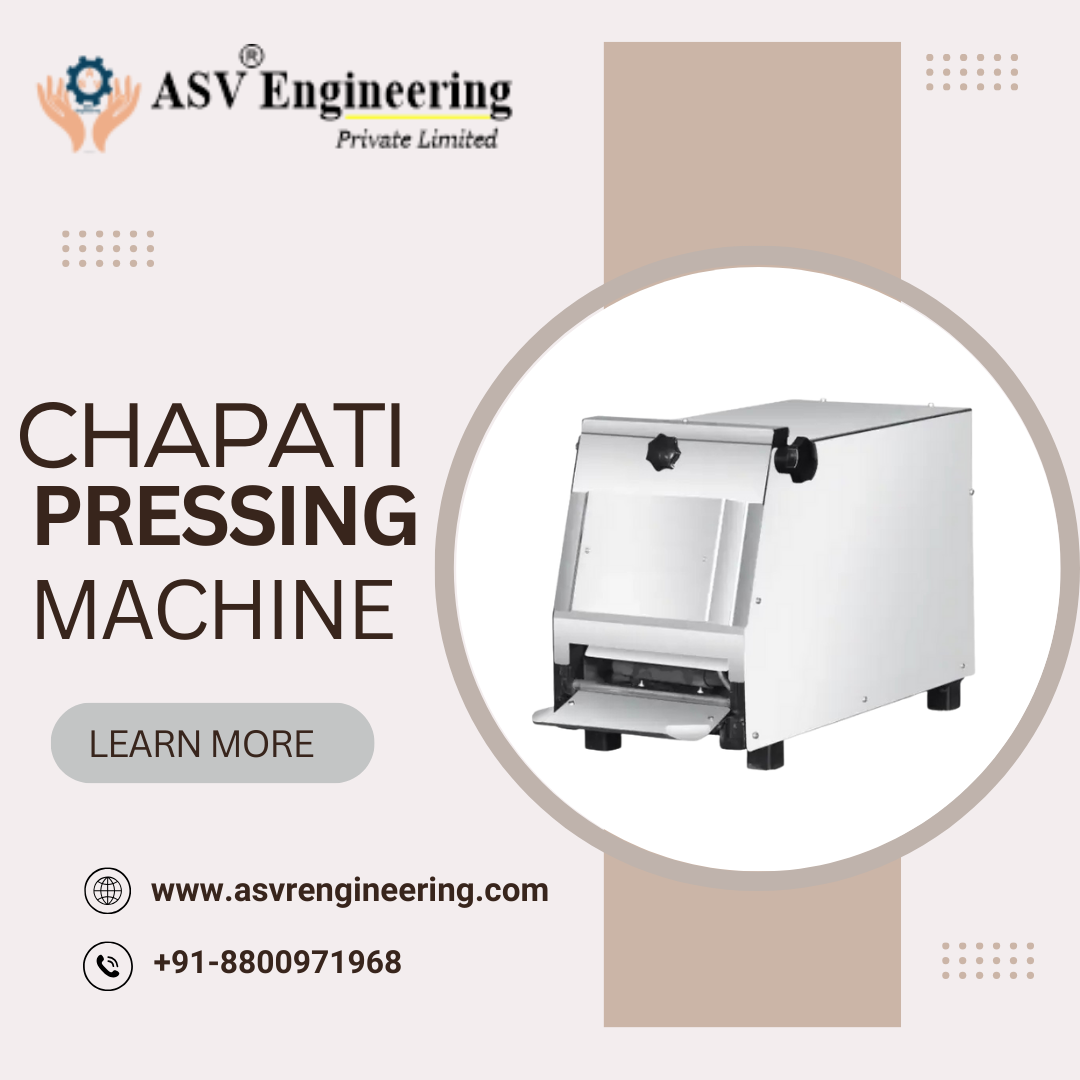

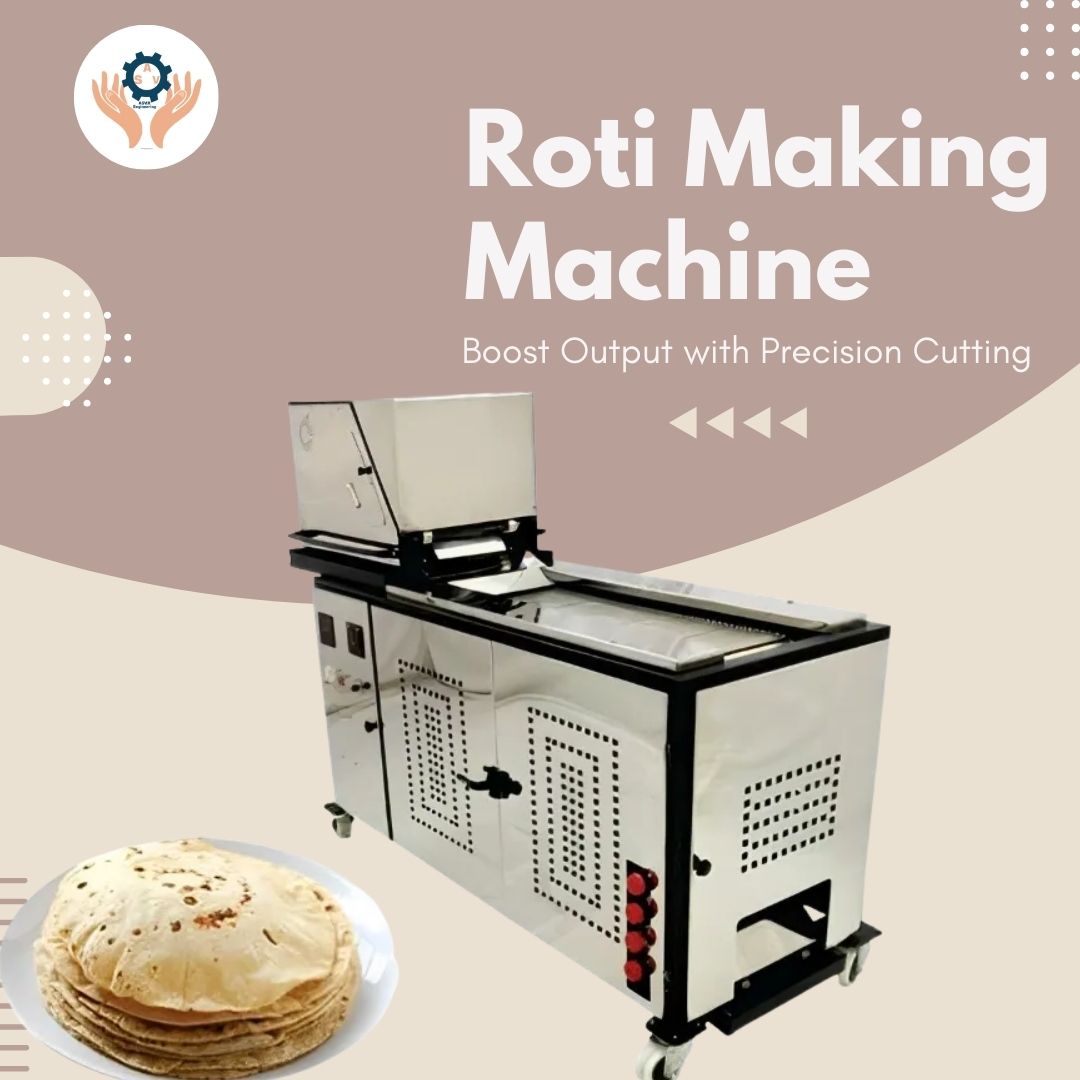

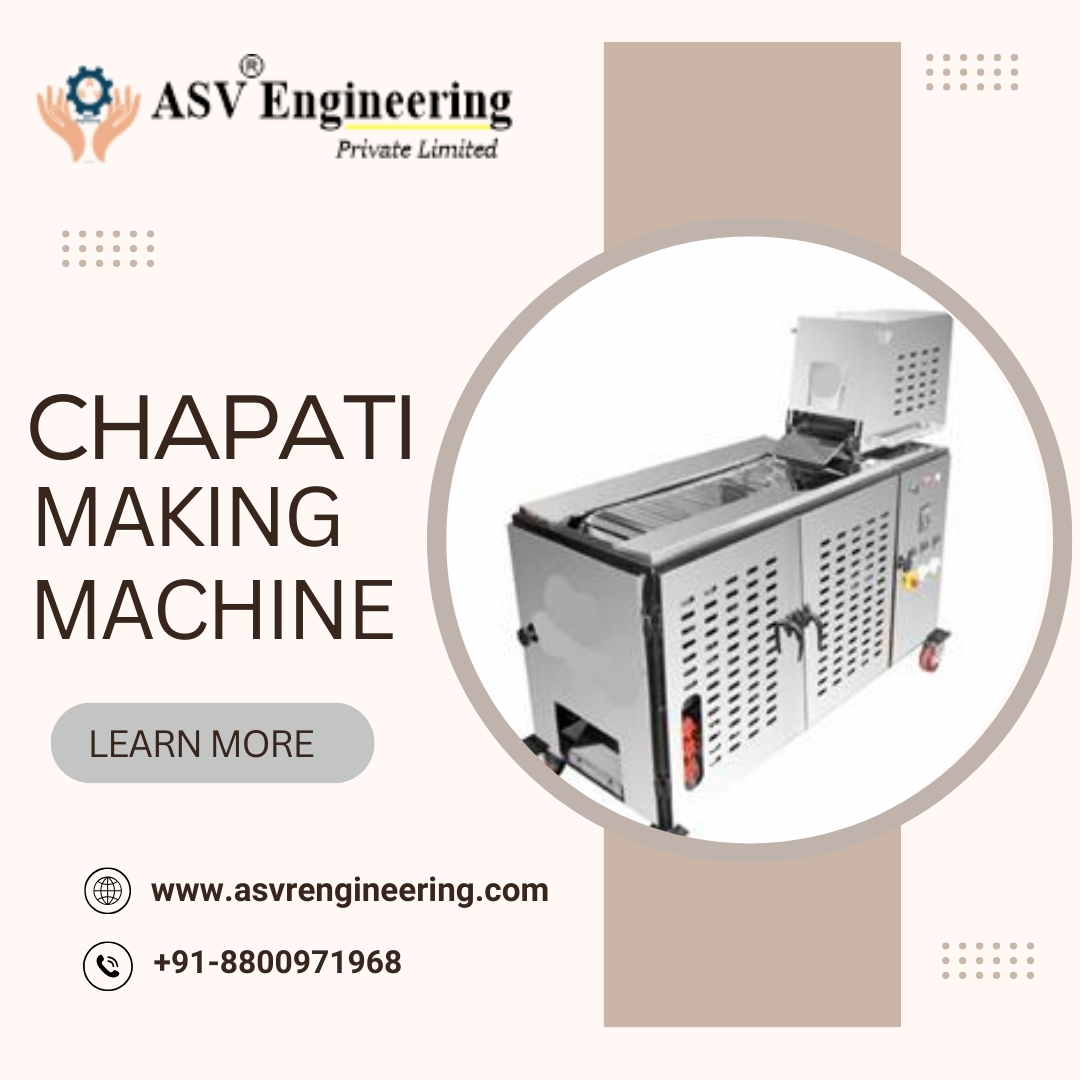

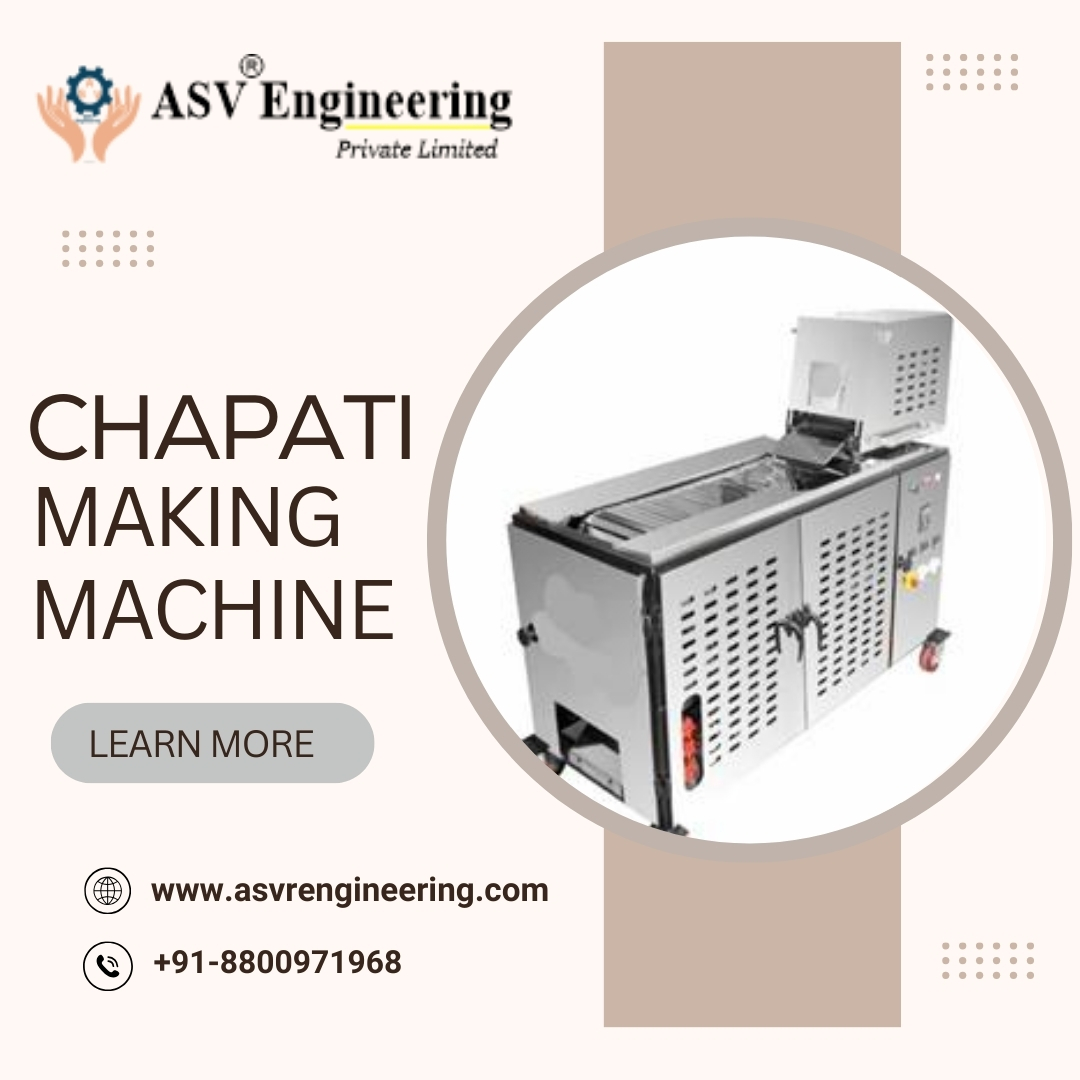

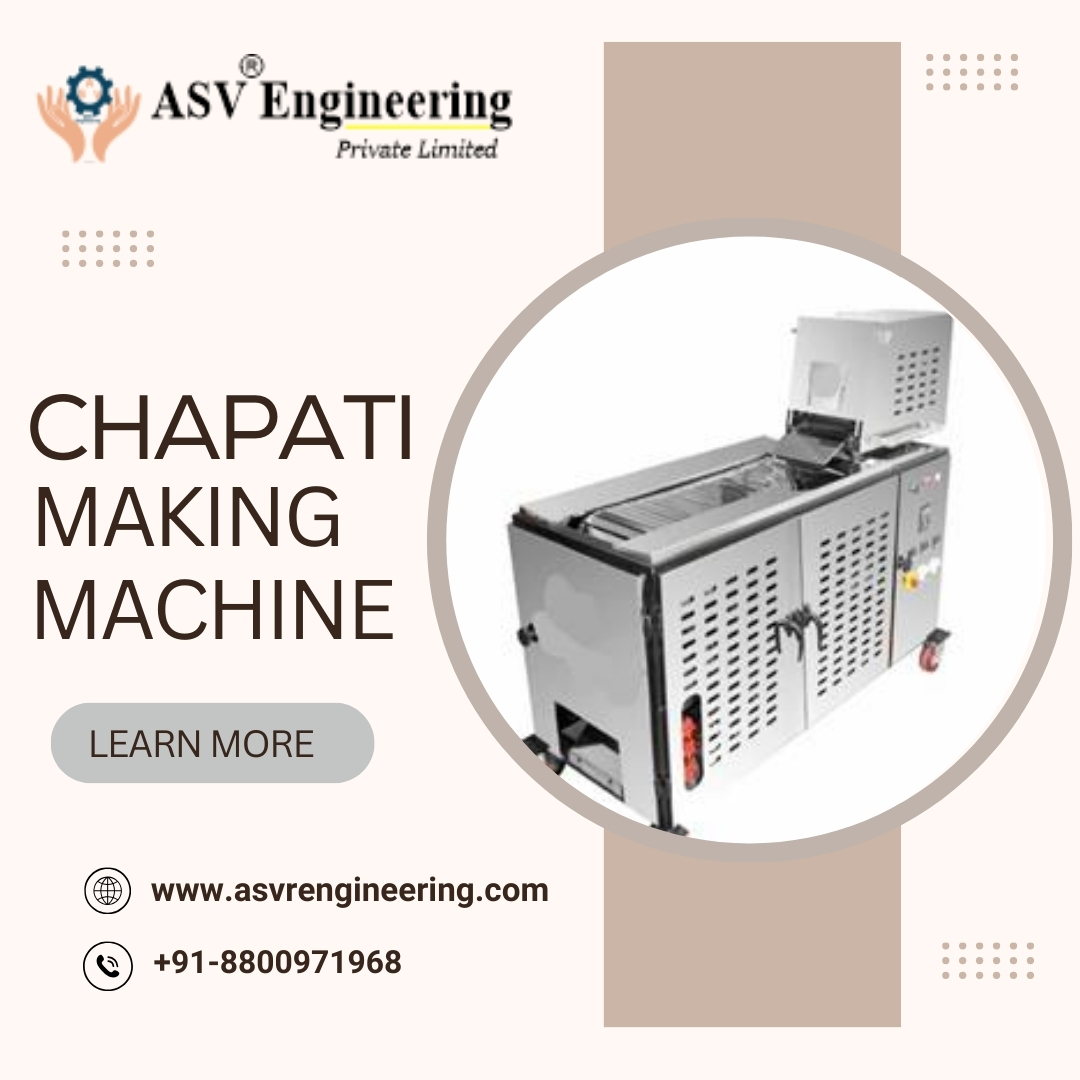

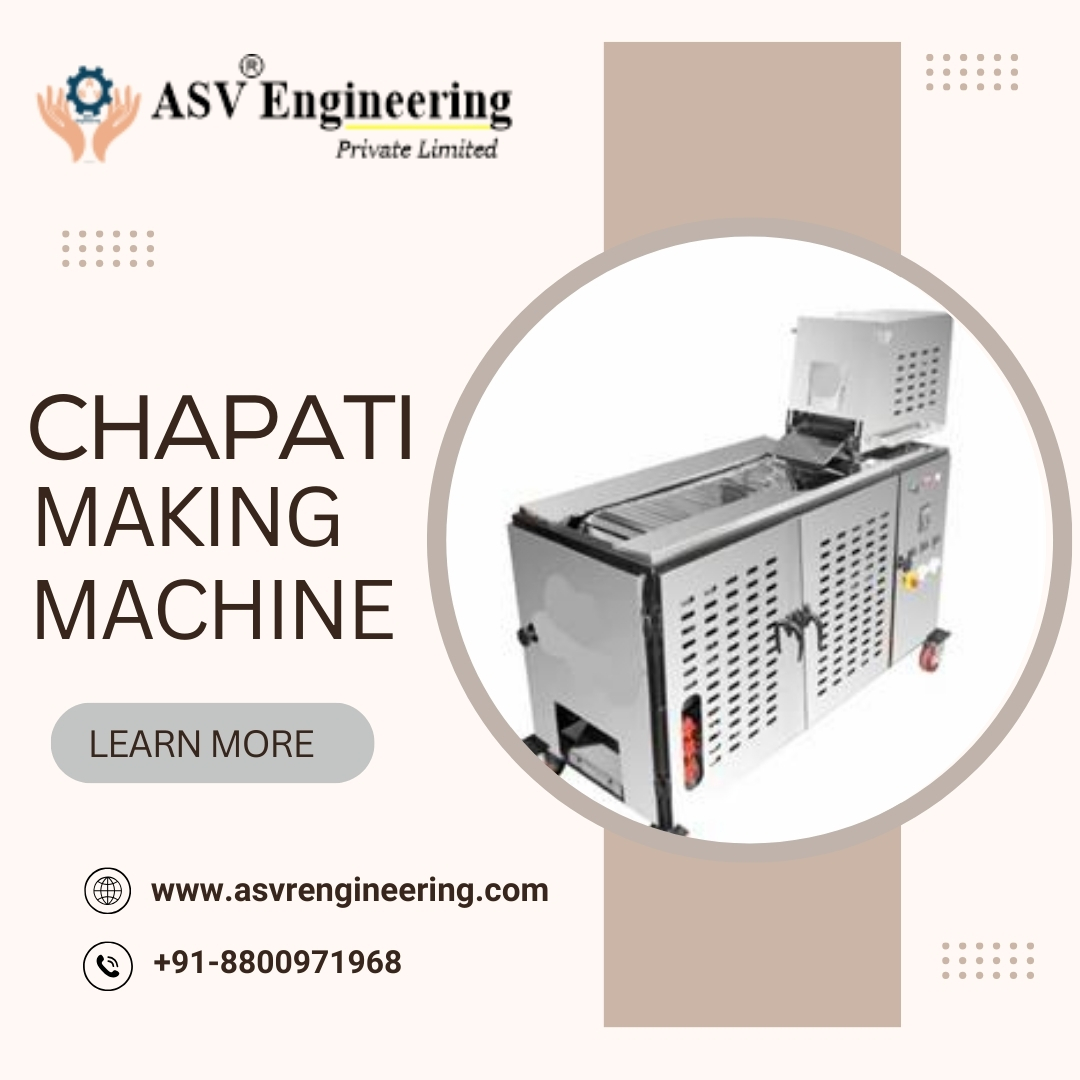

Top Chapati Pressing Machine Manufacturers for Hotels, Cloud Kitchens & Large-Scale Food Units

Price: ₹64000

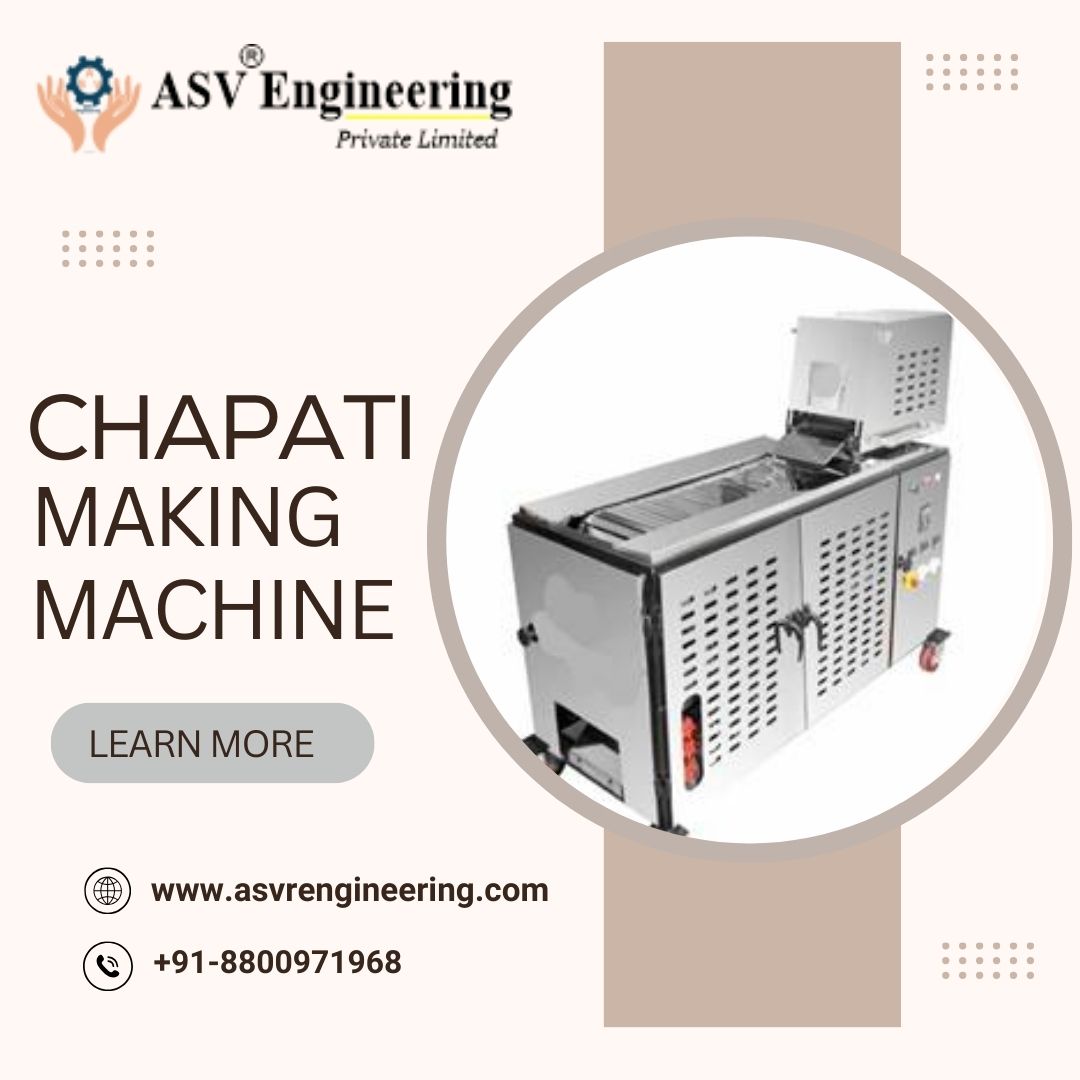

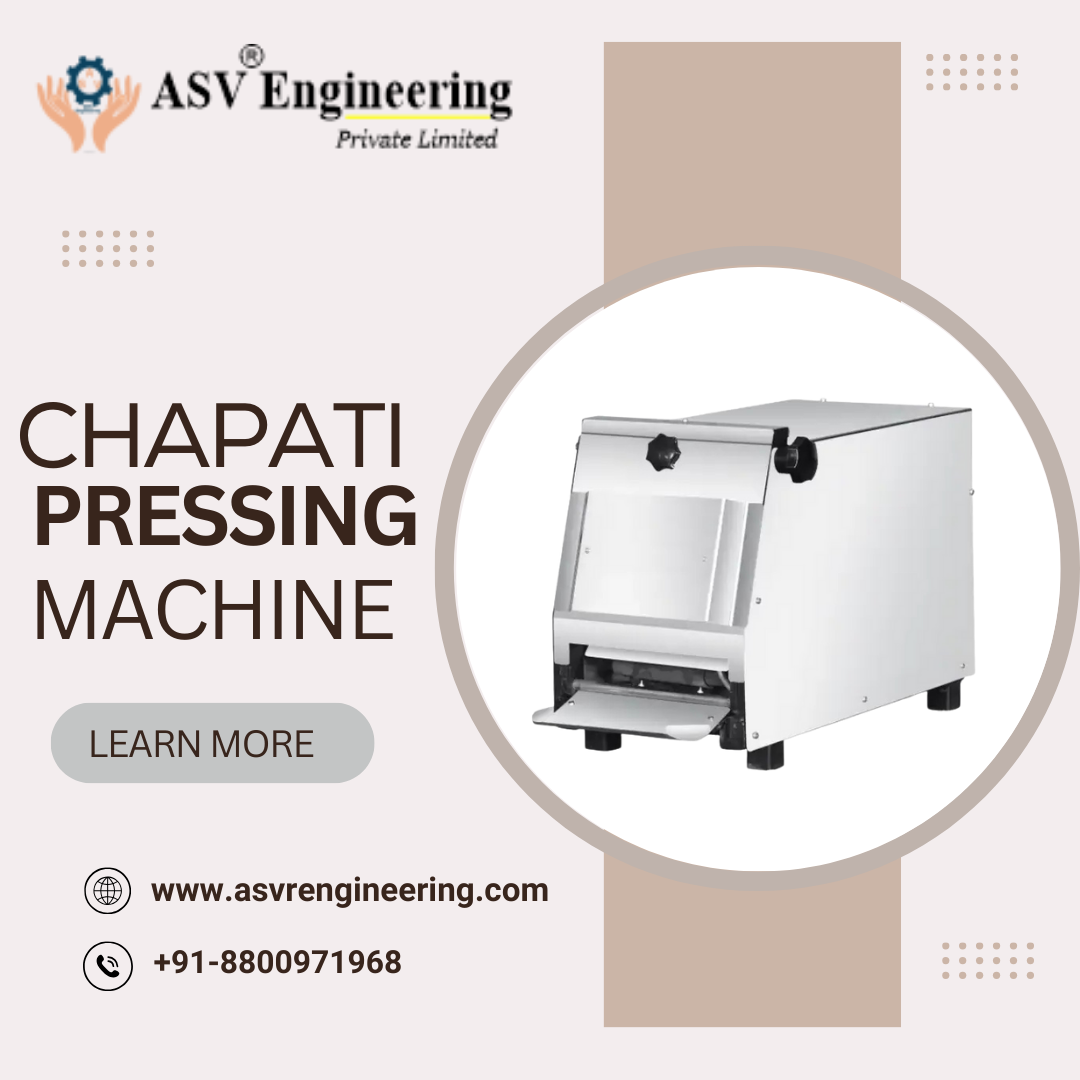

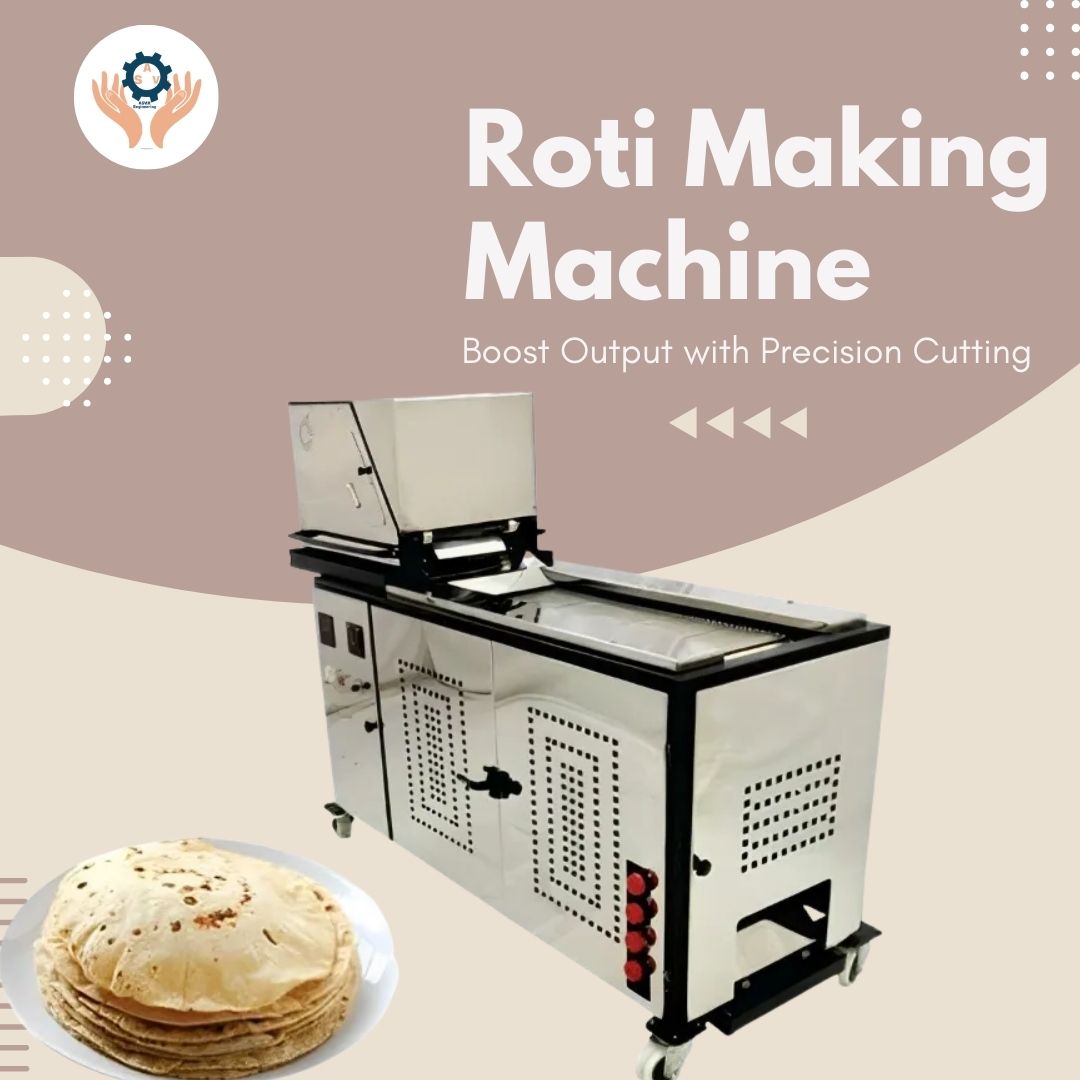

In today’s fast-paced food service industry, consistency, speed, and hygiene are no longer optional—they are essential. Whether you are running a busy hotel kitchen, a rapidly expanding cloud kitchen, or a large-scale food production unit, the demand for perfectly shaped, uniformly cooked chapatis is constant. Manual preparation not only limits output but also introduces variations in size, thickness, and quality. This is where a professionally engineered chapati pressing machine becomes a vital investment.

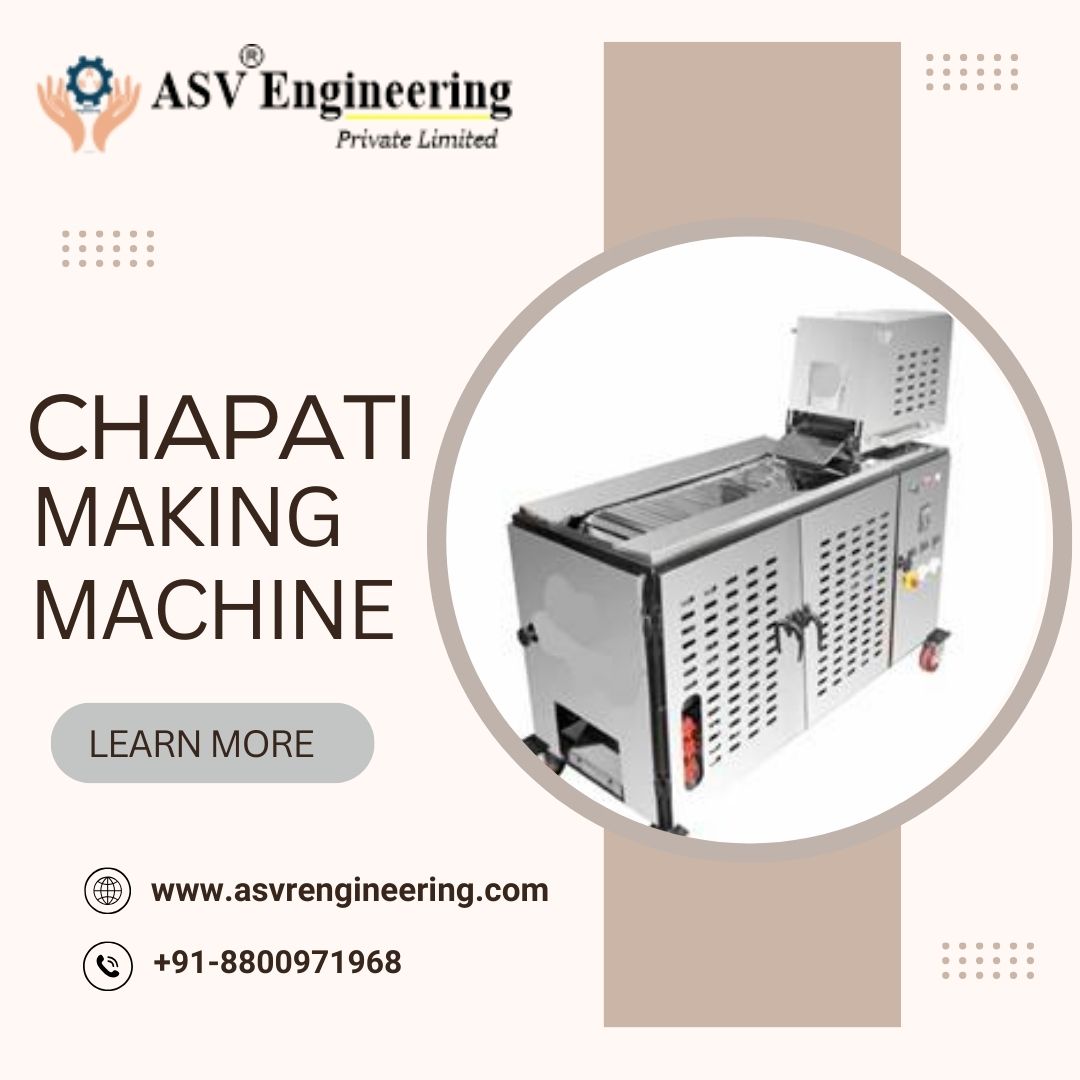

ASVR Engineering has established itself as one of the most trusted chapati pressing machine manufacturers in India, delivering robust, efficient, and long-lasting solutions tailored for commercial kitchens and industrial food units. With a strong focus on engineering precision and real-world usability, ASVR Engineering supports businesses that value quality, scalability, and operational efficiency.

Understanding the Importance of Chapati Pressing Machines in Commercial Kitchens

Chapati is a staple food across India and many parts of the world. In hotels, hostels, hospitals, corporate canteens, and cloud kitchens, thousands of chapatis are prepared daily. Producing such volumes manually is labor-intensive, time-consuming, and inconsistent. A chapati pressing machine eliminates these issues by automating the flattening process, ensuring every chapati is uniform in diameter and thickness.

For businesses, this consistency translates into predictable cooking times, reduced wastage, and a better dining experience for customers. Moreover, automation reduces dependency on skilled labor, which is becoming increasingly scarce and expensive.

Why Hotels Prefer Automatic Chapati Pressing Machines

Hotels operate under tight schedules, especially during breakfast, lunch, and dinner rush hours. A delay of even a few minutes can disrupt service flow and impact customer satisfaction. Automatic chapati pressing machines are designed to handle high workloads without compromising quality.

With adjustable pressure controls, hotel kitchens can prepare soft chapatis that suit different cuisines and customer preferences. Machines manufactured by ASVR Engineering are designed keeping real hotel kitchen conditions in mind—compact footprints, easy cleaning, and durable components that withstand continuous use.

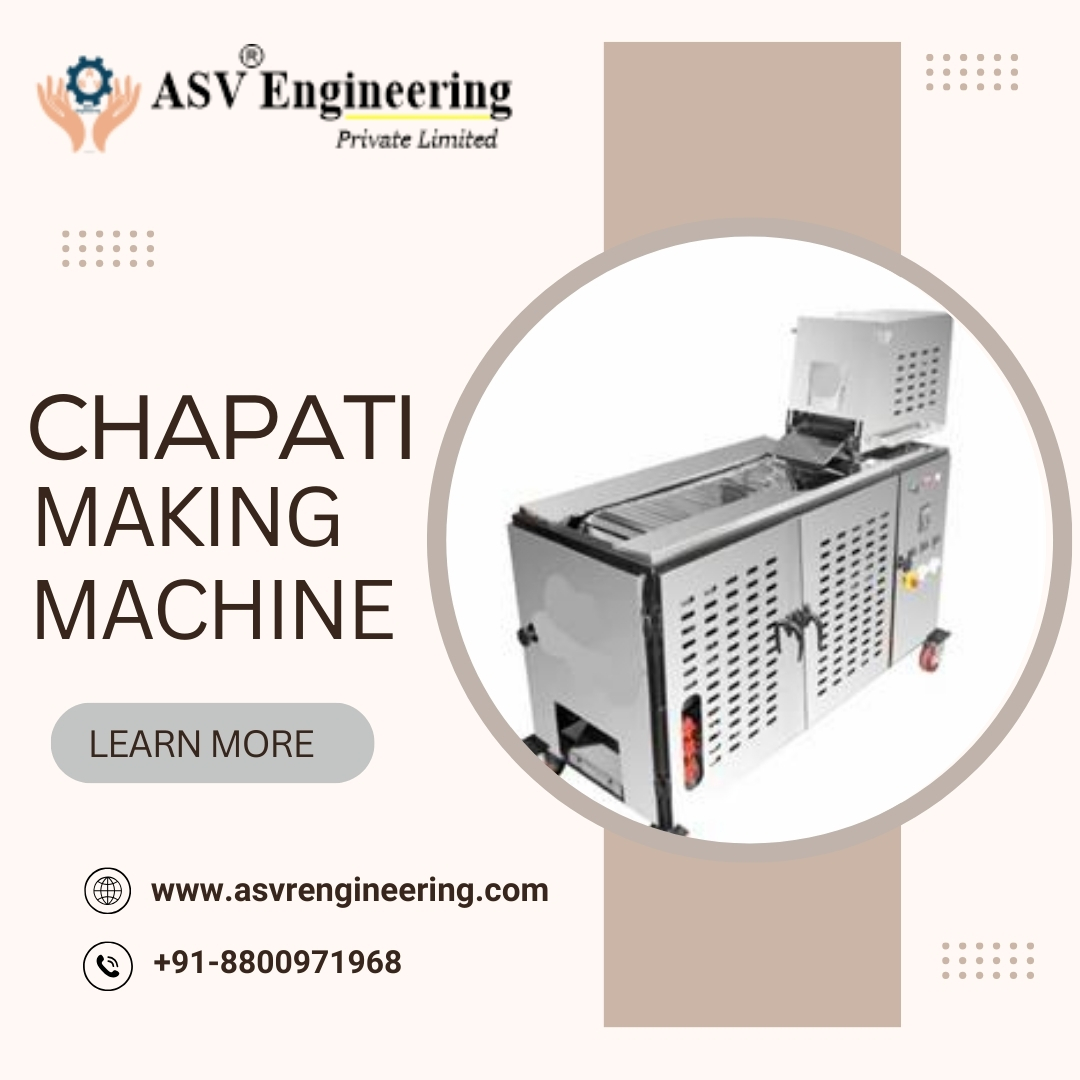

Role of Chapati Pressing Machines in Cloud Kitchens

Cloud kitchens focus on speed, standardization, and cost control. Since there is no dine-in experience, the quality of food delivered must speak for itself. Uniform chapatis ensure even cooking, better packaging, and consistent taste across orders.

For cloud kitchens operating multiple brands from a single facility, chapati pressing machines help maintain standard portion sizes and cooking quality. This consistency strengthens brand reputation and reduces customer complaints. ASVR Engineering offers machines that integrate seamlessly into cloud kitchen workflows, helping businesses scale without chaos.

Large-Scale Food Units and Industrial Chapati Production

In large-scale food units supplying chapatis to institutions like schools, hospitals, railways, and airlines, production volume is massive. Here, reliability is more important than anything else. A machine breakdown can halt operations and cause significant losses.

ASVR Engineering understands these challenges and manufactures chapati pressing machines using heavy-duty materials and precision engineering. These machines are built for continuous operation, ensuring minimal downtime and long service life. Their designs prioritize operator safety, hygiene compliance, and ease of maintenance—critical factors in industrial environments.

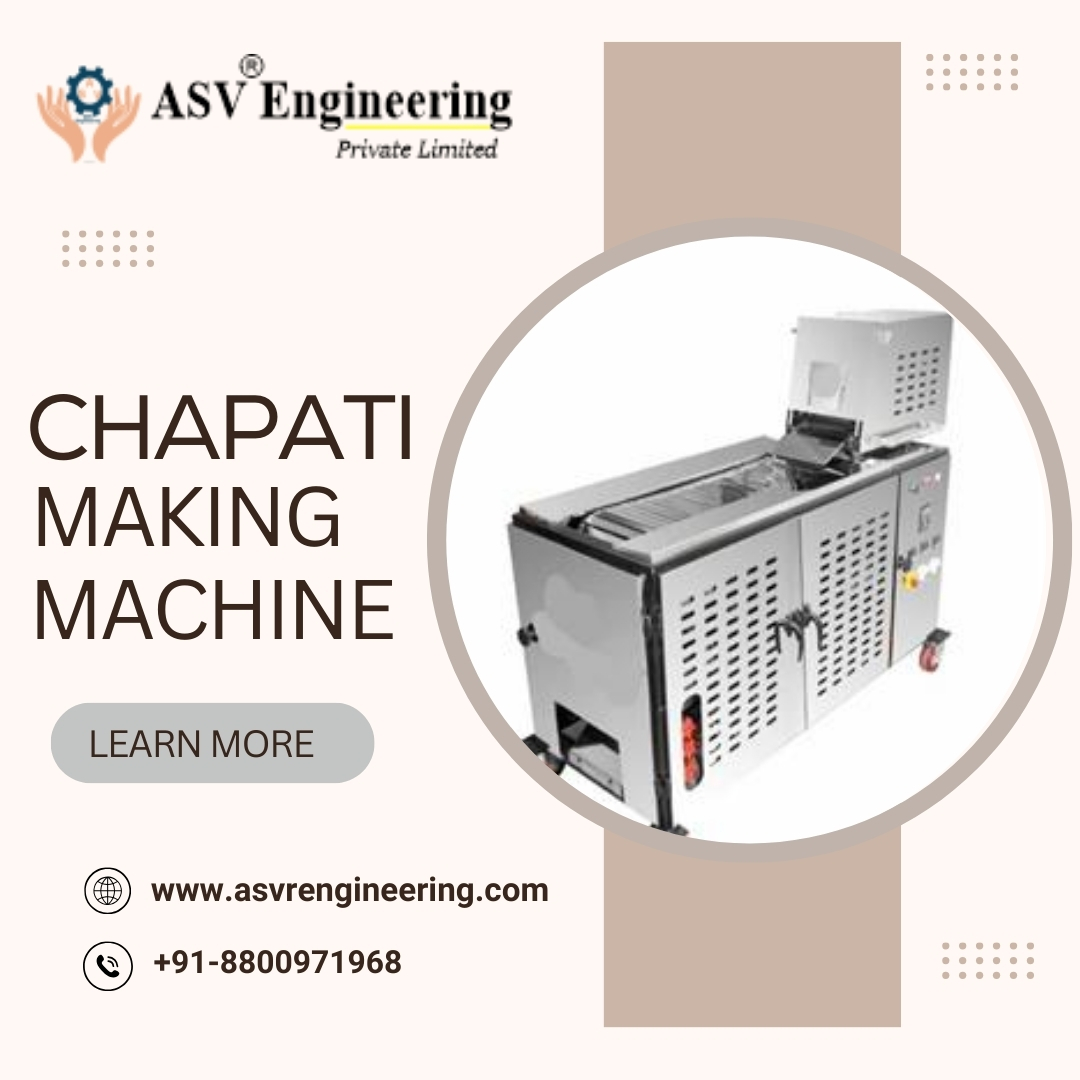

Key Features That Define a High-Quality Chapati Pressing Machine

When choosing a chapati pressing machine manufacturer, businesses should look beyond price and focus on long-term value. Some essential features include:

-

Uniform Pressure Application: Ensures even thickness and perfect shape.

-

Food-Grade Materials: Stainless steel construction for hygiene and durability.

-

Energy Efficiency: Optimized power consumption for cost-effective operations.

-

Ease of Operation: Simple controls suitable for semi-skilled operators.

-

Low Maintenance: Easily accessible components and reliable spare support.

ASVR Engineering incorporates all these features into its machines, making them suitable for both growing kitchens and established food processing units.

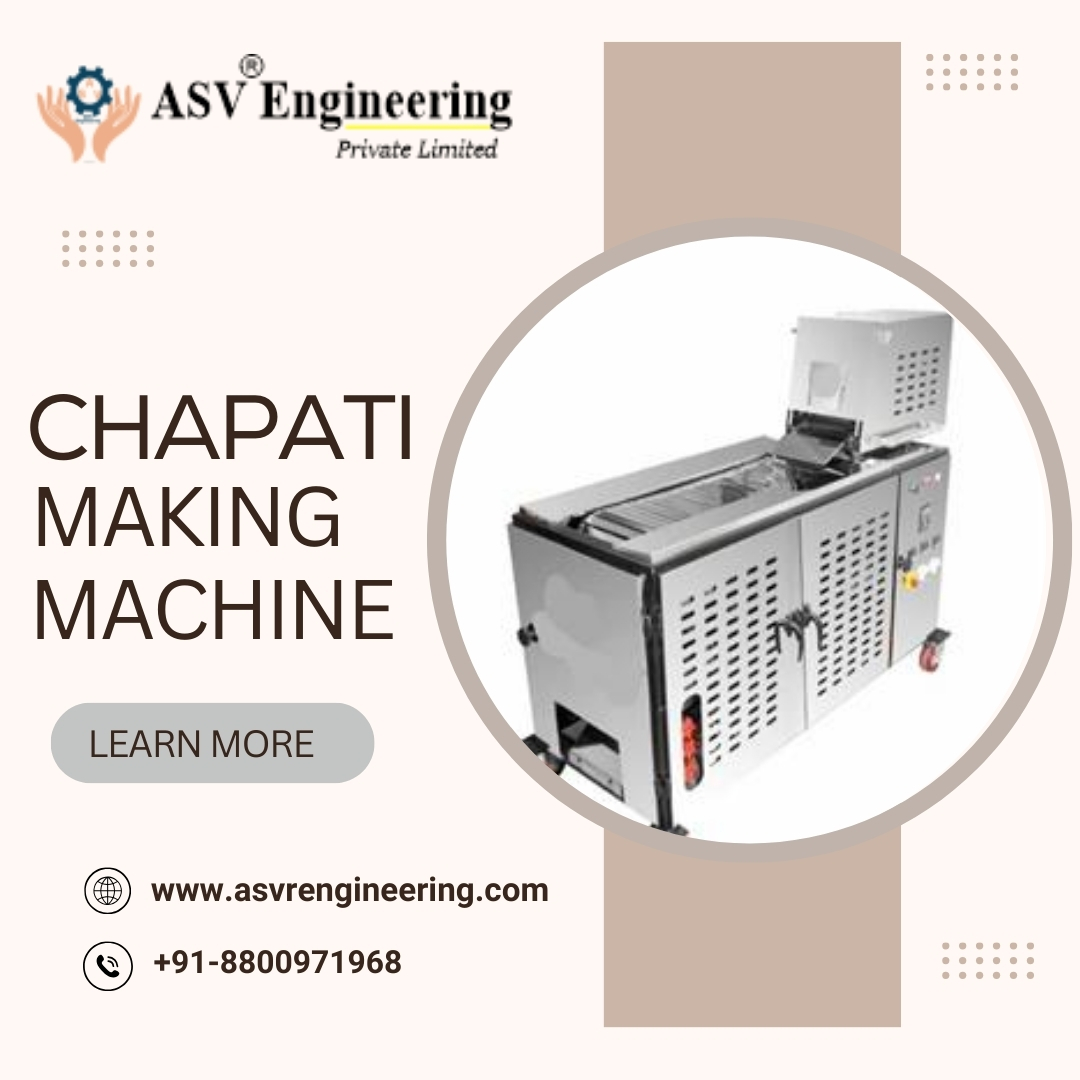

Engineering Excellence and Manufacturing Standards

What sets ASVR Engineering apart is its commitment to engineering excellence. Every chapati pressing machine undergoes strict quality checks before dispatch. From raw material selection to final assembly, each stage follows defined standards to ensure consistent performance.

The company’s manufacturing process blends modern machinery with skilled craftsmanship. This balance allows customization based on client requirements while maintaining high production standards. Whether you need a compact machine for a boutique hotel or a heavy-duty unit for an industrial kitchen, ASVR Engineering can deliver a tailored solution.

Hygiene and Safety Compliance

Food safety regulations are becoming stricter across India. Commercial kitchens must comply with hygiene and safety standards to avoid penalties and protect customer health. Chapati pressing machines from ASVR Engineering are designed with smooth surfaces, minimal crevices, and easy dismantling options for thorough cleaning.

Safety features such as heat-resistant handles, protective covers, and stable bases reduce workplace accidents. These considerations are especially important in high-pressure kitchen environments where speed and safety must go hand in hand.

Cost Efficiency and Return on Investment

Investing in a chapati pressing machine is not an expense—it is a long-term cost-saving decision. By reducing labor requirements, minimizing wastage, and increasing output, businesses can recover their investment quickly.

ASVR Engineering focuses on delivering machines that offer excellent value for money. Their durability ensures years of service, while energy-efficient designs keep operating costs under control. For hotels, cloud kitchens, and food units looking to scale profitably, this balance is crucial.

After-Sales Support and Customer Trust

A machine is only as good as the support behind it. ASVR Engineering believes in building long-term relationships with clients. Their after-sales service includes installation guidance, operational training, and prompt technical support.

With readily available spare parts and experienced technicians, downtime is minimized. This reliability has earned ASVR Engineering the trust of clients across different sectors of the food industry.

Why ASVR Engineering Is a Preferred Choice

There are many chapati pressing machine manufacturers in the market, but few combine quality, customization, and customer support as effectively as ASVR Engineering. Their deep understanding of commercial kitchen challenges allows them to design machines that perform consistently under real-world conditions.

From small hotels to large institutional kitchens, their machines are trusted for efficiency, durability, and hygienic operation. Businesses looking for long-term solutions rather than short-term fixes find ASVR Engineering to be a dependable partner.

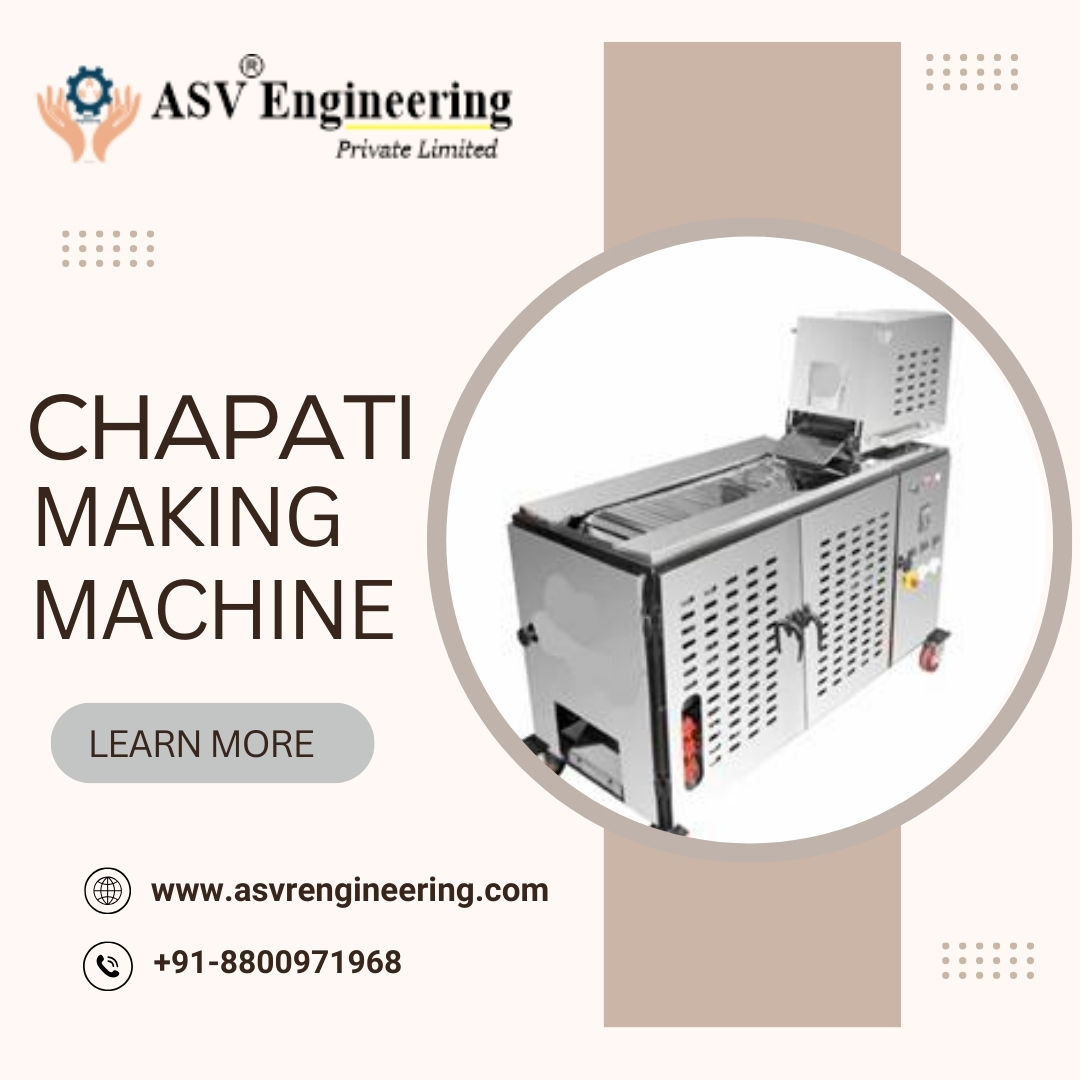

Partner with a Manufacturer That Understands Your Kitchen

Choosing the right chapati pressing machine manufacturer can transform your kitchen operations. With the right equipment, you can improve productivity, maintain consistent food quality, and reduce operational stress.

ASVR Engineering continues to support India’s growing food service sector with reliable chapati pressing machines designed for hotels, cloud kitchens, and large-scale food units.

📞 Contact Numbers: +91-8076004849, +91-8800971968

🌐 Website: https://www.asvrengineering.com

Buy Now