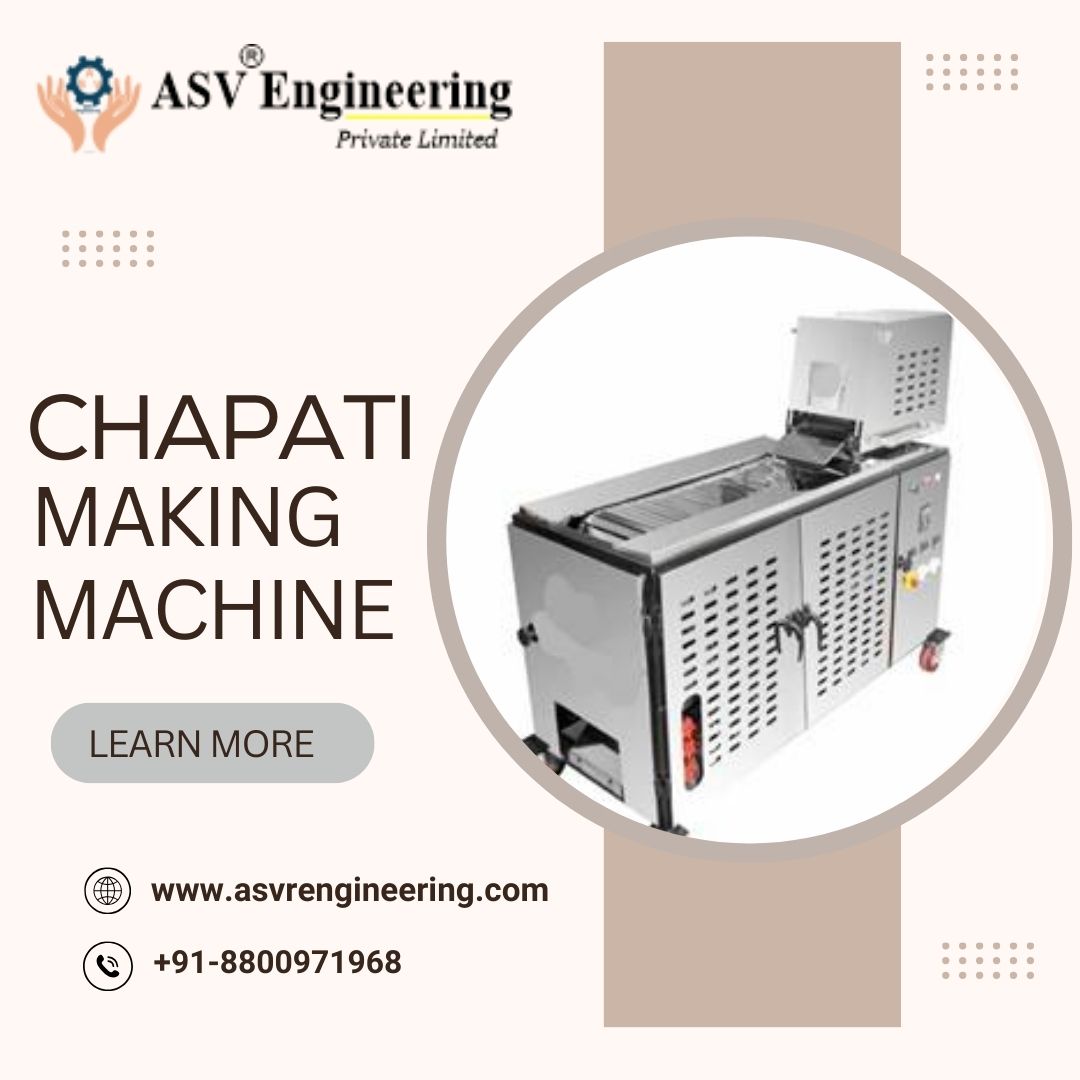

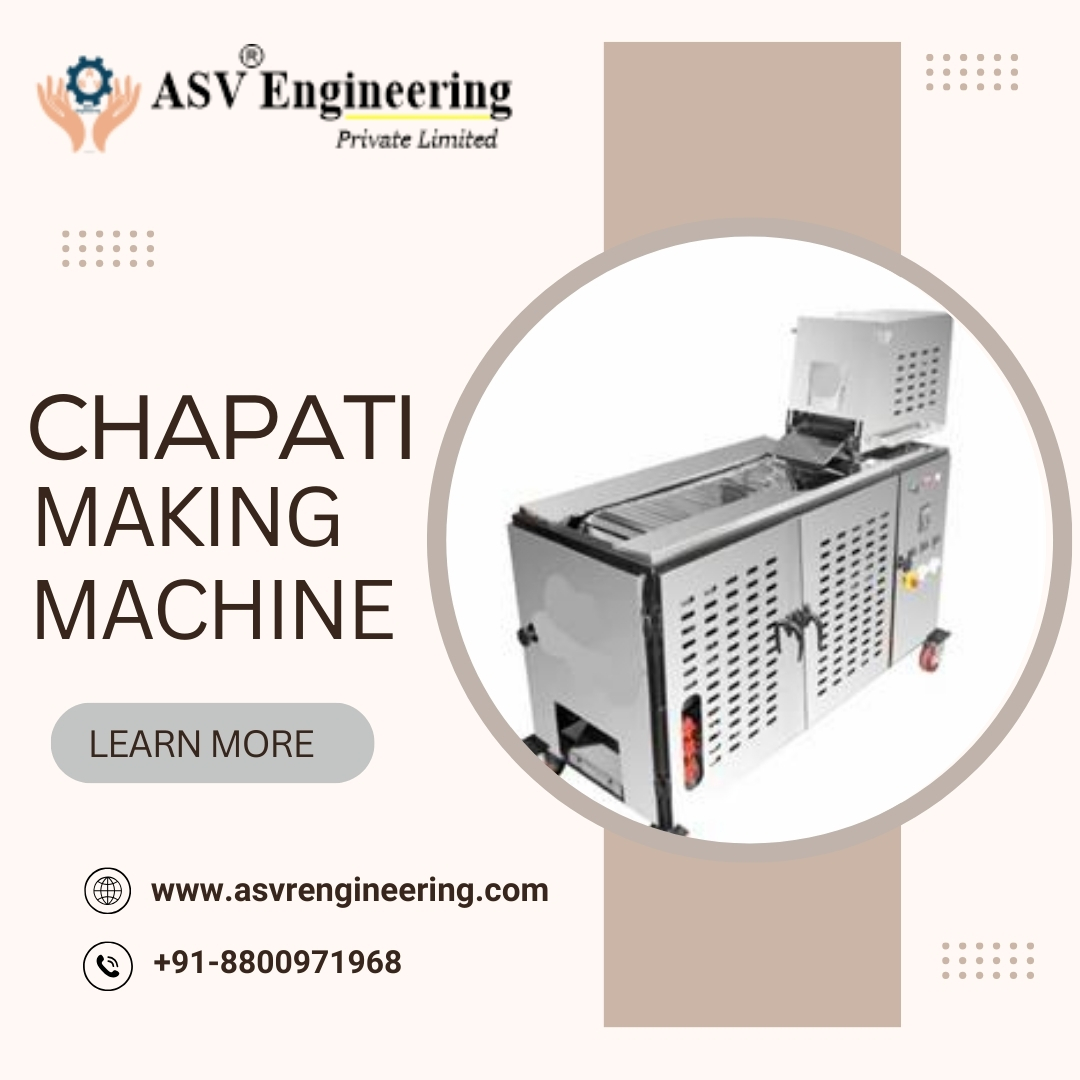

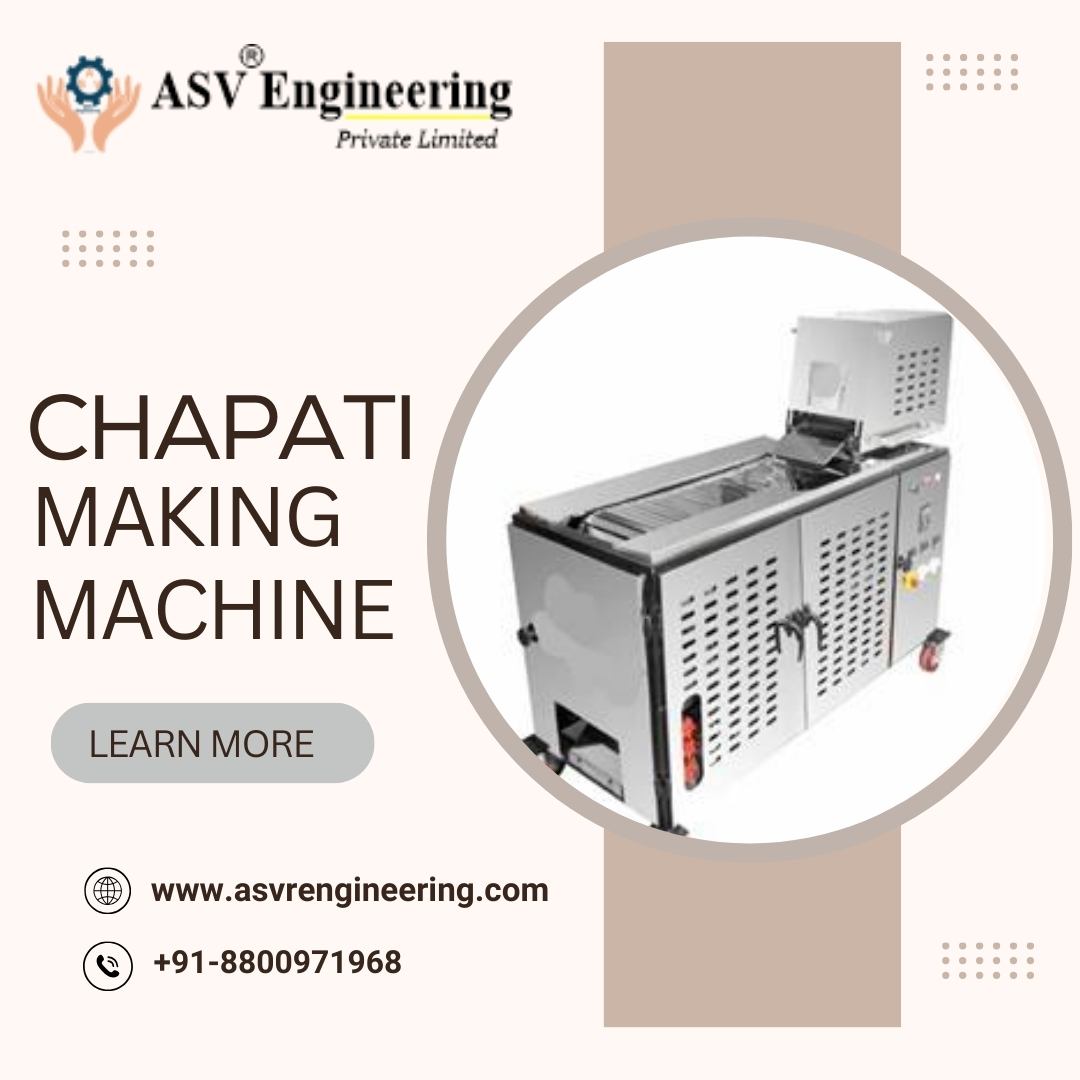

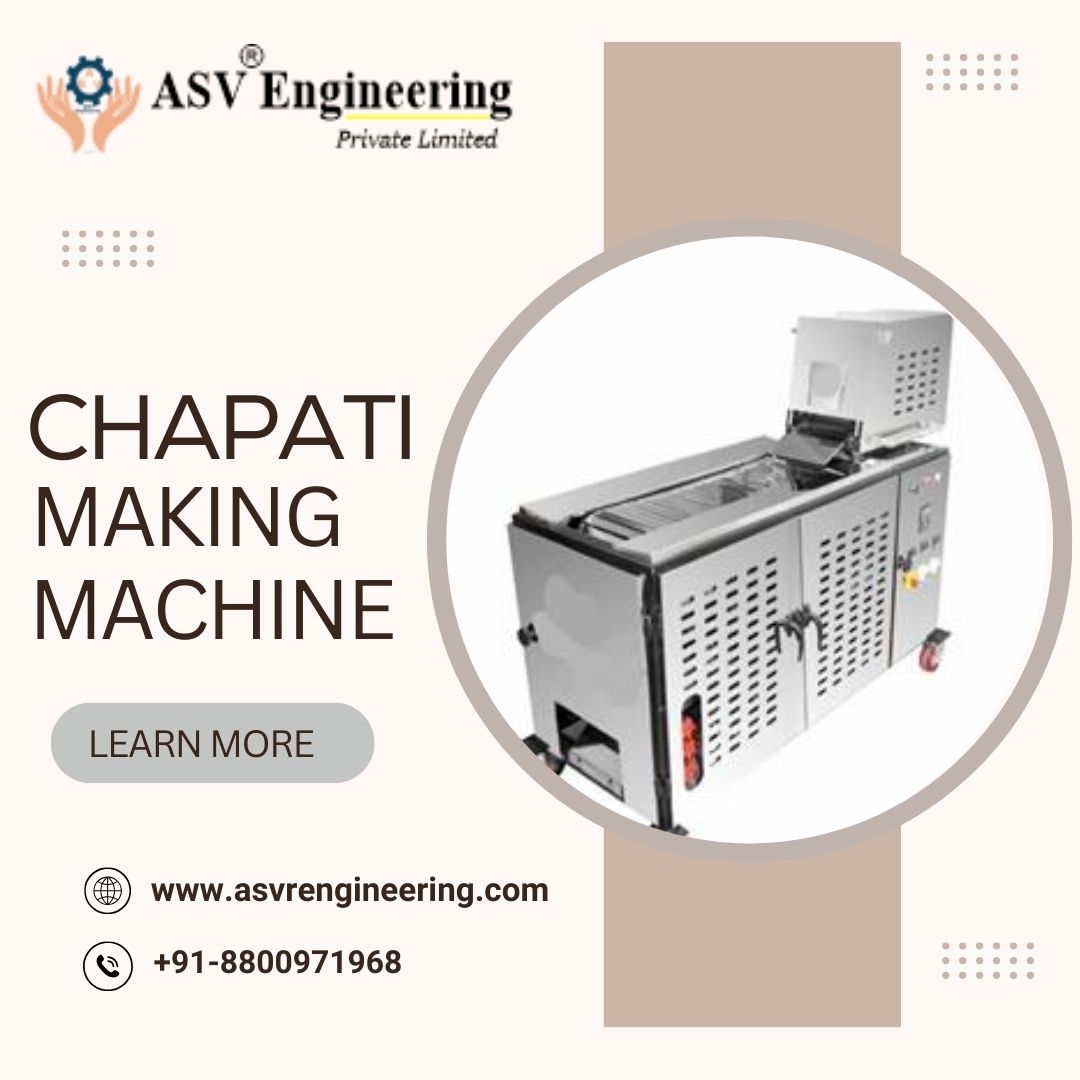

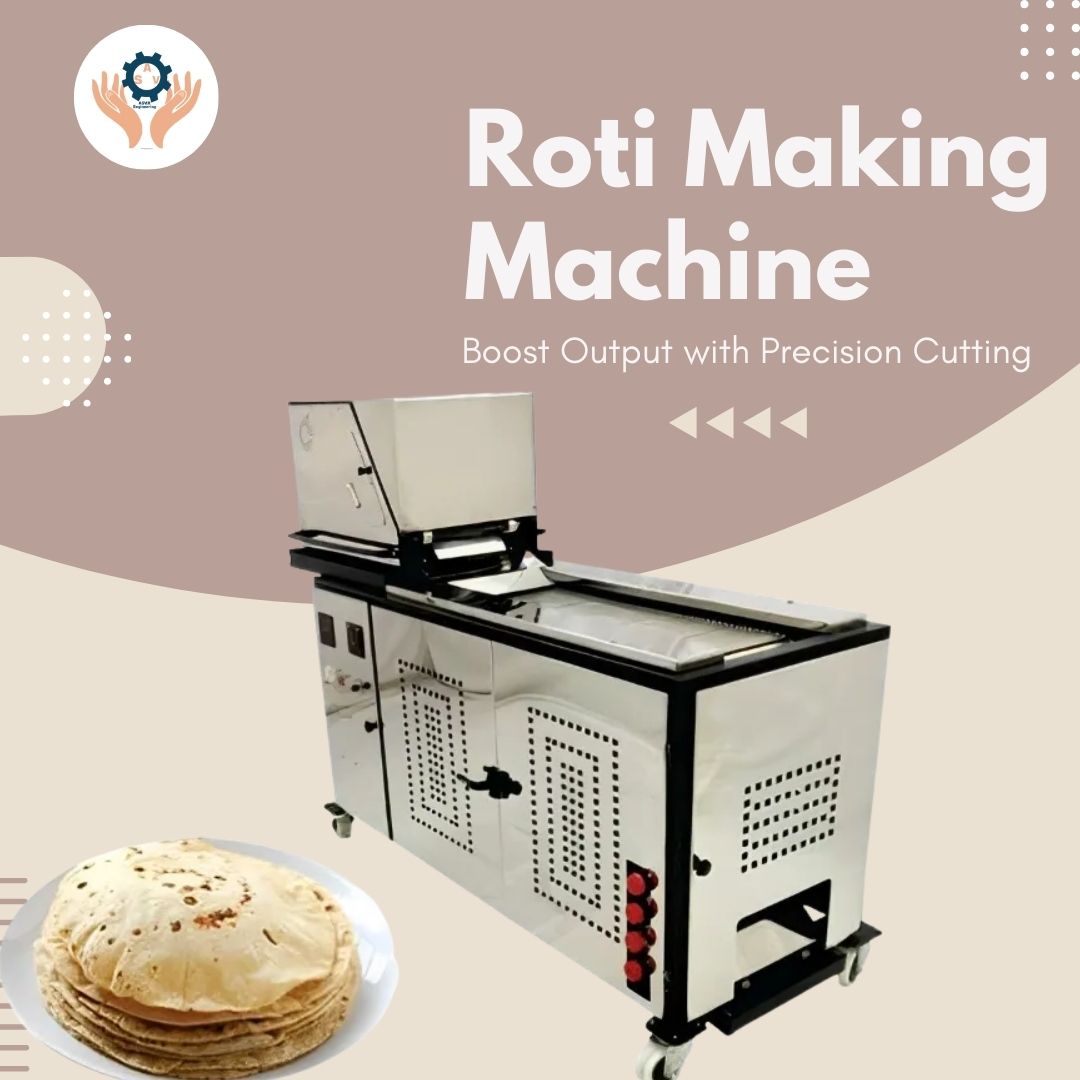

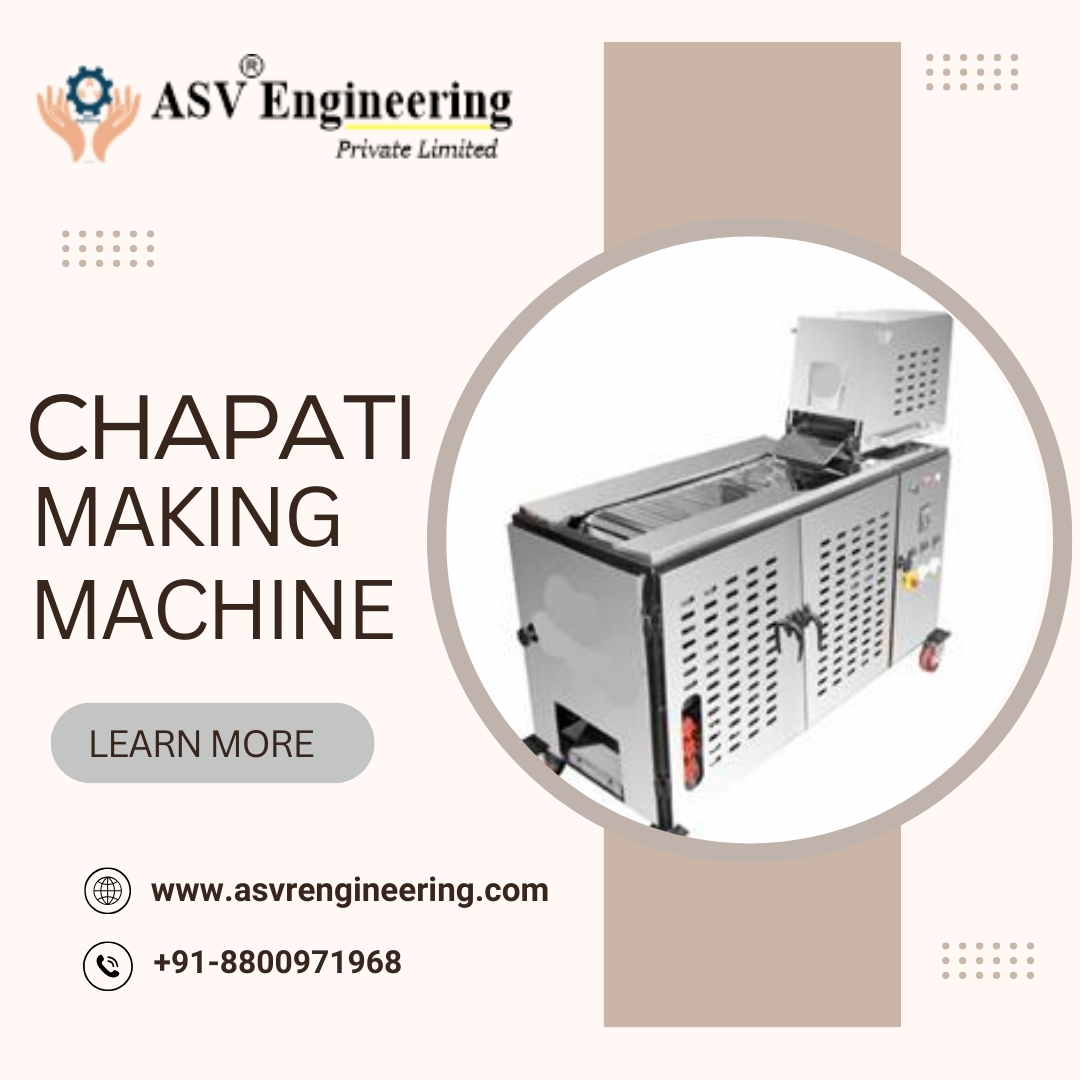

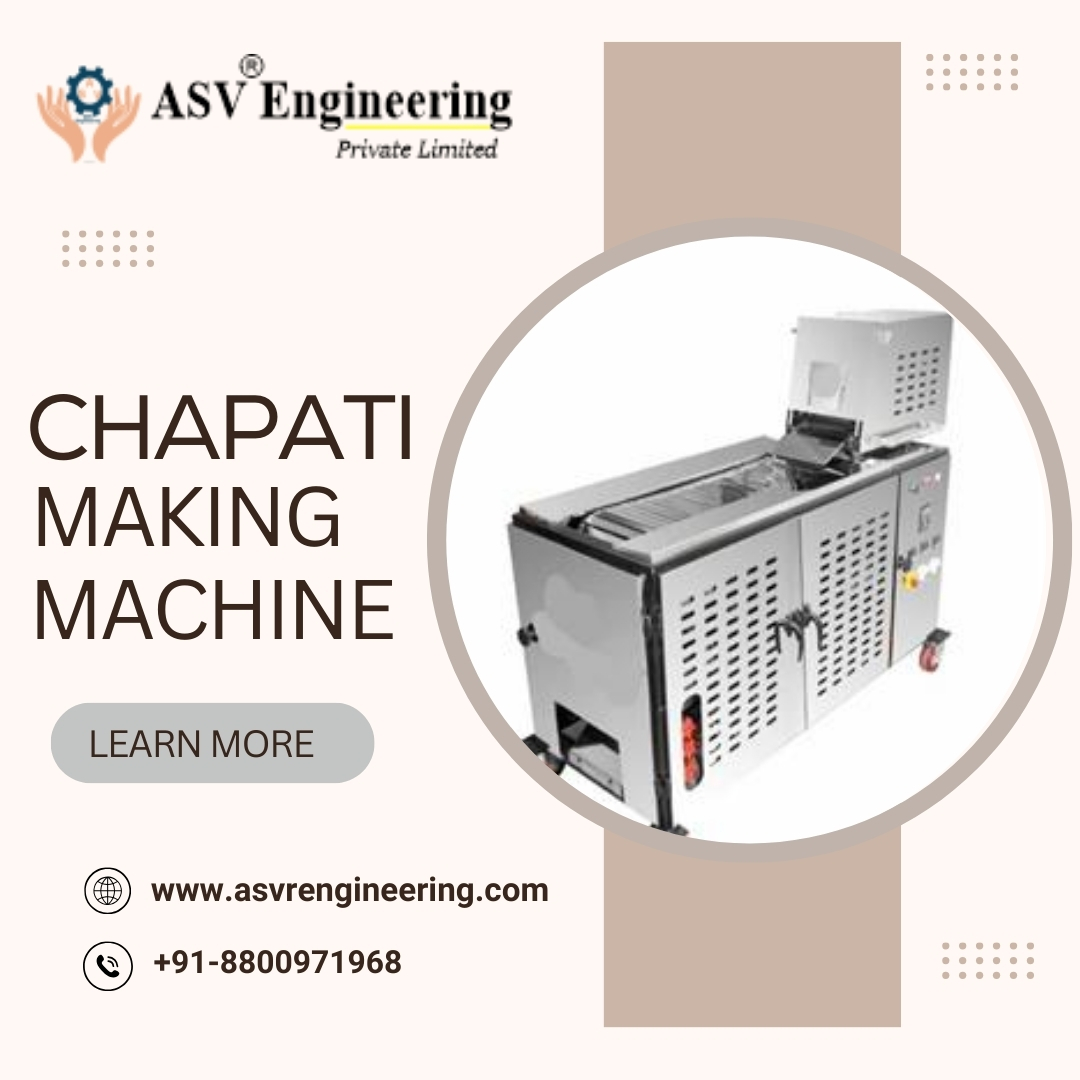

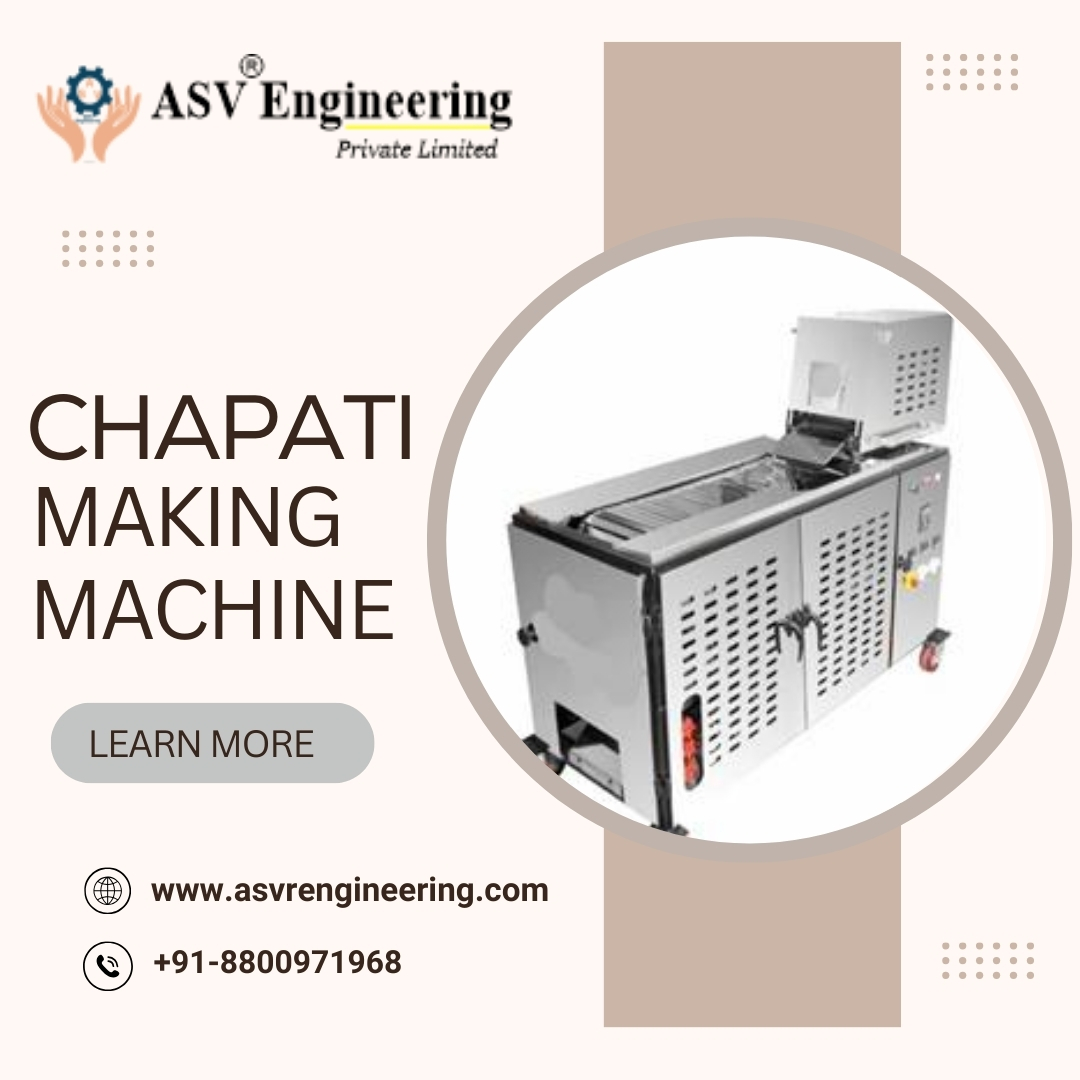

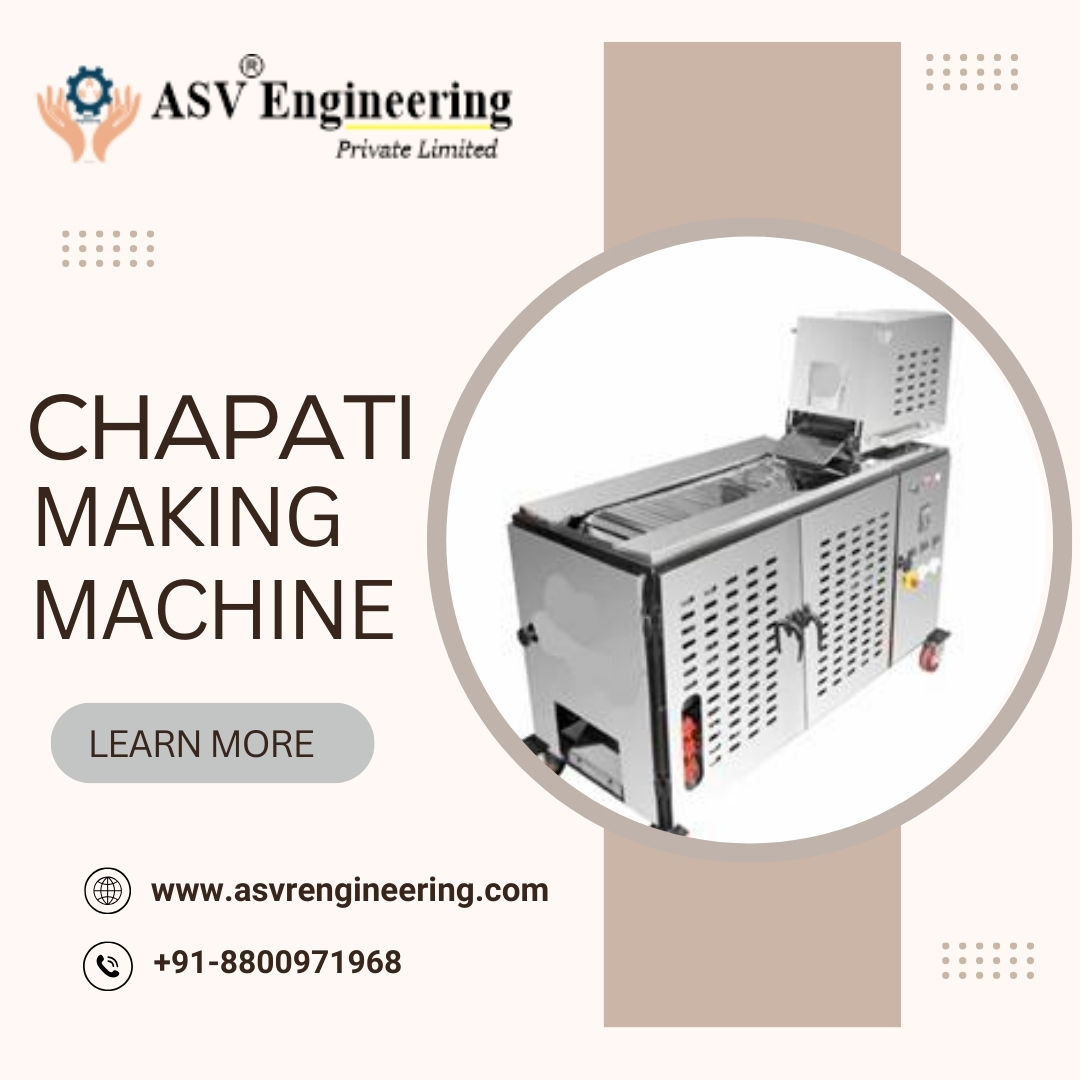

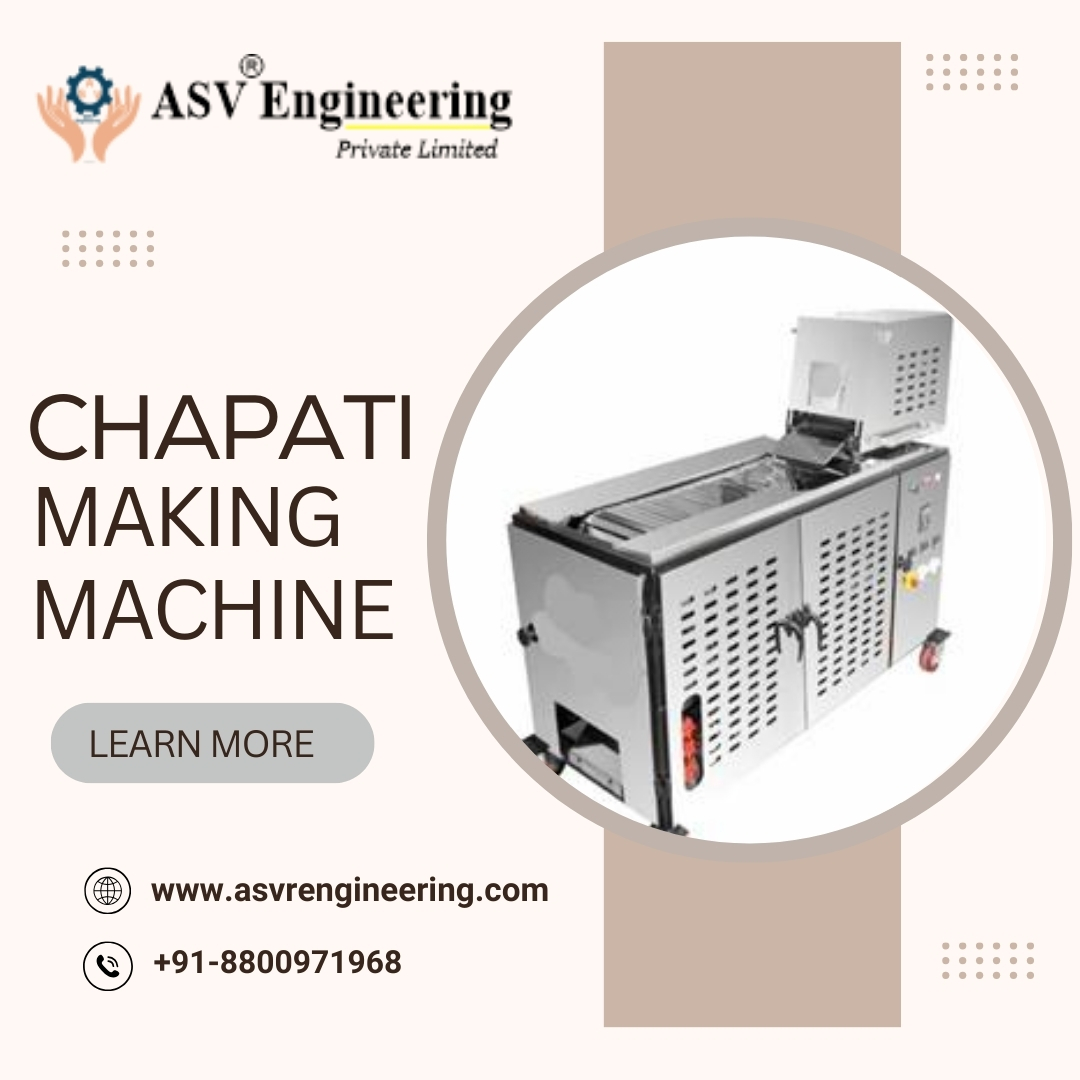

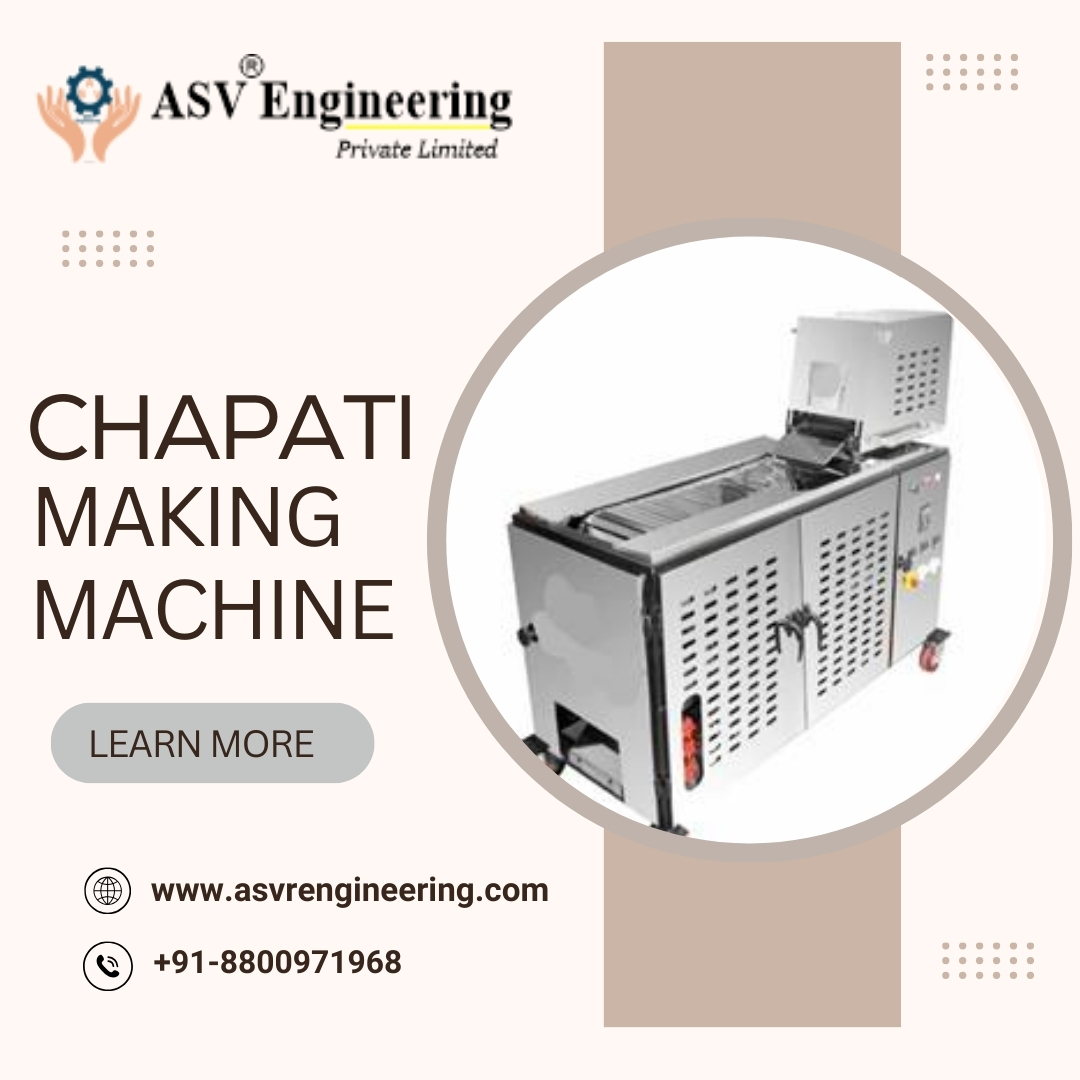

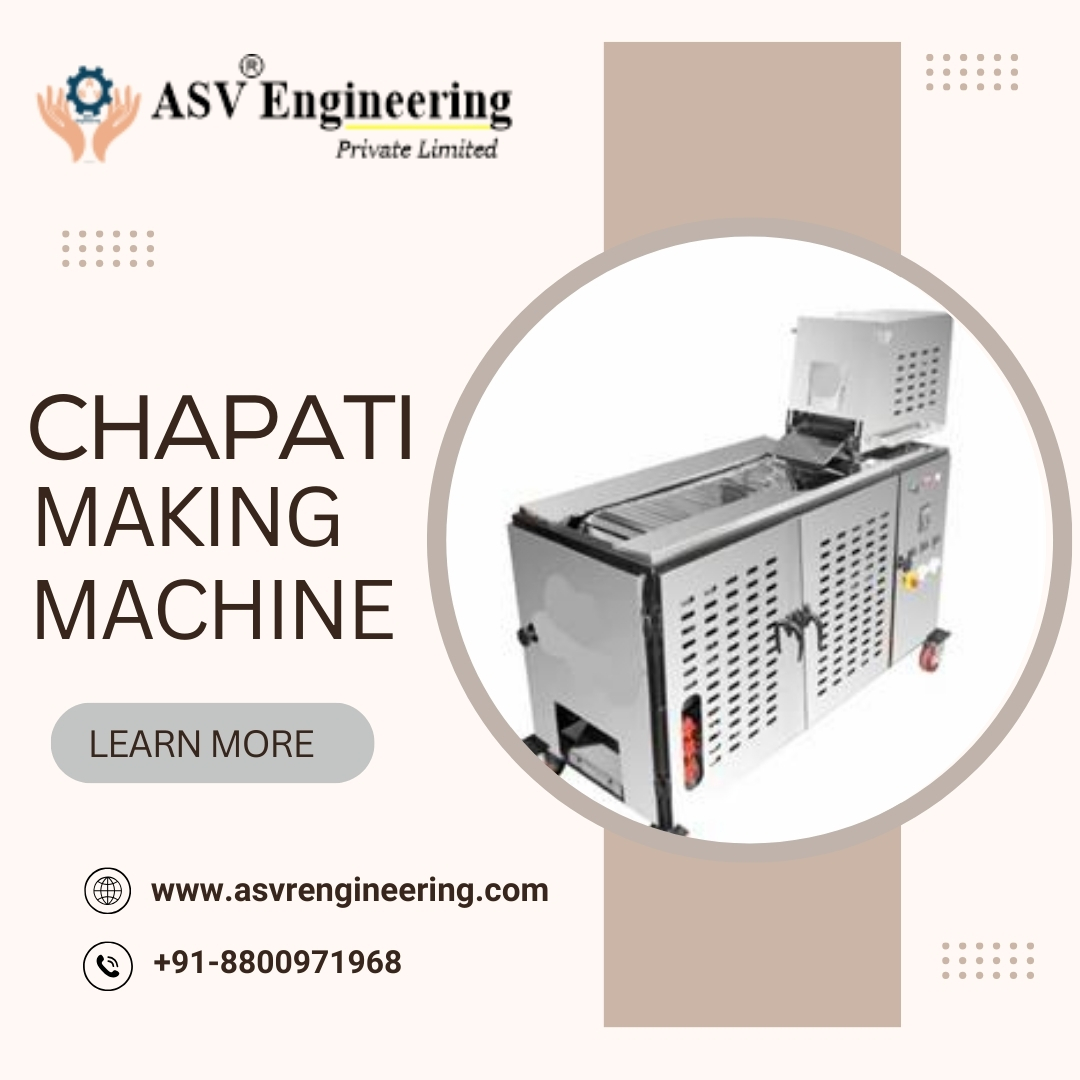

Semi Automatic Chapati Making Machine

Price: ₹225000

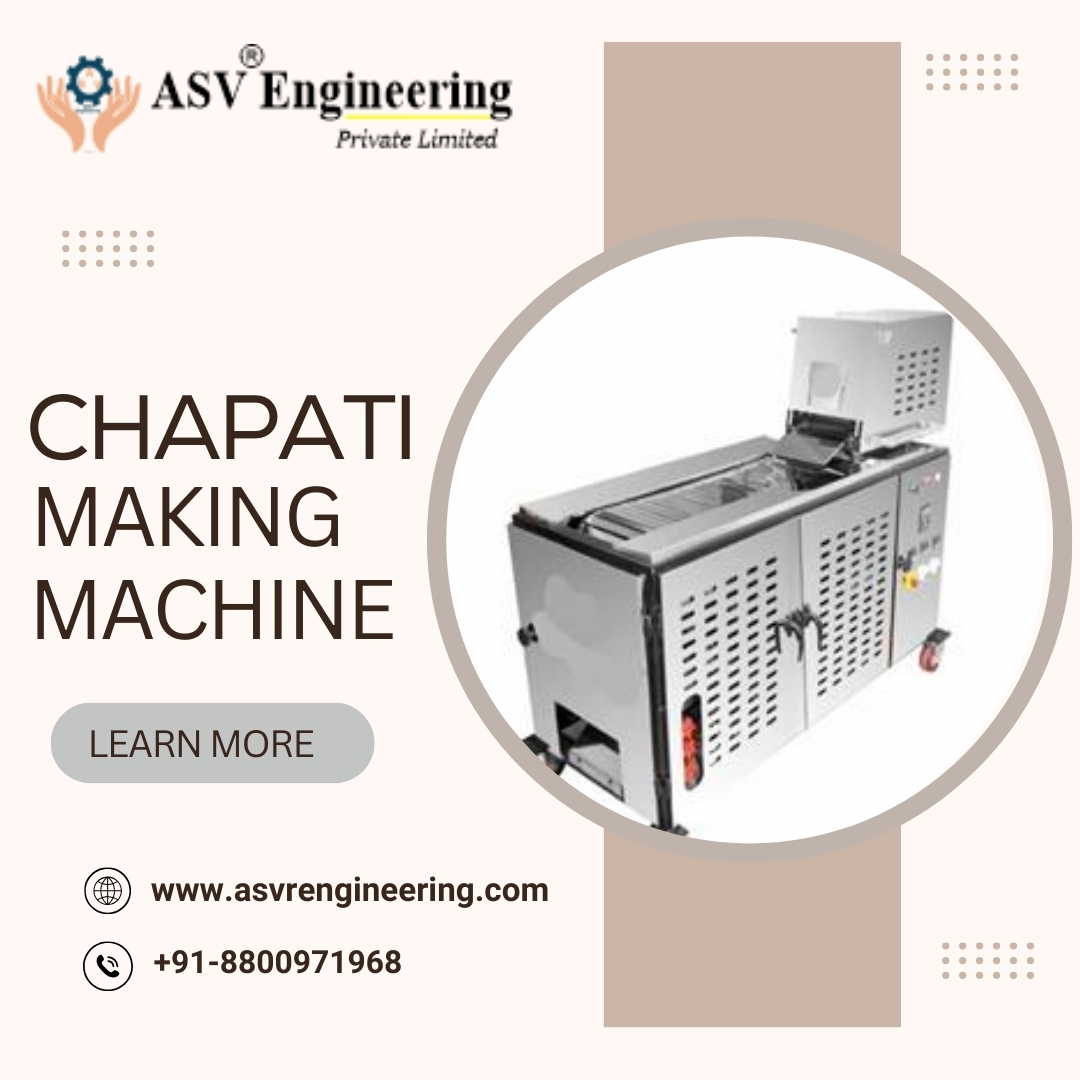

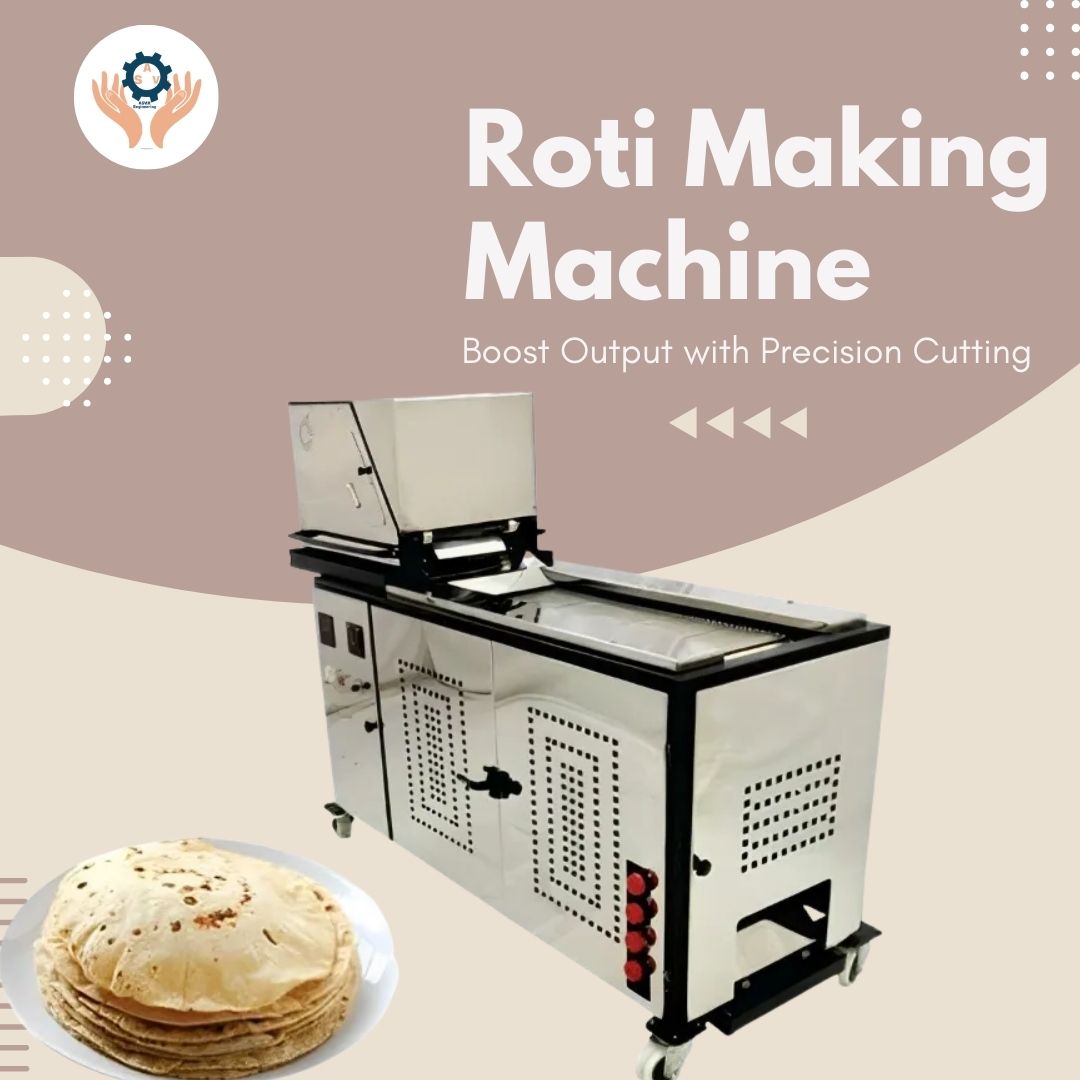

In India and many parts of the world, chapati is not just food—it is a daily necessity. From homes to hotels, from roadside eateries to large industrial kitchens, chapati remains at the heart of everyday meals. As food businesses grow and customer expectations rise, the need for consistency, hygiene, and speed has become more important than ever. This is where a Semi Automatic Chapati Making Machine plays a crucial role.

A semi automatic chapati making machine is designed to support commercial kitchens by reducing manual effort while maintaining the traditional taste and texture of handmade chapatis. It combines modern engineering with practical usability, making it ideal for small to medium-scale food operations. Whether you are running a hotel, restaurant, hostel, hospital kitchen, factory canteen, or catering unit, investing in a semi automatic chapati machine can significantly improve productivity and profitability.

At ASVR Engineering, we specialize in manufacturing and supplying high-quality semi automatic chapati making machines that are durable, efficient, and easy to operate. Our machines are built keeping Indian kitchen conditions and food habits in mind.

What is a Semi Automatic Chapati Making Machine?

A semi automatic chapati making machine is a food processing machine that automates major steps of chapati preparation while still allowing manual control at key stages. Unlike fully automatic machines, semi automatic models require human involvement for dough preparation and feeding, but the pressing and baking process is mechanized.

Typically, the operator places a dough ball into the machine, which then presses it into a round chapati and bakes it evenly using heated plates. This balance between automation and manual control ensures better quality, flexibility, and cost-effectiveness.

Why Choose a Semi Automatic Chapati Making Machine?

1. Maintains Traditional Taste

One of the biggest advantages of a semi automatic chapati machine is that it preserves the homemade taste of chapati. Since dough preparation is manual, the texture, softness, and flavor remain authentic.

2. Cost-Effective Solution

Compared to fully automatic machines, semi automatic chapati making machines are more affordable. They offer excellent performance at a lower investment, making them perfect for startups and growing food businesses.

3. Higher Productivity

A single machine can produce hundreds of chapatis per hour, far exceeding manual output. This ensures faster service during peak hours without compromising quality.

4. Consistent Size and Thickness

Uniform chapatis enhance presentation and customer satisfaction. The machine ensures consistent diameter and thickness in every batch.

5. Reduced Labor Dependency

With rising labor costs and shortages, this machine reduces dependency on skilled manpower while improving overall efficiency.

Applications of Semi Automatic Chapati Making Machine

A semi automatic chapati making machine is widely used across multiple food sectors:

-

Hotels and Restaurants

-

Industrial and Factory Canteens

-

Hospitals and Educational Institutions

-

Hostels and PG Kitchens

-

Catering and Event Management Companies

-

Cloud Kitchens and Central Kitchens

-

Religious Kitchens (Langar, Community Kitchens)

Its versatility makes it a valuable asset wherever chapatis are prepared in bulk.

Working Process of Semi Automatic Chapati Making Machine

The working of a semi automatic chapati machine is simple and operator-friendly:

-

Dough Preparation

Dough is prepared manually or using a dough kneader, ensuring the desired softness. -

Dough Ball Feeding

The operator places dough balls into the pressing section of the machine. -

Pressing

The machine presses the dough ball into a round chapati with uniform thickness. -

Baking

The pressed chapati is transferred to heated plates where it is evenly cooked on both sides. -

Collection

Freshly cooked chapatis are collected and ready for serving.

This semi-automated workflow ensures control, quality, and speed.

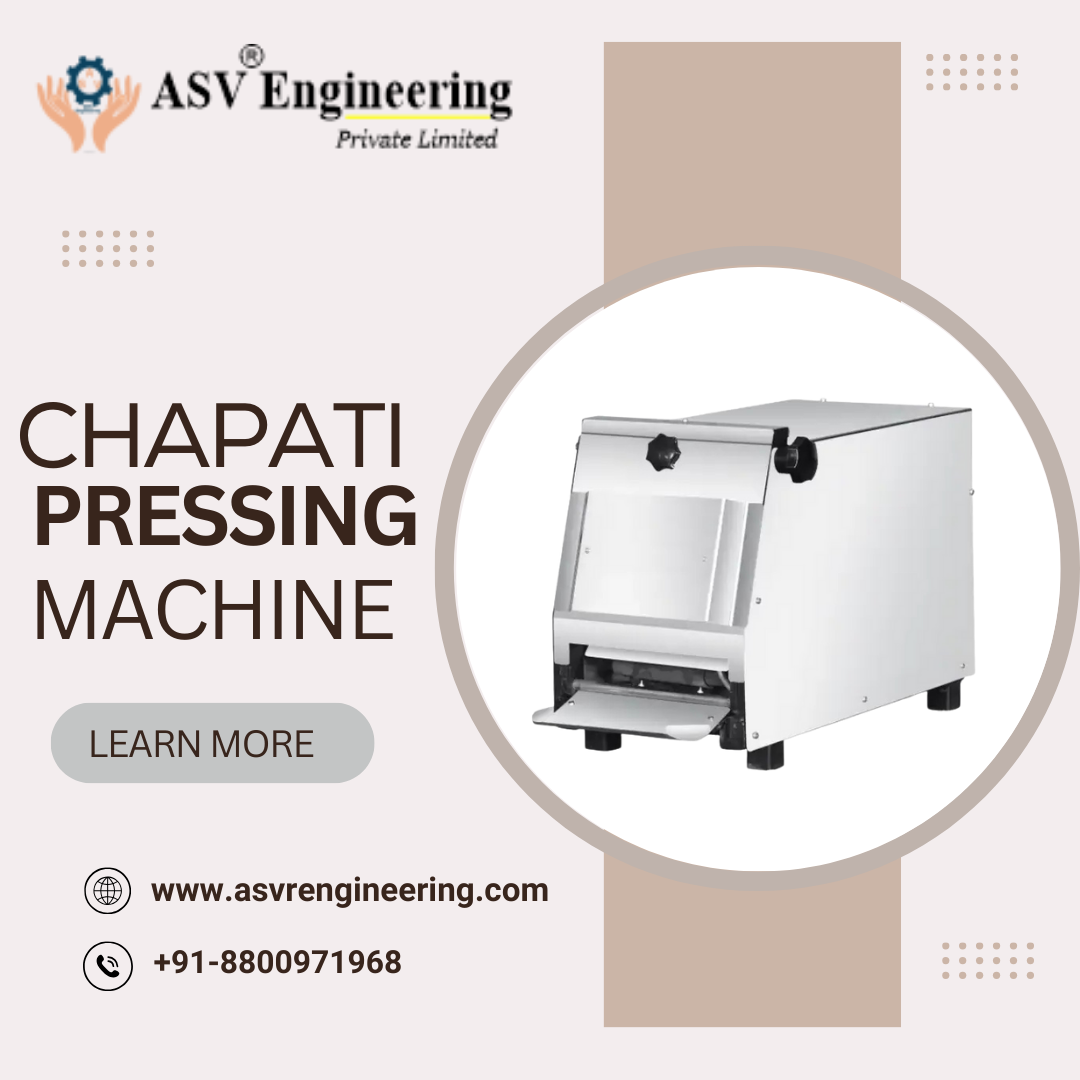

Key Features of ASVR Engineering Semi Automatic Chapati Making Machine

At ASVR Engineering, every machine is designed with precision and reliability in mind. Our semi automatic chapati making machines come with:

-

Heavy-duty stainless steel body

-

Food-grade components for hygiene and safety

-

Uniform heating system for perfect cooking

-

Adjustable thickness and size control

-

Easy operation and minimal training required

-

Low maintenance and long service life

-

Energy-efficient performance

-

Compact design suitable for commercial kitchens

Each machine undergoes strict quality checks before delivery.

Benefits for Your Food Business

Improved Efficiency

By automating repetitive tasks, kitchen staff can focus on preparation, hygiene, and service.

Faster Service

High output capacity ensures timely serving, especially during rush hours.

Better Profit Margins

Reduced labor cost and higher output directly improve profitability.

Hygiene and Safety

Minimal hand contact ensures better food hygiene and compliance with food safety standards.

Scalability

As demand grows, a semi automatic chapati machine helps scale operations without major changes.

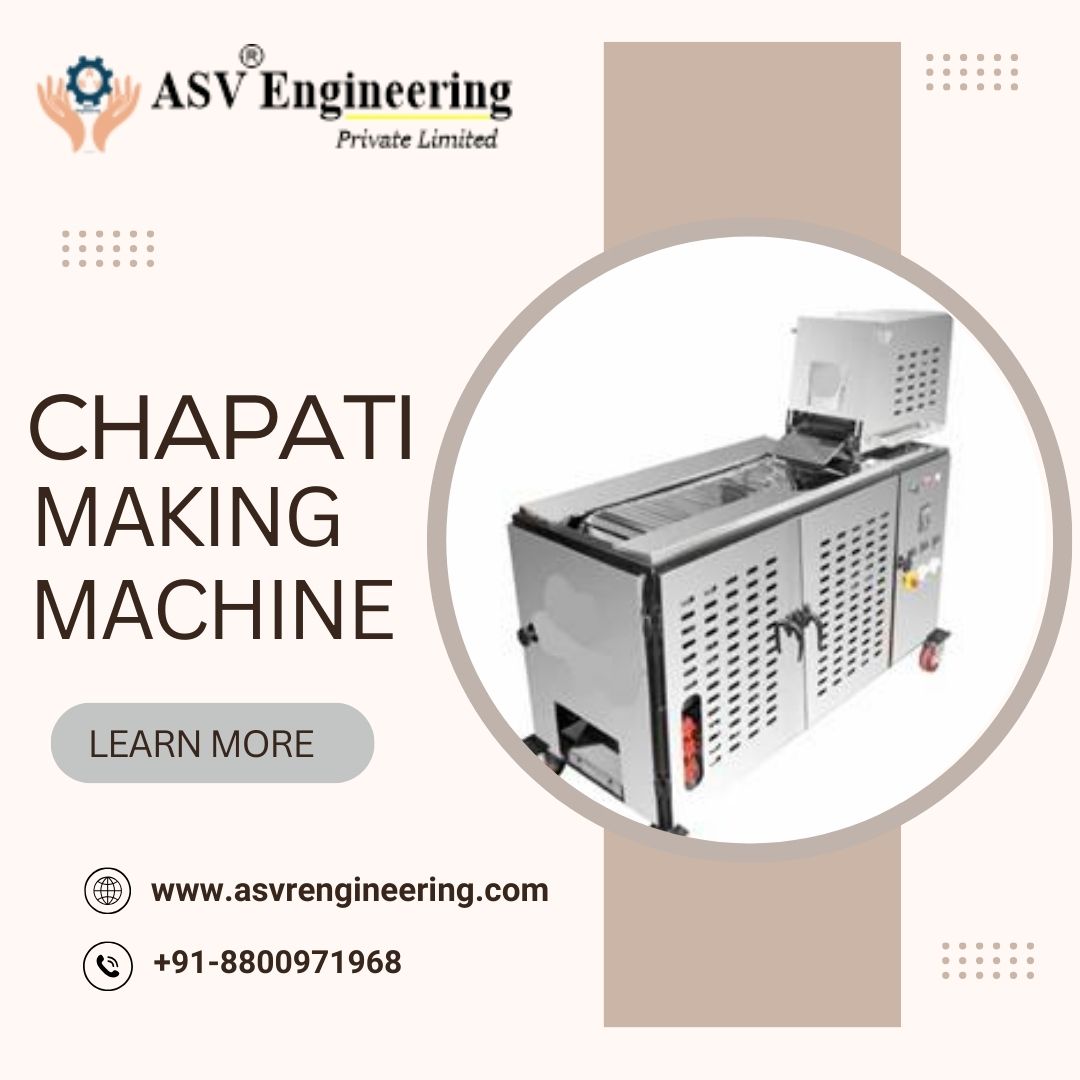

Why Buy from ASVR Engineering?

ASVR Engineering is a trusted name in the field of food processing and packaging machinery. Our commitment to quality, performance, and customer satisfaction sets us apart.

What Makes Us Different?

-

Years of experience in machine manufacturing

-

Customized solutions as per client requirements

-

Competitive pricing without compromising quality

-

Reliable after-sales support and service

-

Pan-India delivery and support

-

Machines designed for Indian cooking conditions

We understand the real challenges faced by food business owners and design machines that offer practical, long-term value.

Semi Automatic Chapati Making Machine Price

The price of a semi automatic chapati making machine depends on factors such as:

-

Production capacity (chapatis per hour)

-

Machine size and configuration

-

Material quality and build

-

Custom features or modifications

For the best price and detailed quotation, it is recommended to contact ASVR Engineering directly.

📞 Contact Numbers:

+91-8076004849

+91-8800971968

🌐 Website:

https://www.asvrengineering.com

Maintenance and Care Tips

Proper maintenance ensures long life and consistent performance:

-

Clean the machine daily after use

-

Use recommended food-grade lubricants

-

Check heating plates regularly

-

Avoid overloading the machine

-

Schedule periodic servicing

Following these simple steps can keep your machine running smoothly for years.

Future of Chapati Automation

With increasing demand for hygienic and standardized food, chapati automation is becoming essential. Semi automatic chapati making machines act as a perfect bridge between manual cooking and full automation. They offer flexibility, affordability, and reliability—making them an ideal choice for today’s evolving food industry.

As more businesses shift toward organized food production, machines like these will continue to play a vital role in improving efficiency and maintaining quality standards.

Conclusion

A Semi Automatic Chapati Making Machine is a smart investment for any commercial kitchen aiming to improve productivity without losing the traditional taste of chapatis. It offers the perfect balance of automation and manual control, making it suitable for a wide range of food businesses.

With robust construction, consistent output, and user-friendly operation, ASVR Engineering’s semi automatic chapati making machines are designed to meet the real needs of modern kitchens. If you are looking to scale your chapati production while maintaining quality and hygiene, this machine is the right solution.

For expert guidance, competitive pricing, and reliable after-sales support, get in touch with ASVR Engineering today.

Buy Now