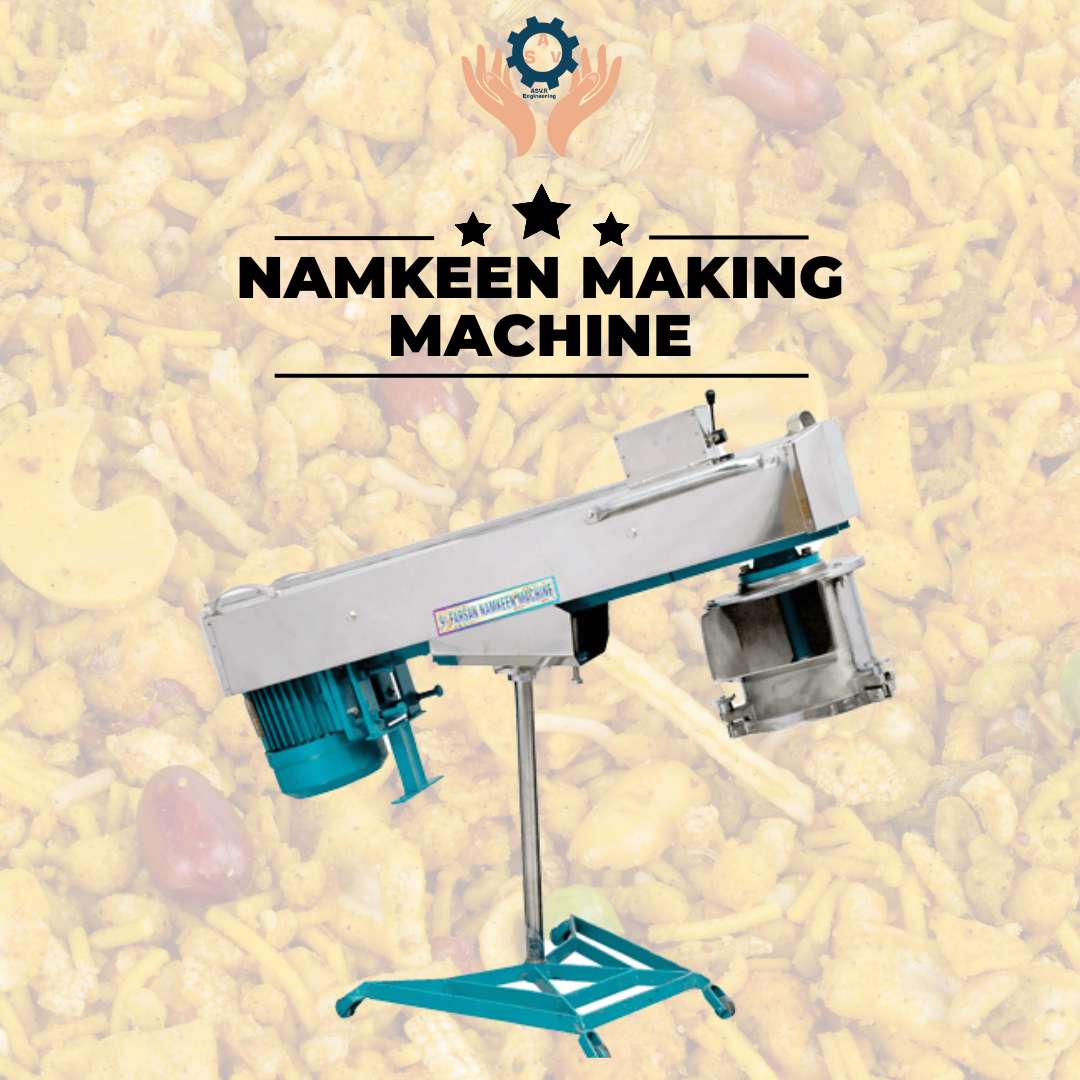

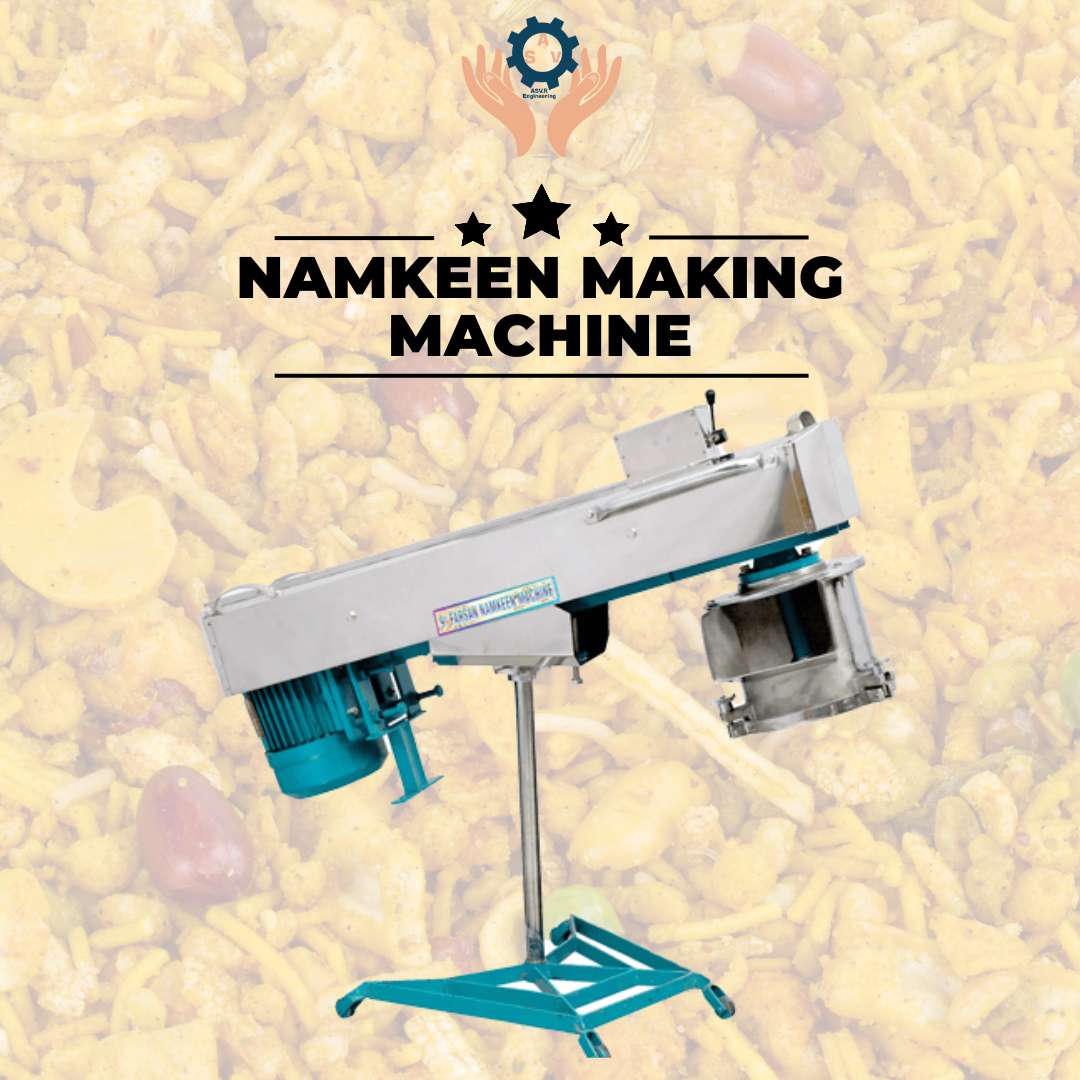

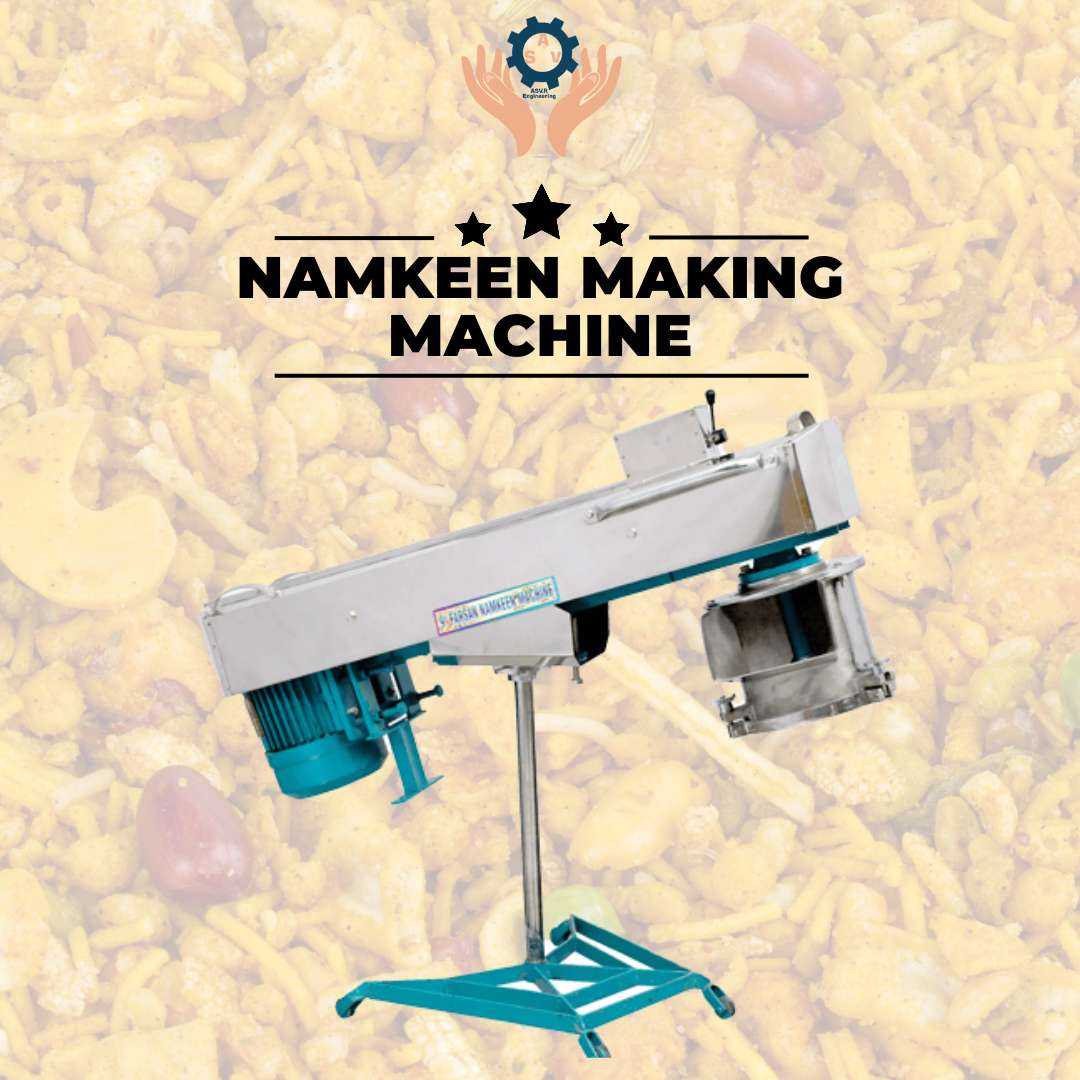

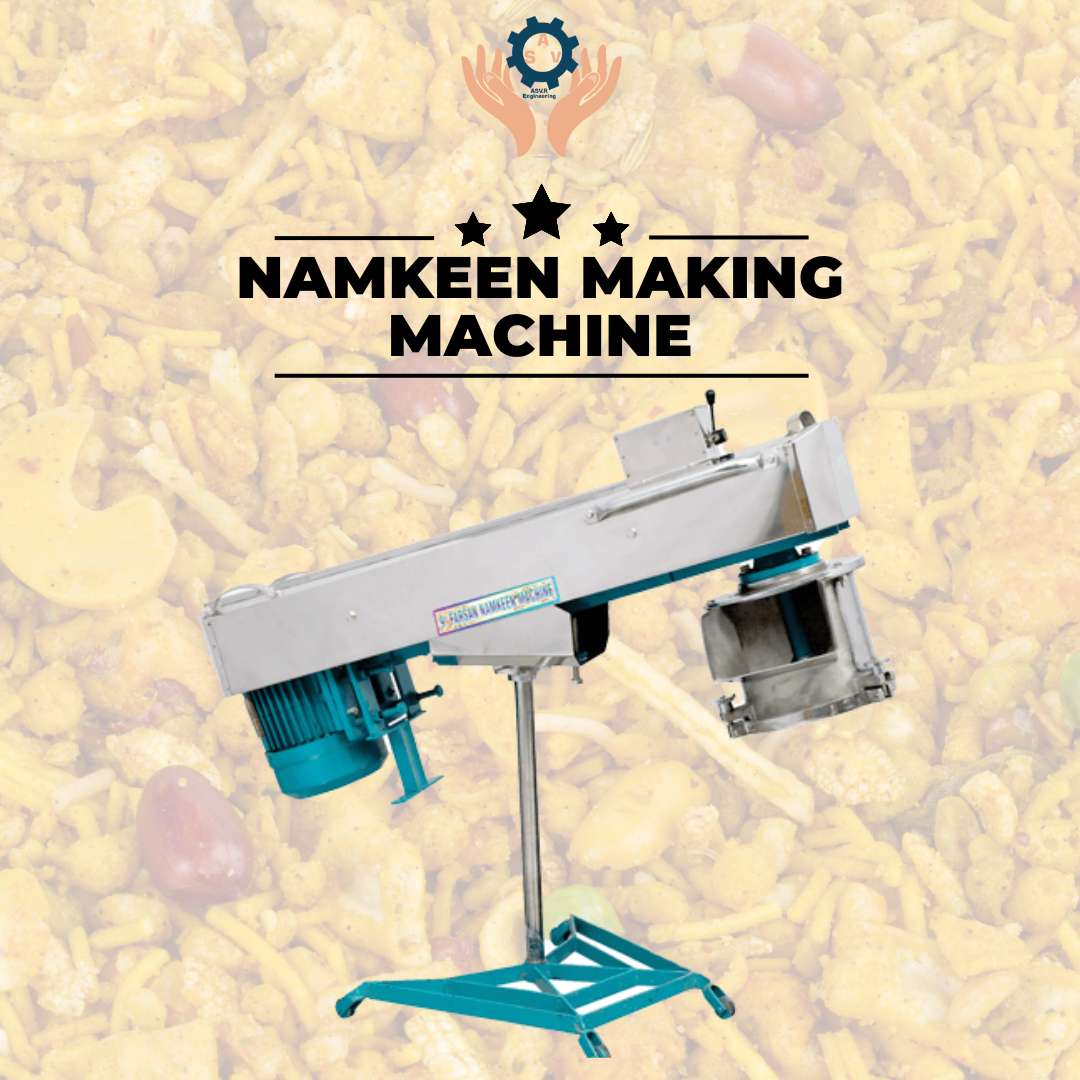

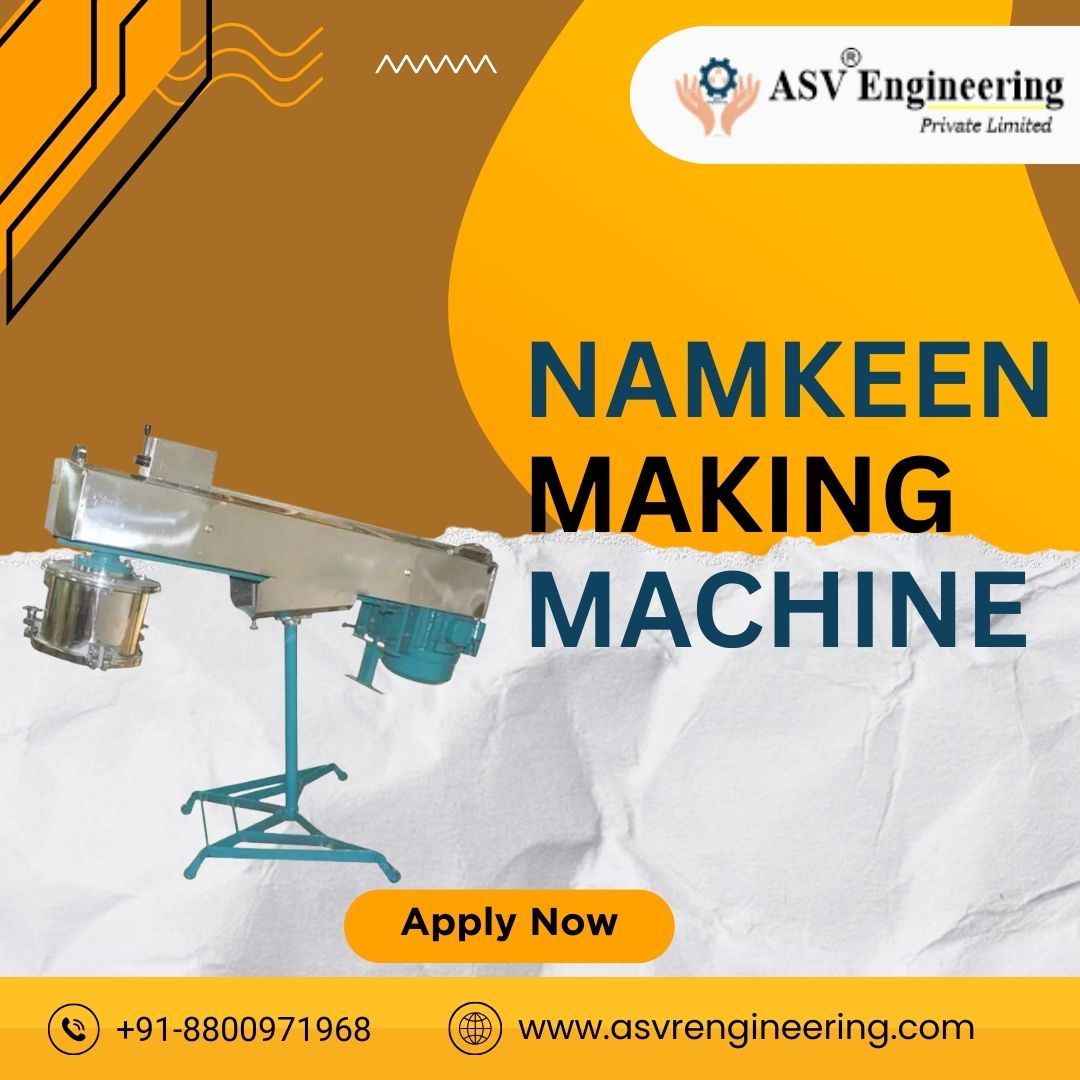

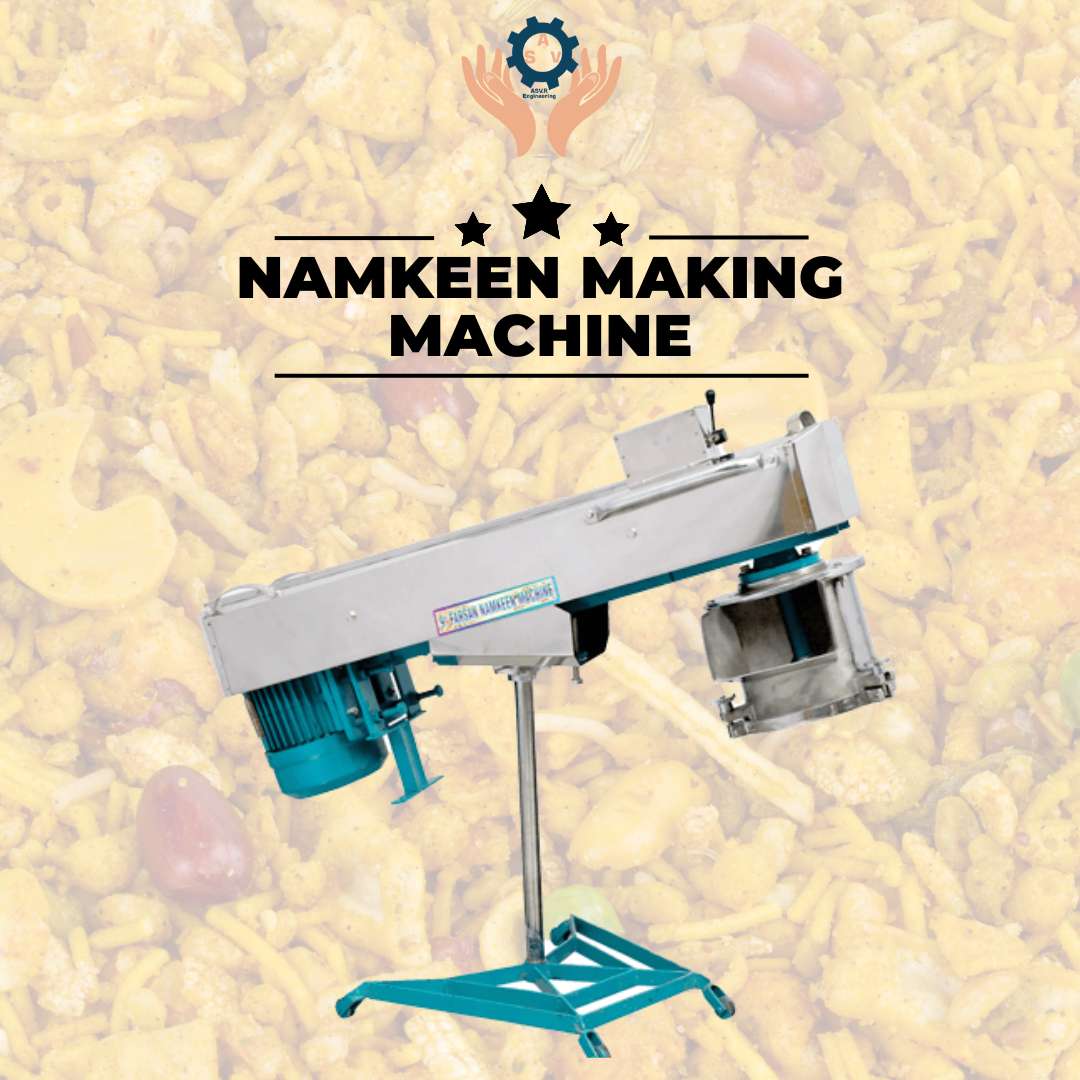

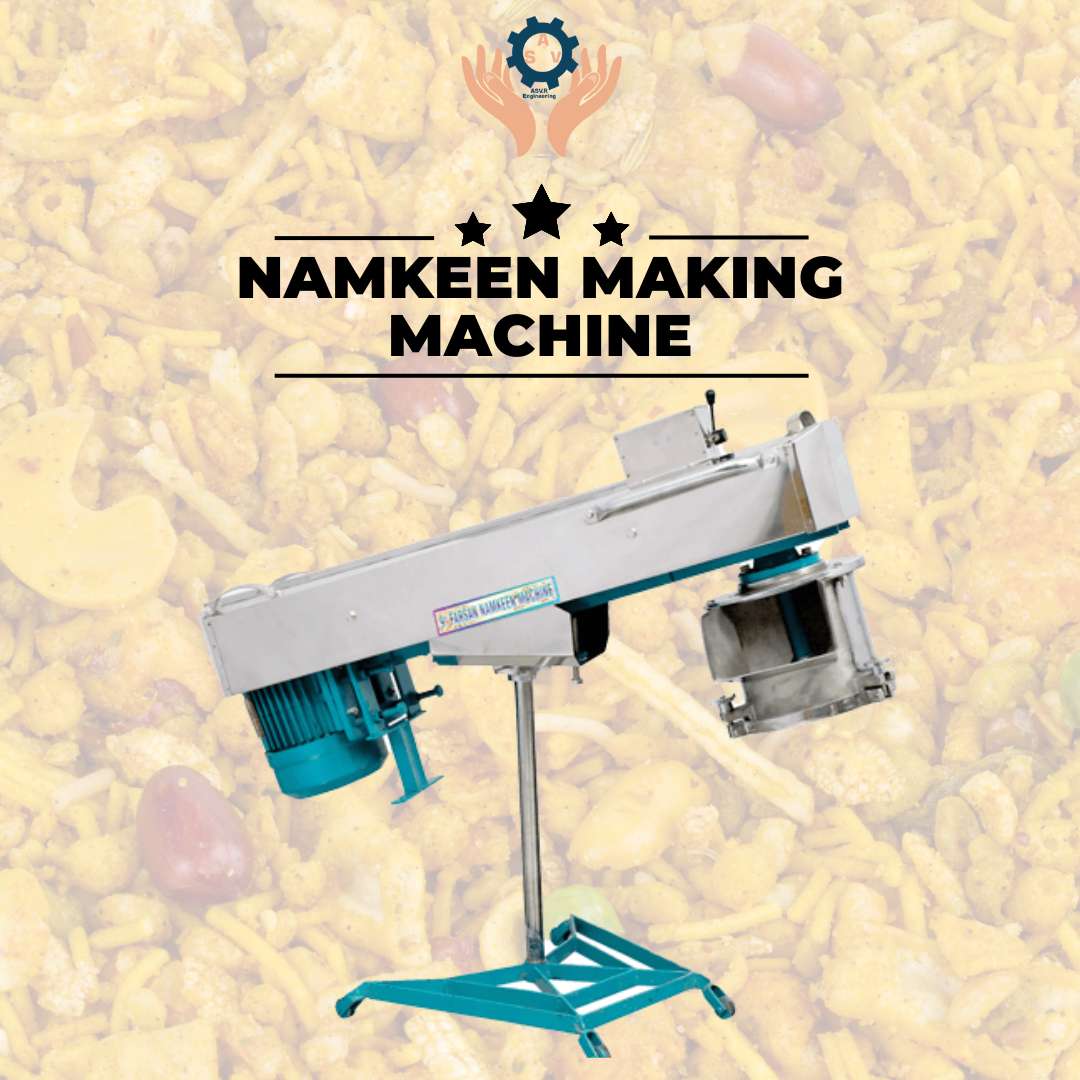

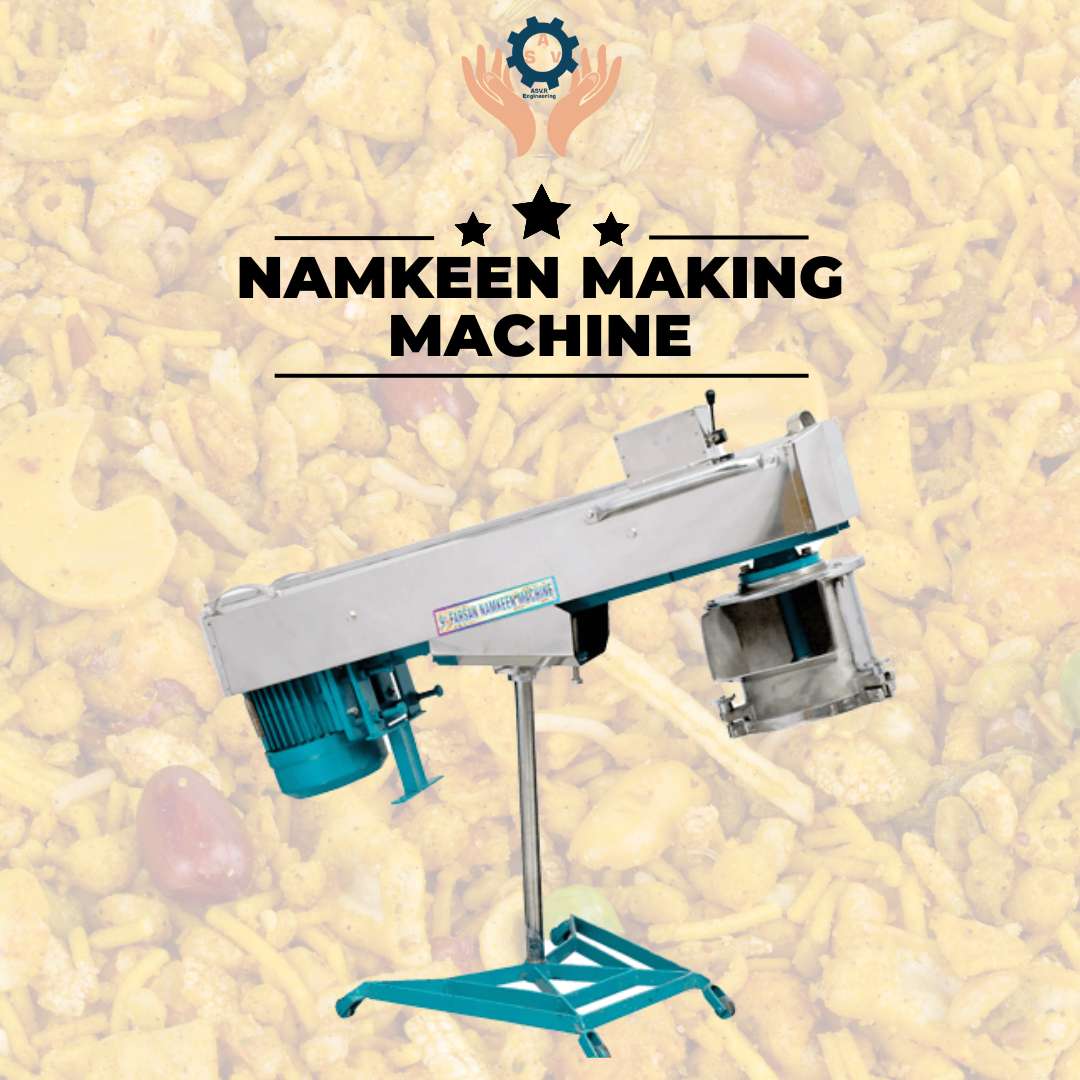

Automatic Namkeen Making Machine

Price: ₹42500

The Indian snack food industry is expanding rapidly, and namkeen has become one of the most consumed snacks across urban and rural markets. From small tea stalls to large retail chains, the demand for hygienically produced and consistently flavored namkeen is increasing every year. To meet this growing requirement, manufacturers are shifting from manual or semi-automatic methods to Automatic Namkeen Making Machines that ensure high output, uniform quality, and lower production costs.

An Automatic Namkeen Making Machine is a complete solution designed to handle the entire production process—from dough preparation and shaping to frying, seasoning, and cooling. These machines are ideal for businesses aiming to scale operations, maintain hygiene standards, and meet bulk market demand efficiently.

What is an Automatic Namkeen Making Machine?

An Automatic Namkeen Making Machine is an advanced food processing system engineered to produce a wide variety of namkeen products such as sev, bhujiya, aloo bhujia, gathiya, kurkure-type snacks, and other fried savory items. The machine integrates multiple stages of production into a continuous and automated workflow.

Unlike traditional setups that require extensive manual labor, this machine uses precision-controlled mechanisms to ensure consistency in size, texture, taste, and frying quality. It is widely used by commercial snack manufacturers, food processing units, and entrepreneurs planning to start a namkeen manufacturing business.

Key Components of an Automatic Namkeen Plant

A complete automatic namkeen plant generally includes the following components:

1. Dough Mixer

The process begins with a heavy-duty dough mixer that blends flour, spices, oil, and water uniformly. Consistent dough quality is essential for producing namkeen with the right texture and taste.

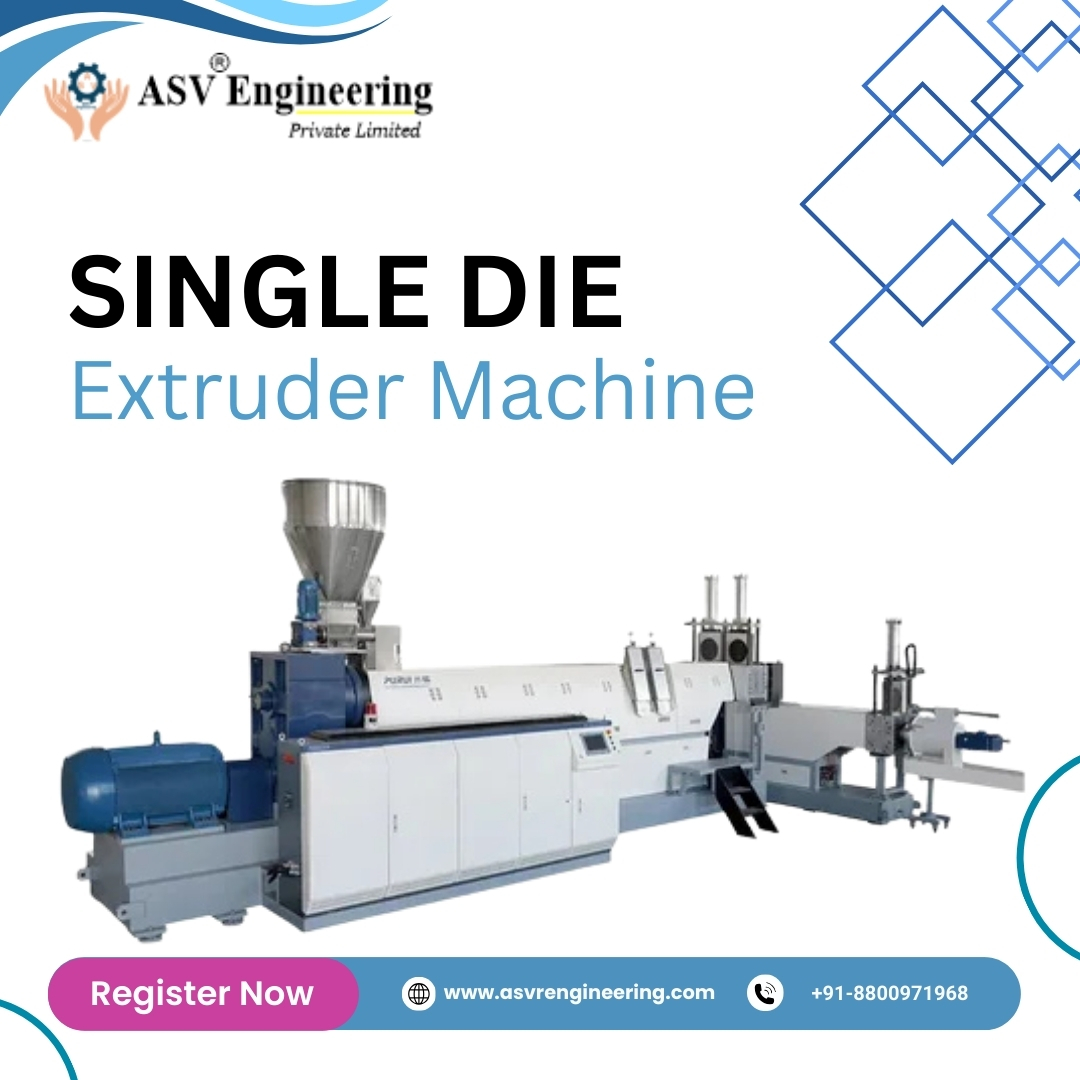

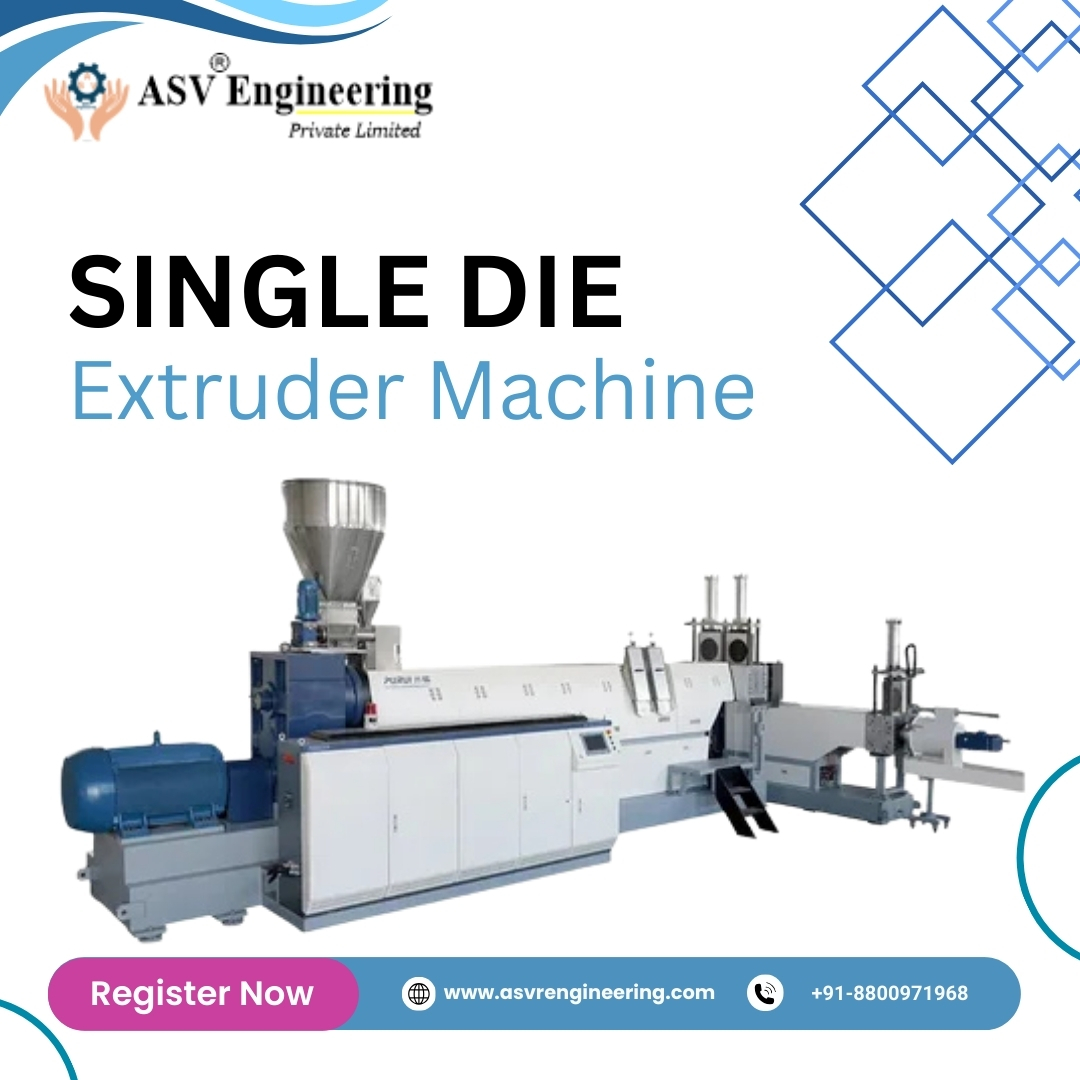

2. Extruder or Forming Machine

This unit shapes the dough into desired forms such as sev, sticks, or pellets. Interchangeable dies allow manufacturers to produce multiple namkeen varieties using the same machine.

3. Continuous Fryer System

The formed namkeen is automatically transferred to a continuous fryer where it is fried at controlled temperatures. This ensures even cooking, proper crispiness, and minimal oil absorption.

4. De-Oiling and Cooling Conveyor

After frying, excess oil is removed using centrifugal or conveyor-based de-oiling systems. The product is then cooled naturally or with forced air to maintain freshness.

5. Seasoning and Flavoring Drum

The namkeen is evenly coated with spices and flavoring agents in a rotating seasoning drum, ensuring uniform taste across every batch.

6. Control Panel and Automation System

PLC-based control panels allow operators to monitor temperature, speed, oil levels, and output, making the entire process efficient and user-friendly.

Types of Namkeen Products You Can Make

With an Automatic Namkeen Making Machine, manufacturers can produce a wide range of popular snacks, including:

-

Sev and Nylon Sev

-

Bhujiya and Aloo Bhujiya

-

Gathiya and Papdi Gathiya

-

Kurkure-type extruded snacks

-

Masala sticks and rings

-

Mixed namkeen blends

This versatility makes the machine a profitable investment for businesses targeting diverse consumer preferences.

Advantages of Using an Automatic Namkeen Making Machine

High Production Capacity

Automatic machines can produce large quantities of namkeen continuously, making them ideal for commercial-scale operations.

Consistent Quality

Uniform shaping, controlled frying, and precise seasoning ensure every batch meets the same quality standards.

Reduced Labor Cost

Automation minimizes dependency on skilled labor, significantly reducing operational expenses.

Improved Hygiene

Stainless steel construction and enclosed processing reduce contamination risks and comply with food safety standards.

Energy and Oil Efficiency

Modern machines are designed to optimize fuel and oil usage, lowering long-term production costs.

Why Choose Automatic Over Semi-Automatic Machines?

While semi-automatic namkeen machines may seem economical initially, automatic machines offer better long-term value. They provide higher output, lower wastage, and reduced human error. For businesses planning to scale or supply to wholesalers, supermarkets, and export markets, automatic namkeen plants are a smarter and more sustainable choice.

Applications and Market Demand

Automatic Namkeen Making Machines are widely used in:

-

Commercial namkeen manufacturing units

-

Food processing factories

-

FMCG snack brands

-

Startups entering the packaged snack segment

-

Export-oriented snack producers

With the rising demand for branded and hygienically packed snacks, investing in an automatic namkeen plant opens doors to significant growth opportunities.

Quality, Build, and Compliance

High-quality Automatic Namkeen Making Machines are manufactured using food-grade stainless steel, robust motors, and precision-engineered components. These machines are designed to operate continuously with minimal maintenance and comply with industry safety and hygiene norms.

About the Manufacturer

ASVR Engineering is a trusted name in the field of food processing machinery. Known for engineering excellence and reliable after-sales support, the company designs and supplies advanced automatic namkeen making machines tailored to the needs of Indian and international markets.

Their machines are built to deliver consistent performance, easy operation, and long service life, making them a preferred choice for snack manufacturers across India.

Installation, Training, and Support

A professional automatic namkeen machine supplier provides complete support, including:

-

On-site installation and commissioning

-

Operator training for smooth production

-

Technical guidance for recipe standardization

-

Prompt after-sales service and spare parts availability

This ensures that customers can start production quickly and operate the plant efficiently.

How to Choose the Right Automatic Namkeen Making Machine

Before investing, consider the following factors:

-

Desired production capacity (kg/hour)

-

Types of namkeen products to be manufactured

-

Available space and power supply

-

Budget and future expansion plans

-

After-sales service and technical support

Choosing the right configuration helps maximize returns and ensures smooth long-term operations.

Conclusion

An Automatic Namkeen Making Machine is an essential investment for businesses aiming to produce high-quality, hygienic, and consistent namkeen at a commercial scale. With growing consumer demand and increasing competition, automation is no longer optional—it is a necessity.

By investing in a reliable automatic namkeen plant, manufacturers can improve productivity, reduce costs, and build a strong brand presence in the competitive snack food market. Whether you are starting a new namkeen business or upgrading an existing unit, a fully automatic namkeen making machine offers the efficiency and scalability required for success.

Contact Details

Company Website: https://www.asvrengineering.com

Call Now: +91-8076004849, +91-8800971968

Buy Now

Related Posts

Trusted Automatic Namkeen Making Machine Importers Supplying Cost-Effective & Fully Automated Plants

(9).jpg)

(9).jpg)

(9).jpg)

(9).jpg)

(1).png)

(1).png)

(1).png)

(12).jpg)

(12).jpg)

(12).jpg)