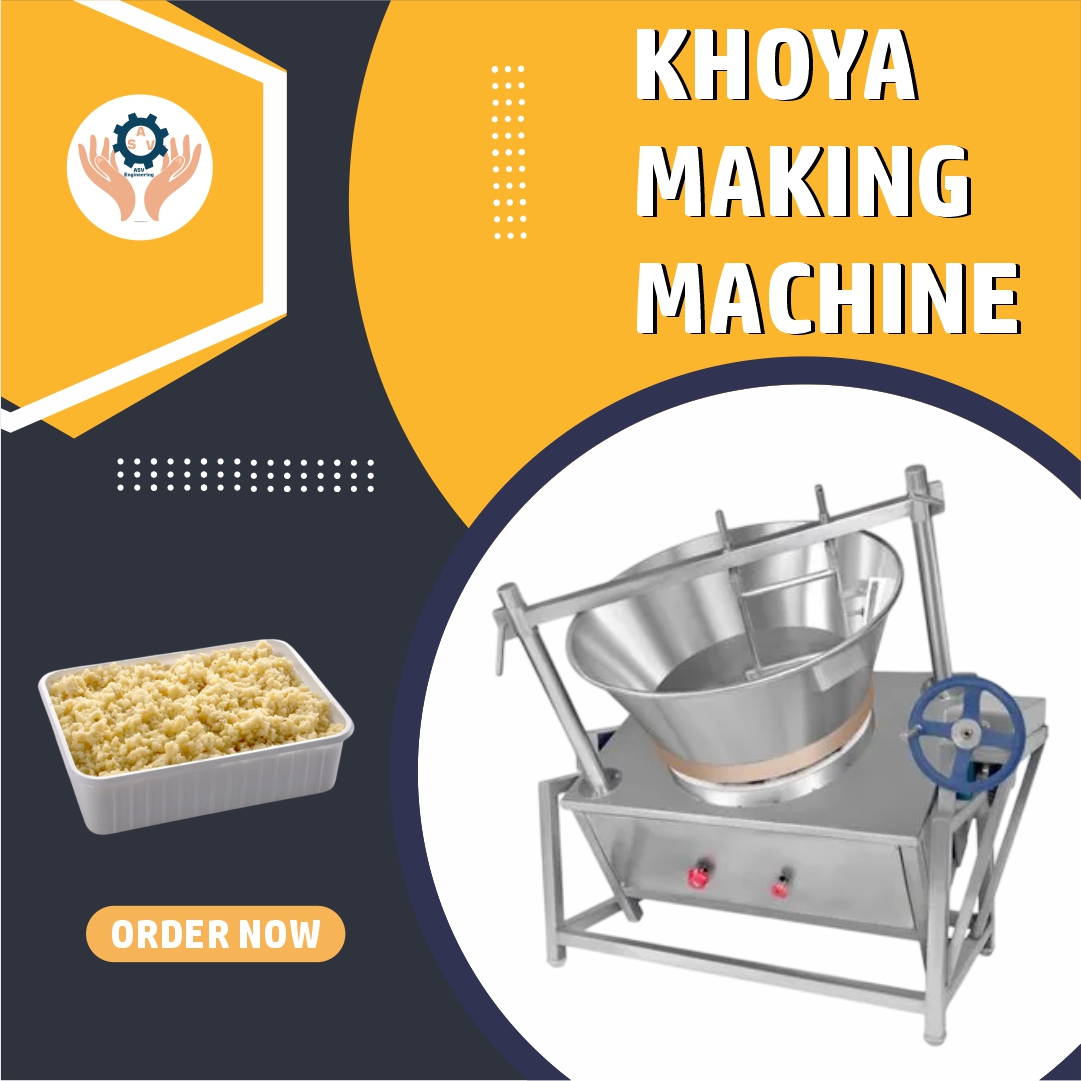

Khoya Making Machine

Price: ₹72000

In India, khoya (mawa) is not just a dairy product—it is the backbone of our traditional sweet industry. From gulab jamun, peda, barfi, kalakand to milk cakes, khoya plays a vital role in taste, texture, and quality. With rising demand from sweet shops, dairies, hotels, and food manufacturers, manual khoya preparation is no longer practical. This is where a Khoya Making Machine becomes an essential investment.

ASVR Engineering offers advanced, durable, and hygienic Khoya Making Machines designed for consistent output, superior quality, and long-term performance.

What Is a Khoya Making Machine?

A Khoya Making Machine is a dairy processing machine used to convert milk into thick, semi-solid khoya by controlled heating and continuous stirring. Unlike traditional open-pan methods that require constant manual effort and supervision, this machine automates the entire process, ensuring:

-

Uniform heating

-

No milk burning

-

Consistent khoya texture

-

Higher production capacity

-

Reduced labor cost

It is widely used in sweet shops, dairy plants, milk processing units, hotels, and food manufacturing industries.

Why Manual Khoya Making Is No Longer Ideal

Traditional khoya preparation using iron pans and wooden stirrers has several limitations:

-

High labor dependency

-

Risk of uneven heating

-

Milk sticking or burning

-

Inconsistent product quality

-

Lower hygiene standards

-

Time-consuming process

With increasing food safety regulations and customer expectations, modern businesses need mechanized and hygienic solutions. A khoya making machine solves all these challenges efficiently.

How a Khoya Making Machine Works

The working principle is simple yet highly effective:

-

Fresh milk is poured into the machine’s stainless-steel vessel

-

Heating system gradually raises the temperature

-

Motorized agitator continuously stirs the milk

-

Moisture evaporates evenly without burning

-

Milk thickens into soft, uniform khoya

-

Final product is discharged easily

This controlled process ensures better yield, taste, and shelf life.

Key Features of Khoya Making Machine

1. Heavy-Duty Stainless Steel Body

Manufactured using food-grade SS 304, ensuring hygiene, corrosion resistance, and long life.

2. Uniform Heating System

Provides consistent heat distribution to prevent milk burning and uneven thickening.

3. Powerful Stirring Mechanism

Continuous agitation avoids sticking at the bottom and ensures smooth texture.

4. Energy Efficient Design

Consumes less fuel or electricity while delivering high output.

5. Easy Operation & Maintenance

User-friendly controls allow even semi-skilled operators to run the machine smoothly.

6. High Production Capacity

Available in multiple capacities suitable for small sweet shops to large dairy plants.

Types of Khoya Making Machines Available

Depending on production needs, machines are available in different configurations:

-

Manual Khoya Making Machine

-

Semi-Automatic Khoya Machine

-

Fully Automatic Khoya Making Machine

-

Gas-Fired Khoya Machine

-

Electric Khoya Machine

Each type is designed to meet specific business requirements and budgets.

Applications of Khoya Making Machine

Khoya making machines are widely used in:

-

Sweet shops & mithai stores

-

Dairy farms and milk plants

-

Hotels & restaurants

-

Food processing industries

-

Catering businesses

-

Milk collection centers

Whether you are a small halwai or a large-scale dairy entrepreneur, this machine boosts productivity and consistency.

Benefits of Using Khoya Making Machine

✔ Consistent Product Quality

Every batch delivers the same taste, texture, and color.

✔ Increased Production

Produce more khoya in less time compared to manual methods.

✔ Reduced Labor Cost

Automation reduces dependency on skilled labor.

✔ Better Hygiene

Closed stainless-steel system meets food safety standards.

✔ Higher Profit Margins

Less wastage, higher yield, and faster processing improve overall profitability.

Why Choose ASVR Engineering for Khoya Making Machine?

ASVR Engineering is a trusted name in dairy machinery manufacturing. Our machines are designed keeping Indian working conditions and customer needs in mind.

What Sets Us Apart:

-

Robust machine design

-

Premium quality raw materials

-

Custom capacity options

-

Competitive pricing

-

Excellent after-sales support

-

On-time delivery across India

We focus on long-term reliability, not just selling machines.

Technical Specifications (Typical)

-

Material: SS 304 Food Grade

-

Heating Type: Gas / Electric

-

Agitator: Heavy-duty motorized

-

Capacity: Customizable (50L to 500L+)

-

Power Consumption: Energy efficient

-

Operation: Easy & safe

Specifications can be customized based on your production needs.

Khoya Making Machine Price in India

The price of a khoya making machine depends on:

-

Capacity

-

Automation level

-

Heating source

-

Custom requirements

Maintenance & Longevity

Proper maintenance ensures long machine life:

-

Regular cleaning after use

-

Timely lubrication of moving parts

-

Checking heating elements periodically

-

Using good quality milk

With basic care, the machine delivers years of trouble-free performance.

Ideal for Business Growth

Investing in a khoya making machine is not an expense—it’s a business upgrade. It allows you to:

-

Expand production

-

Meet bulk orders easily

-

Maintain consistent quality

-

Build brand reputation

-

Increase profits

In today’s competitive food industry, automation is the key to sustainability.

Conclusion

A Khoya Making Machine is an essential asset for any dairy or sweet manufacturing business aiming for quality, efficiency, and growth. With strong construction, hygienic processing, and reliable performance, machines from ASVR Engineering offer excellent value for money.

If you are planning to upgrade or start khoya production, this is the right time to invest in a professional solution that delivers results every day.

📞 Call Now: +91-8076004849 | +91-8800971968

🌐 Visit: https://www.asvrengineering.com

Buy Now