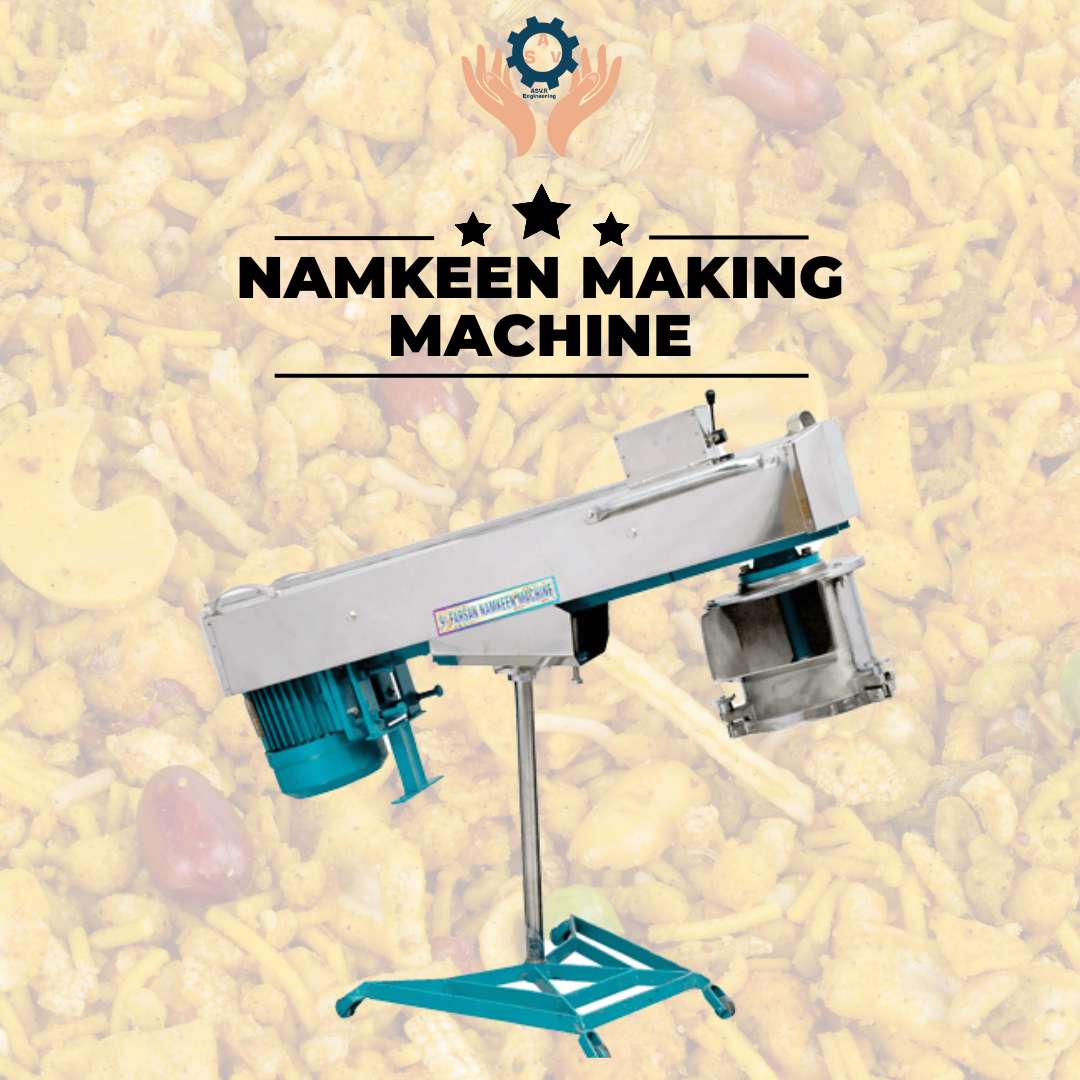

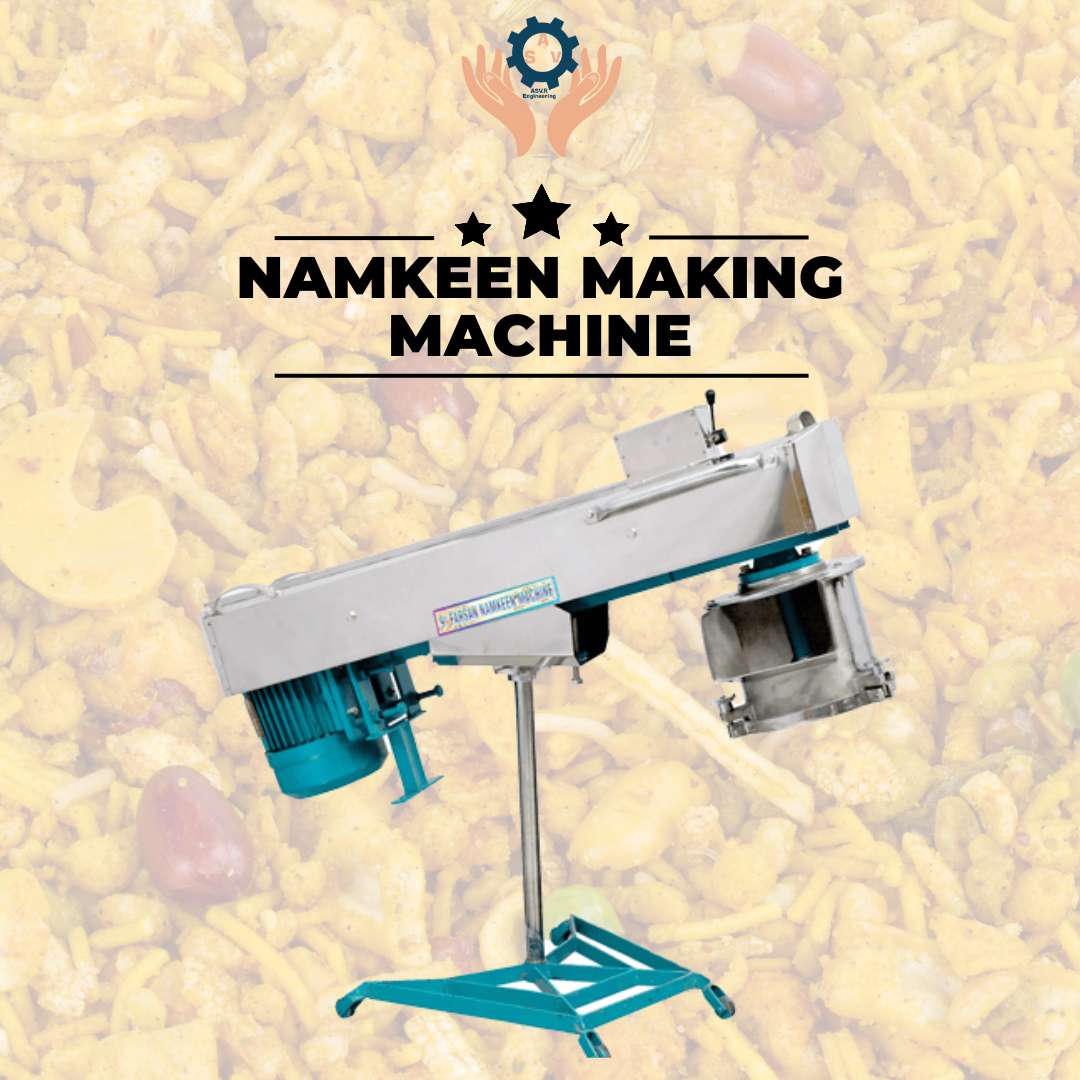

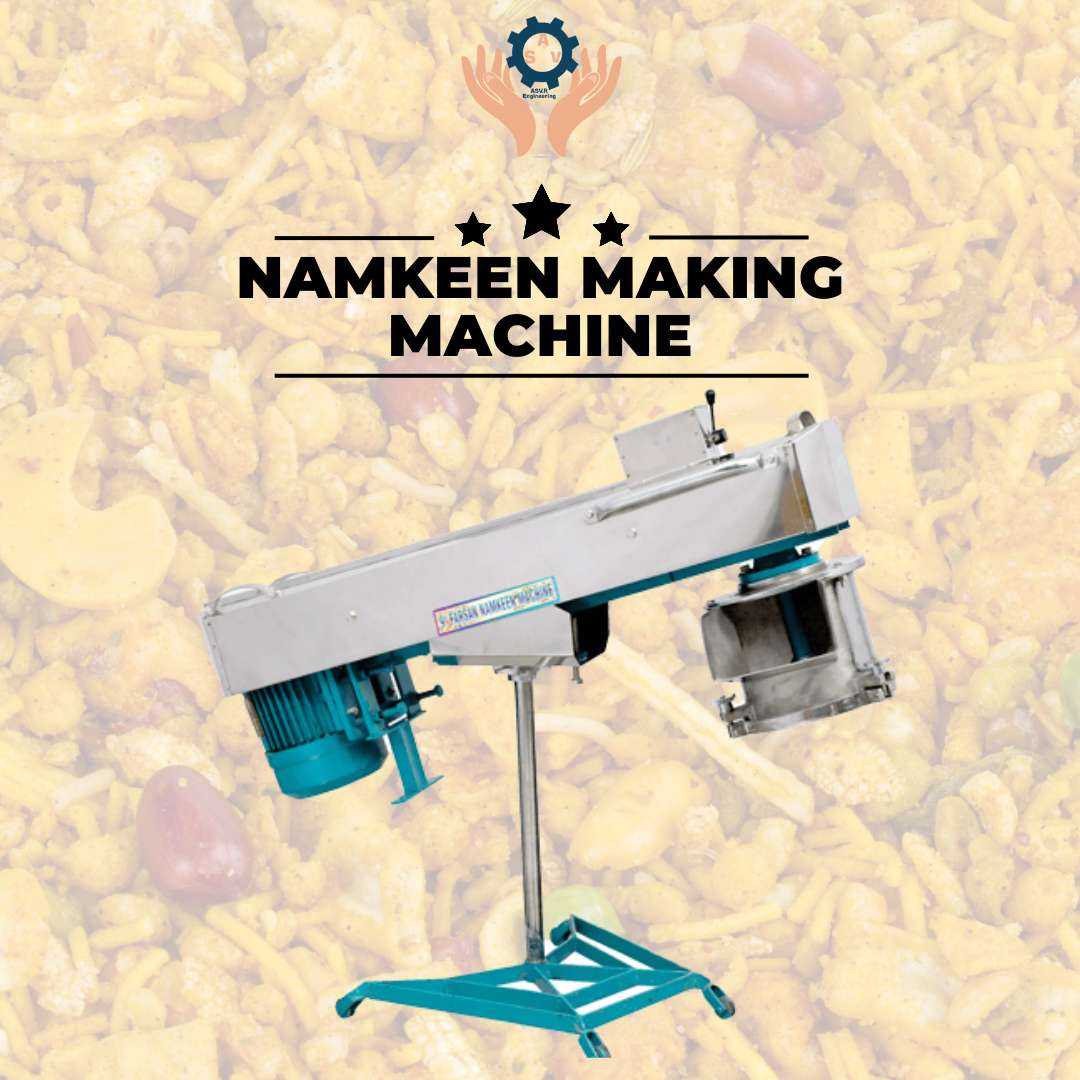

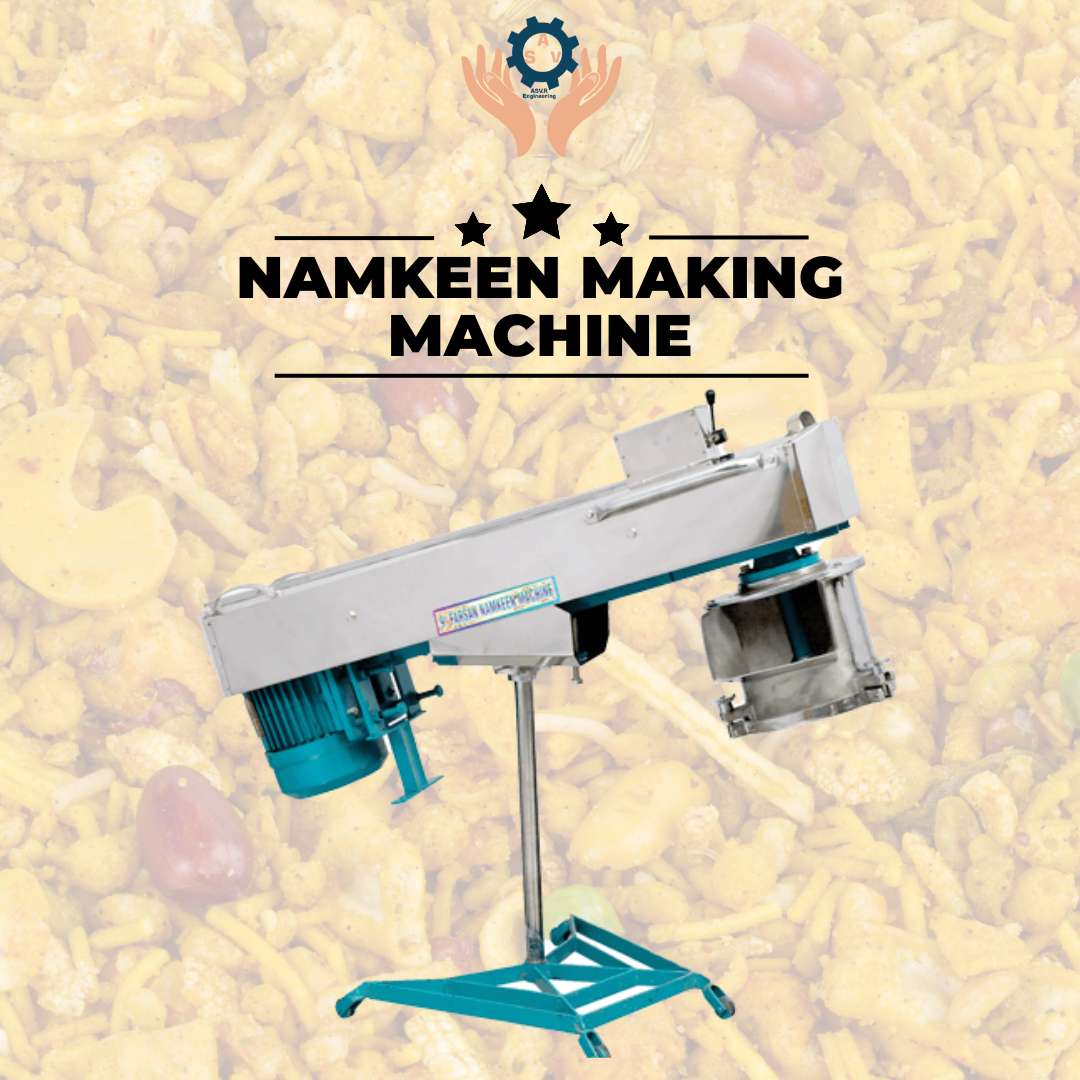

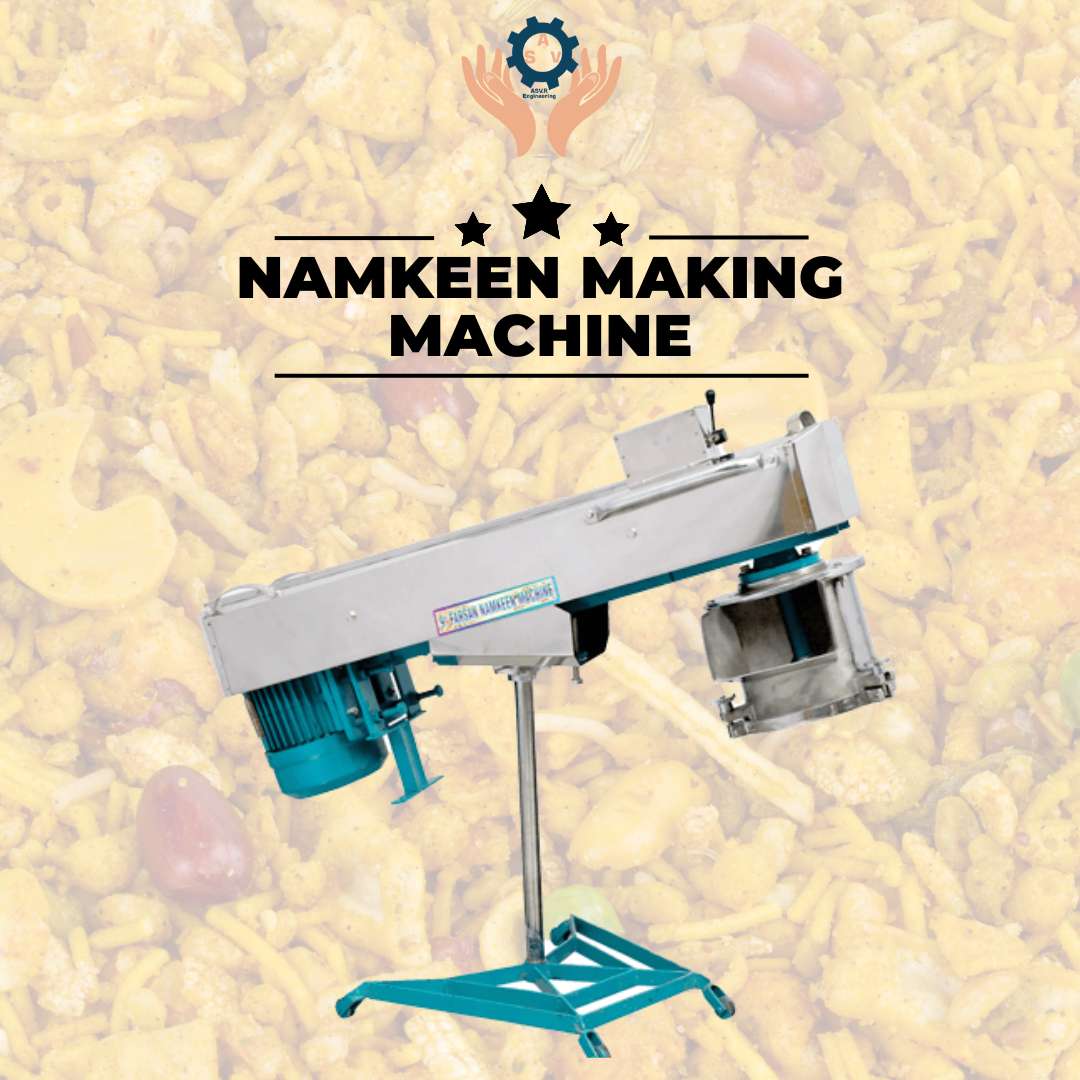

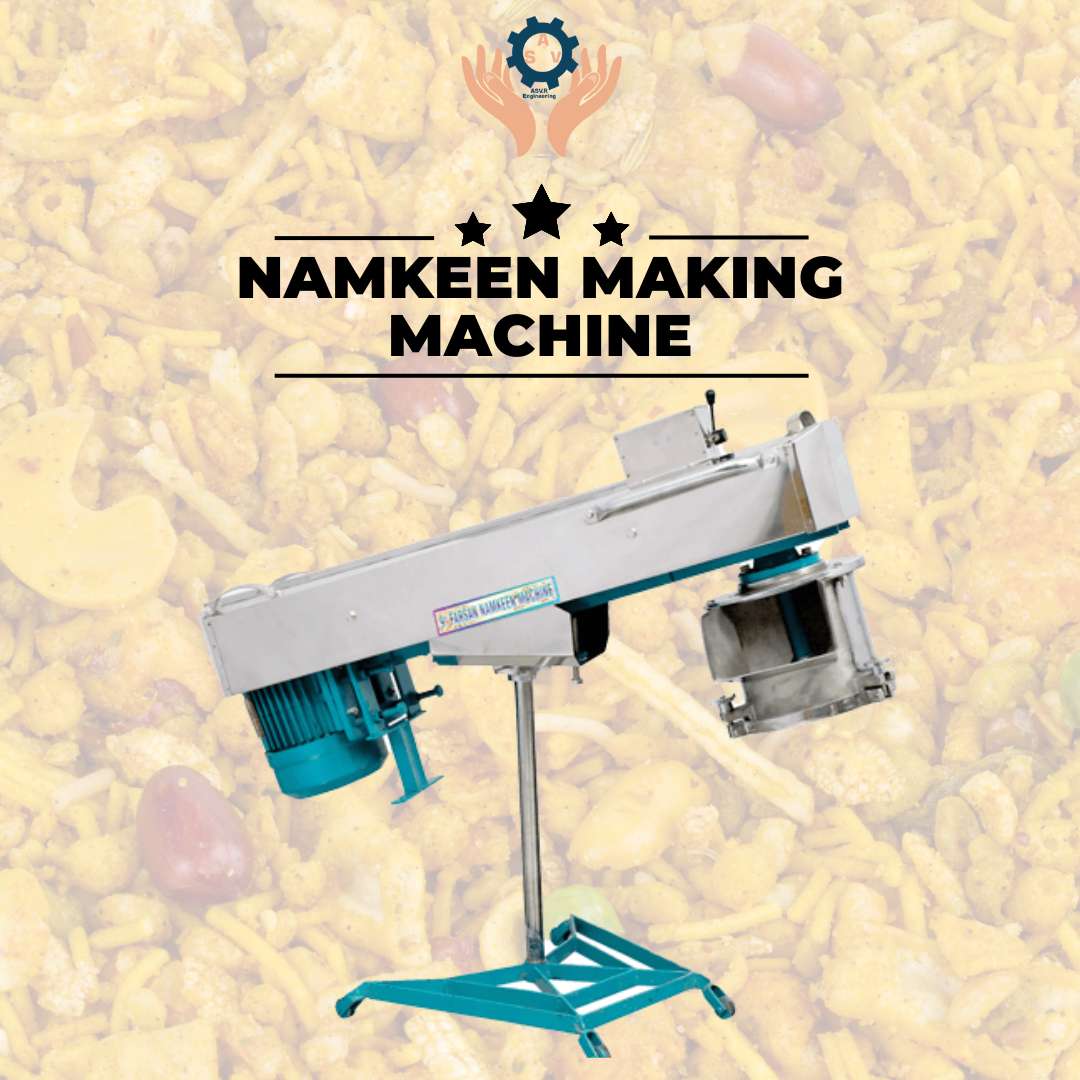

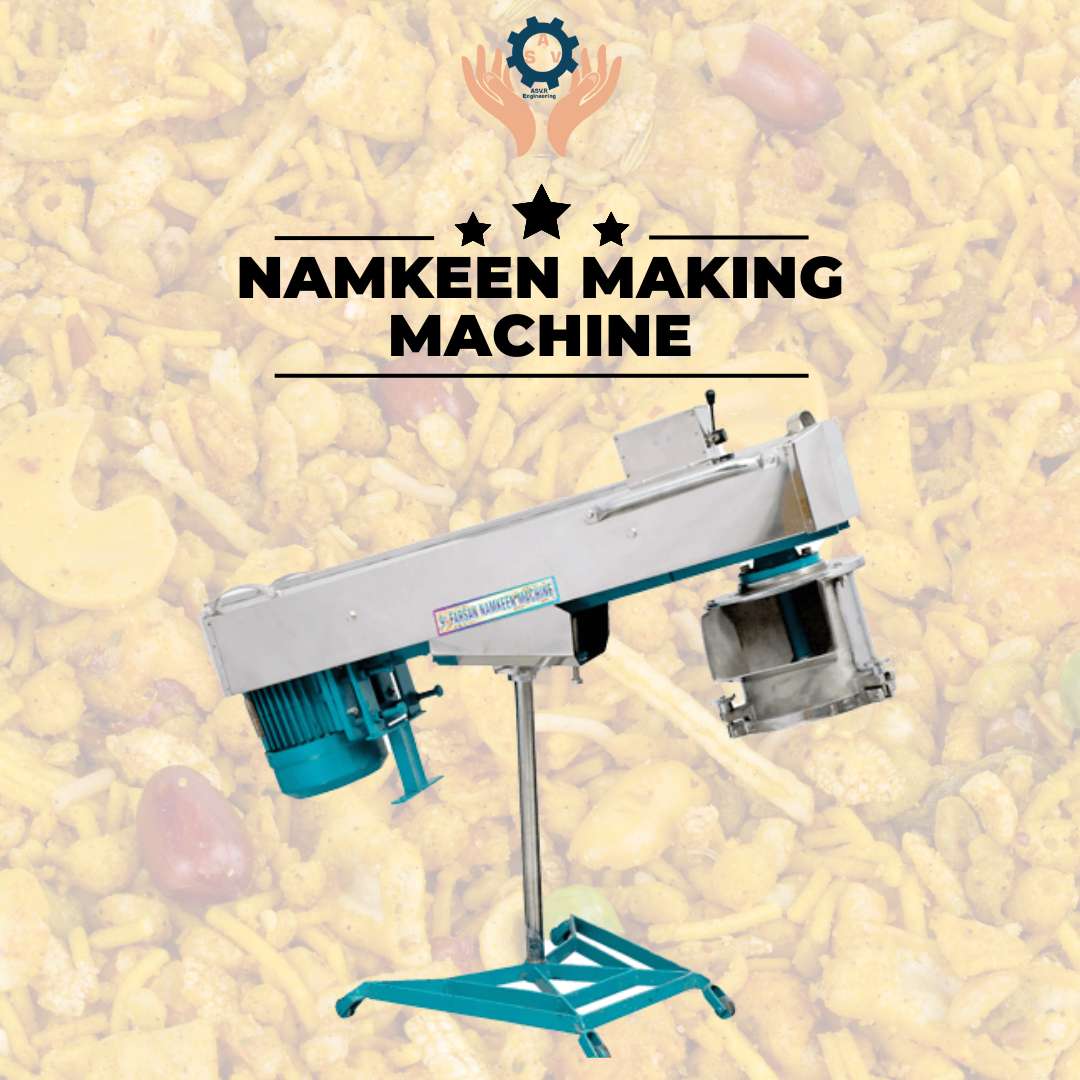

Automatic Namkeen Making Machine

Price: ₹42000

The Indian snack industry has grown into a multi-billion-rupee market, driven by the ever-increasing demand for hygienic, tasty, and consistently produced namkeen. From small kirana stores to large retail chains, consumers expect uniform quality, rich flavor, and safe food practices. To meet these expectations while maintaining profitability, manufacturers are rapidly shifting from manual or semi-automatic processes to Automatic Namkeen Making Machines.

An automatic namkeen making machine is a complete solution designed to streamline the entire process of namkeen production—from raw material handling and dough preparation to frying, seasoning, cooling, and sometimes even packaging. These machines not only improve production speed but also ensure uniformity, reduce labor dependency, and minimize wastage. For businesses aiming to scale operations or start a professional namkeen manufacturing unit, investing in an automatic system is a strategic decision.

What Is an Automatic Namkeen Making Machine?

An automatic namkeen making machine is an integrated industrial setup that produces a wide variety of namkeen products such as sev, bhujiya, aloo bhujia, dal sev, gathiya, peanuts, chivda, and other traditional farsan items. Unlike manual setups, these machines operate continuously with minimal human intervention.

The system typically includes:

-

Dough mixing unit

-

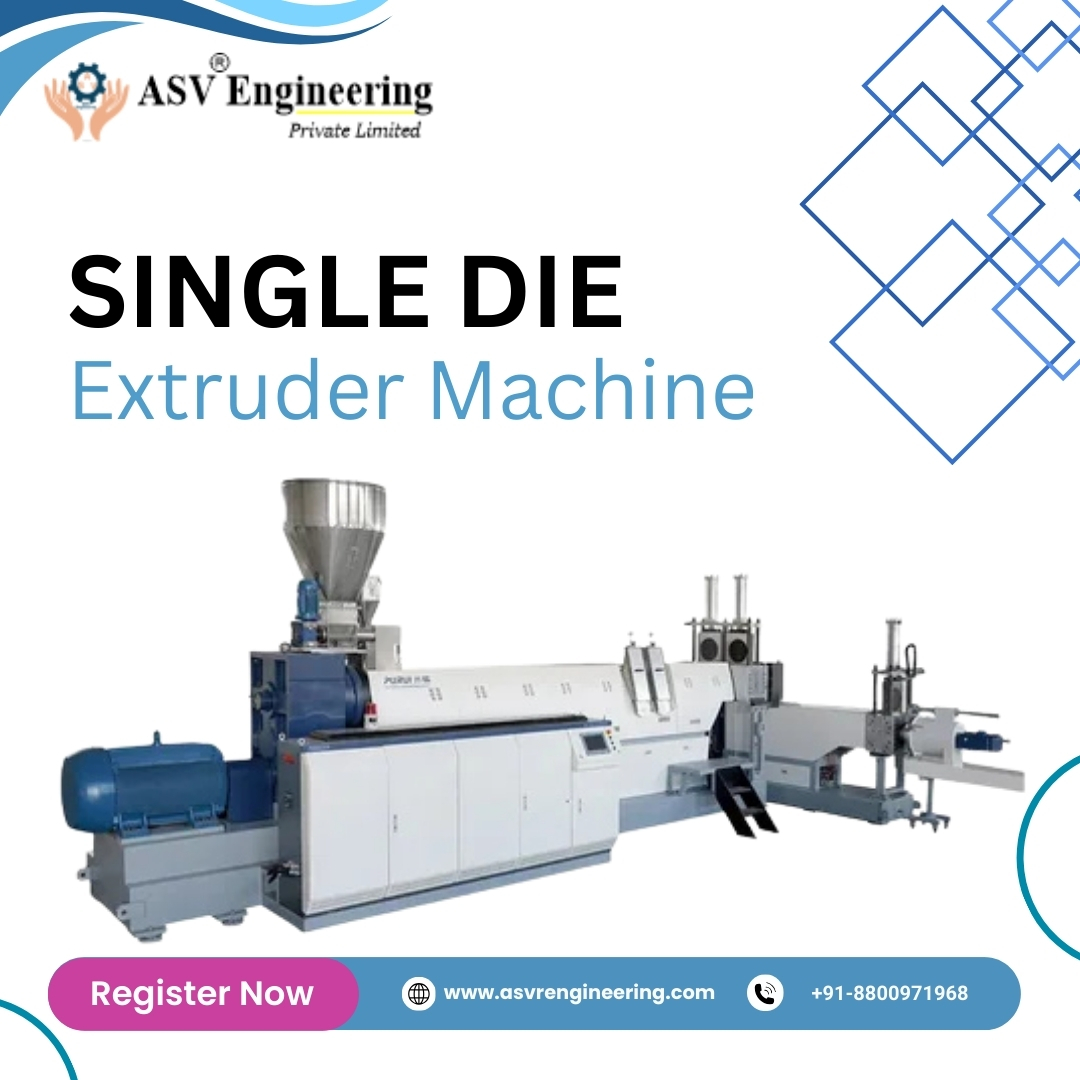

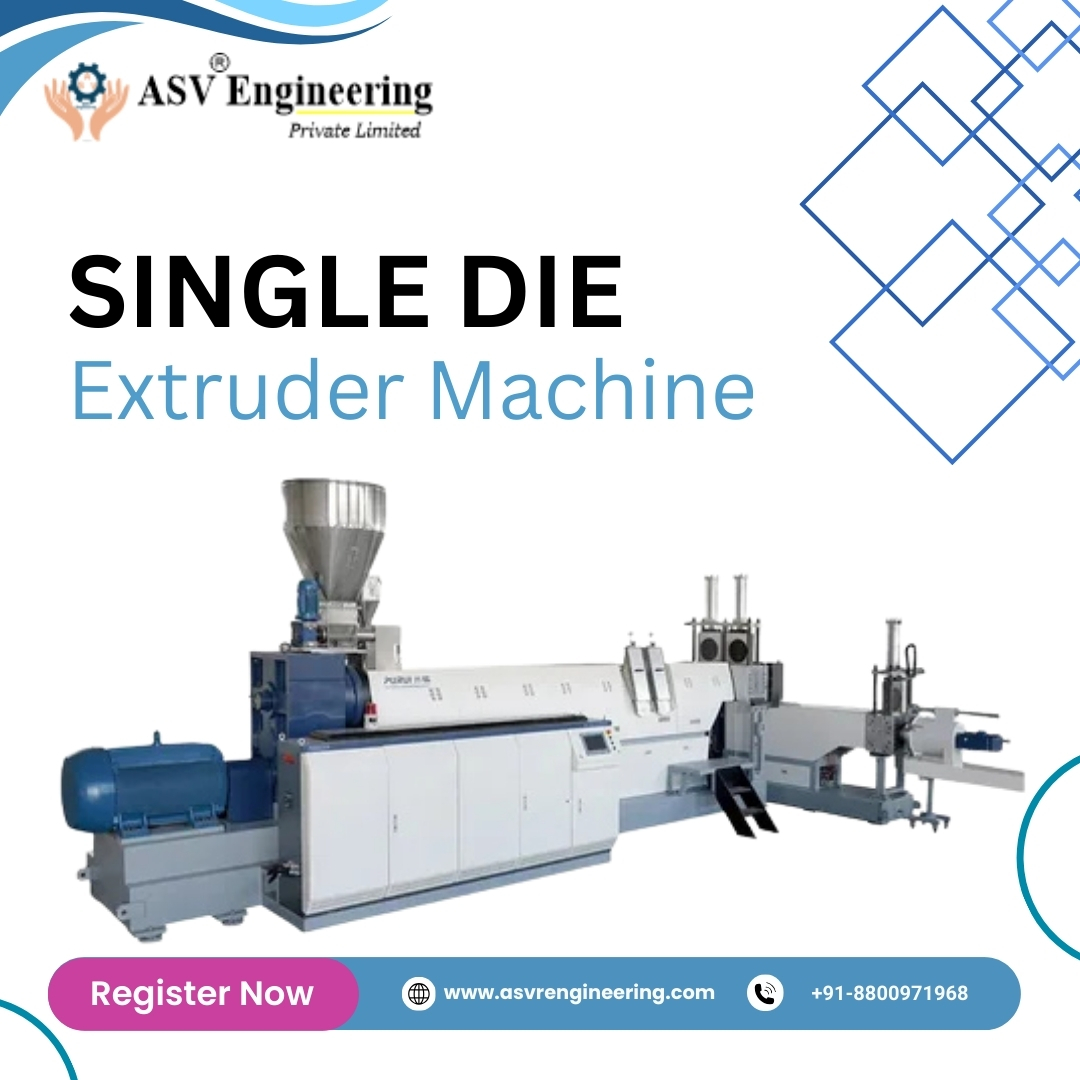

Extrusion or forming machine

-

Continuous fryer

-

De-oiling and cooling conveyor

-

Automatic seasoning or coating drum

-

Optional packaging integration

Each stage is synchronized to ensure smooth flow, consistent frying temperature, controlled oil absorption, and even distribution of spices.

Key Features of Automatic Namkeen Making Machines

1. Fully Automated Operation

The biggest advantage of an automatic namkeen making machine is its automation. Once raw materials are loaded and parameters are set, the machine handles the entire process with precision. This reduces dependency on skilled labor and ensures repeatable quality in every batch.

2. Consistent Taste and Texture

Manual frying often leads to uneven cooking, which affects taste and shelf life. Automatic machines maintain uniform temperature, frying time, and seasoning levels, resulting in consistent crunch, color, and flavor.

3. High Production Capacity

These machines are designed for continuous operation, making them ideal for medium to large-scale production units. Depending on the model, output can range from a few hundred kilograms per hour to several tons per day.

4. Hygienic and Food-Grade Design

Manufactured using food-grade stainless steel, automatic namkeen machines comply with modern hygiene standards. Enclosed systems reduce human contact, lowering the risk of contamination and improving product safety.

5. Energy and Cost Efficiency

Advanced heating systems and optimized oil circulation help reduce fuel and electricity consumption. Lower wastage, reduced manpower, and faster production cycles significantly bring down the cost per kilogram of namkeen.

Types of Namkeen Products You Can Produce

An automatic namkeen making machine offers versatility, allowing manufacturers to diversify their product range without major additional investment. Common products include:

-

Sev and bhujiya varieties

-

Gathiya and papdi gathiya

-

Aloo bhujia

-

Moong dal and chana dal namkeen

-

Peanut and cashew namkeen

-

Chivda and mixture namkeen

-

Regional farsan snacks

By changing dies, seasoning blends, or raw material proportions, producers can easily introduce new variants to match market demand.

Advantages for Small, Medium, and Large Manufacturers

For Startups and Small Units

Automatic machines help new entrepreneurs enter the snack manufacturing industry with confidence. Consistent quality builds brand trust early, while automation keeps operating costs under control.

For Medium-Scale Businesses

As demand grows, automatic namkeen machines support scaling without compromising quality. Faster production and reduced labor issues allow businesses to focus on marketing and distribution.

For Large Manufacturers

For established brands, automation ensures uniformity across large volumes, simplifies compliance with food safety regulations, and improves overall profitability.

Why Automation Matters in the Namkeen Industry

The namkeen market is highly competitive. Brands that succeed are those that maintain consistent taste, attractive packaging, and reliable supply. Automation plays a critical role by:

-

Ensuring batch-to-batch consistency

-

Reducing production downtime

-

Improving shelf life through controlled frying

-

Enhancing brand reputation with uniform products

In today’s organized retail environment, automation is no longer a luxury—it is a necessity.

Maintenance and Ease of Operation

Modern automatic namkeen making machines are designed with user-friendly controls and easy maintenance in mind. Digital control panels allow operators to adjust temperature, speed, and seasoning levels with precision. Modular construction ensures that cleaning, inspection, and part replacement are simple and time-efficient.

Regular preventive maintenance helps extend machine life, maintain efficiency, and avoid unexpected breakdowns.

Customization and Plant Layout Support

Every manufacturing unit has unique space, capacity, and product requirements. Automatic namkeen machines can be customized in terms of output capacity, fuel type (electric, gas, diesel), and layout configuration. Manufacturers also assist with plant layout planning to ensure smooth workflow, safety, and future scalability.

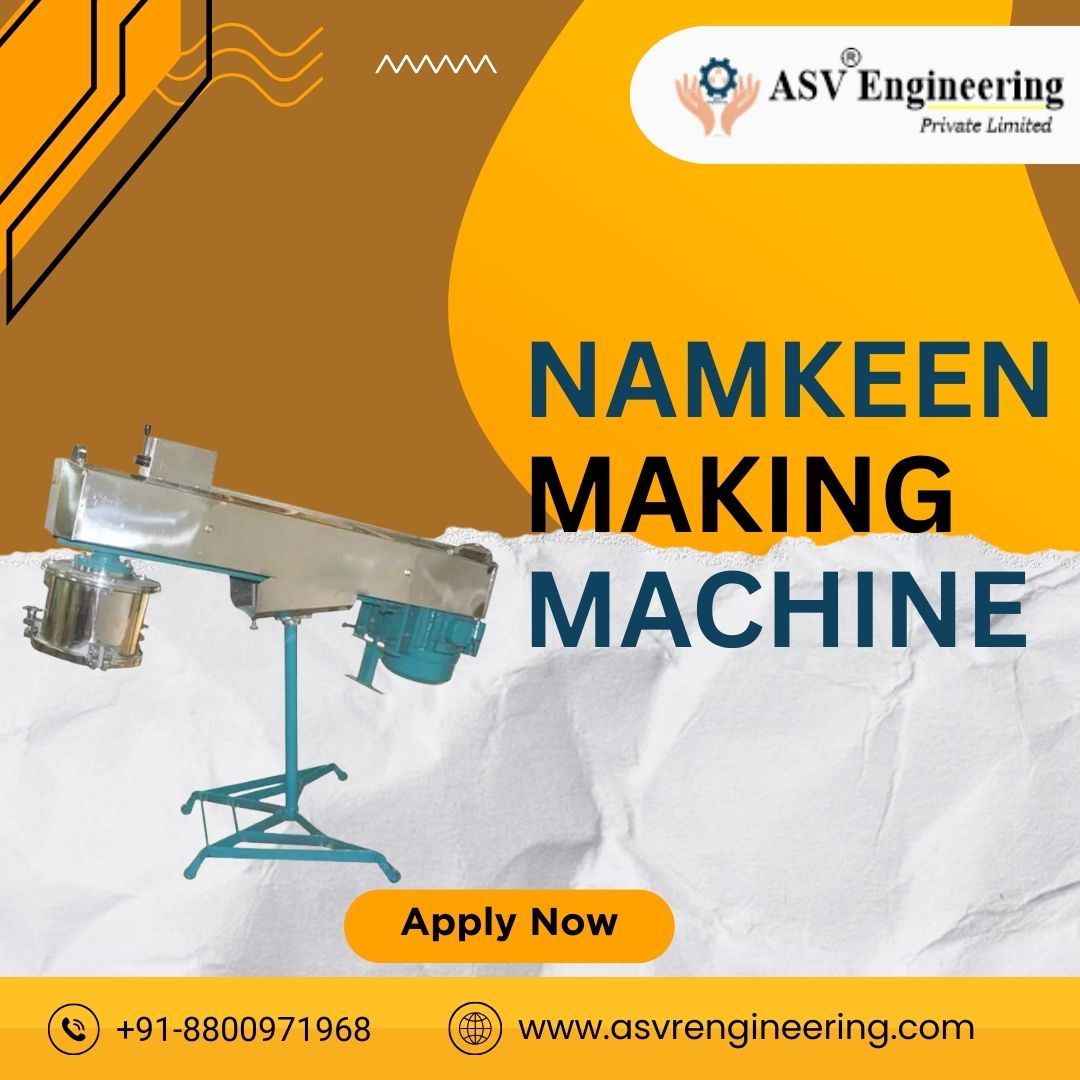

Why Choose ASVR Engineering?

ASVR Engineering is a trusted name in the field of food processing and snack manufacturing machinery. With a strong focus on quality engineering, durability, and customer satisfaction, the company offers reliable automatic namkeen making machines suitable for diverse production needs.

Key reasons to choose ASVR Engineering:

-

Robust machine design with long service life

-

Use of premium food-grade materials

-

Technical support and after-sales service

-

Custom-built solutions for different capacities

-

Proven performance in Indian snack manufacturing conditions

Applications Across the Food Industry

Automatic namkeen making machines are widely used in:

-

Commercial namkeen manufacturing units

-

Food processing factories

-

Contract snack manufacturers

-

Private label snack brands

-

Export-oriented snack units

Their ability to produce large volumes with consistent quality makes them ideal for both domestic and international markets.

Investment That Delivers Long-Term Returns

While the initial investment in an automatic namkeen making machine may be higher than manual systems, the long-term benefits far outweigh the cost. Reduced manpower, lower wastage, faster production, and superior product quality translate into higher margins and quicker return on investment.

For businesses planning long-term growth, automation is a future-proof decision.

Contact Information

If you are planning to start or upgrade your namkeen manufacturing unit, an automatic namkeen making machine from ASVR Engineering can give your business a competitive edge.

📞 Contact Numbers:

+91-8076004849

+91-8800971968

🌐 Website:

https://www.asvrengineering.com

Buy Now

Related Posts

Trusted Automatic Namkeen Making Machine Importers Supplying Cost-Effective & Fully Automated Plants

(9).jpg)

(9).jpg)

(9).jpg)

(9).jpg)

(1).png)

(1).png)

(1).png)

(12).jpg)

(12).jpg)

(12).jpg)