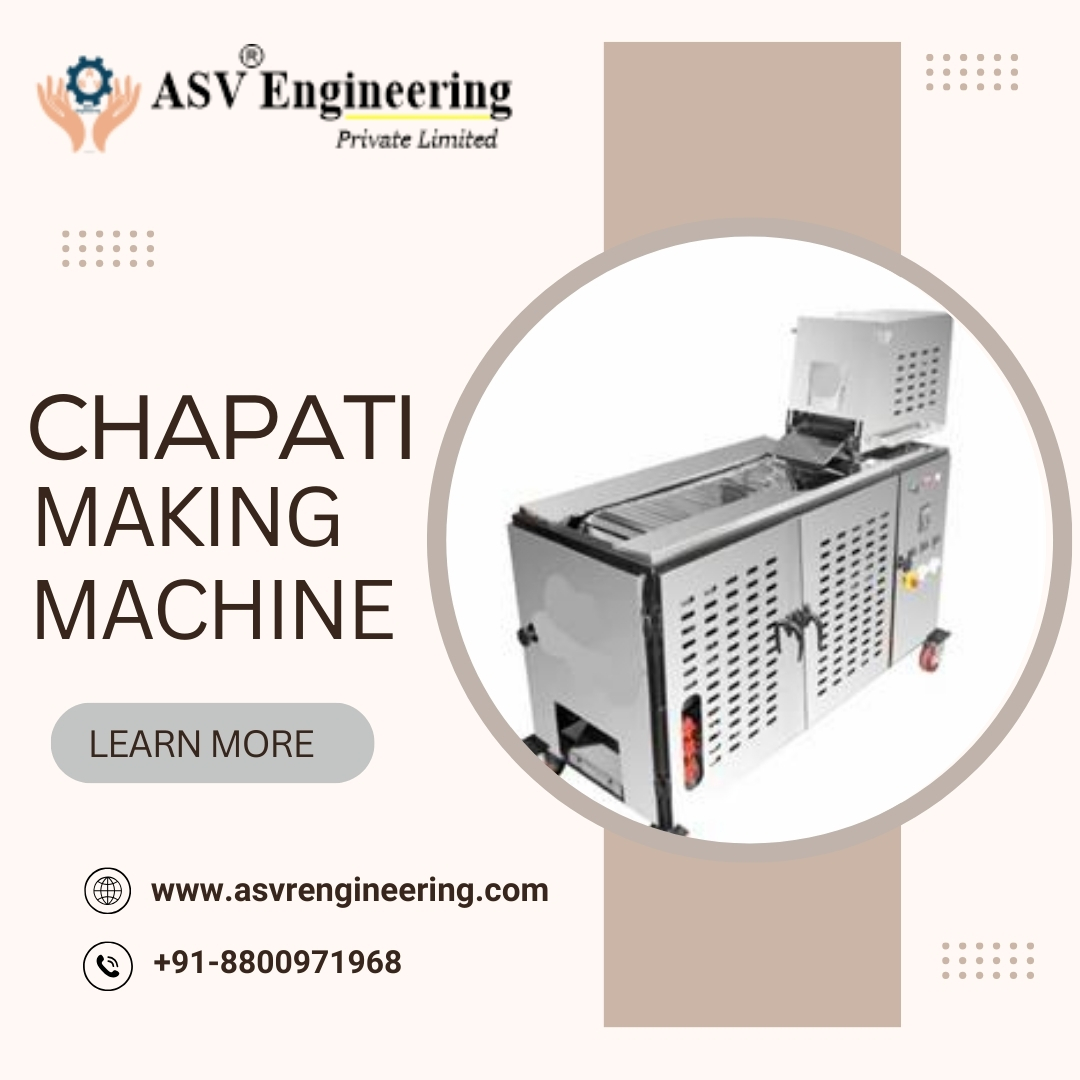

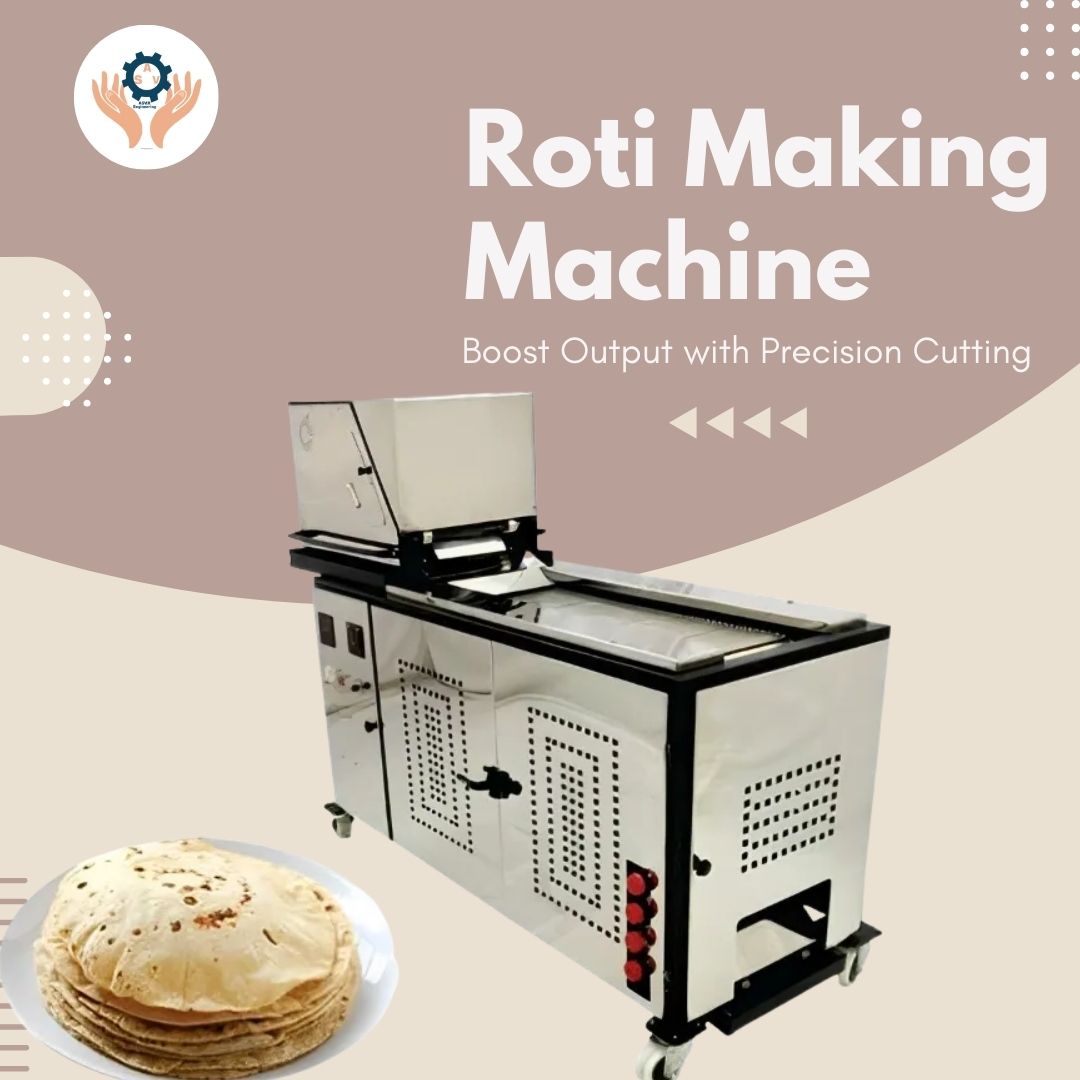

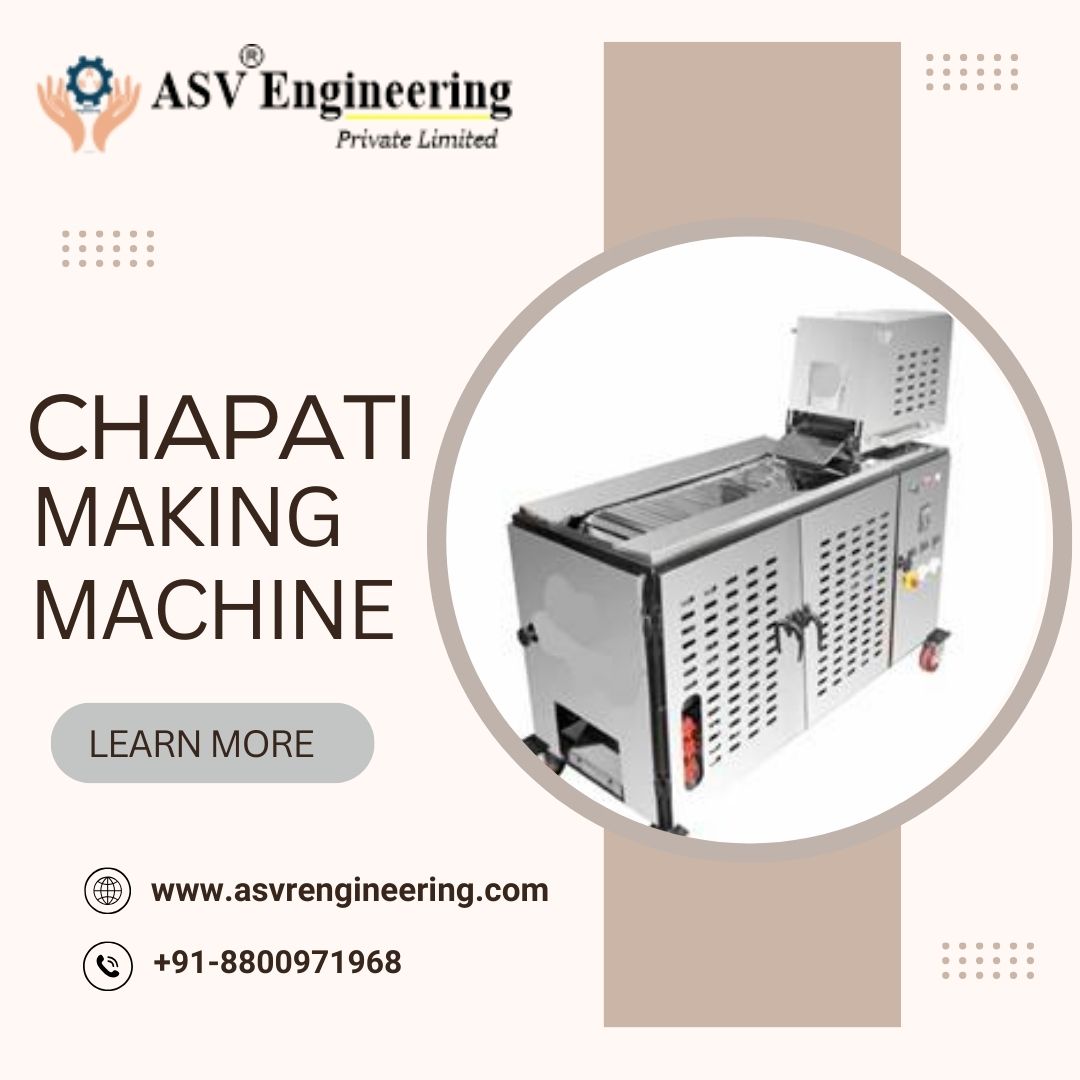

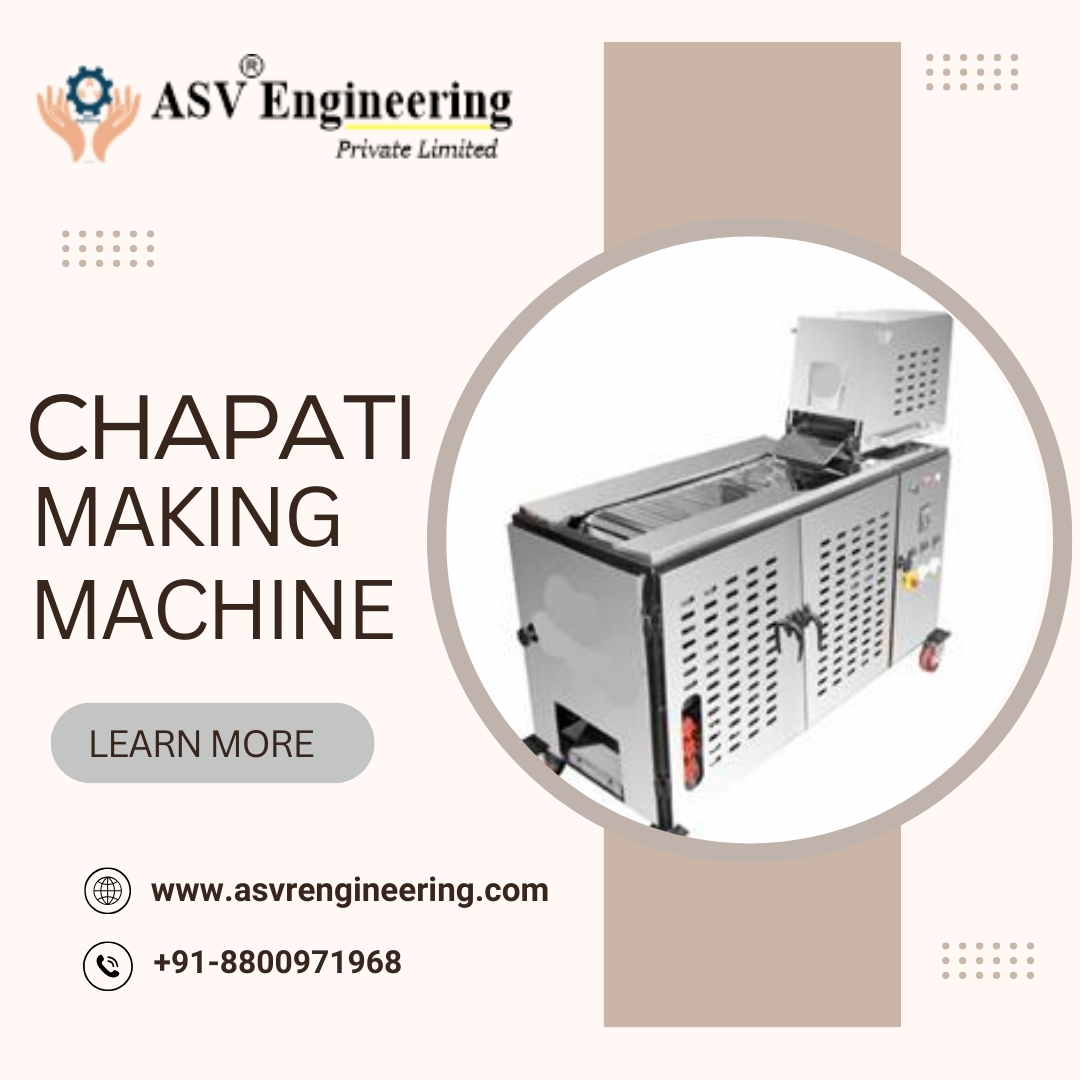

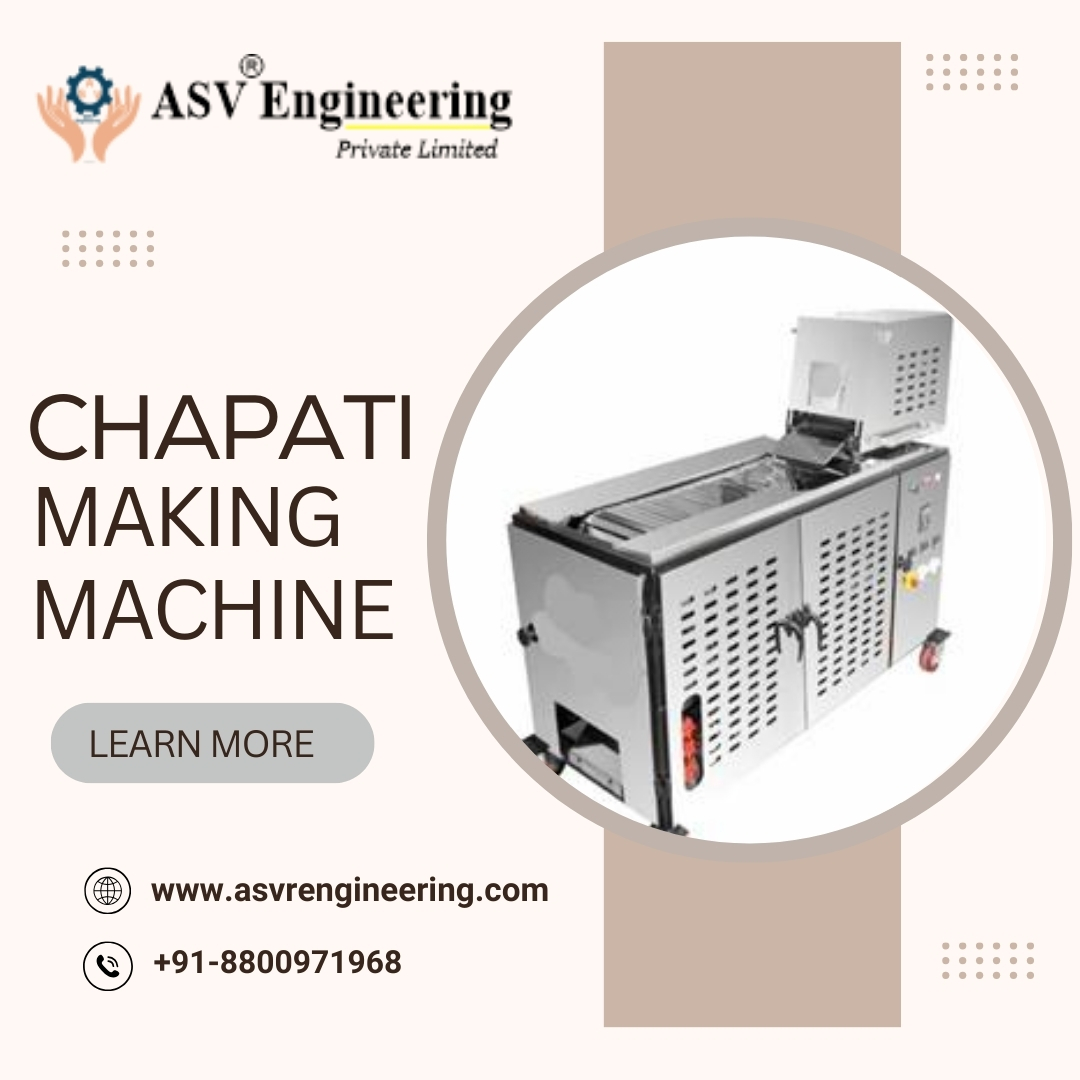

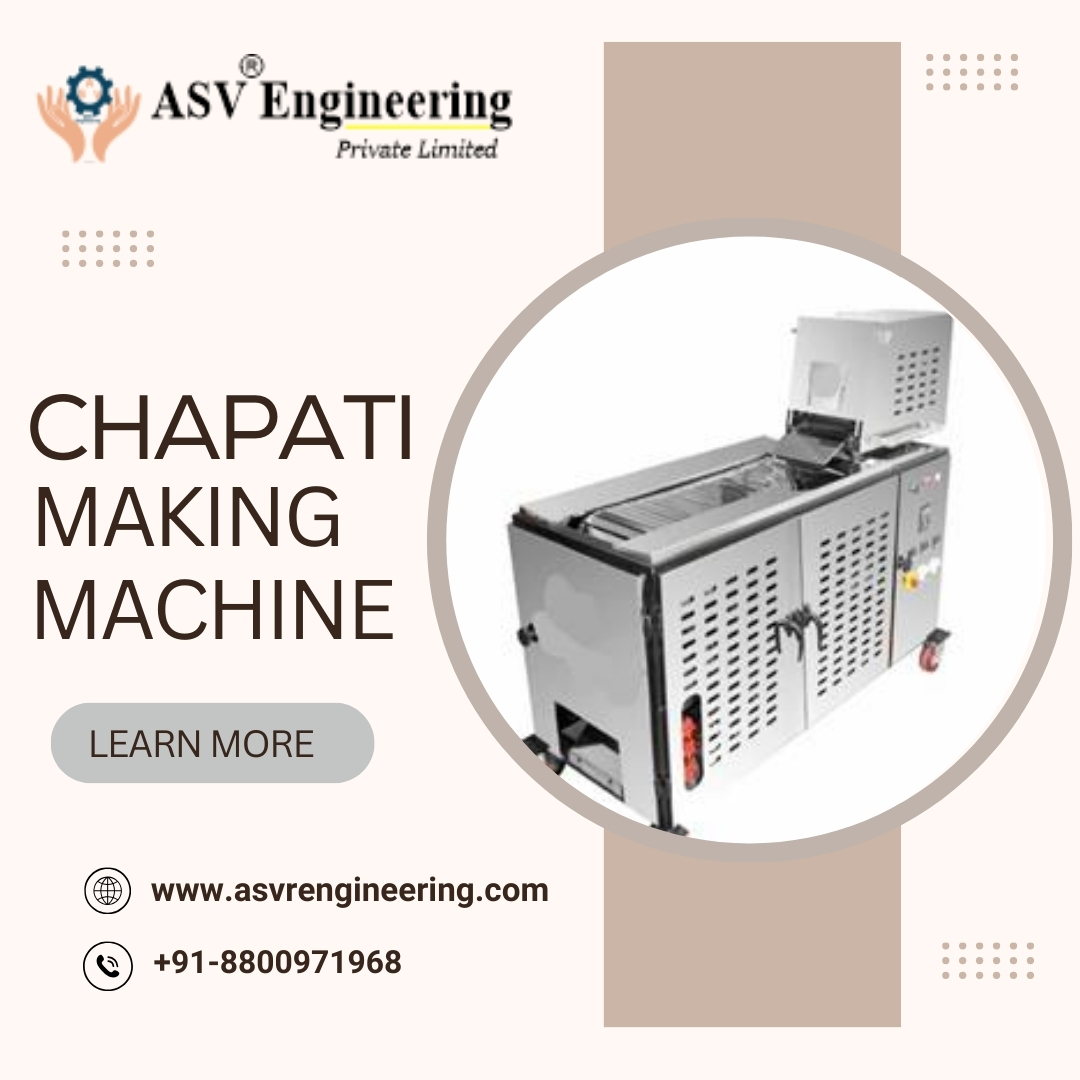

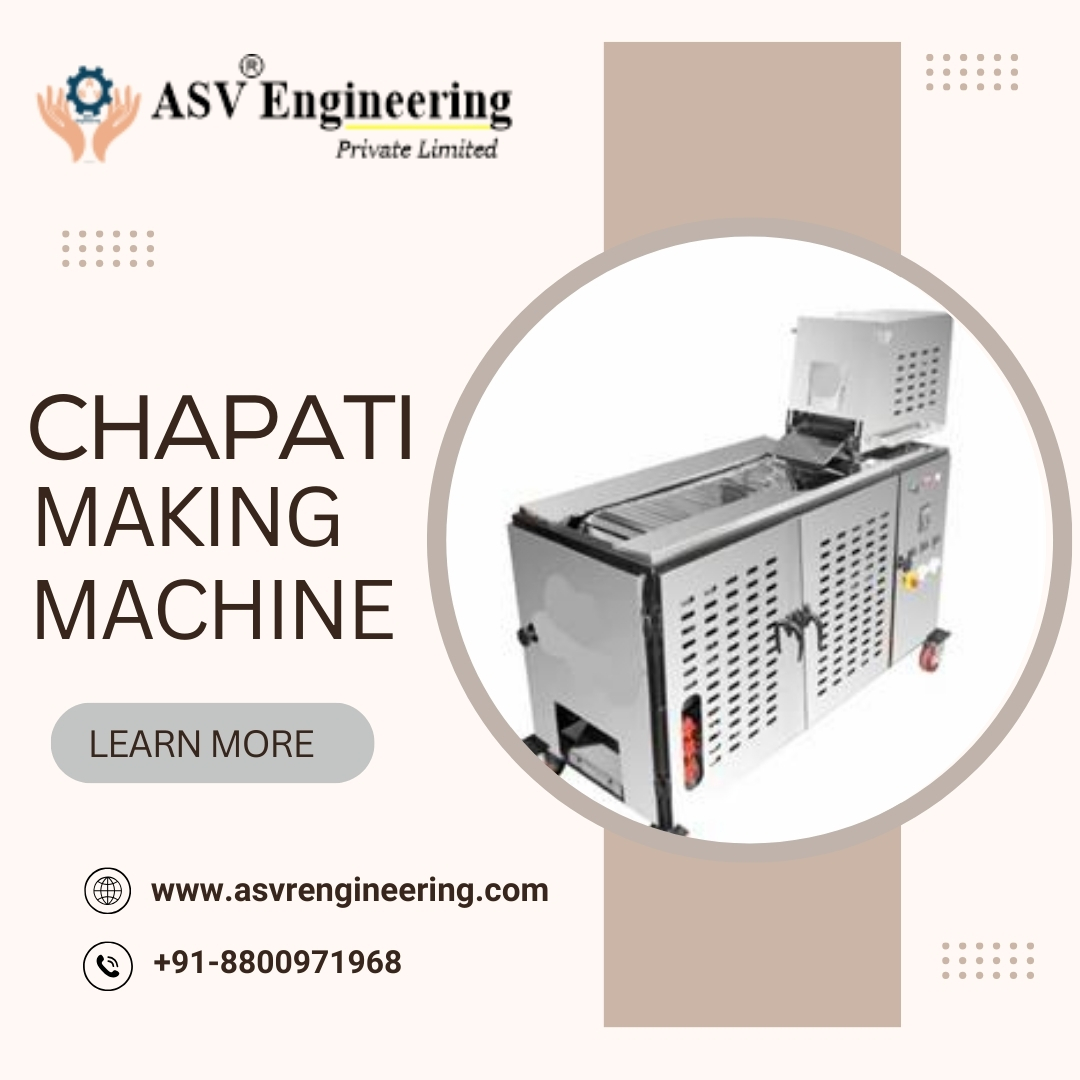

Leading Semi Automatic Chapati Making Machine Wholesalers Offering Durable & Energy-Efficient Machines

Price: ₹215000

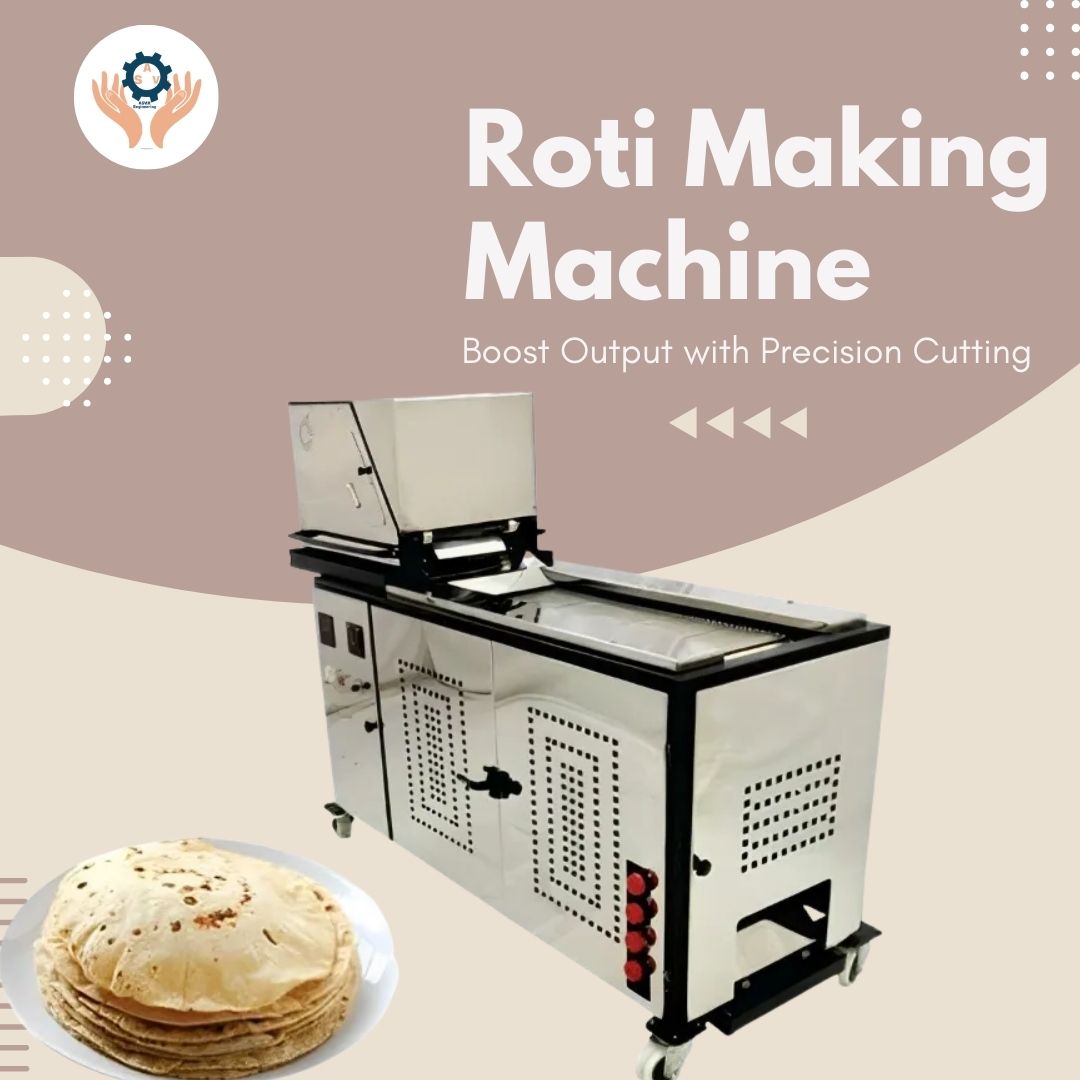

In India, chapati is more than just food—it is a daily necessity across homes, hotels, restaurants, hostels, canteens, and large-scale catering units. As demand for hygienic, uniform, and high-volume chapati production continues to rise, businesses are steadily moving away from labor-intensive manual preparation. This shift has made semi automatic chapati making machines an essential investment for commercial kitchens and food production units.

As leading semi automatic chapati making machine wholesalers, ASVR Engineering brings advanced, reliable, and energy-efficient chapati-making solutions designed specifically for Indian cooking conditions. With a strong focus on durability, performance, and affordability, the company supports businesses of all sizes—from small eateries to large institutional kitchens.

Understanding Semi Automatic Chapati Making Machines

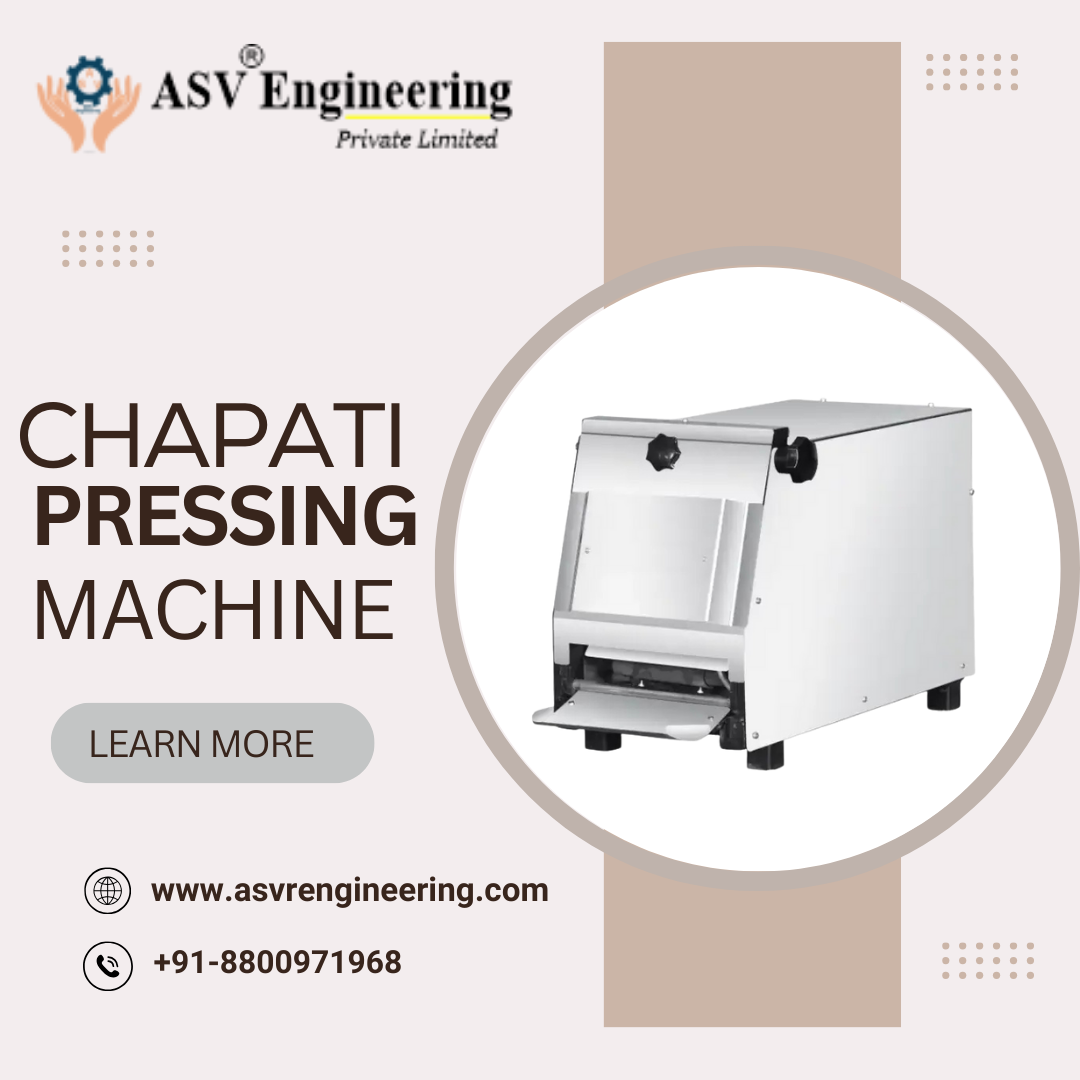

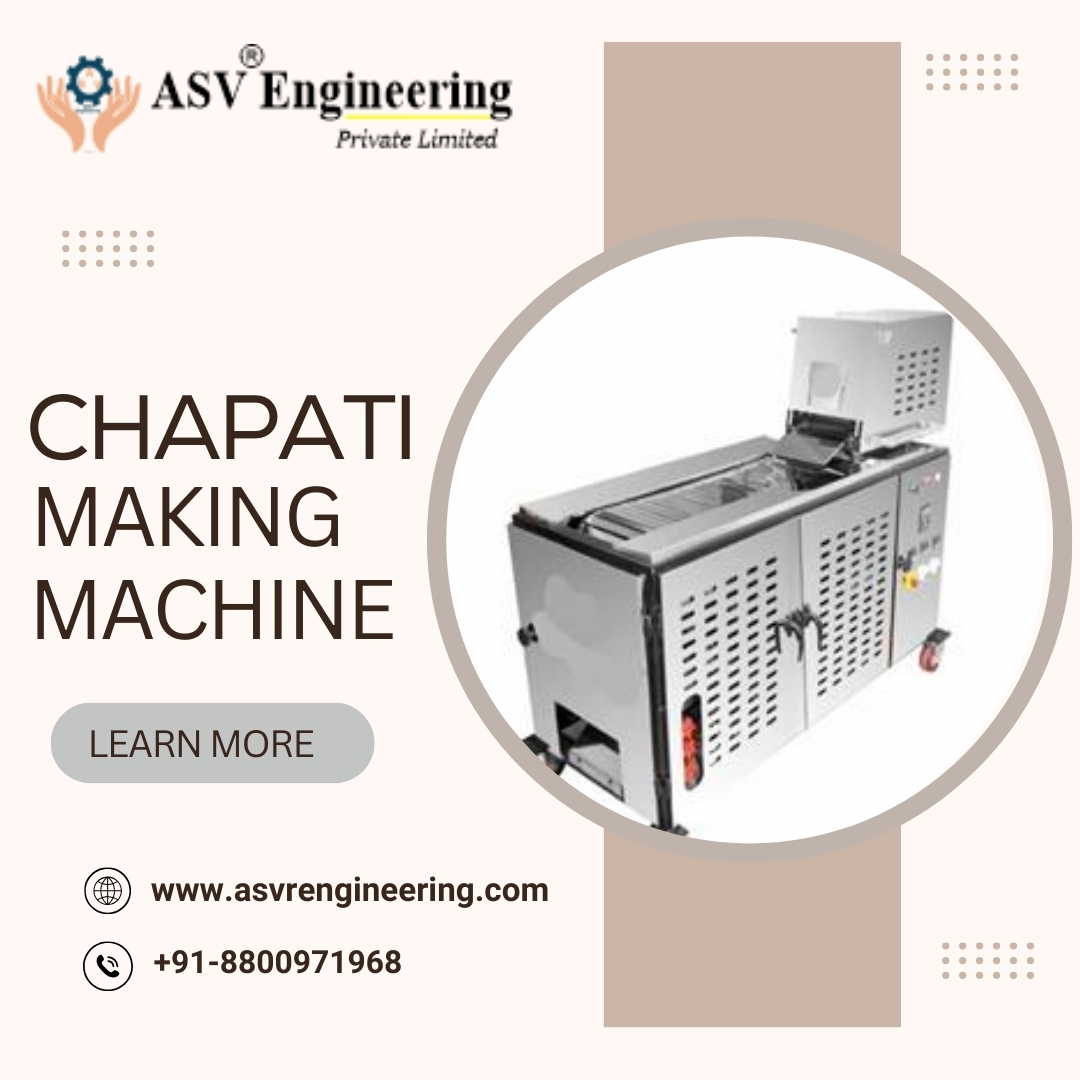

A semi automatic chapati making machine is designed to simplify and speed up chapati production while still allowing operator control over key processes. Unlike fully manual methods that depend heavily on skilled labor, or fully automatic machines that require higher investment, semi automatic machines offer a balanced solution.

These machines typically handle dough pressing and partial roasting, while the operator manages dough feeding and final cooking stages. This ensures consistent thickness, even cooking, and uniform size—qualities that are difficult to maintain with hand-rolled chapatis during peak working hours.

Why Semi Automatic Chapati Machines Are in High Demand

The popularity of semi automatic chapati making machines has grown rapidly due to several practical advantages:

1. Consistency and Quality

Each chapati produced is uniform in size, thickness, and texture. This consistency improves customer satisfaction and brand reputation, especially for hotels and restaurants.

2. Increased Productivity

A single machine can produce hundreds to thousands of chapatis per hour, significantly reducing preparation time and labor dependency.

3. Energy Efficiency

Modern machines are designed to consume less electricity or gas while delivering optimal output. Energy-efficient heating systems help lower operational costs over time.

4. Reduced Labor Costs

By automating repetitive tasks, businesses can reduce reliance on skilled manpower, minimize fatigue, and allocate staff to other kitchen operations.

5. Hygienic Food Processing

Stainless steel construction and minimal hand contact ensure hygienic production, complying with food safety standards.

Durable Construction for Long-Term Use

One of the key factors buyers consider while choosing chapati making machines is durability. Machines supplied by reputed wholesalers are built using high-grade stainless steel and heavy-duty components that can withstand continuous usage in demanding kitchen environments.

Durable rollers, precision-engineered pressing plates, and robust motors ensure smooth performance even during extended operating hours. Heat-resistant materials and food-grade finishes further enhance safety and longevity.

Energy-Efficient Design for Cost Savings

Energy efficiency is no longer optional—it is a necessity. Semi automatic chapati making machines offered by established wholesalers are engineered to optimize power consumption without compromising performance.

Advanced heating mechanisms distribute heat evenly, reducing wastage and ensuring faster cooking cycles. This not only lowers electricity or gas bills but also supports sustainable kitchen operations, making these machines an environmentally responsible choice.

Applications Across Multiple Industries

Semi automatic chapati making machines are widely used across various sectors, including:

-

Hotels and Restaurants – To maintain consistent quality during high customer footfall

-

Catering Services – Ideal for bulk food preparation at events and functions

-

Hostels and Mess Facilities – Ensures quick and hygienic daily meal preparation

-

Hospitals and Institutional Kitchens – Meets large-volume dietary requirements efficiently

-

Food Manufacturing Units – Supports standardized production for packaged chapatis

Their flexibility makes them suitable for both small kitchens and large industrial setups.

Features That Matter Most

When sourcing machines from trusted wholesalers, buyers benefit from features designed for ease of use and reliability:

-

User-friendly controls for easy operation

-

Adjustable thickness settings to suit regional preferences

-

Compact design requiring minimal floor space

-

Low maintenance requirements with easily accessible components

-

Compatibility with gas or electric heating options

These features collectively enhance productivity while keeping operational challenges minimal.

Why Choose a Wholesaler Over a Retail Supplier?

Purchasing from a wholesale supplier offers several advantages:

-

Cost Efficiency – Competitive pricing due to bulk manufacturing and distribution

-

Product Variety – Access to multiple models with different capacities

-

Customization Options – Machines tailored to specific production needs

-

After-Sales Support – Reliable installation, training, and service assistance

-

Spare Parts Availability – Ensures uninterrupted operations in the long run

Leading wholesalers act as long-term partners rather than just equipment sellers.

Importance of After-Sales Service and Support

A chapati making machine is a long-term investment. Proper installation, operator training, and timely maintenance play a crucial role in maximizing its lifespan. Reputed wholesalers provide comprehensive after-sales support, including technical guidance, spare parts supply, and troubleshooting assistance.

This commitment ensures minimal downtime and consistent performance, allowing businesses to focus on serving quality food without operational interruptions.

Custom Solutions for Diverse Business Needs

Every kitchen has unique requirements. Factors such as daily production volume, available space, fuel preference, and menu style influence machine selection. Leading wholesalers offer expert consultation to help buyers choose the right model.

From compact machines for small restaurants to high-output units for industrial kitchens, customized solutions ensure optimal return on investment.

Trusted Name in Chapati Making Machinery

With years of experience in food processing machinery, ASVR Engineering has built a reputation for quality, reliability, and customer satisfaction. Their semi automatic chapati making machines are known for sturdy construction, efficient performance, and compliance with industry standards.

By combining engineering expertise with practical kitchen insights, the company continues to support India’s growing food service sector with dependable machinery solutions.

Contact & Business Information

For businesses looking to upgrade their chapati production process with durable and energy-efficient machines, expert assistance is just a call away.

Contact Numbers:

+91-8076004849

+91-8800971968

Website:

https://www.asvrengineering.com

Buy Now