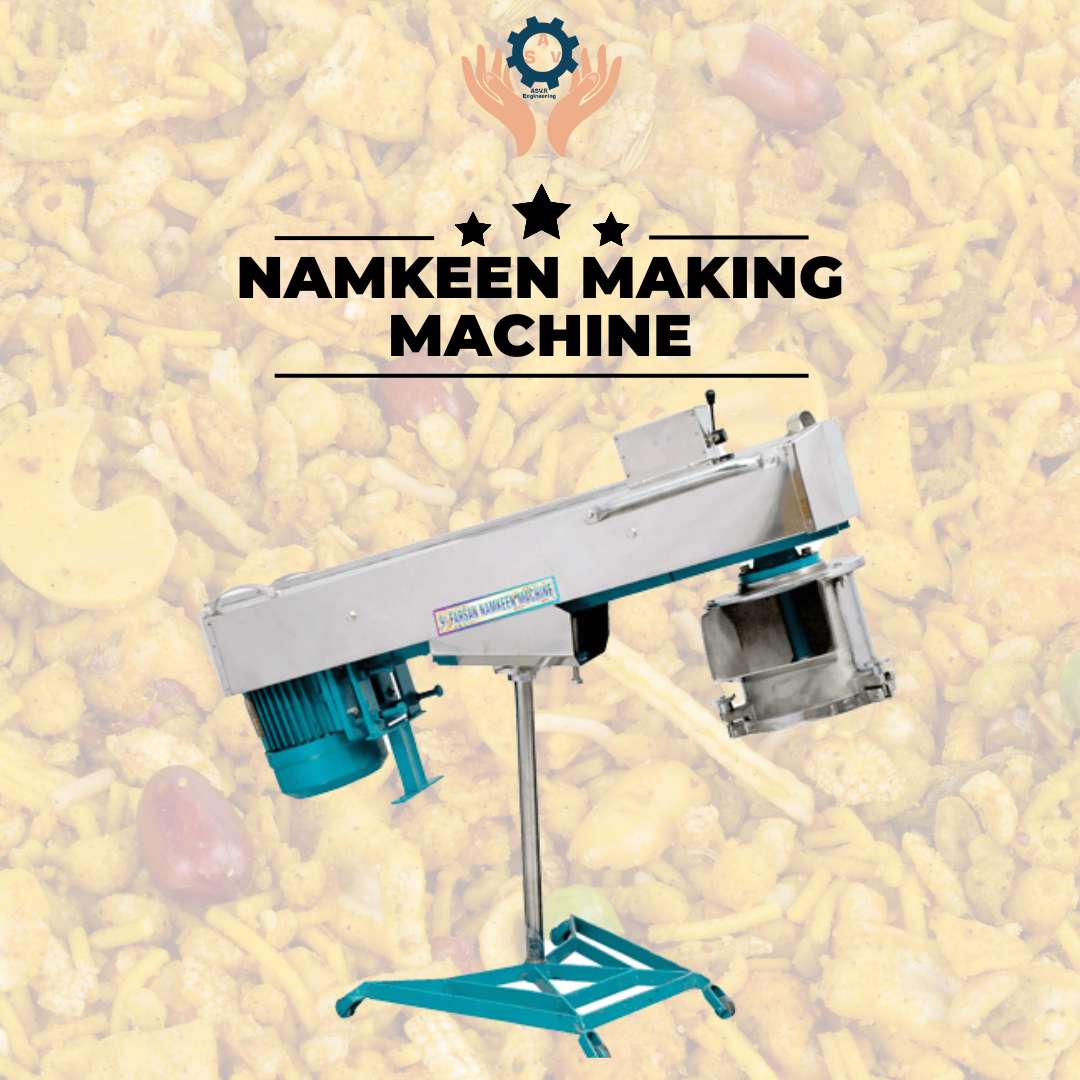

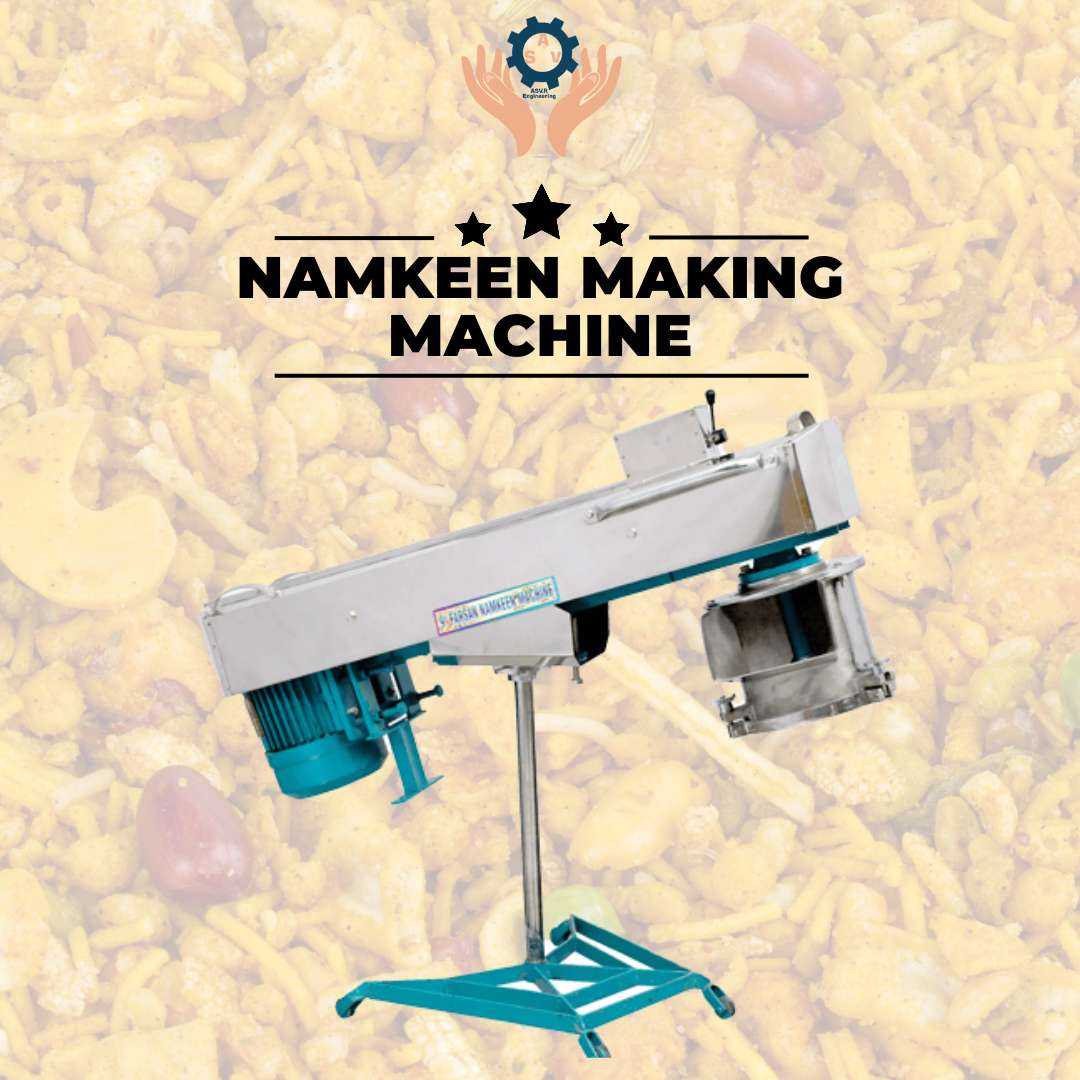

Trusted Semi Automatic Namkeen Making Machine Exporters for High-Efficiency Snacks Production Plants

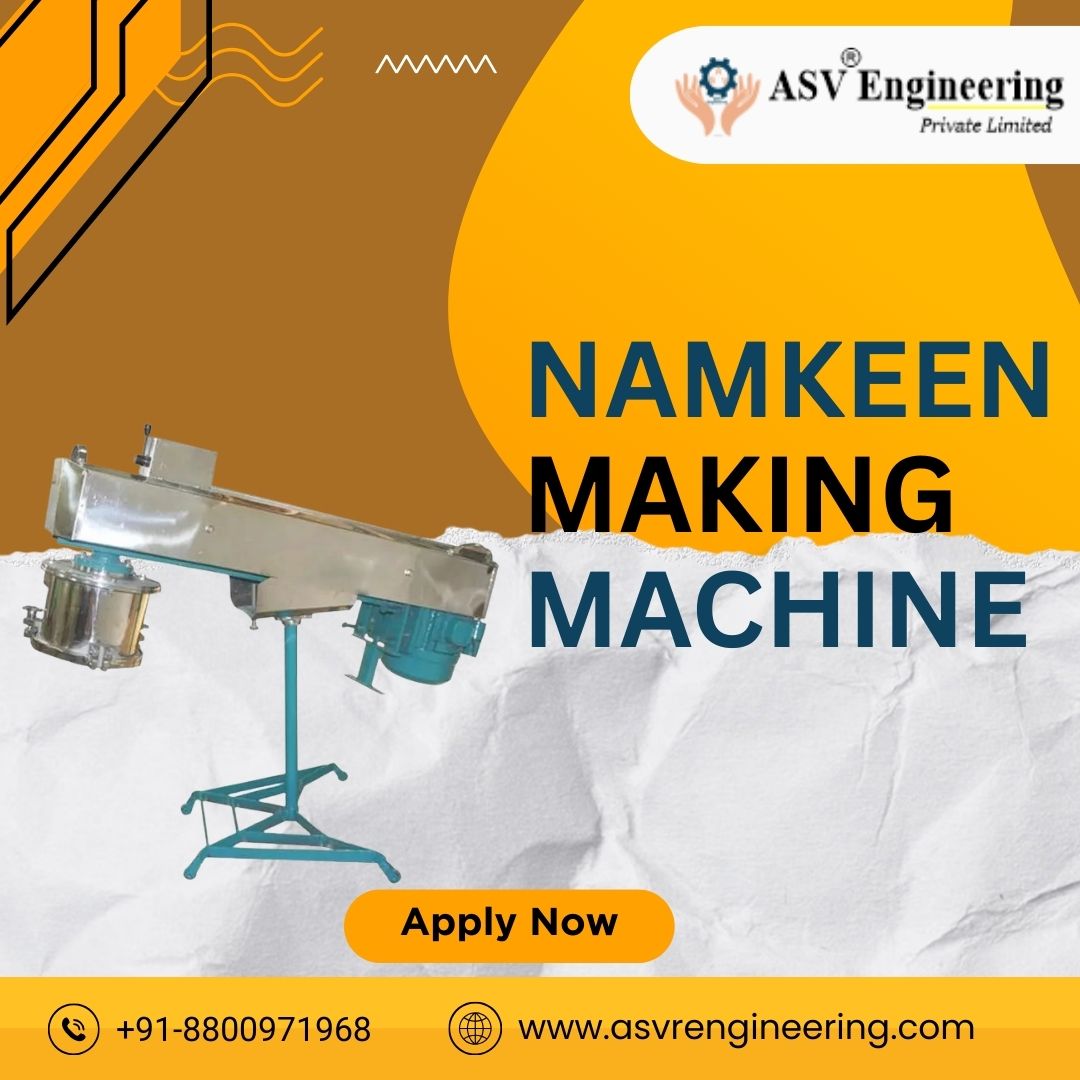

Price: ₹39000

The global snack food market has witnessed consistent growth over the past decade, and namkeen has emerged as one of the most consumed savory snacks across Asia, the Middle East, Africa, and several Western markets. With increasing demand for quality, hygiene, and consistency, snack manufacturers are rapidly shifting from traditional manual processes to semi automatic and automated solutions.

In this evolving landscape, ASVR Engineering has positioned itself as one of the most trusted semi automatic namkeen making machine exporters, catering to small, medium, and large-scale snack production plants. The company focuses on providing machines that balance productivity, quality control, and affordability—making them ideal for businesses looking to scale operations without compromising product authenticity.

Why Semi Automatic Namkeen Making Machines Are the Industry’s Smart Choice

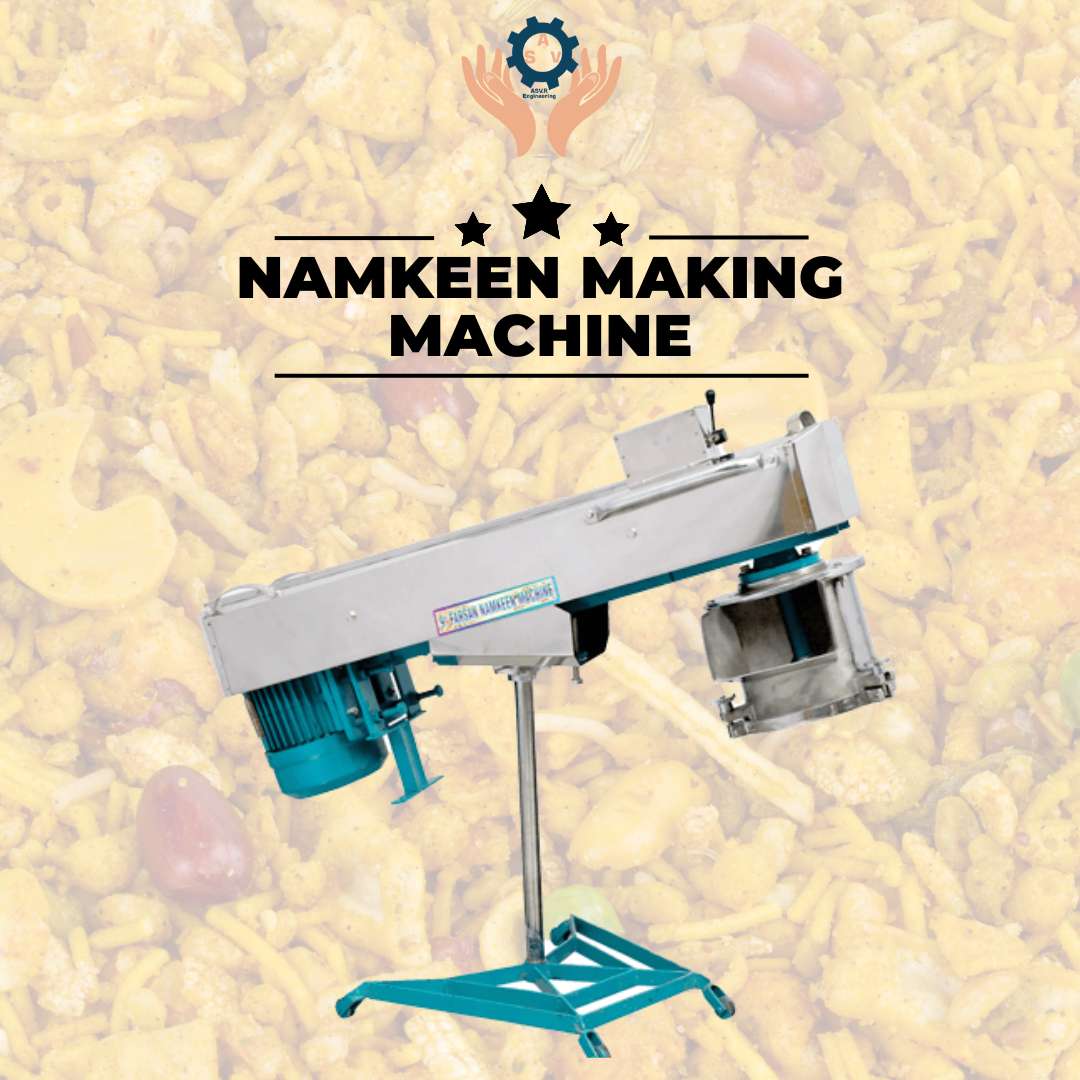

Semi automatic namkeen making machines are designed for manufacturers who seek higher output than manual methods while retaining flexibility and control. These machines reduce labor dependency, maintain uniformity in taste and texture, and significantly improve production efficiency.

Key reasons why semi automatic systems are preferred include:

-

Balanced automation that allows human supervision and customization

-

Lower investment cost compared to fully automatic lines

-

Easy operation and maintenance for operators with basic training

-

Consistent quality output across batches

-

Scalability for growing snack businesses

ASVR Engineering understands the operational challenges faced by namkeen manufacturers and designs machines that integrate seamlessly into existing production setups.

ASVR Engineering: A Name Synonymous with Reliability and Performance

ASVR Engineering has earned its reputation by delivering machinery that performs reliably even under demanding industrial conditions. As a dedicated exporter of namkeen making equipment, the company emphasizes precision engineering, food-grade materials, and compliance with international quality standards.

Core Strengths of ASVR Engineering

-

Proven expertise in snack food processing machinery

-

Export-oriented manufacturing standards

-

Customizable machine configurations

-

Strong after-sales support and technical guidance

-

Competitive pricing without quality compromise

Every machine exported by ASVR Engineering is built with the understanding that snack production is not just about volume—it is about taste consistency, hygiene, and long-term operational efficiency.

Comprehensive Range of Semi Automatic Namkeen Making Machines

ASVR Engineering offers a complete ecosystem of semi automatic machines required for setting up or upgrading a namkeen production plant. These machines can operate independently or as part of an integrated production line.

1. Dough Mixer and Preparation Units

Uniform dough preparation is the foundation of quality namkeen. ASVR Engineering’s mixers ensure even blending of ingredients, spices, and oil, resulting in consistent texture and flavor.

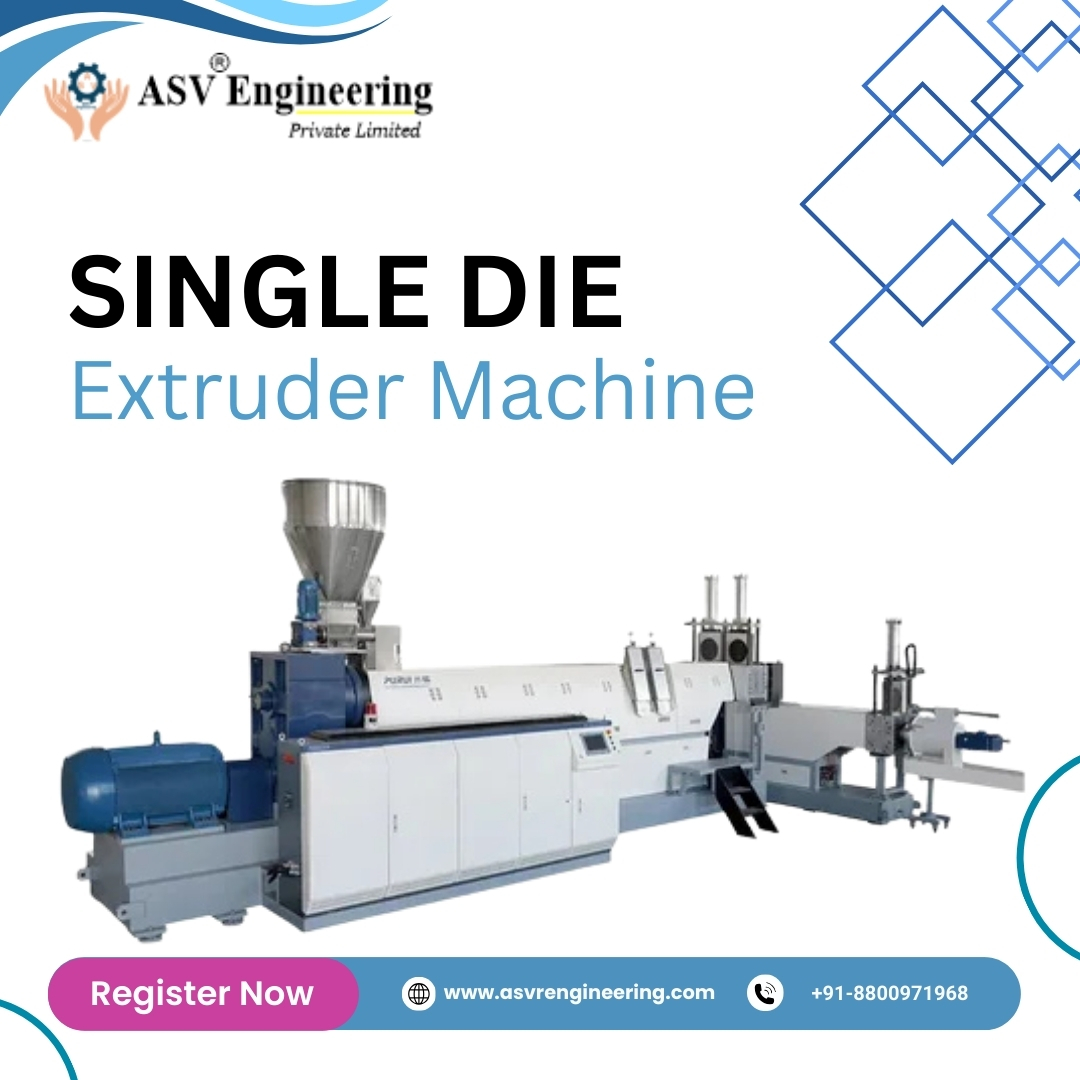

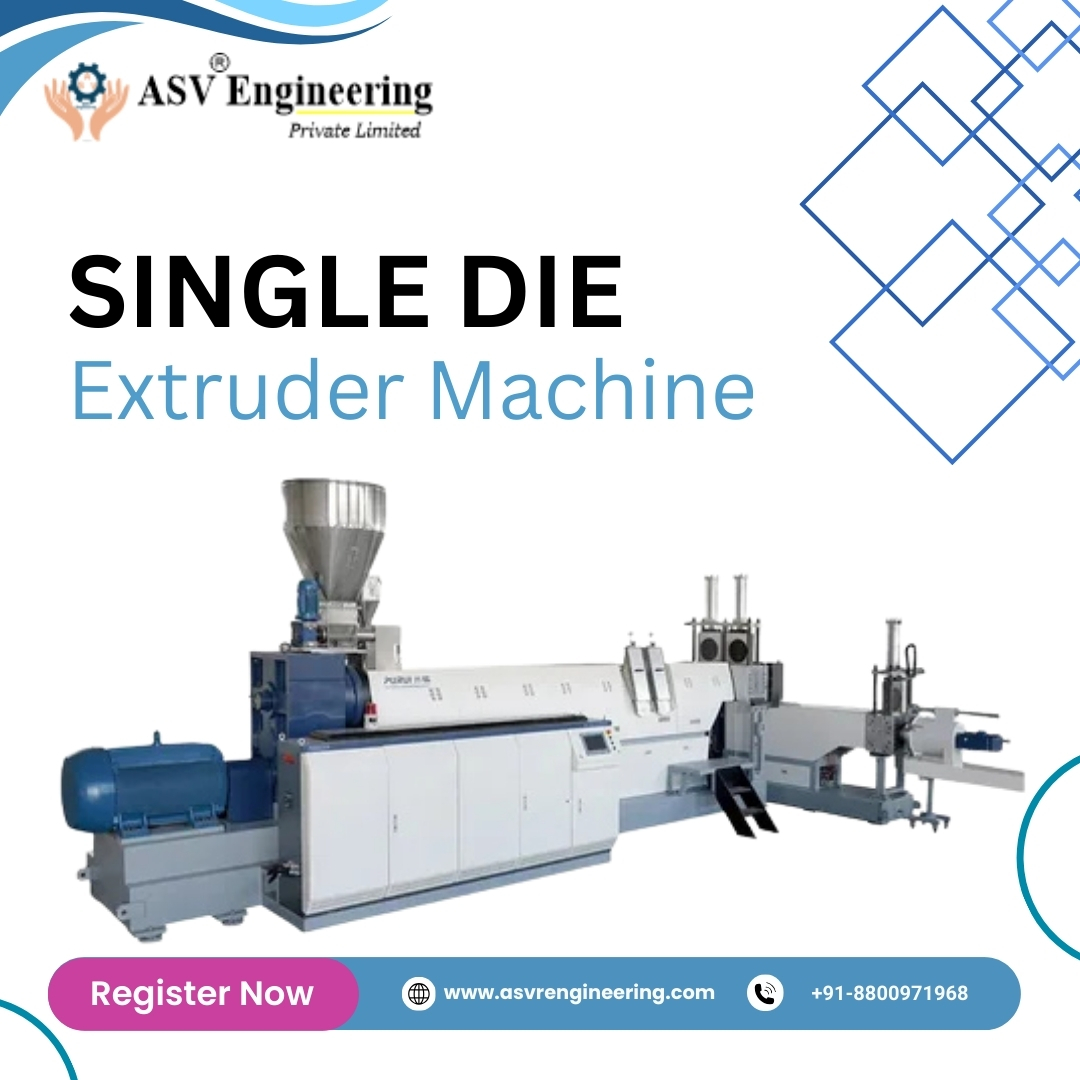

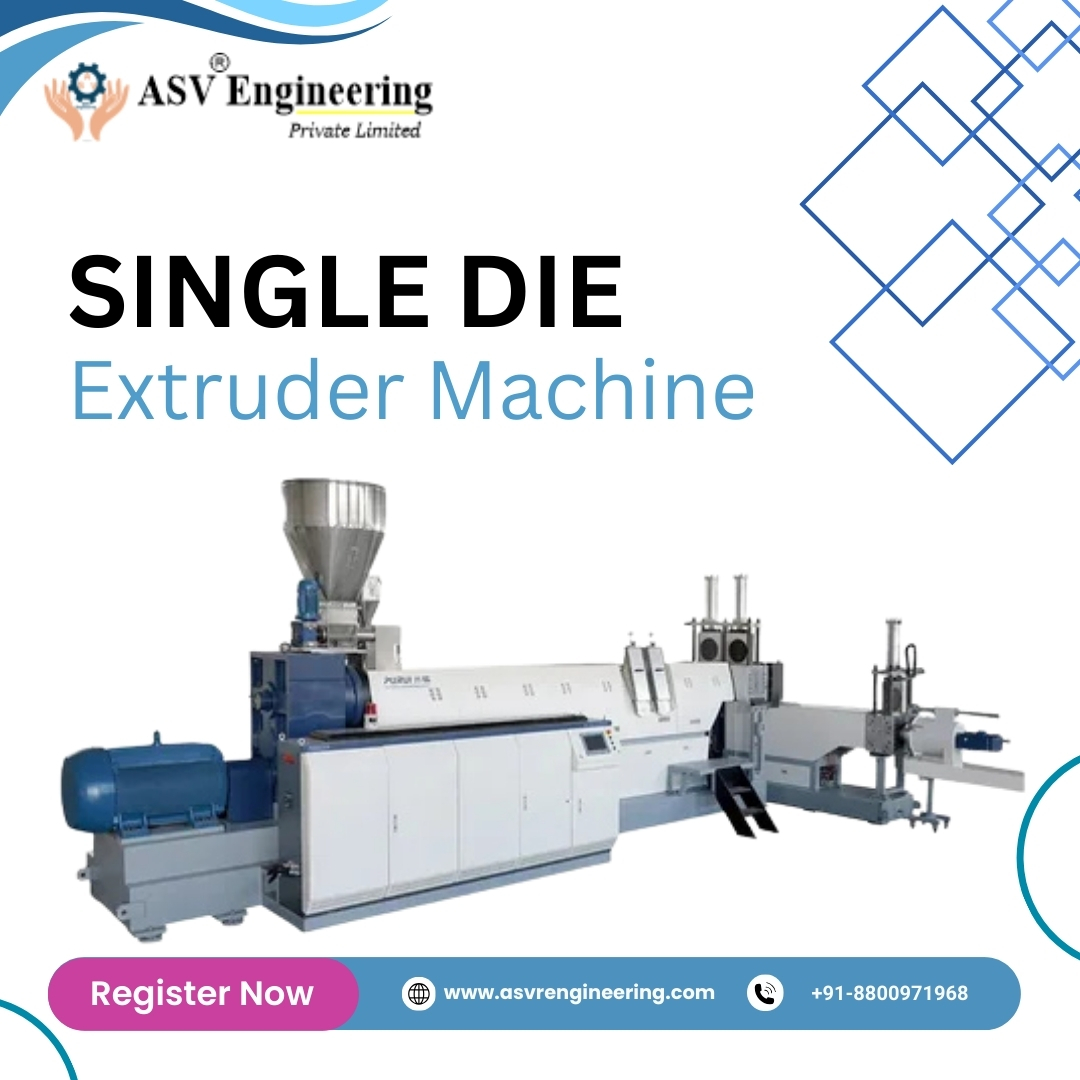

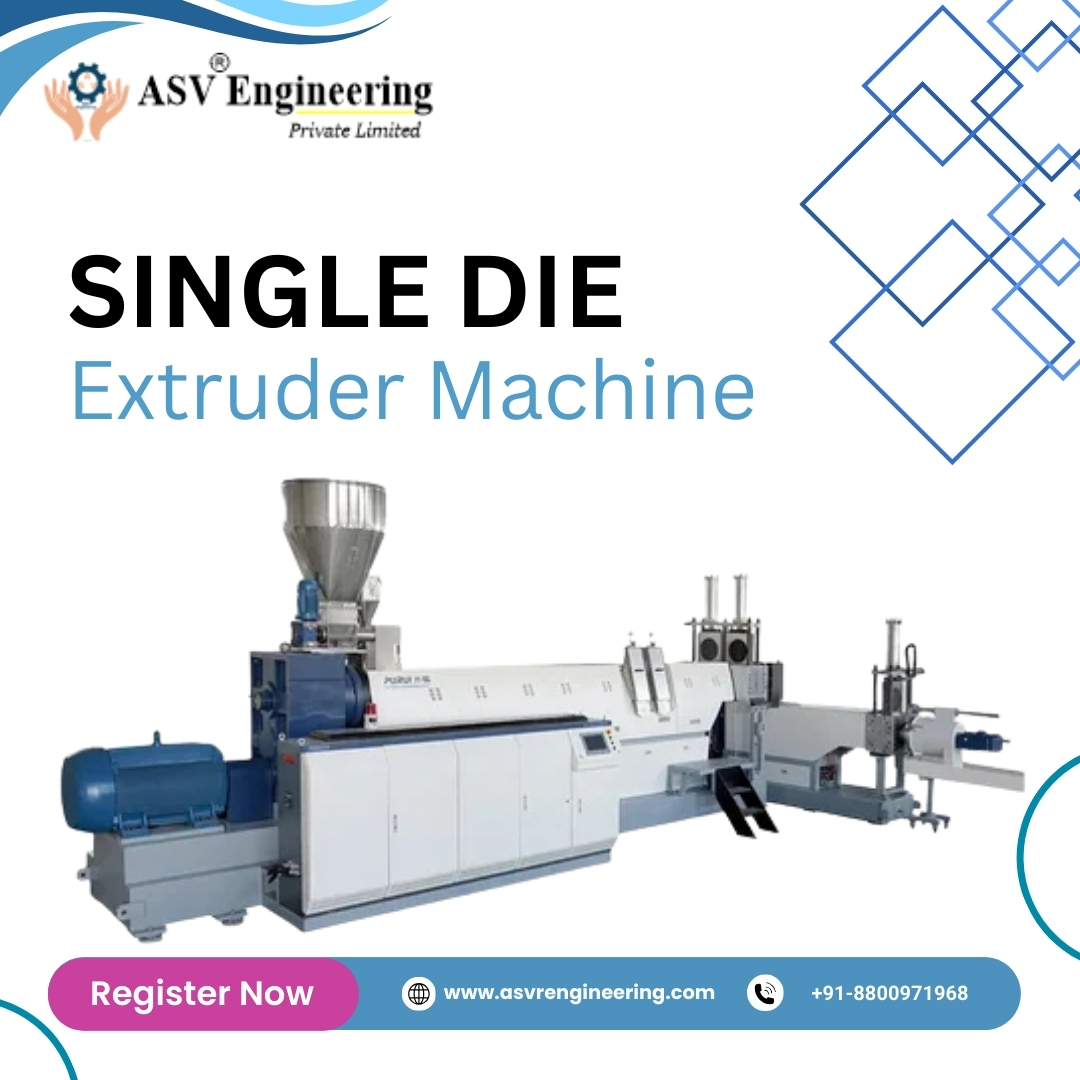

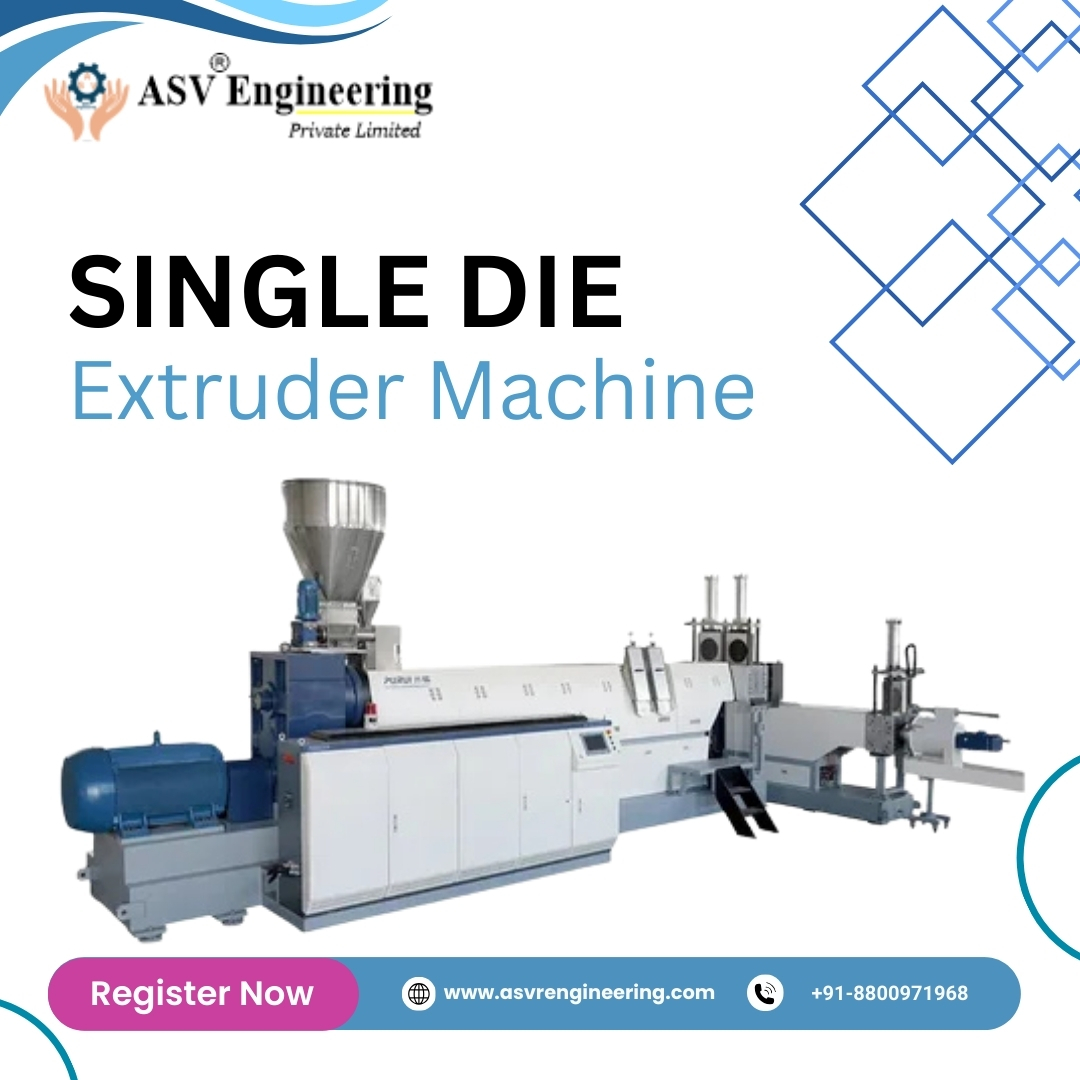

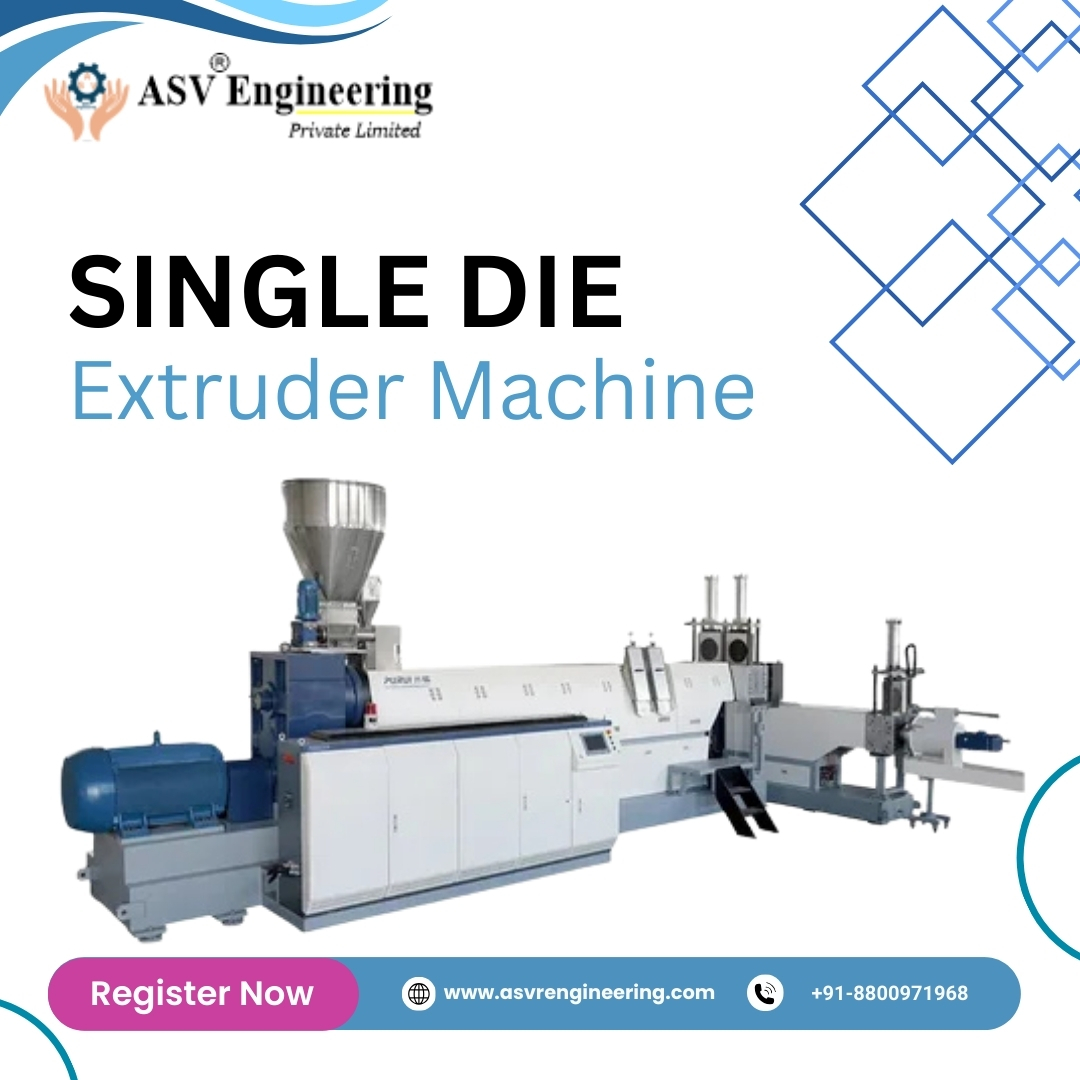

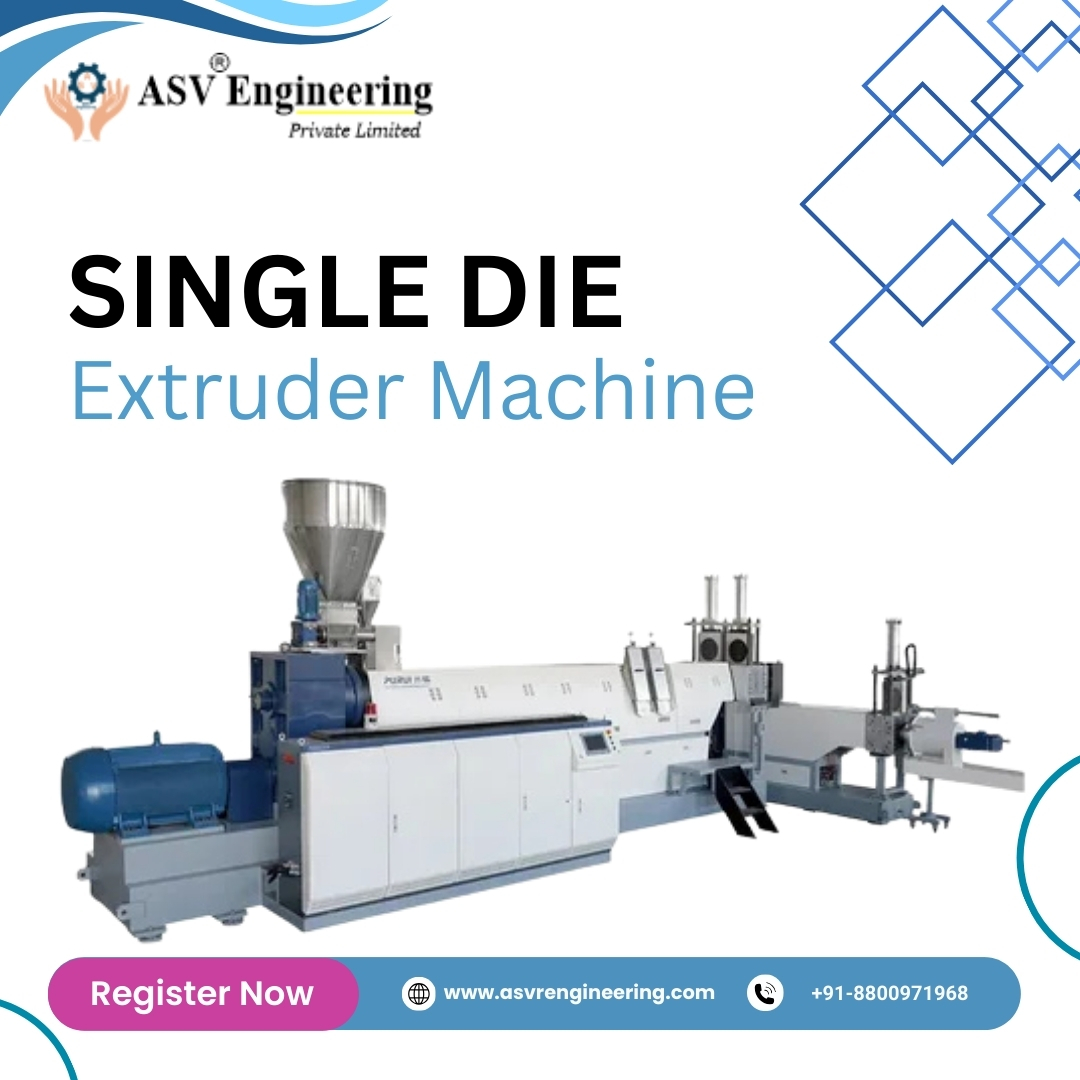

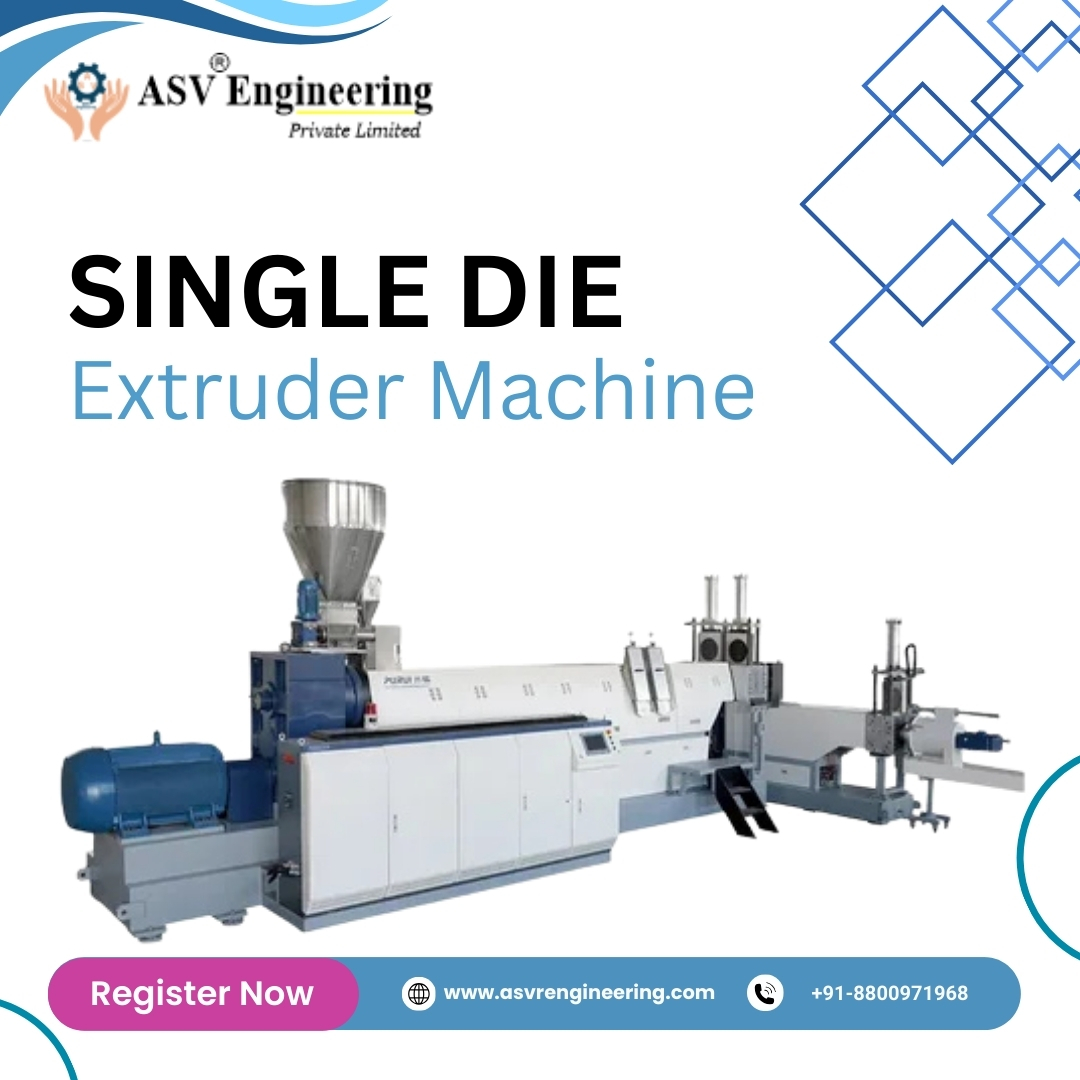

2. Namkeen Extrusion and Forming Machines

These machines shape namkeen into desired forms such as sev, bhujia, gathiya, or custom snack profiles. Precision dies and robust motors ensure uniform size and smooth output.

3. Frying Systems

Semi automatic fryers are designed for controlled temperature frying, ensuring crispness while preserving taste. Efficient oil circulation and heating mechanisms reduce oil wastage and enhance product quality.

4. De-Oiling and Cooling Conveyors

Excess oil removal is crucial for shelf life and health standards. ASVR Engineering’s de-oiling systems help achieve lighter, less greasy snacks.

5. Seasoning and Mixing Drums

Uniform seasoning enhances flavor consistency. Semi automatic seasoning drums evenly coat namkeen with spices, masala blends, or special flavor mixes.

Designed for Export: International Standards and Compliance

As trusted semi automatic namkeen making machine exporters, ASVR Engineering follows strict quality protocols to ensure machines meet global regulatory and operational standards.

-

Food-grade stainless steel construction

-

Hygienic design for easy cleaning

-

Energy-efficient motors and components

-

Compliance with export packaging norms

-

Machines suitable for different voltage and frequency requirements

These features make ASVR Engineering’s machines suitable for export to multiple regions, including the Middle East, Africa, South-East Asia, and beyond.

Customization for Diverse Snack Manufacturing Needs

Every snack brand has its own identity, taste profile, and production requirement. ASVR Engineering offers customization options to align machines with specific business goals.

Customization options include:

-

Output capacity variations

-

Product shape and size customization

-

Fryer type and oil capacity selection

-

Material upgrades based on regional regulations

-

Integration with existing plant layouts

This flexibility ensures that manufacturers receive machines that fit their production vision rather than forcing operations to adapt to rigid equipment.

Efficiency, Productivity, and Cost Control

One of the biggest advantages of choosing ASVR Engineering is the focus on operational efficiency. Semi automatic machines are engineered to deliver high output while keeping energy consumption and maintenance costs under control.

Operational Benefits

-

Reduced manpower requirements

-

Faster batch processing

-

Minimal product wastage

-

Lower downtime due to robust design

-

Long service life with consistent performance

These benefits directly translate into improved profitability for snack manufacturers.

Supporting Small and Medium Snack Entrepreneurs

ASVR Engineering understands that many namkeen businesses start small and gradually expand. Semi automatic namkeen making machines are ideal for startups and growing enterprises because they provide industrial-grade output without heavy capital investment.

For entrepreneurs, this means:

-

Faster break-even periods

-

Ability to test new snack varieties

-

Gradual scaling of production capacity

-

Improved brand consistency and customer trust

After-Sales Support and Technical Assistance

Exporting machinery is not just about delivery—it is about long-term partnership. ASVR Engineering offers reliable after-sales support, including:

-

Installation guidance

-

Operator training

-

Maintenance support

-

Spare parts availability

-

Technical troubleshooting assistance

This commitment ensures smooth operations even after the machines are installed overseas.

Why Global Buyers Choose ASVR Engineering

Global snack manufacturers prefer ASVR Engineering because of its transparent business practices, technical expertise, and customer-centric approach. The company combines Indian engineering excellence with export-ready quality standards, making it a preferred partner for namkeen production solutions.

Reasons to Choose ASVR Engineering:

-

Proven exporter of namkeen making machinery

-

High-efficiency semi automatic solutions

-

Competitive international pricing

-

Custom-engineered machines

-

Strong reputation for reliability

Conclusion: Your Trusted Partner in Namkeen Production Excellence

In a competitive snack food market, the right machinery partner can define long-term success. ASVR Engineering stands out as one of the most trusted semi automatic namkeen making machine exporters, offering solutions that empower manufacturers to produce high-quality snacks efficiently and profitably.

Whether you are setting up a new namkeen production plant or upgrading an existing facility, ASVR Engineering delivers machines that combine performance, durability, and value—helping your brand grow across local and international markets.

Company Contact Details

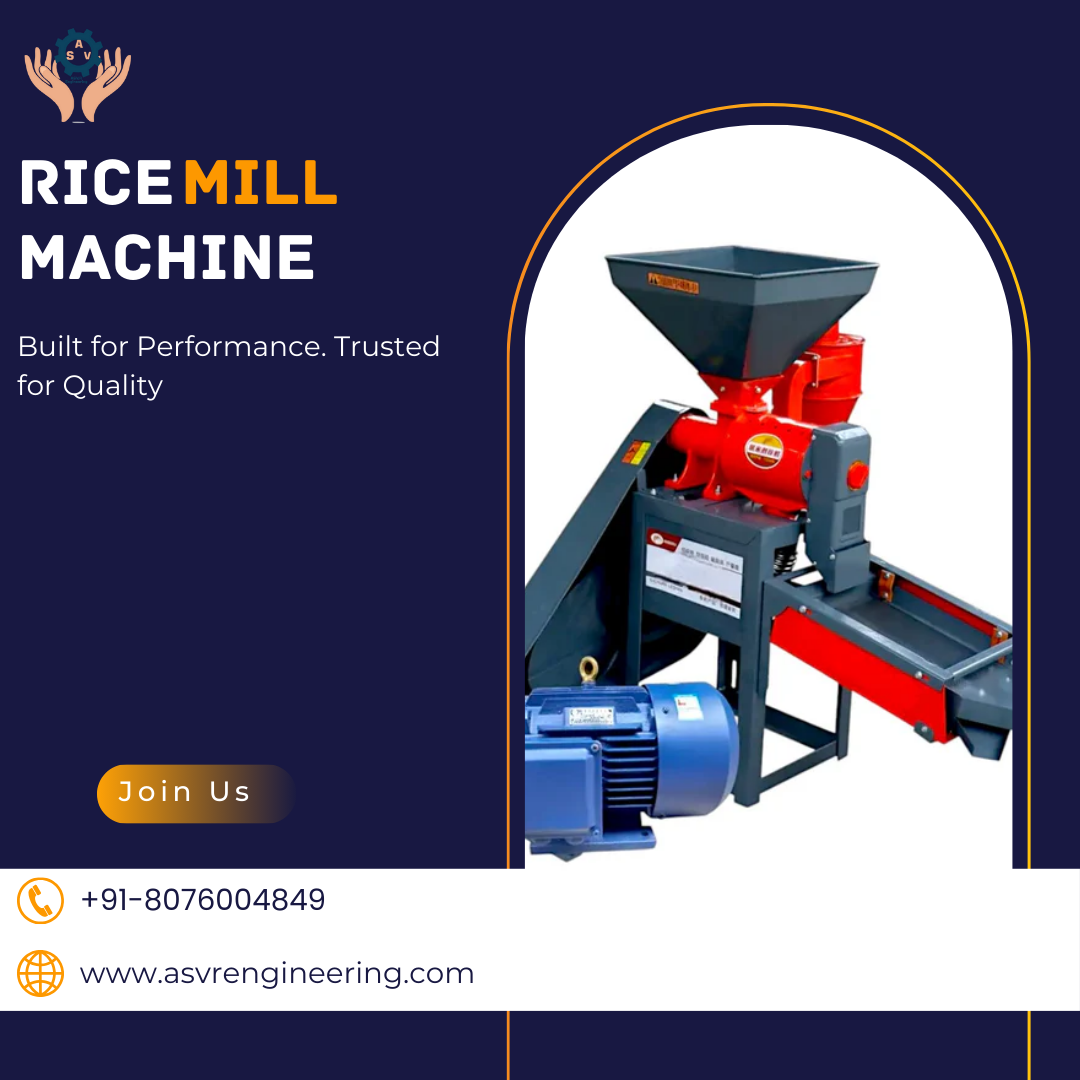

Company Name: ASVR Engineering

Website: https://www.asvrengineering.com

Contact Numbers: +91-8076004849, +91-8800971968

Buy Now

Related Posts

Trusted Automatic Namkeen Making Machine Importers Supplying Cost-Effective & Fully Automated Plants

(9).jpg)

(9).jpg)

(9).jpg)

(9).jpg)

(1).png)

(1).png)

(1).png)

(12).jpg)

(12).jpg)

(12).jpg)