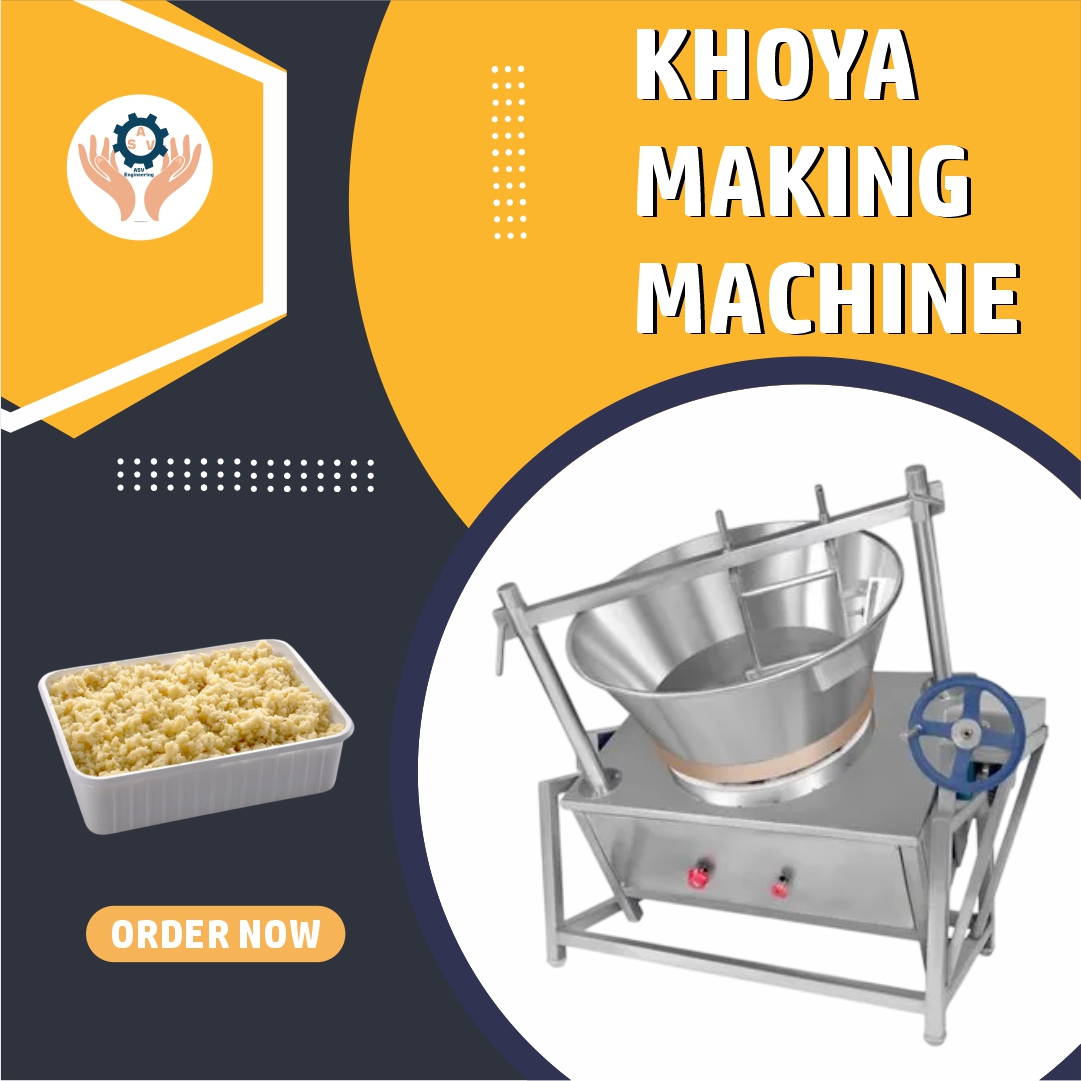

Top Khoya Making Machine Distributors for Dairy Businesses | High Output, Low Maintenance & Best Pricing

Price: ₹61000

In India, khoya (also known as mawa) is not just a dairy product—it is the backbone of countless sweets, mithai shops, dairy farms, and food processing businesses. From traditional halwais to modern dairy plants, the demand for consistent-quality khoya is always rising. To meet this demand efficiently, investing in a reliable and high-performance khoya making machine has become essential.

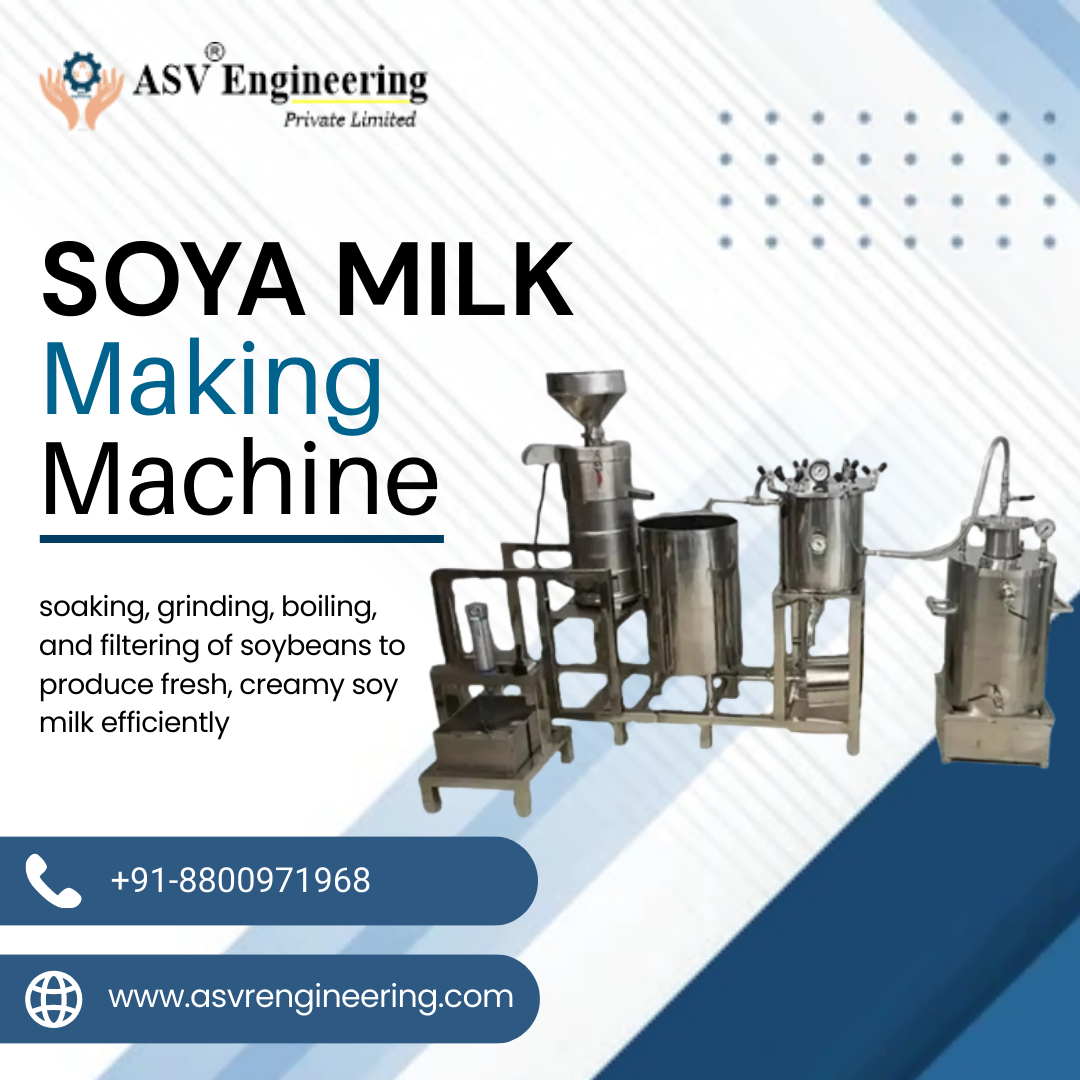

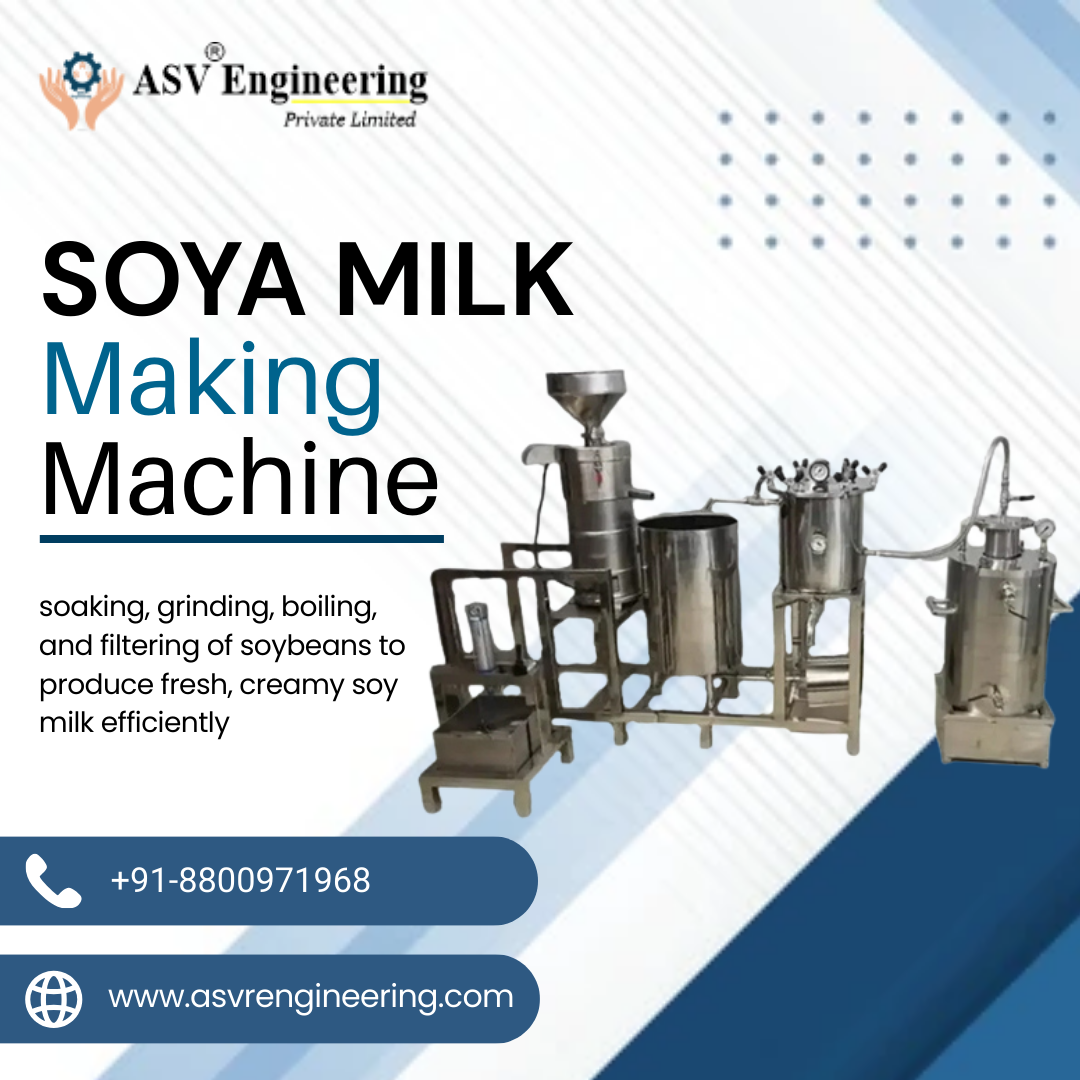

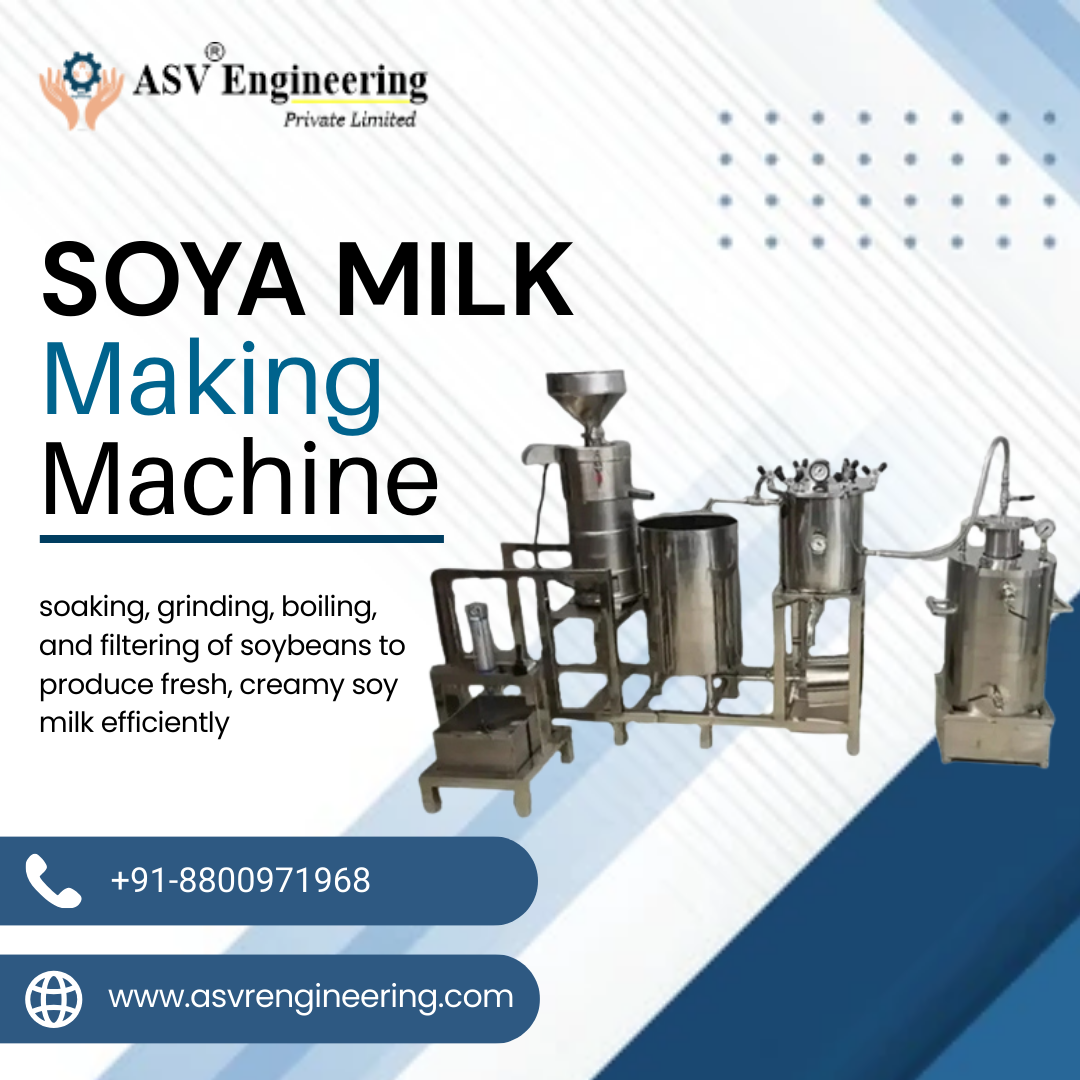

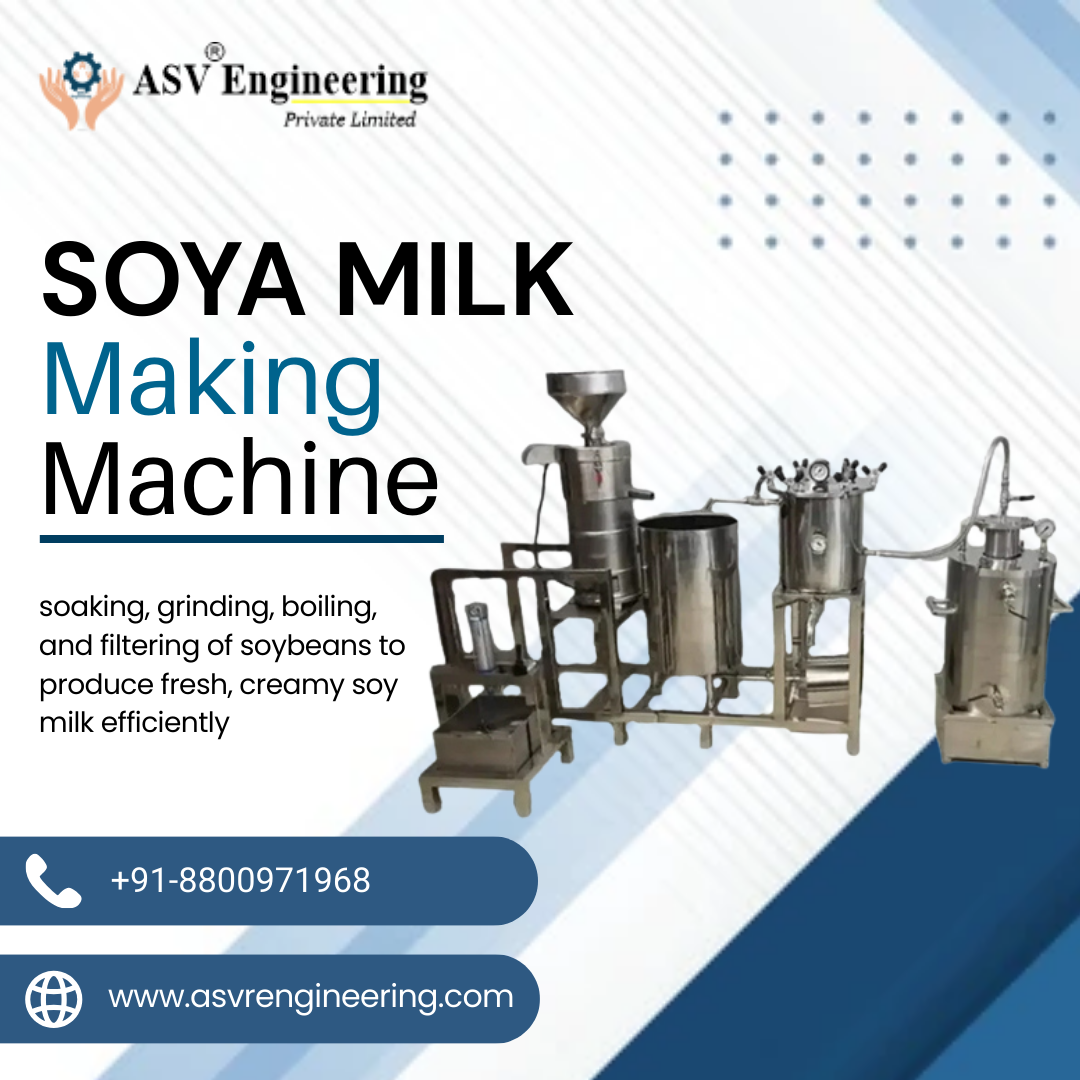

As one of the trusted names in dairy machinery, ASVR Engineering stands out as a leading distributor of khoya making machines designed for performance, durability, and cost-effectiveness. With a strong focus on quality engineering and customer satisfaction, ASVR Engineering supports dairy businesses of all sizes—from small sweet shops to large-scale milk processing units.

Understanding the Importance of a Khoya Making Machine

Traditional khoya preparation involves boiling milk for long hours with continuous manual stirring. While this method preserves taste, it is labor-intensive, time-consuming, and inconsistent in output. Modern khoya making machines solve these challenges by offering:

-

Uniform heating and controlled temperature

-

Higher production capacity in less time

-

Reduced labor dependency

-

Consistent texture, color, and taste

-

Improved hygiene and safety

For dairy entrepreneurs looking to scale their operations, a professionally designed khoya making machine is no longer a luxury—it is a necessity.

Why Choose ASVR Engineering for Khoya Making Machines?

ASVR Engineering has built a solid reputation as one of the most dependable khoya making machine distributors in India. Their machines are engineered to meet Indian dairy conditions while maintaining international manufacturing standards.

1. High Output for Growing Dairy Businesses

Whether you need small-batch production or continuous large-scale output, ASVR Engineering offers machines that deliver maximum khoya yield with minimal milk wastage. Optimized heating systems ensure faster evaporation without compromising product quality.

2. Low Maintenance, Long Service Life

Maintenance costs often determine the real value of a machine. ASVR khoya making machines are manufactured using food-grade stainless steel, corrosion-resistant components, and robust fabrication. This results in fewer breakdowns, easy cleaning, and longer machine life.

3. Energy-Efficient Design

Fuel and electricity costs are major concerns for dairy units. ASVR Engineering focuses on energy-efficient heating systems that reduce operational expenses while maintaining high productivity.

4. Competitive Pricing with Honest Value

As direct distributors, ASVR Engineering offers the best pricing without compromising on build quality. Their transparent pricing structure ensures you get maximum return on investment.

Types of Khoya Making Machines Available

Automatic Khoya Making Machines

Ideal for large dairies and sweet manufacturers, automatic machines handle milk heating, stirring, and thickening with minimal manual intervention. These machines ensure uniform consistency and are suitable for continuous production.

Semi-Automatic Khoya Machines

Best suited for medium-scale operations, semi-automatic machines provide flexibility while reducing labor effort. They are cost-effective and easy to operate.

Steam-Based Khoya Making Units

Steam-operated machines are preferred where centralized boilers are available. They offer uniform heating, better control, and enhanced safety.

Custom-Built Khoya Plants

ASVR Engineering also provides customized solutions based on milk input capacity, space availability, and production requirements.

Applications Across the Dairy and Food Industry

Khoya making machines supplied by ASVR Engineering are widely used in:

-

Sweet and mithai manufacturing units

-

Dairy processing plants

-

Milk collection centers

-

Food processing industries

-

Catering and bulk dessert production

-

Cooperative dairy societies

The versatility of these machines makes them suitable for both traditional and modern dairy operations.

Quality, Hygiene, and Food Safety Standards

Food safety is critical in dairy processing. ASVR Engineering designs khoya machines that comply with hygienic manufacturing standards. Smooth internal surfaces prevent milk residue buildup, while easy-to-clean designs ensure compliance with food safety norms.

Using stainless steel construction, precision welding, and controlled heating systems, these machines help maintain the authentic taste of khoya while ensuring product safety.

After-Sales Support and Technical Assistance

One of the biggest strengths of ASVR Engineering is its commitment beyond sales. The company provides:

-

Installation guidance

-

Operator training

-

Technical support

-

Availability of spare parts

-

Preventive maintenance advice

This ensures uninterrupted production and peace of mind for dairy business owners.

Why Khoya Making Machines Are a Smart Investment

Investing in a high-quality khoya making machine results in:

-

Faster production cycles

-

Consistent product quality

-

Lower manpower costs

-

Reduced fuel and energy consumption

-

Higher profitability

With rising demand for dairy sweets across India, mechanized khoya production helps businesses stay competitive and scalable.

Serving Dairy Businesses Across India

ASVR Engineering caters to dairy entrepreneurs across India, supporting both urban and rural dairy initiatives. Their understanding of local market needs and technical expertise makes them a preferred choice for khoya making machine distribution.

Contact ASVR Engineering – Trusted Khoya Making Machine Distributors

If you are planning to start or upgrade your dairy production unit, choosing the right machinery partner is crucial. ASVR Engineering combines engineering excellence with practical industry knowledge to deliver machines that truly perform.

📞 Contact Numbers:

+91-8076004849

+91-8800971968

🌐 Website:

https://www.asvrengineering.com

Buy Now