Top Rasgulla Making Machine Manufacturers Offering High-Capacity Industrial Equipment

Price: ₹263000

India is known for its rich tradition of sweets, and Rasgulla holds a special place in every celebration. From weddings to festivals and daily sweet consumption, rasgulla is one of the most demanded dairy-based sweets across the country. With rising demand and increasing competition in the sweet manufacturing industry, traditional hand-made production methods are no longer sufficient for large-scale businesses.

This is where high-capacity industrial rasgulla making machines come into play.

If you are searching for reliable and experienced Rasgulla Making Machine Manufacturers, ASVR Engineering stands out as a trusted name offering advanced, hygienic, and cost-effective industrial equipment designed for maximum output and long-term durability.

Growing Demand for Industrial Rasgulla Making Machines

The Indian sweets industry has grown rapidly in recent years. With the expansion of sweet chains, dairy brands, and export businesses, manufacturers require equipment that ensures:

-

Uniform size and shape of rasgullas

-

Consistent texture and softness

-

Hygienic production environment

-

Faster production cycles

-

Reduced labor dependency

Manual preparation is time-consuming and inconsistent in large batches. Industrial rasgulla making machines help sweet manufacturers increase production while maintaining premium quality.

Why Choose High-Capacity Rasgulla Making Machines?

For commercial sweet shops, dairy plants, and food processing industries, high-capacity machines are essential. These machines are specifically designed for bulk production and continuous operation.

1. Increased Production Capacity

Industrial rasgulla machines can produce thousands of pieces per hour, making them ideal for large sweet factories and distribution networks.

2. Uniform Shape and Size

Consistency plays a major role in customer satisfaction. Automatic forming systems ensure every rasgulla ball is identical in size and weight.

3. Hygienic Stainless Steel Construction

High-grade stainless steel body prevents contamination and ensures food safety standards are maintained.

4. Reduced Labor Costs

Automation minimizes manual handling, reducing labor expenses and improving overall efficiency.

5. Energy Efficient Operation

Modern machines are designed to consume less power while delivering high output.

Complete Rasgulla Production Process with Industrial Equipment

A professional rasgulla production setup generally includes multiple stages, and ASVR Engineering offers machines that integrate seamlessly into a full production line.

Milk Curdling and Chenna Preparation

The process begins with milk coagulation to produce chenna. Proper kneading and moisture control are essential for soft rasgullas.

Ball Forming Mechanism

Automatic forming machines shape chenna into perfectly round balls with adjustable size settings.

Cooking in Sugar Syrup

The formed balls are cooked in boiling sugar syrup inside specialized steam or gas-heated cooking vessels.

Cooling and Soaking

After cooking, rasgullas are transferred to soaking tanks for proper absorption and texture development.

Each stage requires precision and controlled temperature. High-capacity machines ensure uniform results across large batches.

Features of ASVR Engineering Rasgulla Making Machines

ASVR Engineering designs equipment that meets the practical needs of sweet manufacturers. Their machines are built keeping Indian sweet production conditions in mind.

Robust Construction

Heavy-duty stainless steel structure ensures long operational life.

Automatic Ball Forming System

Precision-based shaping ensures uniform rasgullas without cracking.

Adjustable Capacity Options

Machines are available in different capacities to suit small-scale to large-scale industries.

Easy Cleaning and Maintenance

Hygienic design allows easy dismantling and cleaning after production.

Low Maintenance Cost

Durable components reduce frequent repair and replacement expenses.

Ideal for Multiple Business Segments

Rasgulla making machines are suitable for:

-

Large sweet manufacturing units

-

Dairy processing plants

-

Sweet chains and franchises

-

Export-oriented sweet manufacturers

-

Catering businesses

-

Centralized production kitchens

Whether you operate a medium-sized sweet shop or a full-fledged industrial sweet factory, investing in automated equipment significantly increases profitability.

Benefits of Investing in Industrial Rasgulla Equipment

Higher Profit Margins

Bulk production reduces per-piece cost, increasing overall profit.

Brand Consistency

Uniform taste, size, and texture help maintain brand identity.

Faster Delivery to Market

High-speed production enables timely supply during festive seasons.

Scalability

As demand grows, capacity can be expanded with additional machinery.

Customization and Technical Support

One of the biggest advantages of choosing ASVR Engineering is their commitment to customer satisfaction. They understand that every production unit has different requirements.

They provide:

-

Customized machine configurations

-

Installation guidance

-

Operational training

-

After-sales technical support

-

Spare parts availability

This ensures uninterrupted production and long-term reliability.

Why ASVR Engineering is a Trusted Manufacturer

When selecting a rasgulla making machine manufacturer, experience and reliability matter. ASVR Engineering has earned a reputation for delivering quality food processing machinery across India.

Their focus includes:

-

Precision engineering

-

Use of premium-grade materials

-

Strict quality testing

-

Affordable pricing

-

Transparent business practices

Their machines are built to perform efficiently even during peak seasonal demand.

Hygiene and Food Safety Standards

Food production demands strict hygiene compliance. Industrial rasgulla machines are designed with:

-

Food-grade stainless steel

-

Smooth finishing to prevent residue accumulation

-

Easy drainage systems

-

Minimal manual handling

These features reduce contamination risk and maintain superior product quality.

Cost-Effective Investment for Long-Term Growth

While traditional sweet making may seem economical initially, long-term growth demands automation. Investing in a high-capacity rasgulla machine reduces:

-

Wastage

-

Labor dependency

-

Production time

-

Inconsistency

Over time, the machine pays for itself through increased output and improved efficiency.

Meeting Festive and Bulk Orders with Ease

India’s festive seasons like Diwali, weddings, and religious celebrations create sudden spikes in demand. Manual production struggles to keep up.

Industrial rasgulla making machines ensure:

-

Quick scaling of production

-

Consistent taste across large orders

-

Faster packaging and distribution

This helps businesses capture seasonal market opportunities effectively.

Future of Sweet Manufacturing in India

The Indian food processing sector is rapidly modernizing. Automation is no longer optional—it is essential for staying competitive. High-capacity sweet-making equipment enhances productivity, ensures uniform quality, and helps businesses expand beyond local markets.

With increasing export demand for Indian sweets, standardized production systems are becoming necessary. Rasgulla making machines play a key role in this transformation.

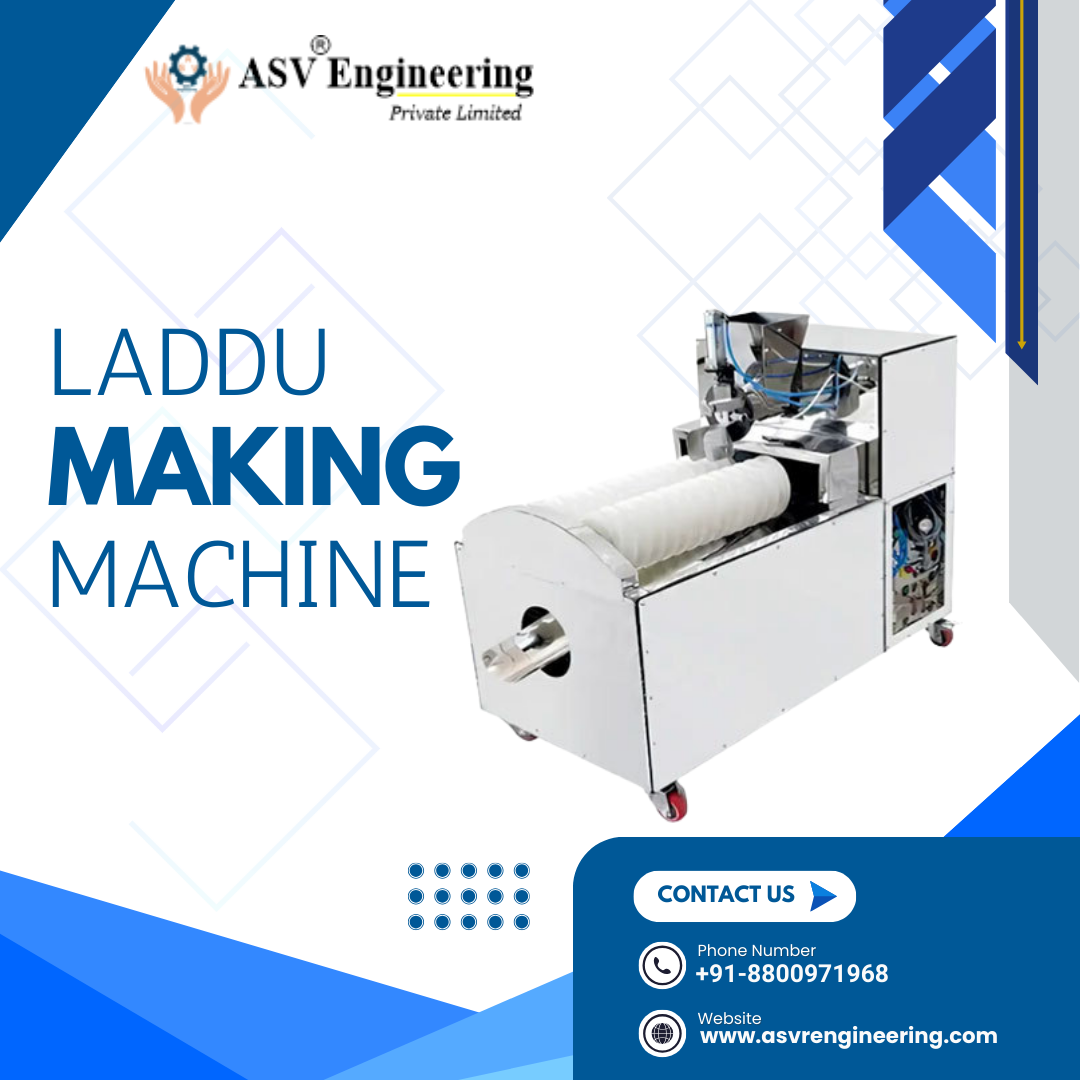

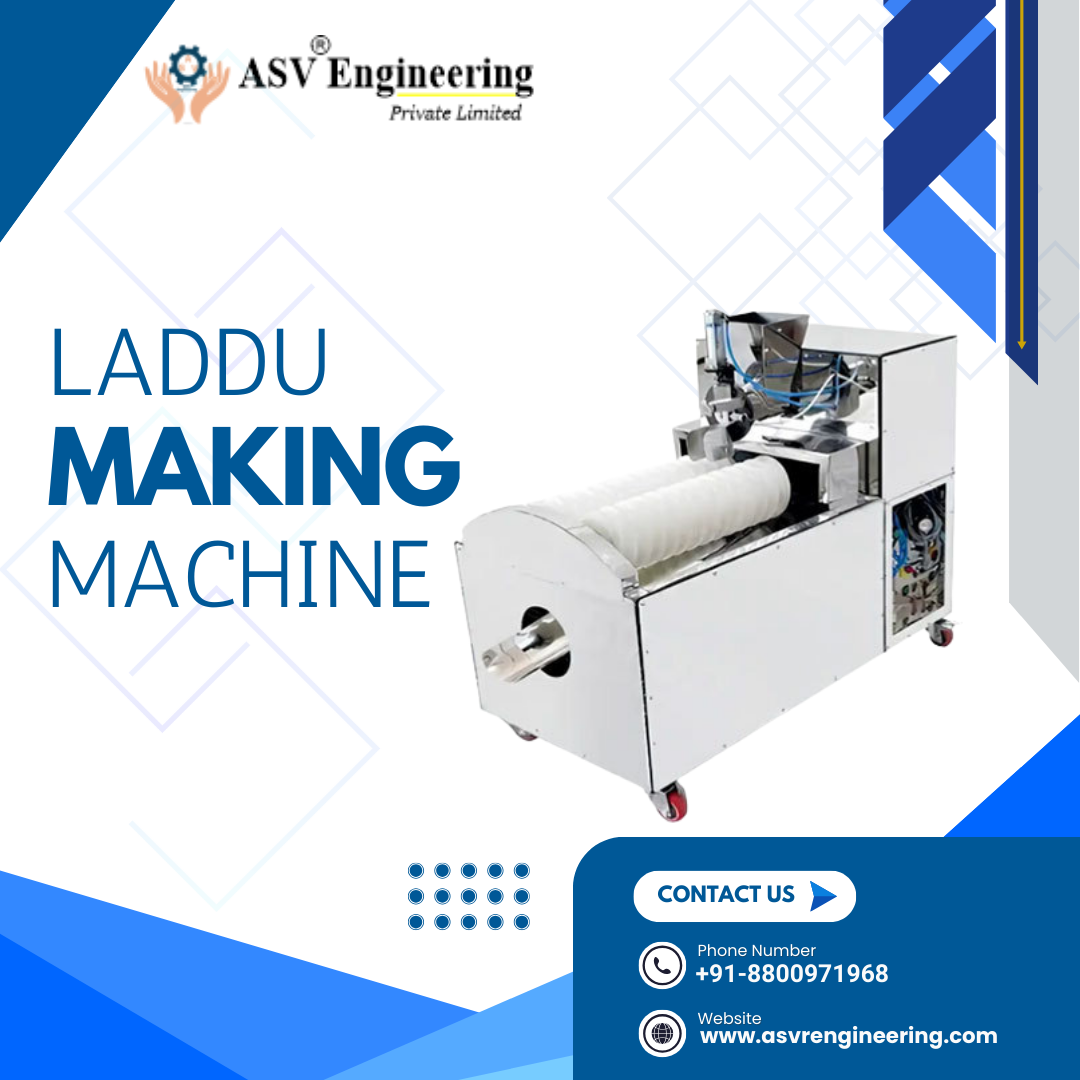

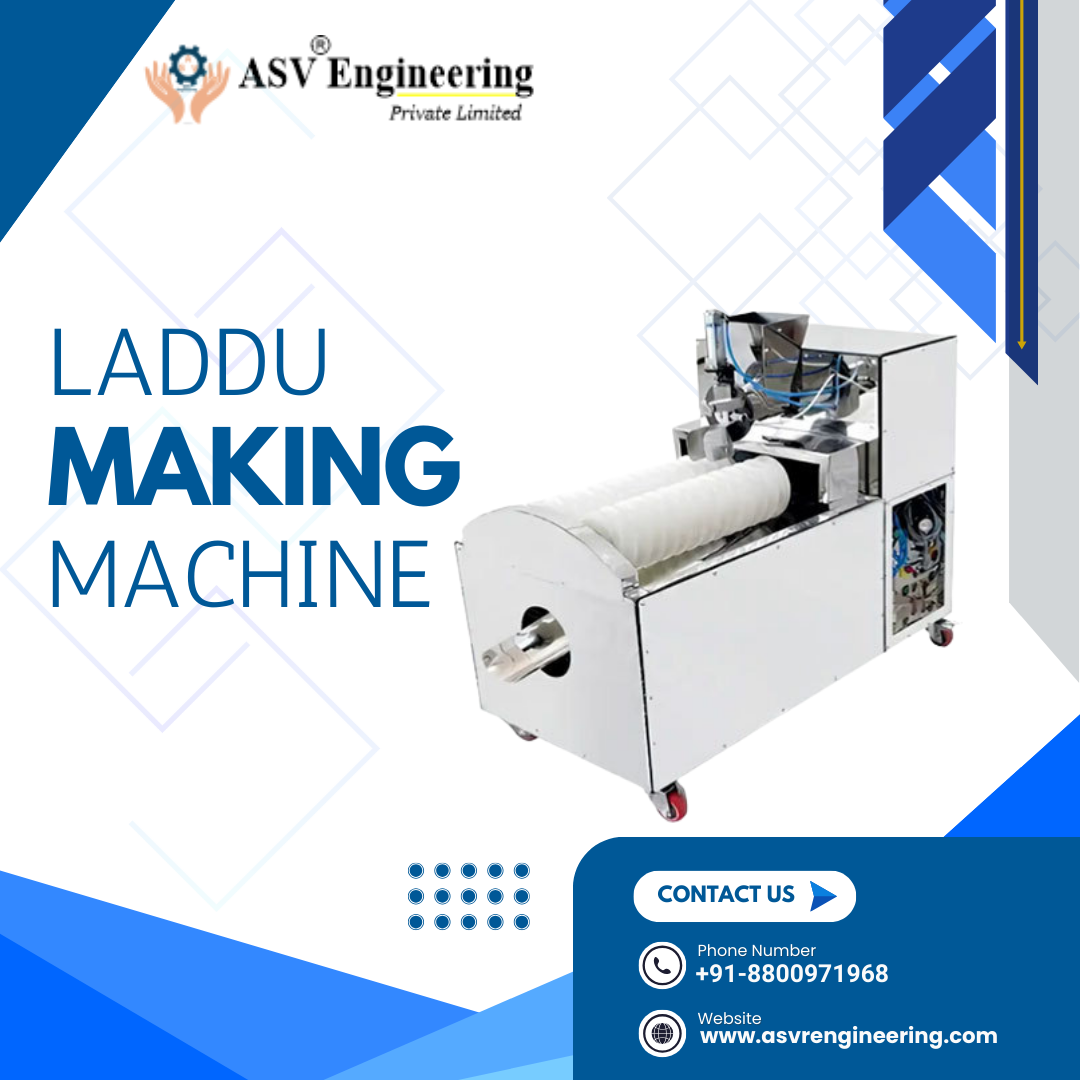

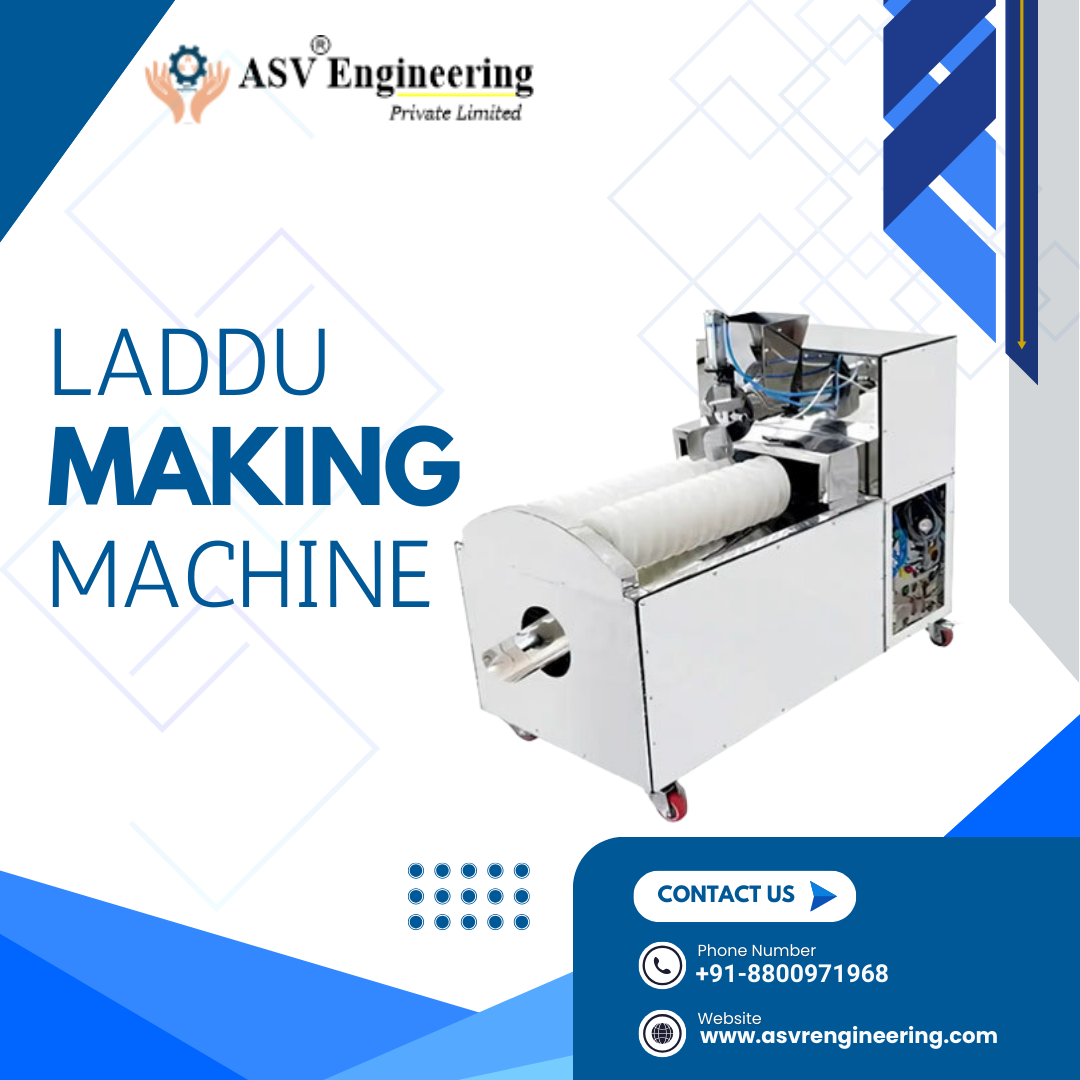

Contact the Experts Today

If you are planning to upgrade your sweet manufacturing setup or start a new industrial rasgulla production unit, ASVR Engineering provides reliable and high-performance solutions.

For detailed specifications, pricing, and consultation:

📞 +91-8076004849

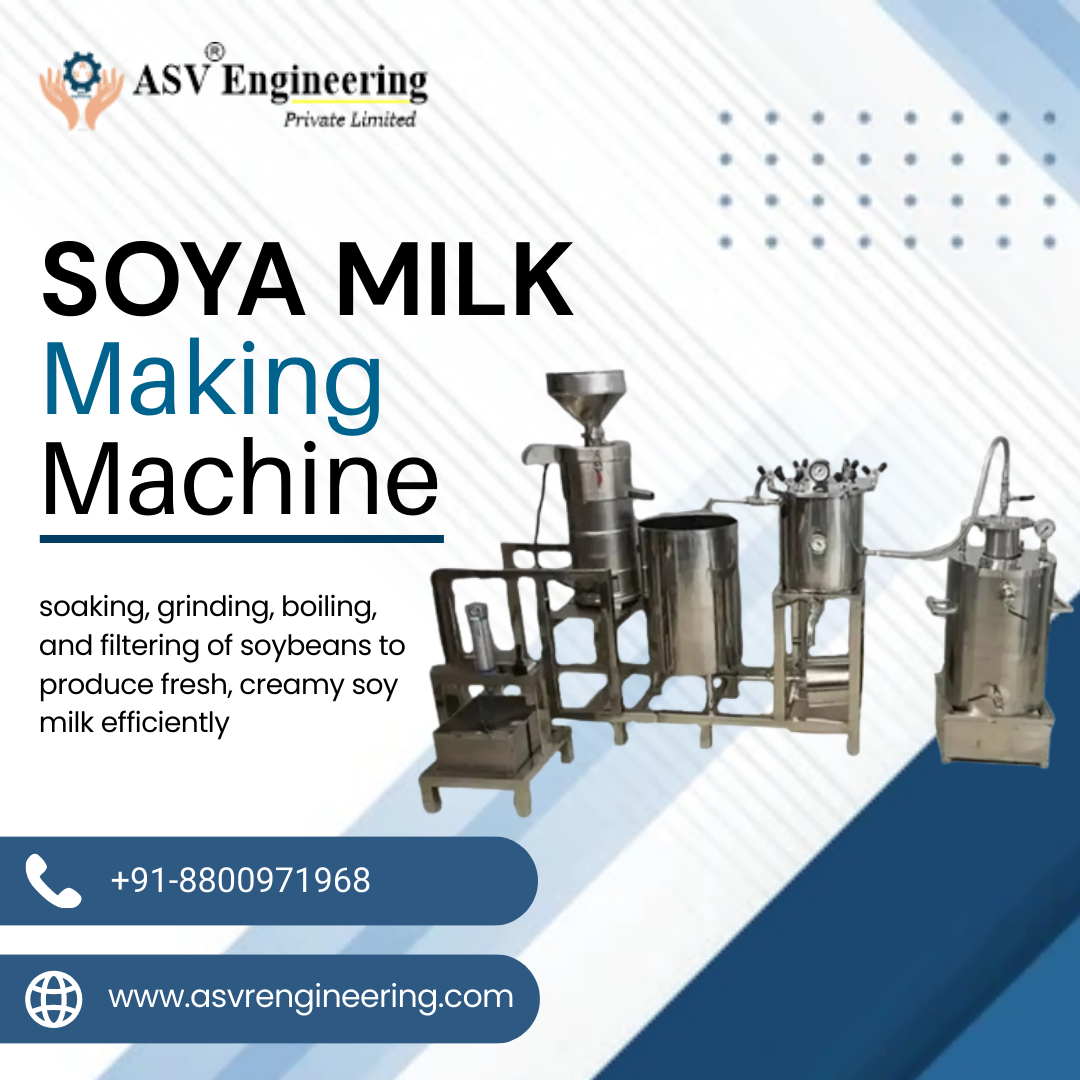

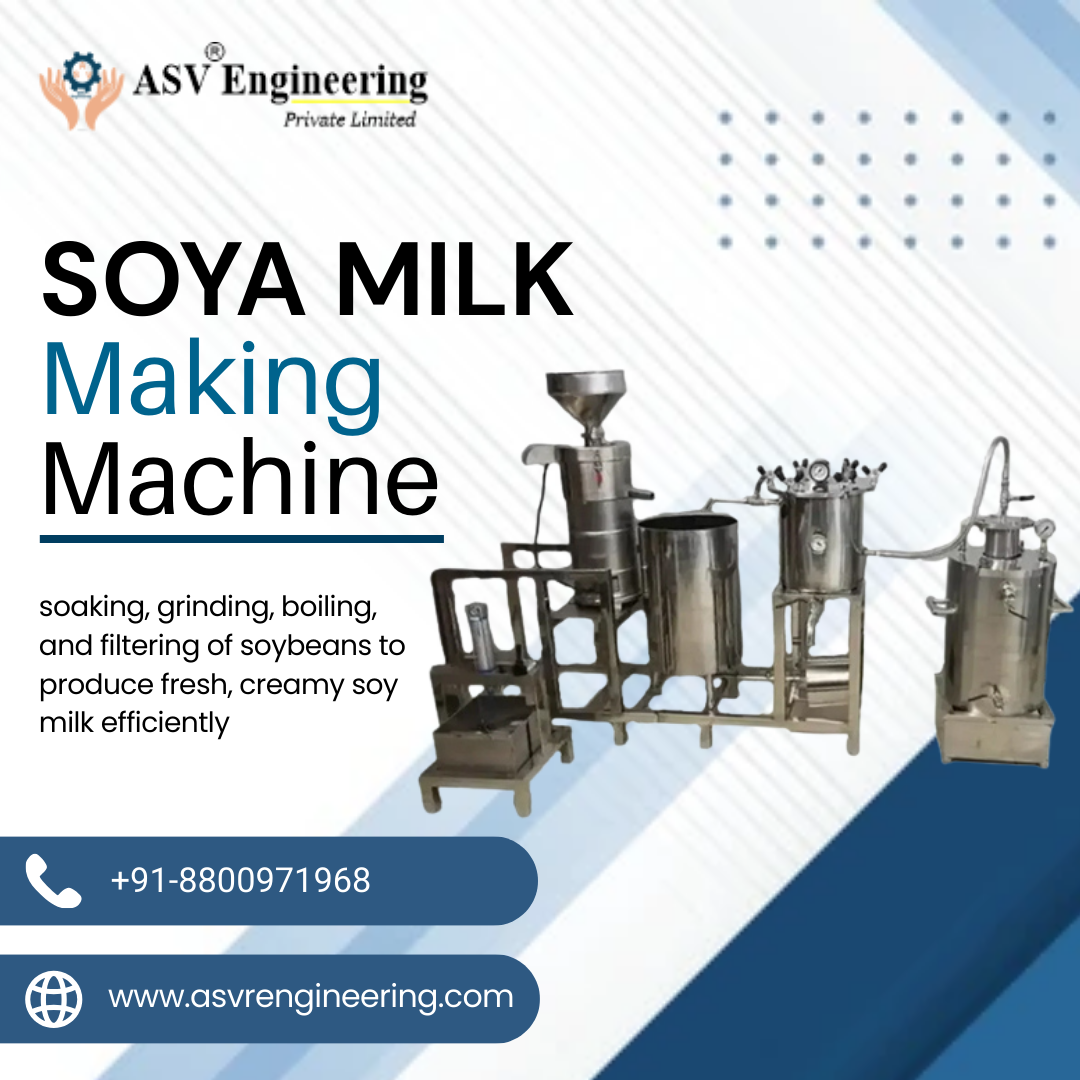

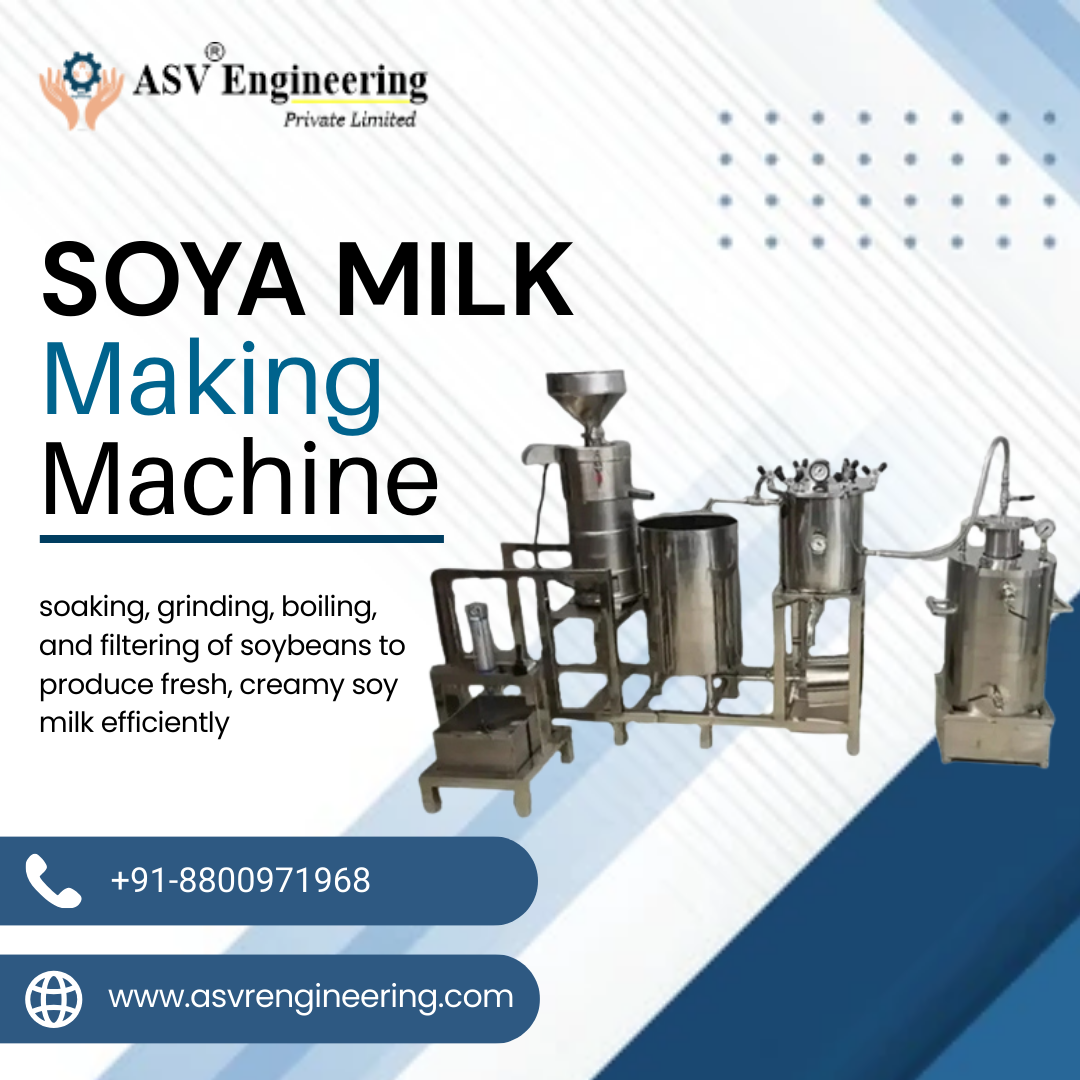

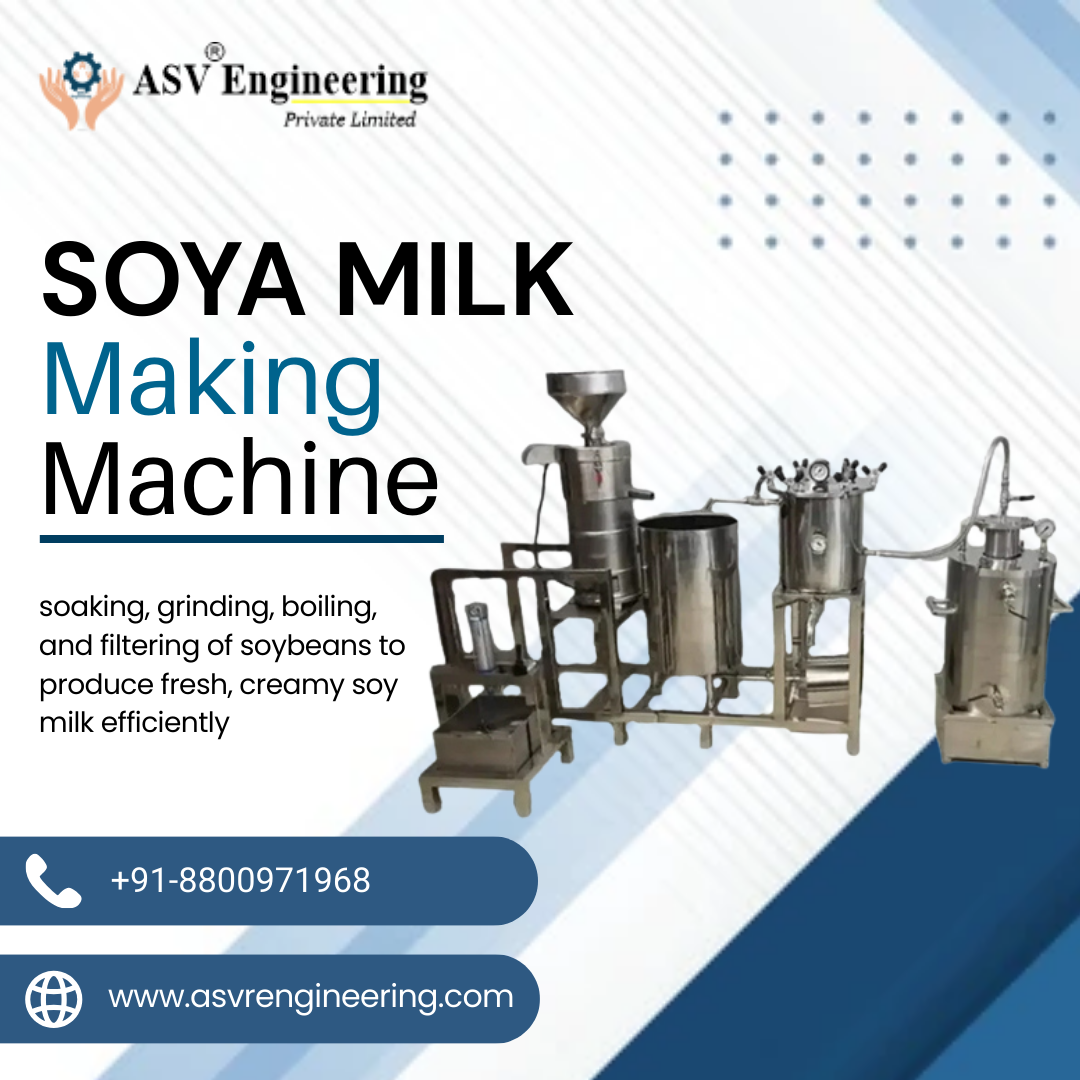

📞 +91-8800971968

🌐 https://www.asvrengineering.com

Invest in advanced rasgulla making machines today and take your sweet business to the next level with high-capacity, hygienic, and cost-effective industrial equipment.

Buy Now