Top Soya Paneer Making Machine Exporters Offering Automatic, Hygienic & High-Output Plants

Price: ₹149000

The demand for soya paneer (soy paneer / tofu paneer) is growing rapidly across India and international markets due to increasing awareness of plant-based protein, vegan diets, and healthy lifestyle choices. Soya paneer is widely used in hotels, restaurants, cloud kitchens, food processing units, and health-focused brands. To meet this rising demand, manufacturers require reliable, automatic, hygienic, and high-output soya paneer making machines that ensure consistent quality and large-scale production.

As one of the top soya paneer making machine exporters, ASVR Engineering offers advanced soya paneer manufacturing plants designed for efficiency, hygiene, and long-term performance. Our machines are engineered to deliver uniform texture, high yield, and smooth operation, making them ideal for both small entrepreneurs and large commercial food industries.

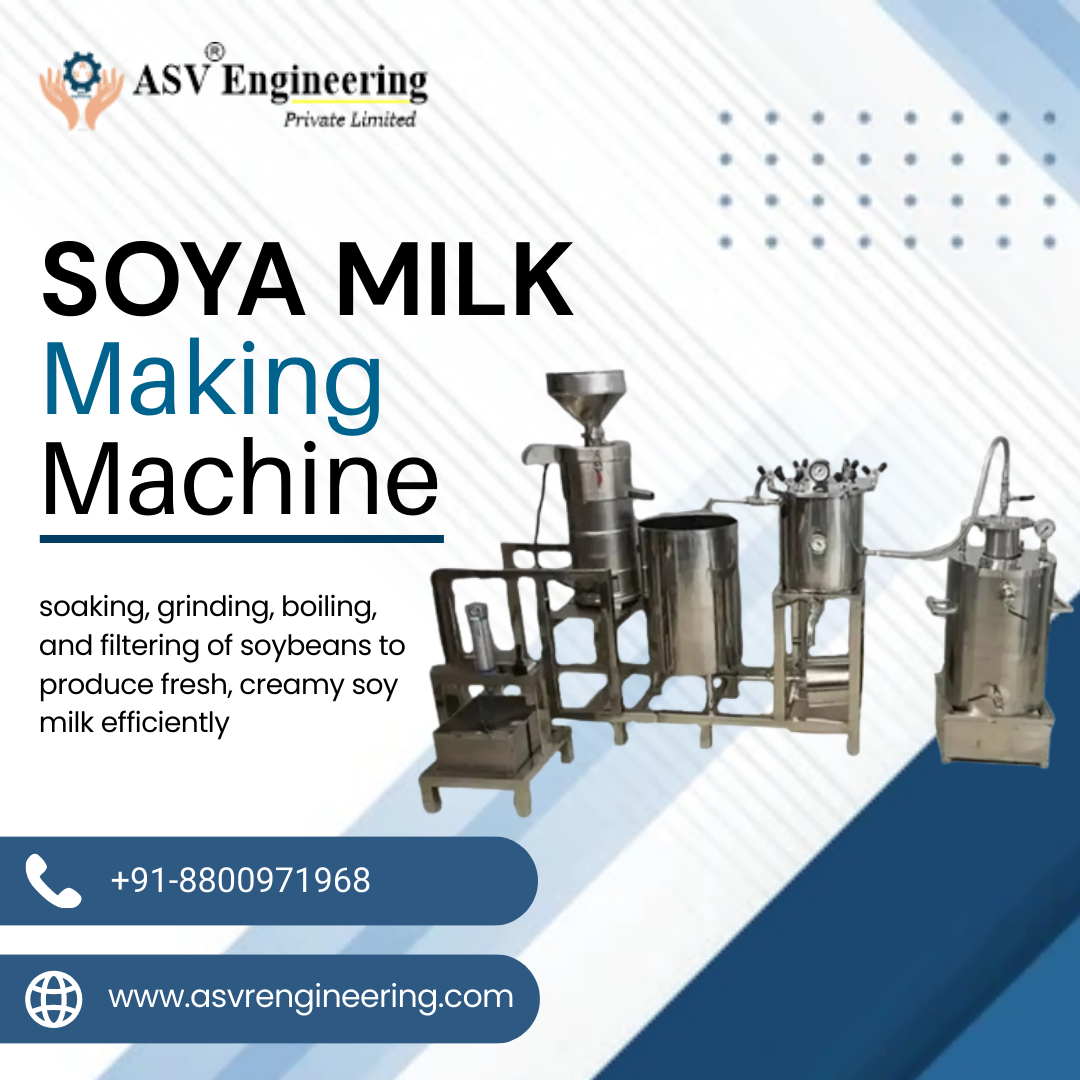

What Is a Soya Paneer Making Machine?

A soya paneer making machine is an automated food processing system used to convert soybeans into fresh, protein-rich soya paneer. The process involves cleaning, soaking, grinding, boiling, coagulation, pressing, and cutting — all carried out in a controlled and hygienic environment.

Modern automatic machines reduce manual labor, minimize wastage, and ensure food safety compliance. These machines are widely used in:

-

Commercial soya paneer manufacturing units

-

Dairy and alternative protein industries

-

Food export businesses

-

Vegan and health food brands

-

Restaurants and catering services

Why Automatic Soya Paneer Making Machines Are in High Demand

Traditional manual production methods are time-consuming, inconsistent, and unhygienic. Automatic soya paneer plants solve these challenges by offering:

1. High Production Capacity

Automatic systems can produce large volumes of soya paneer per hour, making them suitable for commercial and industrial-scale operations.

2. Consistent Quality

Uniform grinding, controlled heating, and precise coagulation ensure consistent taste, texture, and firmness in every batch.

3. Hygienic Processing

Made from food-grade stainless steel, these machines meet hygiene standards required for food processing and export.

4. Reduced Labor Cost

Automation minimizes human involvement, reducing labor dependency and operational costs.

5. Energy Efficiency

Modern designs focus on optimized power consumption while maintaining high output.

Soya Paneer Making Machine Manufacturing Process

Our automatic soya paneer making plants are designed with a step-by-step integrated system:

Soybean Cleaning & Soaking

Raw soybeans are cleaned to remove impurities and soaked to soften them for efficient grinding.

Grinding & Slurry Preparation

The soaked soybeans are ground into a smooth slurry using high-speed grinders.

Boiling & Cooking

The slurry is heated to eliminate raw flavors and enhance protein extraction.

Filtration

Okara (soy fiber residue) is separated from soy milk using advanced filtration units.

Coagulation

Food-grade coagulants are added in controlled quantities to convert soy milk into curd.

Pressing & Shaping

The curd is pressed into blocks, ensuring proper moisture removal and firm texture.

Cutting & Packaging

The paneer blocks are cut into uniform sizes, ready for packaging or bulk supply.

Key Features of Our Soya Paneer Making Machines

-

Fully automatic and semi-automatic options

-

Food-grade stainless steel construction

-

High output with minimal wastage

-

Easy operation and low maintenance

-

Hygienic design compliant with food safety norms

-

Custom capacity options as per client requirement

-

Long service life and robust build quality

Applications of Soya Paneer Making Machines

Our machines are widely used in:

-

Commercial soya paneer production units

-

Vegan food manufacturing plants

-

Health food and protein supplement industries

-

Export-oriented food processing companies

-

Hotels, restaurants, and catering businesses

-

Dairy alternative processing units

Why Choose Us as Your Soya Paneer Making Machine Exporter?

Engineering Expertise

We combine practical food processing knowledge with advanced mechanical engineering to deliver reliable solutions.

Customized Solutions

We offer machines based on required capacity, space availability, and production goals.

Export-Quality Standards

Our machines are designed to meet international export standards for durability, safety, and performance.

After-Sales Support

We provide installation guidance, operational training, and technical support to ensure smooth production.

Trusted by Industry

Our machines are used by clients across India and overseas, making us a preferred exporter in the food processing sector.

Benefits of Investing in a High-Output Soya Paneer Plant

-

Faster return on investment (ROI)

-

Ability to meet bulk orders easily

-

Consistent product quality builds brand trust

-

Expansion opportunities in domestic and export markets

-

Lower operational costs over time

Growing Market Opportunity for Soya Paneer

With rising lactose intolerance, veganism, and fitness awareness, the global market for plant-based protein products is expanding rapidly. Soya paneer has emerged as a popular alternative to dairy paneer due to its:

-

High protein content

-

Low cholesterol

-

Affordable production cost

-

Versatile usage in Indian and international cuisines

Investing in a commercial soya paneer making machine today can position your business for long-term growth in this booming market.

Contact Us for Automatic Soya Paneer Making Machines

If you are looking for top soya paneer making machine exporters offering automatic, hygienic & high-output plants, get in touch with us today.

📞 Contact Numbers:

+91-8076004849

+91-8800971968

🌐 Website:

https://www.asvrengineering.com

Our team will help you choose the right machine based on your production needs and business goals.

Buy Now