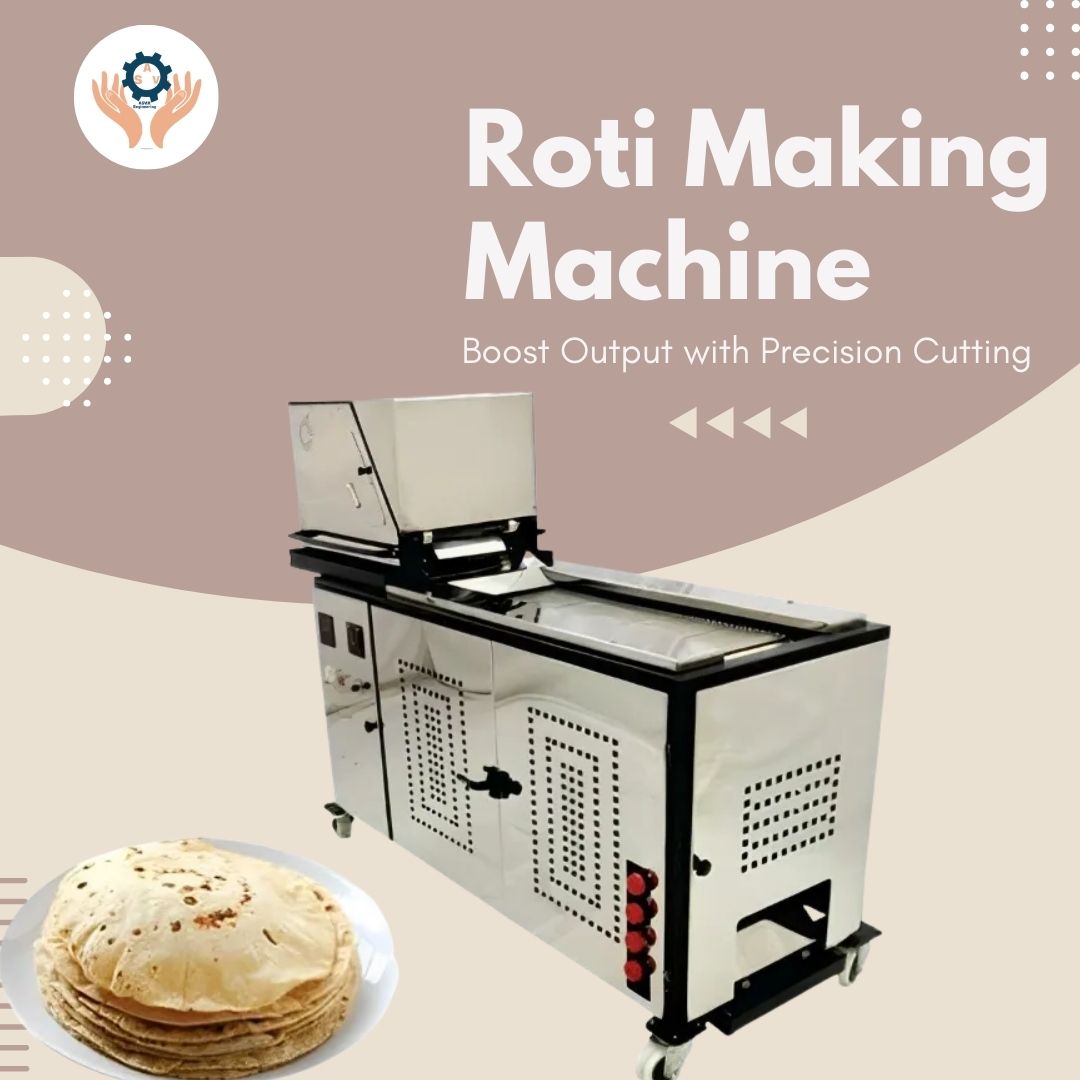

In today’s fast-paced food industry, speed, hygiene, and consistency are no longer optional—they are essential. The Automatic Chapati Making Machine has emerged as a game-changing solution for businesses that need to produce large volumes of soft, fresh, and perfectly round chapatis without manual labor. Whether it’s a hotel kitchen serving hundreds of guests daily, a factory canteen, a cloud kitchen, or a catering unit, this machine ensures uninterrupted production with uniform quality.

Traditional chapati preparation requires skilled labor, time, and constant supervision. Manual rolling, roasting, and flipping often result in inconsistent size, thickness, and texture. With rising labor costs and increasing hygiene standards, commercial kitchens are rapidly shifting towards automation. An automatic chapati machine not only improves productivity but also ensures food safety, standardization, and cost efficiency.

What Is an Automatic Chapati Making Machine?

An Automatic Chapati Making Machine is a fully integrated system that performs the entire chapati-making process—from dough pressing to baking—without manual intervention. The machine uses advanced mechanical and heating technology to produce evenly cooked chapatis at high speed while maintaining softness and taste.

The process typically includes:

-

Dough ball pressing into uniform round shapes

-

Controlled baking on heated plates

-

Automatic flipping for even cooking

-

Collection of ready-to-serve chapatis

The result is perfectly cooked chapatis that look, taste, and feel consistent every single time.

Why Automatic Chapati Machines Are Essential for Commercial Kitchens

1. High Production Capacity

Automatic chapati machines are designed to handle bulk requirements effortlessly. Depending on the model, they can produce hundreds to thousands of chapatis per hour, making them ideal for large-scale operations.

2. Uniform Size & Thickness

Consistency is key in professional kitchens. These machines ensure every chapati has the same diameter and thickness, which enhances presentation and customer satisfaction.

3. Hygienic Food Processing

Minimal human contact significantly reduces contamination risks. Machines are built using food-grade stainless steel, ensuring compliance with hygiene and safety standards.

4. Reduced Labor Dependency

One machine can replace multiple workers, helping businesses manage labor shortages and reduce recurring costs.

5. Energy Efficient & Cost Effective

Modern automatic chapati machines are designed for optimal power consumption, delivering high output while keeping operational costs under control.

Key Features of Automatic Chapati Making Machine

-

Fully Automatic Operation – No skilled labor required

-

Food-Grade Stainless Steel Body – Rust-free and hygienic

-

Adjustable Thickness & Size – Customizable as per requirement

-

High-Speed Production – Ideal for bulk cooking

-

Uniform Heating System – Even baking on both sides

-

Low Maintenance Design – Easy cleaning and servicing

-

Durable & Long-Lasting Components – Designed for continuous use

Applications of Automatic Chapati Making Machine

The versatility of automatic chapati machines makes them suitable for a wide range of industries:

Hotels & Restaurants

Hotels serving breakfast, lunch, and dinner buffets benefit greatly from consistent chapati output and reduced kitchen workload.

Industrial Canteens

Factories and corporate cafeterias require mass food production within limited time. Automatic chapati machines handle such demands efficiently.

Cloud Kitchens

With online food delivery booming, cloud kitchens need speed and uniform quality. Automated chapati production ensures timely order fulfillment.

Hostels & Educational Institutions

Daily meals for students require bulk cooking with hygiene assurance, making these machines an ideal solution.

Catering Services

Event catering demands large quantities of food within short timeframes. Automatic chapati machines ensure smooth operations even during peak demand.

How the Automatic Chapati Making Machine Works

-

Dough Feeding – Prepared dough balls are fed into the machine

-

Pressing Section – Dough is pressed into round chapatis

-

Baking Plates – Chapatis are cooked evenly using controlled heat

-

Automatic Flipping – Ensures uniform cooking on both sides

-

Final Output – Soft, fresh chapatis are ready to serve

The entire process is synchronized for speed, precision, and quality.

Advantages Over Manual Chapati Making

| Manual Method | Automatic Chapati Machine |

|---|---|

| Inconsistent size | Uniform chapatis |

| High labor cost | Minimal manpower |

| Hygiene risk | Fully hygienic |

| Time-consuming | High-speed output |

| Fatigue-prone | Continuous operation |

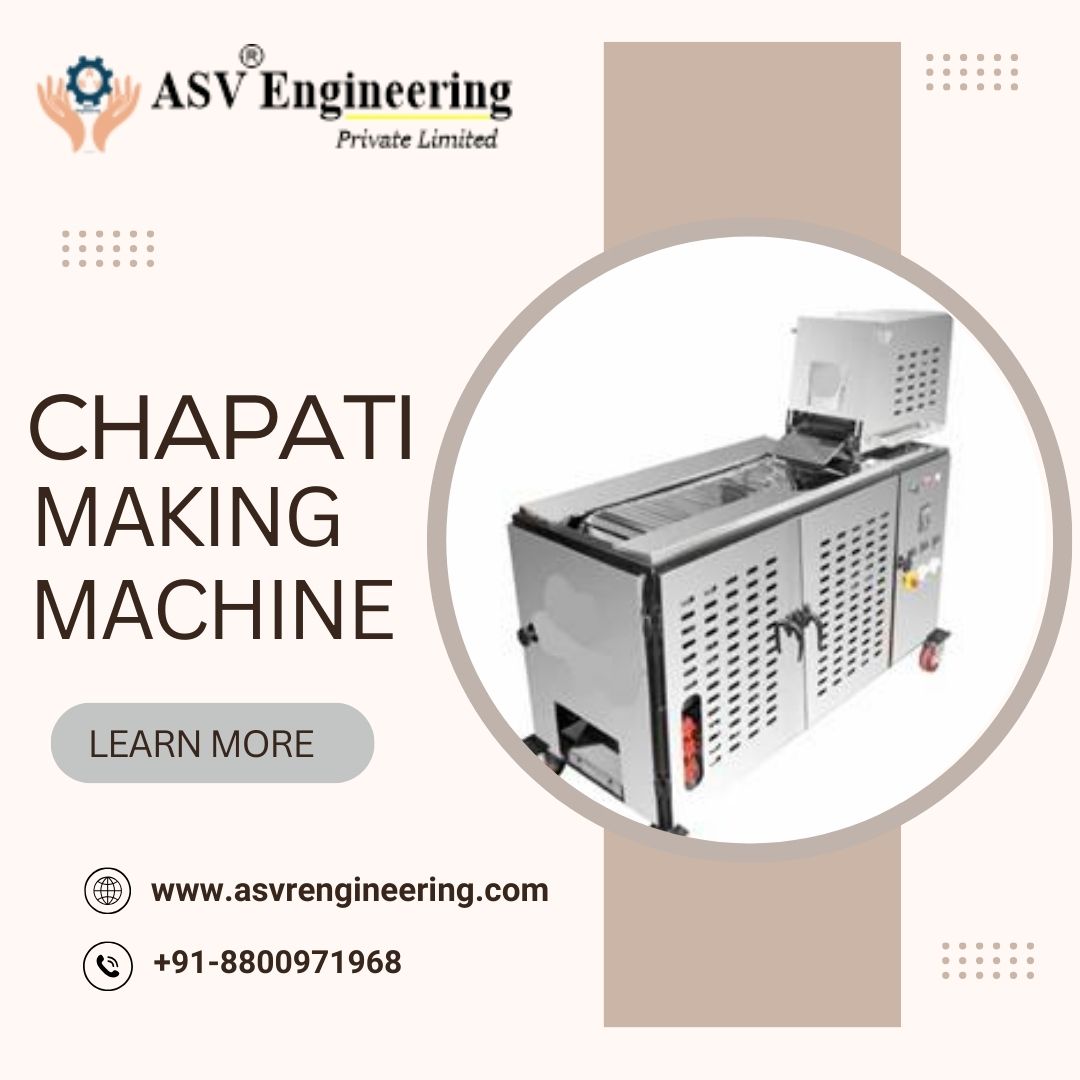

Why Choose ASVR Engineering for Automatic Chapati Machines

ASVR Engineering is a trusted name in manufacturing and supplying high-quality food processing machines for commercial and industrial use. Their automatic chapati making machines are engineered to meet the real-world demands of professional kitchens.

What Sets ASVR Engineering Apart

-

Proven expertise in industrial machinery

-

Robust machine design with long service life

-

Reliable performance even under continuous operation

-

Customer-focused after-sales support

-

Competitive pricing without compromising quality

Their machines are designed keeping Indian food habits, kitchen environments, and operational challenges in mind.

Maintenance & Safety

Automatic chapati making machines require minimal maintenance. Regular cleaning of plates and periodic inspection of mechanical parts ensure long-lasting performance. Safety features such as heat insulation, emergency stop buttons, and stable frames protect operators during use.

Buying Guide – Things to Consider

Before purchasing an automatic chapati making machine, consider:

-

Required chapati output per hour

-

Available kitchen space

-

Power supply compatibility

-

Ease of cleaning and maintenance

-

After-sales service availability

Choosing the right machine ensures maximum return on investment and smooth daily operations.

Conclusion

The Automatic Chapati Making Machine is no longer a luxury—it’s a necessity for modern commercial kitchens aiming for speed, consistency, hygiene, and profitability. By automating chapati production, businesses can focus on scaling operations, improving food quality, and enhancing customer satisfaction.

If you are looking for a reliable, high-performance automatic chapati making machine that delivers consistent results day after day, ASVR Engineering offers solutions tailored to your needs.

Contact Information

📞 Call Now:

+91-8076004849

+91-8800971968

🌐 Website:

https://www.asvrengineering.com

Buy Now