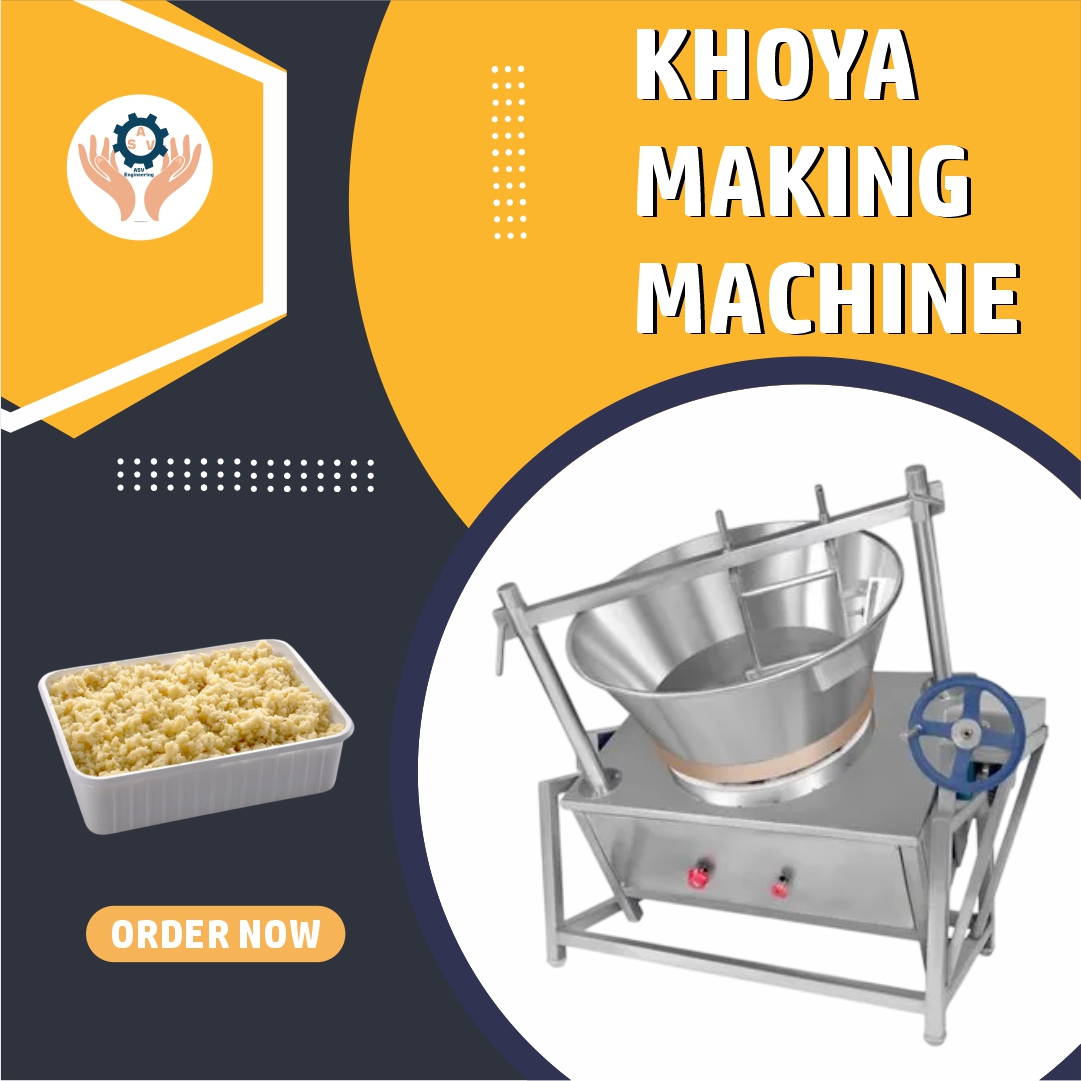

Khoya Making Machine

Price: ₹72000

Khoya, also known as mawa, is the heart of countless Indian sweets—gulab jamun, peda, barfi, kalakand, and many more. For generations, khoya was prepared manually by slowly heating milk for hours, constantly stirring to achieve the right texture and taste. While this traditional method delivers authenticity, it is time-consuming, labor-intensive, and inconsistent when scaled for commercial production.

This is where a Khoya Making Machine becomes essential. Designed to replicate the traditional slow-cooking process with modern efficiency, a khoya making machine helps sweet manufacturers, dairy units, and food processing businesses produce high-quality khoya in a hygienic, uniform, and cost-effective manner.

At ASVR Engineering, we understand the delicate balance between tradition and technology. Our khoya making machines are engineered to preserve authentic taste while meeting today’s demands for speed, hygiene, and scalability.

What Is a Khoya Making Machine?

A khoya making machine is a specialized dairy processing machine used to convert milk into khoya by controlled heating, evaporation, and continuous mixing. The machine ensures even heat distribution, prevents milk from sticking or burning, and delivers a consistent final product every time.

Unlike manual methods, modern khoya machines significantly reduce human effort, processing time, and raw material wastage—making them ideal for both small sweet shops and large dairy plants.

Why Invest in a Khoya Making Machine?

1. Consistent Quality Every Batch

Manual khoya preparation often varies depending on the skill and attention of the worker. A machine maintains uniform temperature and stirring, ensuring the same texture, color, and taste in every batch.

2. Time & Labor Efficiency

What traditionally took several hours can now be completed in a fraction of the time. One machine can replace multiple workers, allowing businesses to optimize manpower.

3. Hygienic Production

Manufactured using food-grade stainless steel, khoya making machines ensure compliance with hygiene standards. Enclosed systems reduce contamination risks and improve shelf life.

4. Cost-Effective in the Long Run

Though the initial investment may seem significant, reduced labor costs, lower milk wastage, and higher production capacity quickly deliver strong returns.

5. Scalable for Growing Businesses

Whether you are a neighborhood halwai or an industrial sweet manufacturer, khoya machines come in different capacities to match your production needs.

Types of Khoya Making Machines

Manual Khoya Making Machine

Best suited for small sweet shops, these machines require partial operator involvement but still offer better consistency and hygiene than traditional methods.

Semi-Automatic Khoya Making Machine

A popular choice for mid-sized businesses, semi-automatic machines balance affordability with efficiency. They automate heating and mixing while allowing manual control where needed.

Fully Automatic Khoya Making Machine

Designed for large-scale dairies and food manufacturers, these machines offer maximum output with minimal human intervention. Ideal for continuous production lines.

Key Features of a High-Quality Khoya Making Machine

-

Stainless Steel Body (SS 304/316) for durability and hygiene

-

Uniform Heating System to prevent burning

-

Heavy-Duty Scraper & Stirrer for continuous mixing

-

Energy-Efficient Design to reduce power consumption

-

Easy Operation & Maintenance

-

Custom Capacity Options as per business requirements

At ASVR Engineering, every machine is designed keeping Indian dairy conditions in mind—robust, reliable, and easy to operate.

Khoya Making Process Using a Machine

-

Milk Feeding – Fresh milk is poured into the machine’s heating pan.

-

Controlled Heating – The machine gradually heats the milk, allowing water content to evaporate slowly.

-

Continuous Stirring – Automatic scrapers ensure milk does not stick to the surface.

-

Thickness Control – As moisture reduces, the milk thickens into khoya.

-

Discharge – The prepared khoya is removed once the desired consistency is achieved.

This process ensures traditional taste with modern precision.

Applications of Khoya Making Machine

-

Sweet shops & halwais

-

Dairy farms & milk cooperatives

-

Food processing industries

-

Mithai manufacturers

-

Catering & bulk sweet production units

Choosing the Right Khoya Making Machine

Before purchasing, consider the following factors:

-

Daily Production Requirement

-

Available Space

-

Power Source (Electric/Gas/Steam)

-

Budget & ROI Expectations

-

After-Sales Support & Service

ASVR Engineering provides expert consultation to help you choose the most suitable model for your business.

Why Choose ASVR Engineering?

ASVR Engineering is a trusted name in manufacturing high-quality food and dairy processing machines. Our khoya making machines are known for durability, performance, and long service life.

What Sets Us Apart:

-

Decades of engineering expertise

-

Custom-built machines as per client needs

-

Strict quality control standards

-

Competitive pricing

-

Reliable after-sales support

Maintenance & Care Tips

-

Clean the machine thoroughly after each batch

-

Use only recommended cleaning agents

-

Regularly inspect scrapers and heating elements

-

Schedule periodic servicing for long-term efficiency

Proper maintenance ensures consistent output and extends machine life.

The Future of Khoya Production

As demand for Indian sweets grows both domestically and internationally, automated khoya production is becoming a necessity. Investing in a khoya making machine not only improves efficiency but also prepares your business for expansion, compliance, and competitive markets.

Contact ASVR Engineering

If you are looking for a reliable, efficient, and hygienic Khoya Making Machine, get in touch with us today:

📞 Contact Numbers:

+91-8076004849

+91-8800971968

🌐 Website:

https://www.asvrengineering.com

Let ASVR Engineering power your sweet business with machines that blend tradition, technology, and trust.

Buy Now