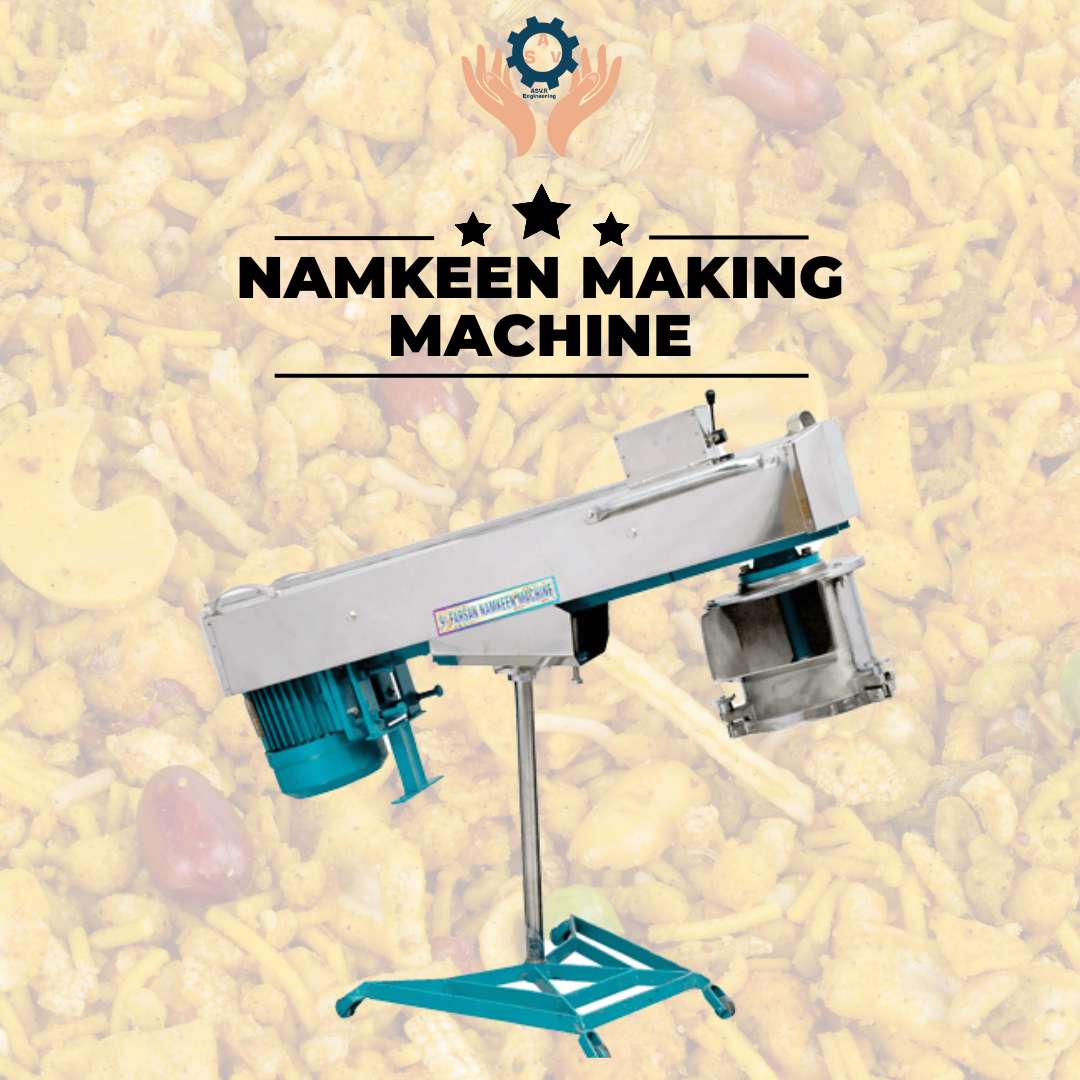

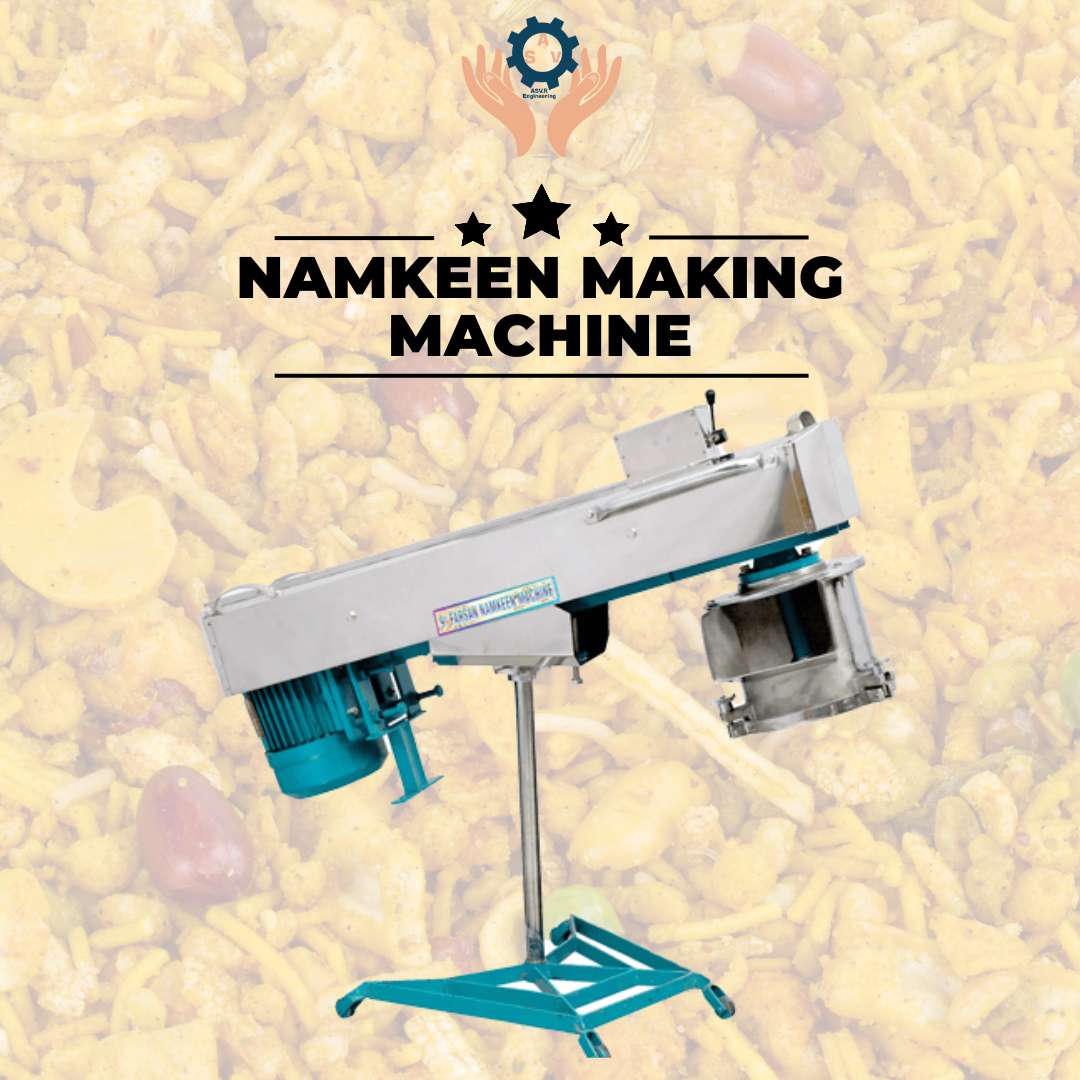

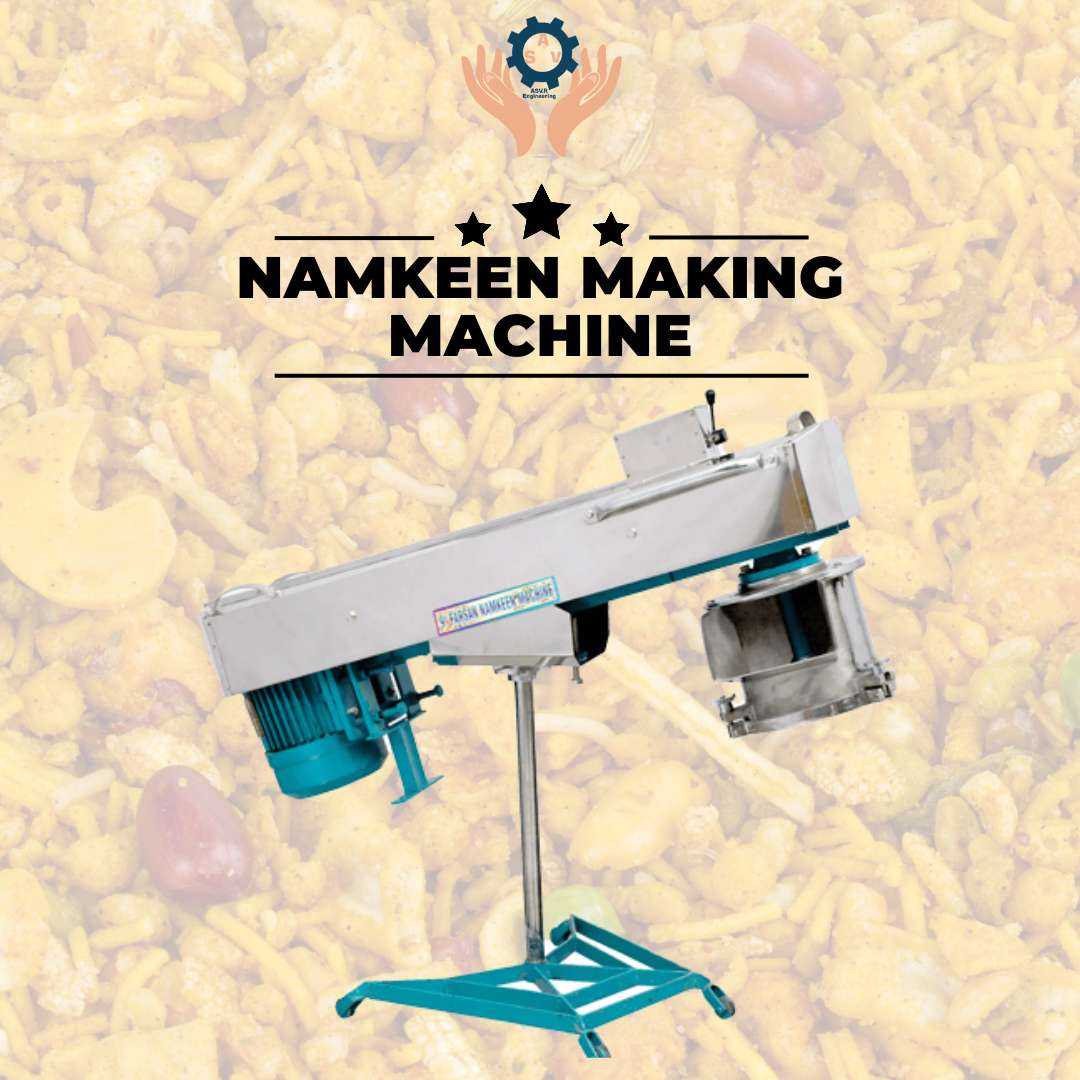

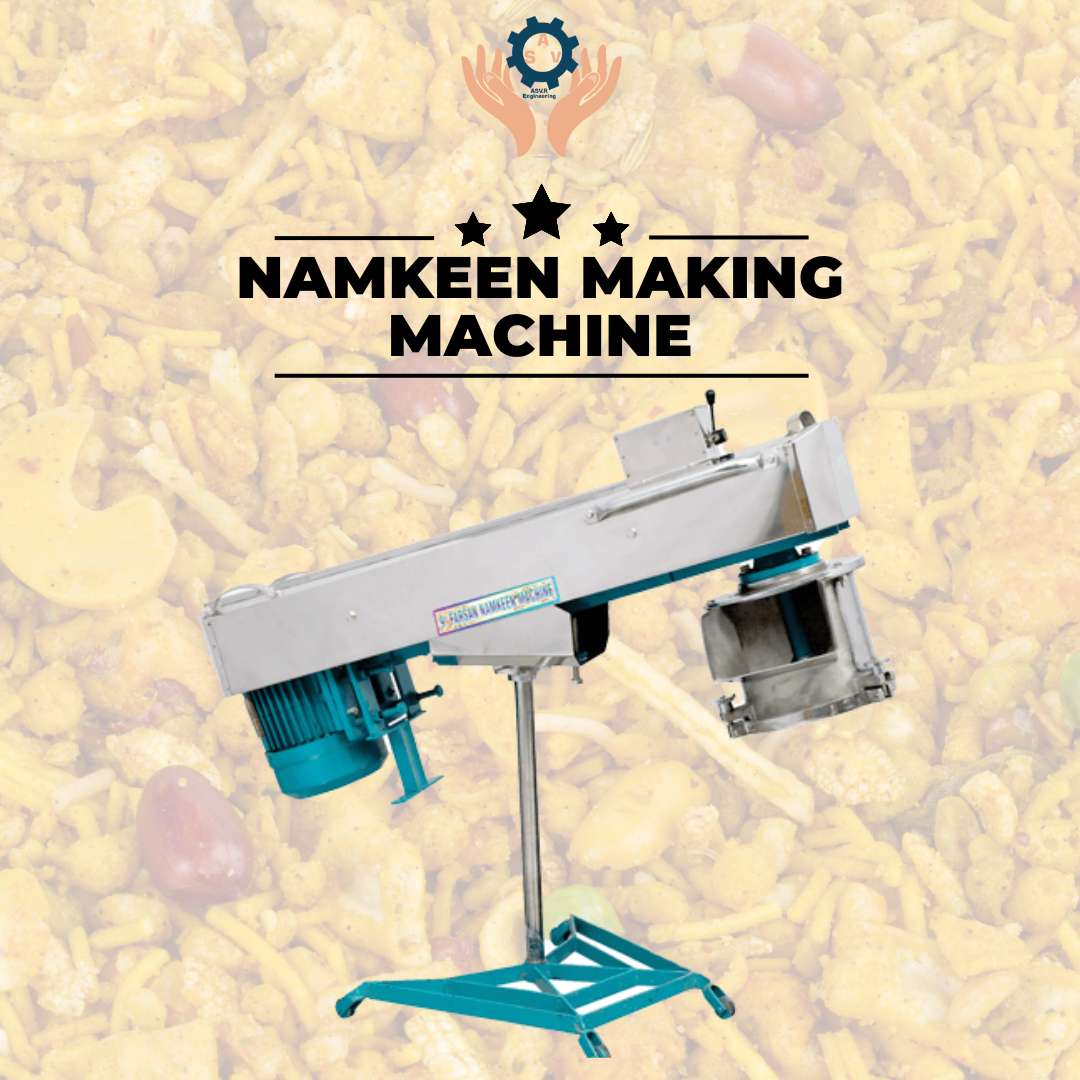

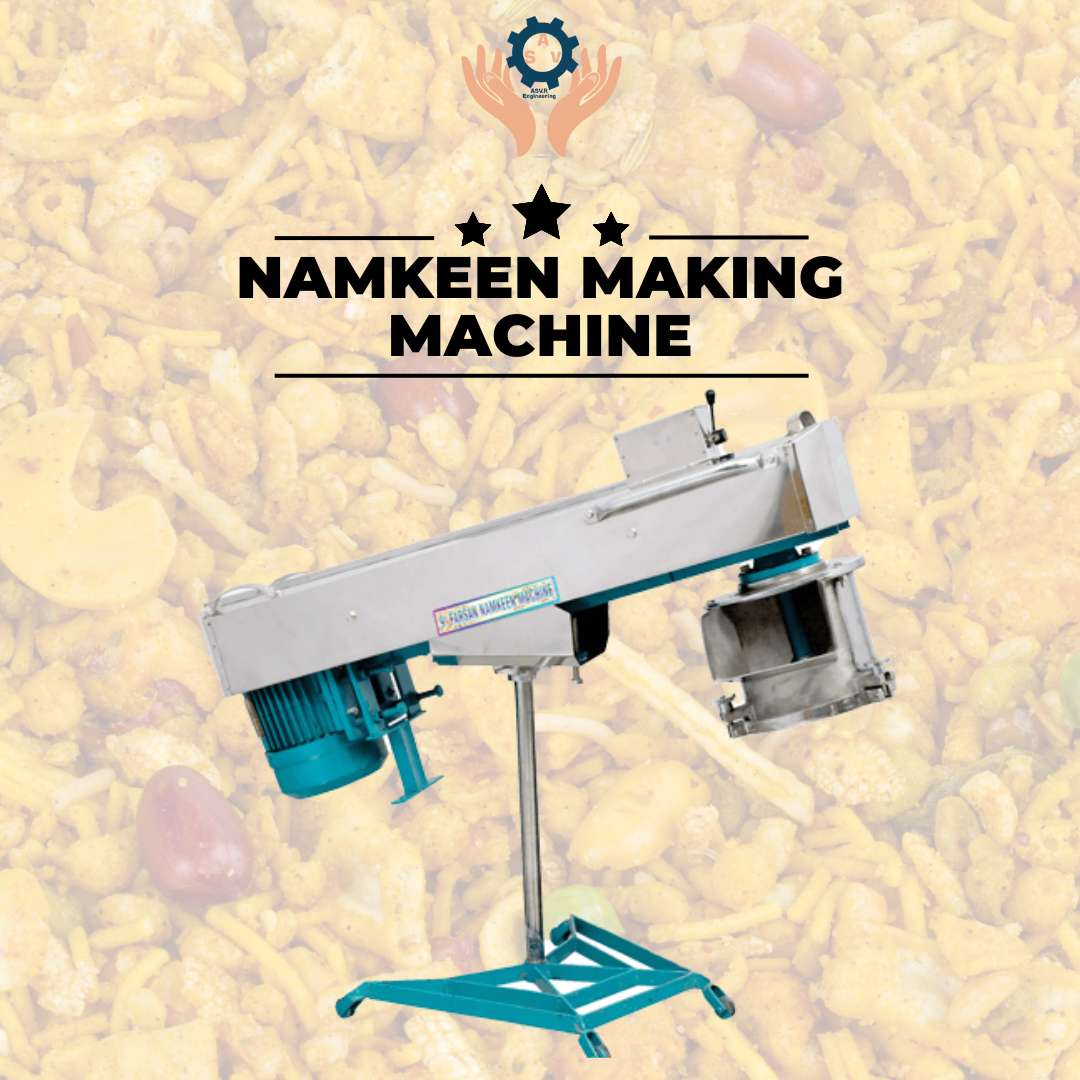

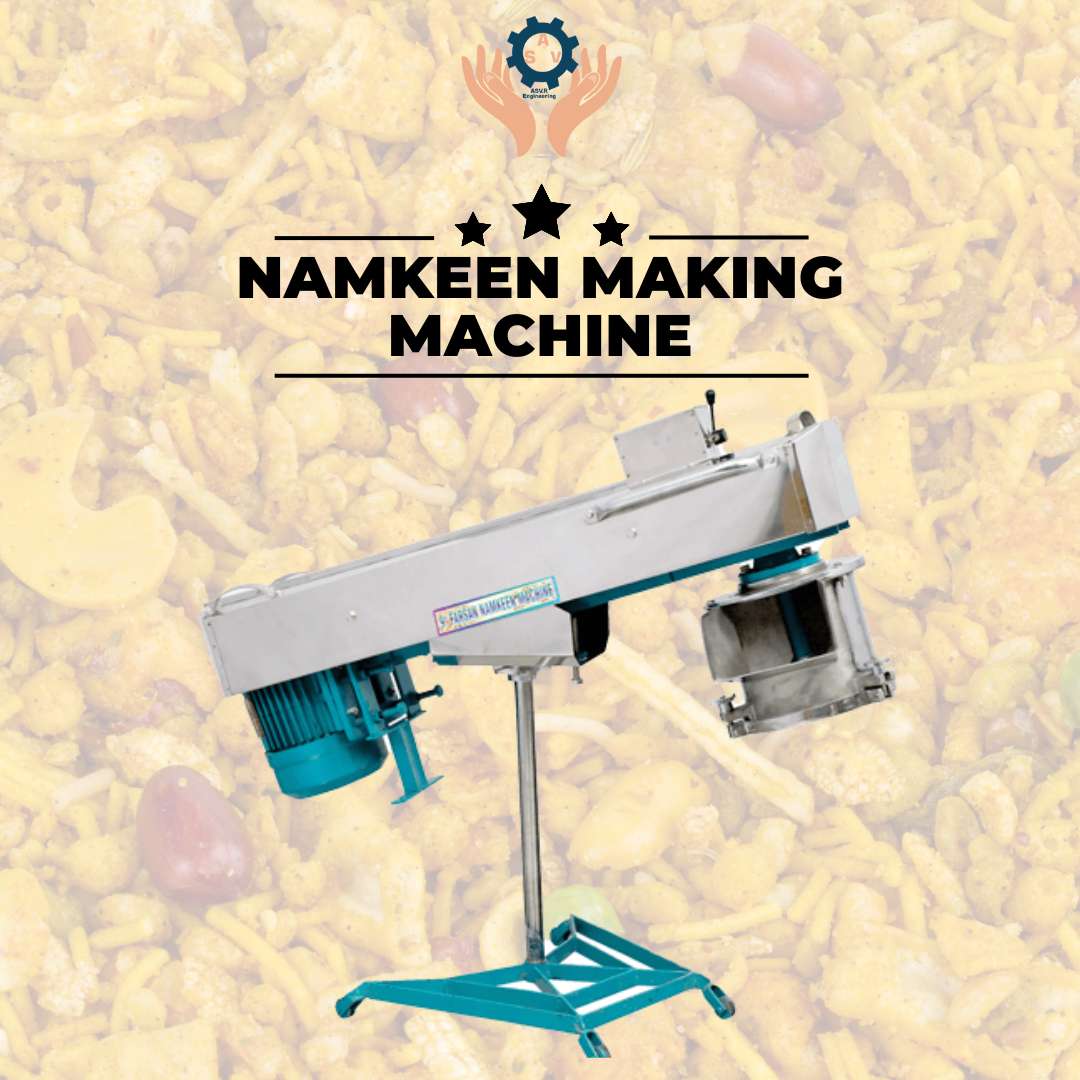

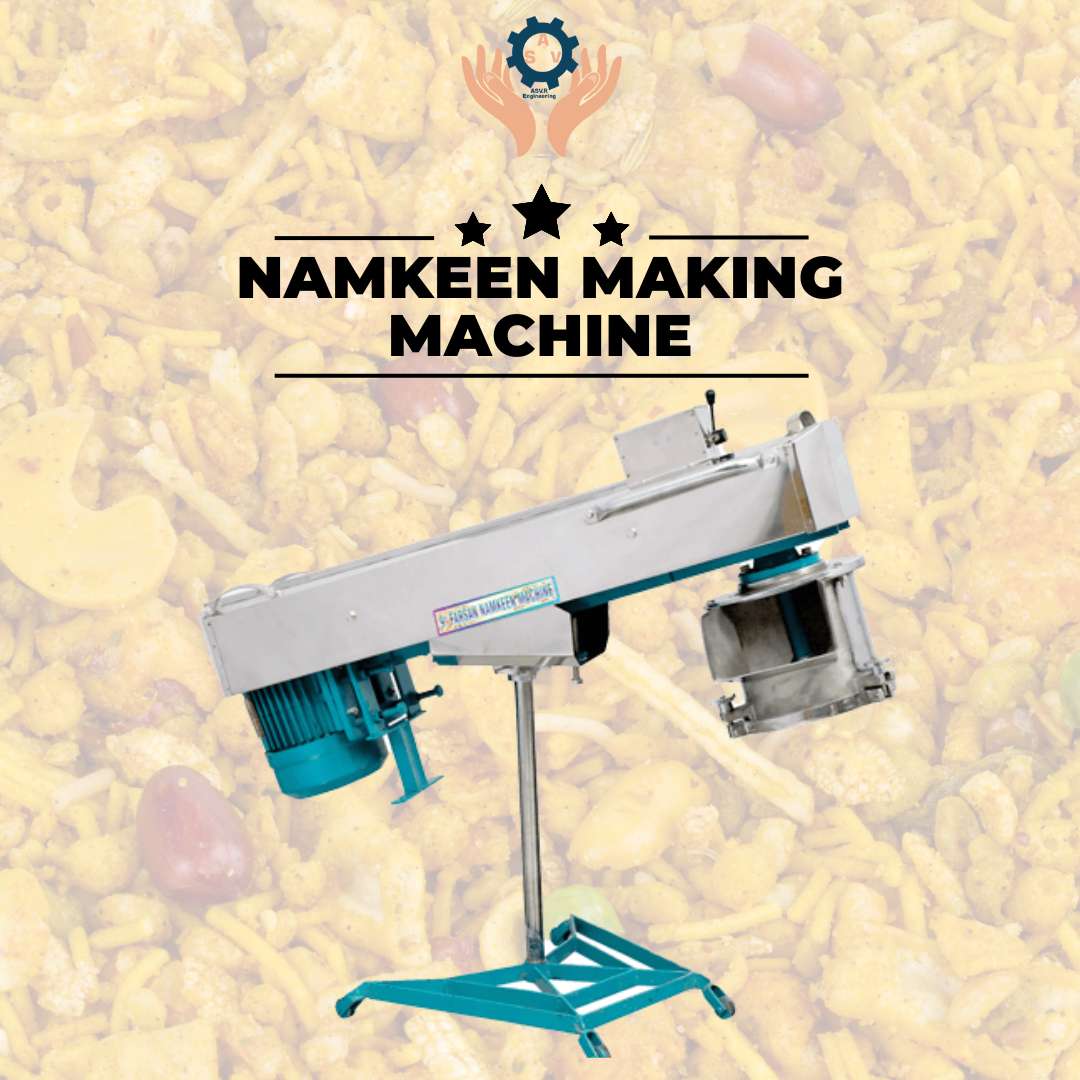

Top Automatic Namkeen Making Machine Exporters for Industrial-Grade Namkeen Production Lines

Price: ₹43500

The Indian snack food industry has witnessed exponential growth over the last decade, with namkeen becoming one of the most widely consumed and exported savory snack categories. From traditional bhujia and sev to innovative flavored mixtures, the demand for hygienically produced, uniform-quality namkeen has never been higher. To meet this rising demand, manufacturers across India and overseas are shifting from manual or semi-automatic methods to fully automated solutions.

This shift has increased the importance of top automatic namkeen making machine exporters who can deliver industrial-grade, high-capacity, and reliable namkeen production lines. A modern automatic namkeen plant not only boosts output but also ensures consistent taste, texture, and food safety standards required for domestic and international markets.

Why Automatic Namkeen Making Machines Are Essential for Large-Scale Production

Manual namkeen production is labor-intensive, inconsistent, and difficult to scale. Automatic namkeen making machines address these challenges by integrating advanced engineering with food-grade materials and intelligent controls.

Key benefits include:

-

High Production Capacity: Ideal for medium to large-scale namkeen manufacturers

-

Consistent Quality: Uniform frying, mixing, and seasoning in every batch

-

Improved Hygiene: Minimal human contact, compliance with food safety norms

-

Reduced Operational Cost: Lower labor dependency and reduced wastage

-

Scalability: Easy expansion as demand grows

For exporters and industrial producers, automation is no longer optional—it is a necessity.

Complete Industrial-Grade Namkeen Production Line

A fully automatic namkeen production line typically consists of multiple integrated machines designed to work seamlessly. Export-quality systems are customized based on product type, capacity, and factory layout.

Core components include:

-

Dough Mixing Unit – Ensures uniform mixing of flour, spices, and oil

-

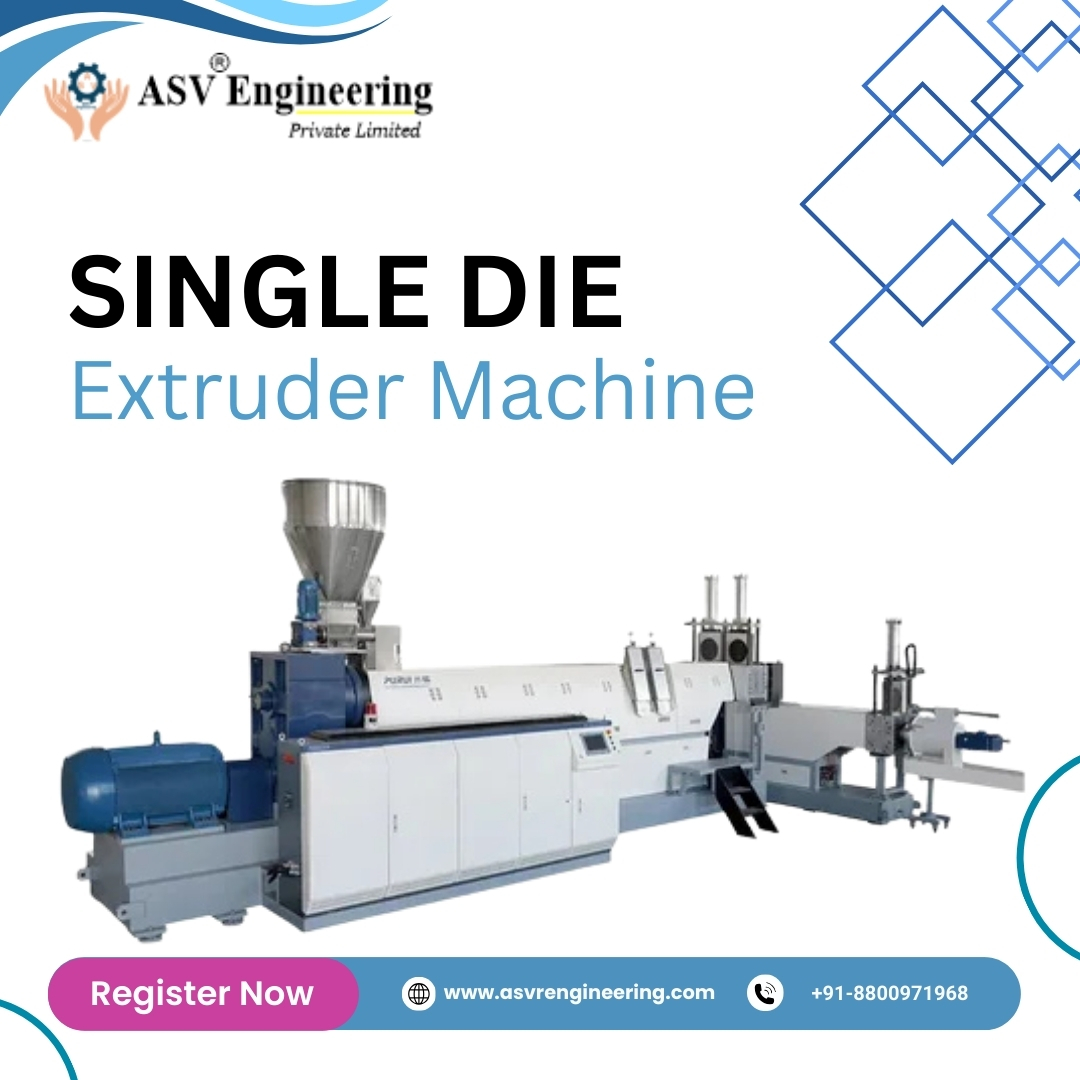

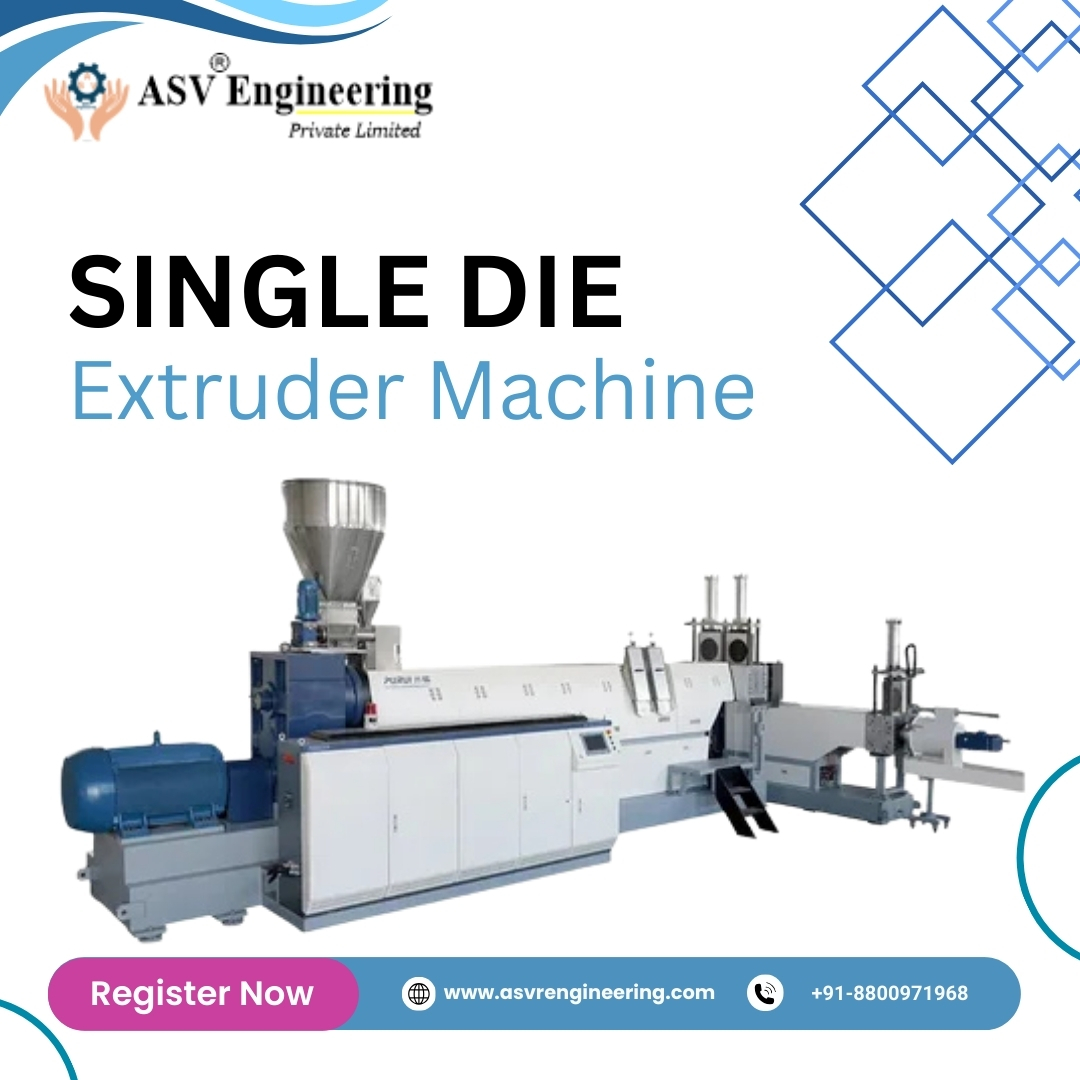

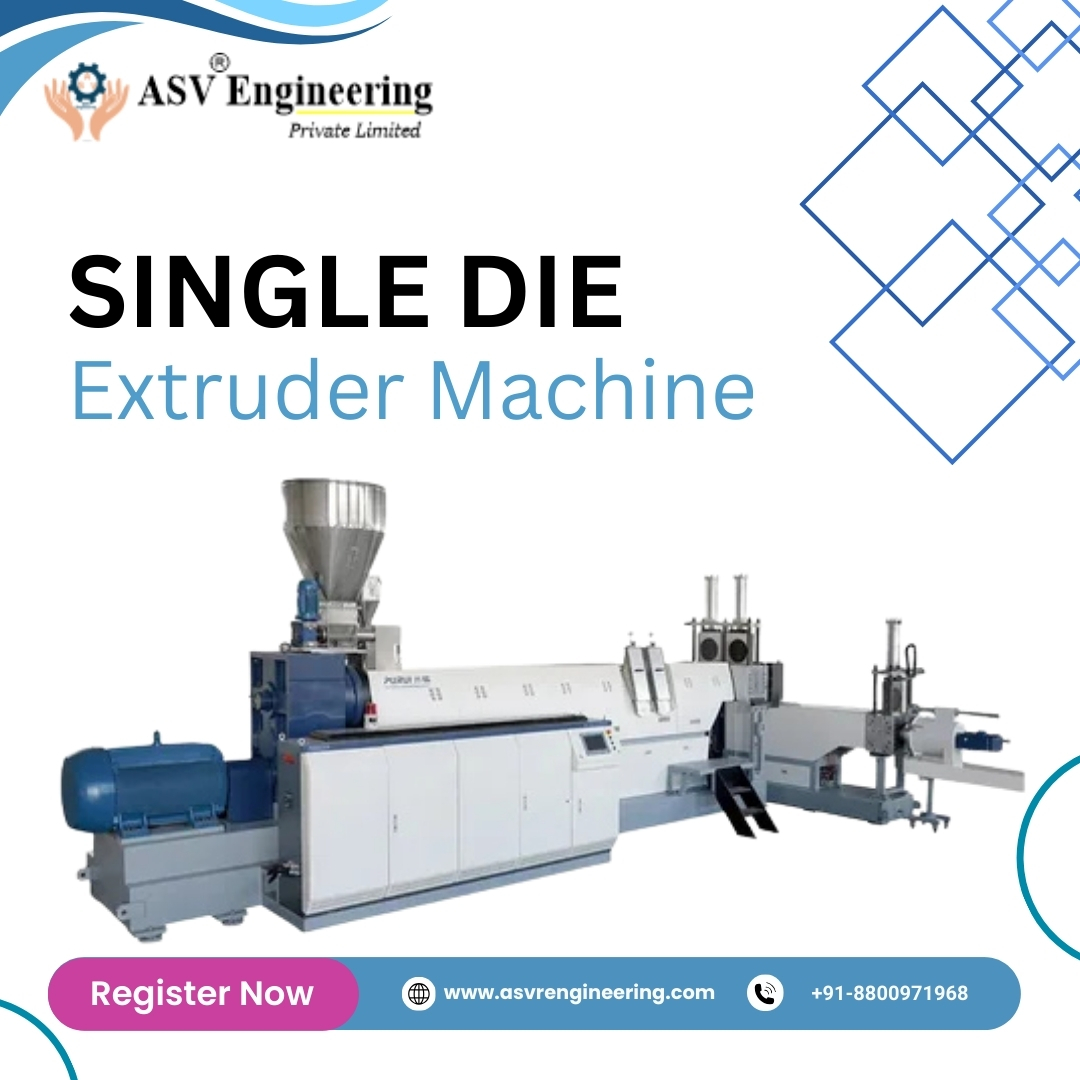

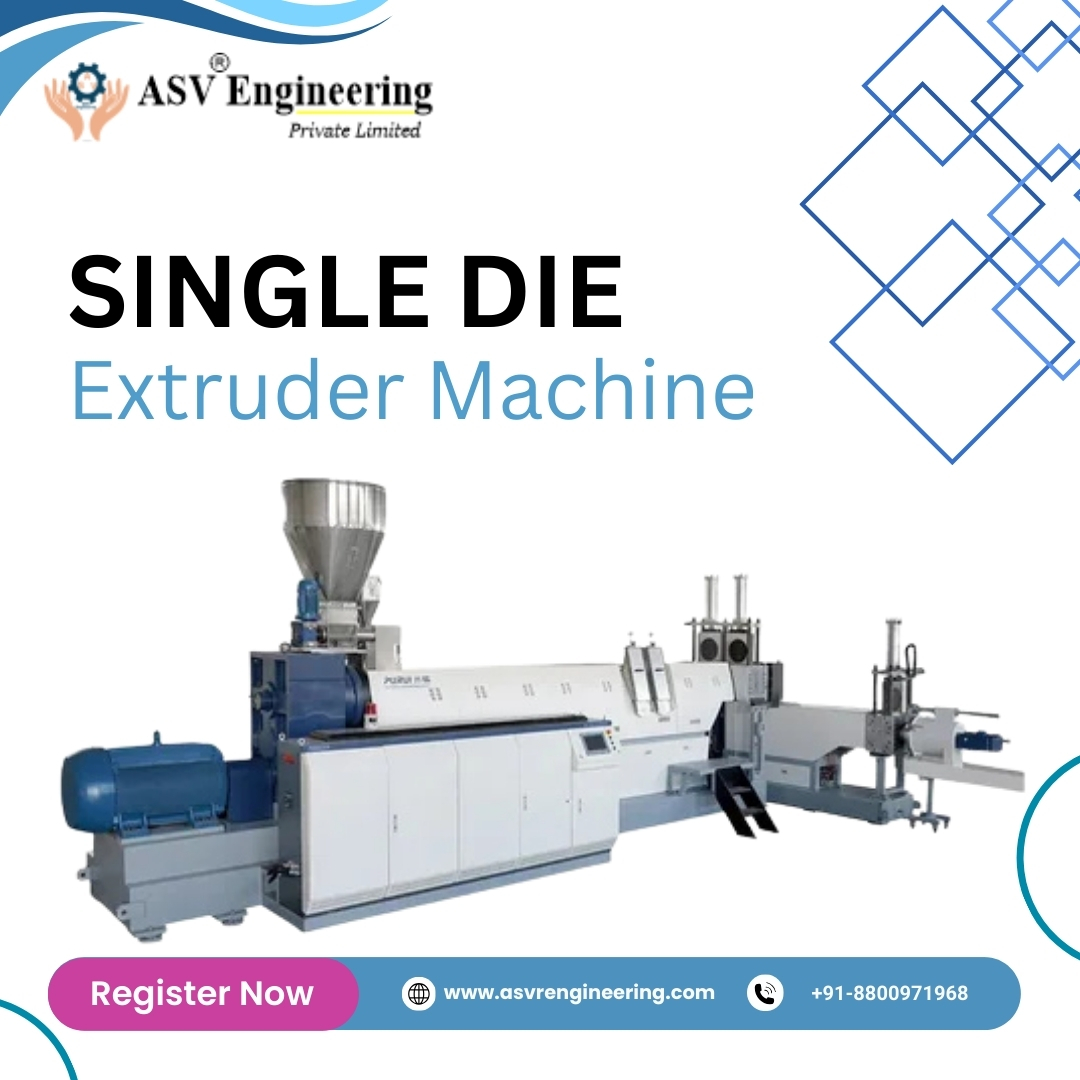

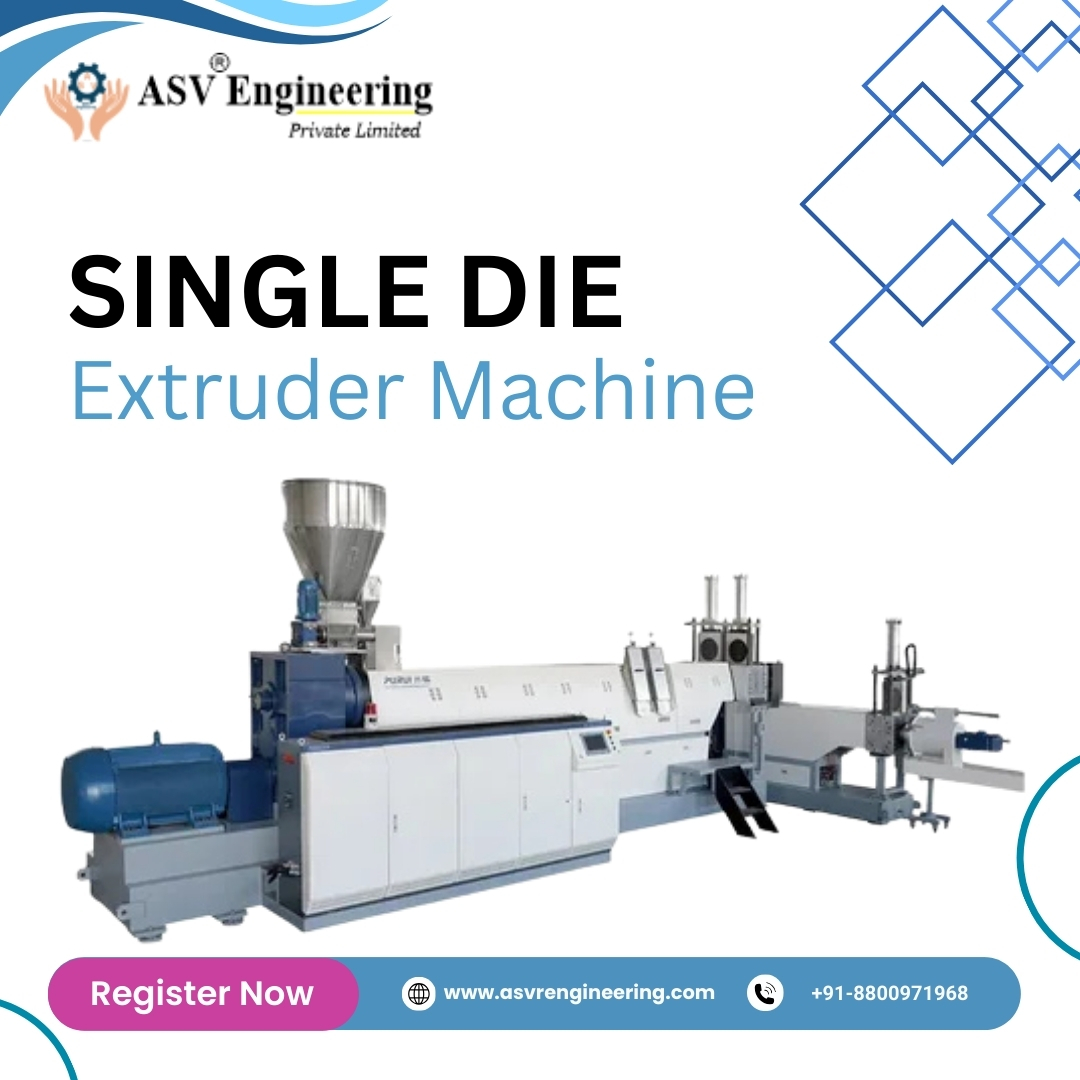

Extruder / Forming Machine – Shapes namkeen like sev, gathiya, or bhujia

-

Continuous Frying System – Maintains consistent temperature and oil quality

-

De-Oiling & Cooling Conveyor – Removes excess oil and cools the product

-

Flavoring & Mixing Drum – Even coating of spices and seasonings

-

Inspection & Conveying System – Smooth transfer to packaging section

Each machine is designed using robust, food-grade stainless steel to ensure durability, hygiene, and long service life.

What Makes a Reliable Automatic Namkeen Making Machine Exporter

Choosing the right exporter is as important as selecting the right machine. The best exporters focus on engineering excellence, after-sales support, and international compliance.

Key qualities to look for:

-

Proven experience in industrial food processing machinery

-

Custom-designed solutions for different namkeen varieties

-

Export-standard manufacturing and packaging

-

Compliance with international food safety norms

-

Strong installation, training, and service support

Exporters who understand both Indian snack traditions and global market requirements deliver the most value.

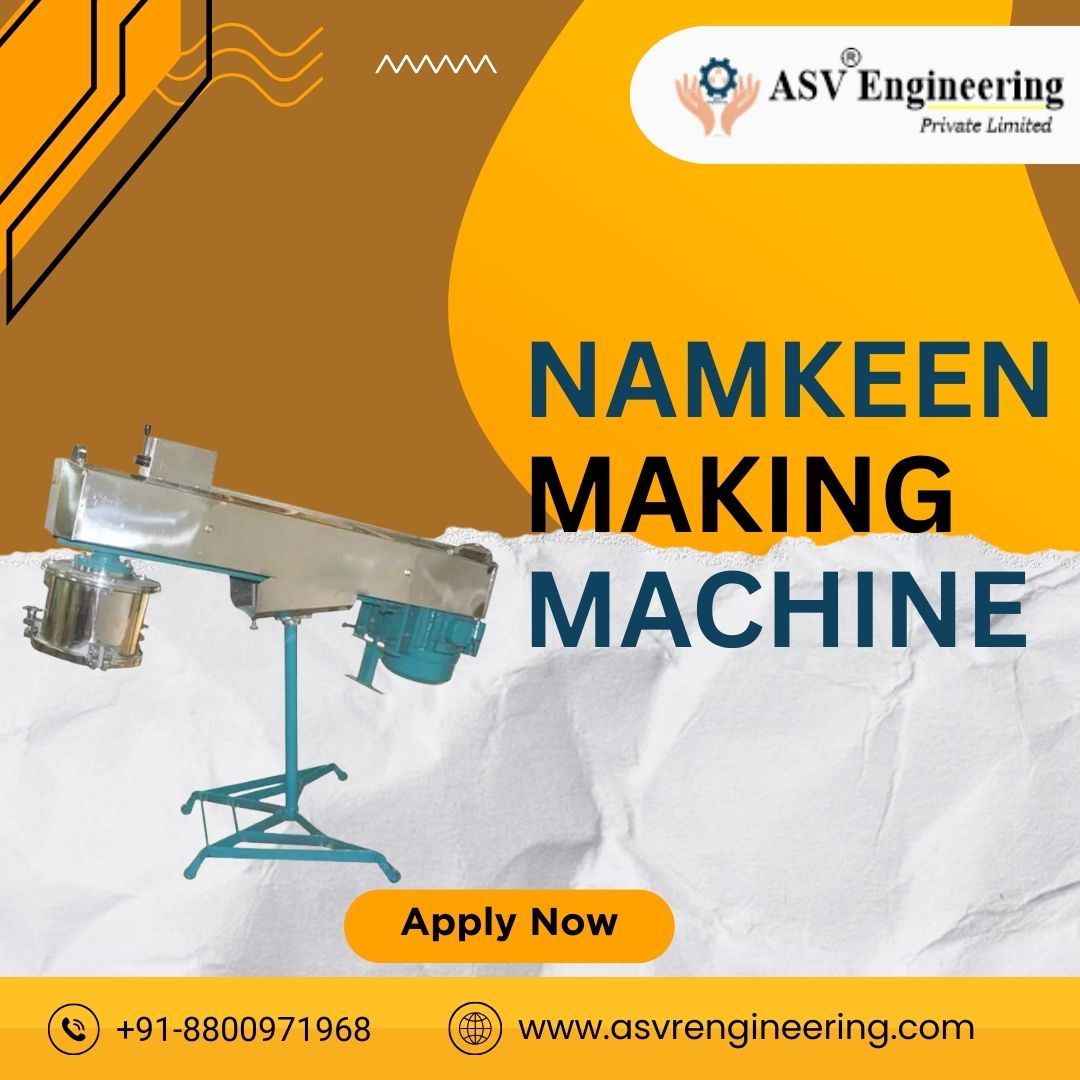

ASVR Engineering – A Trusted Name in Automatic Namkeen Machinery Exports

ASVR Engineering has earned a strong reputation as one of the leading automatic namkeen making machine exporters from India. With a deep understanding of food processing technology and years of hands-on industry experience, the company delivers high-performance namkeen production lines designed for continuous, large-scale operations.

Their machines are widely appreciated for:

-

Robust construction suitable for 24/7 industrial use

-

Energy-efficient motors and optimized oil consumption

-

Precision control systems for uniform frying and seasoning

-

Easy operation and low maintenance design

-

Customization based on product type and output requirement

ASVR Engineering caters to both domestic manufacturers and international buyers seeking dependable snack food processing solutions.

Global Demand for Indian Namkeen Production Technology

Indian namkeen enjoys immense popularity not only in India but also across the Middle East, Africa, Southeast Asia, Europe, and North America. This has fueled international demand for Indian-made automatic namkeen production machinery.

Exporters now design machines that meet:

-

International electrical and safety standards

-

Food-grade material certifications

-

Long-distance shipping durability

-

Easy installation in overseas facilities

As a result, Indian exporters are playing a key role in setting up namkeen manufacturing plants across the globe.

Customization for Different Namkeen Products

Not all namkeen is the same. Different products require specific processing techniques, extrusion dies, frying times, and seasoning methods.

Automatic namkeen machines can be customized for:

-

Sev, bhujia, gathiya

-

Moong dal, chana dal, peanuts

-

Mixture namkeen

-

Farsan and regional snacks

This flexibility allows manufacturers to diversify their product range without investing in entirely new plants.

Energy Efficiency and Cost Optimization

Modern industrial namkeen machines are designed to reduce operational costs while maintaining high output. Features like temperature-controlled frying, oil filtration systems, and optimized heating mechanisms significantly reduce energy and oil consumption.

For exporters and large manufacturers, this translates into:

-

Lower production cost per kg

-

Higher profit margins

-

Sustainable and eco-friendly operations

Quality Control and Food Safety

Food safety is critical, especially for export-oriented namkeen manufacturers. Automatic namkeen making machines ensure strict quality control at every stage.

Advantages include:

-

Consistent frying temperature

-

Controlled oil absorption

-

Uniform seasoning distribution

-

Reduced contamination risk

These factors help manufacturers comply with FSSAI and international food safety regulations.

After-Sales Support and Technical Assistance

A major strength of leading exporters is their commitment to long-term customer support. From installation and commissioning to operator training and spare parts availability, reliable after-sales service ensures uninterrupted production.

ASVR Engineering provides technical guidance and support to help clients achieve maximum efficiency from their namkeen production lines.

Why Invest in an Automatic Namkeen Production Line Now

With rising snack consumption, private labeling, and global demand for Indian flavors, investing in an automatic namkeen making machine is a strategic move.

Benefits include:

-

Faster return on investment

-

Ability to meet bulk and export orders

-

Enhanced brand reputation through consistent quality

-

Long-term scalability

For businesses aiming to grow in the competitive snack food market, automation is the key to sustainability and success.

Contact Details

Company: ASVR Engineering

📞 Contact Numbers: +91-8076004849, +91-8800971968

🌐 Website: https://www.asvrengineering.com

Buy Now

Related Posts

Trusted Automatic Namkeen Making Machine Importers Supplying Cost-Effective & Fully Automated Plants

(9).jpg)

(9).jpg)

(9).jpg)

(9).jpg)

(1).png)

(1).png)

(1).png)

(12).jpg)

(12).jpg)

(12).jpg)