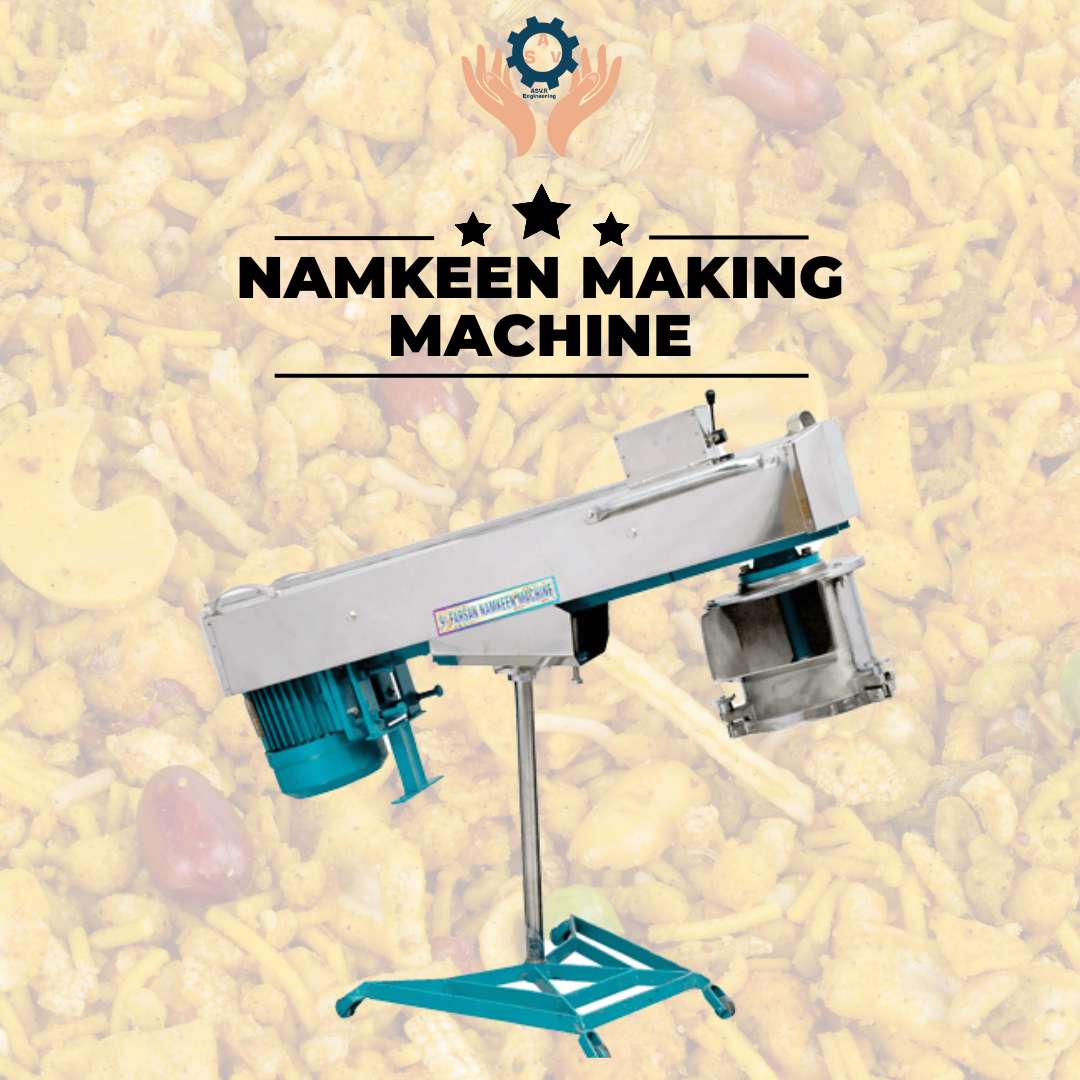

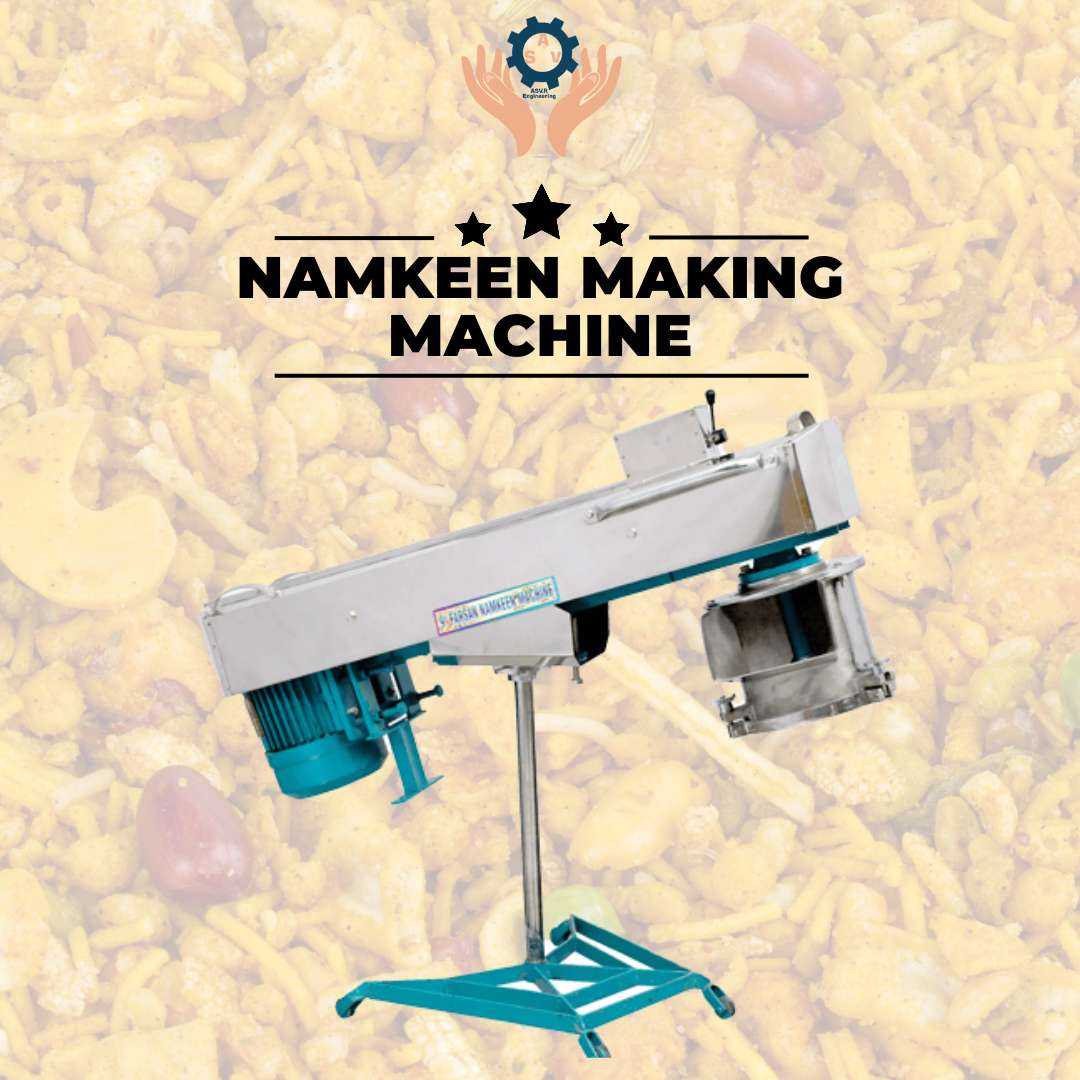

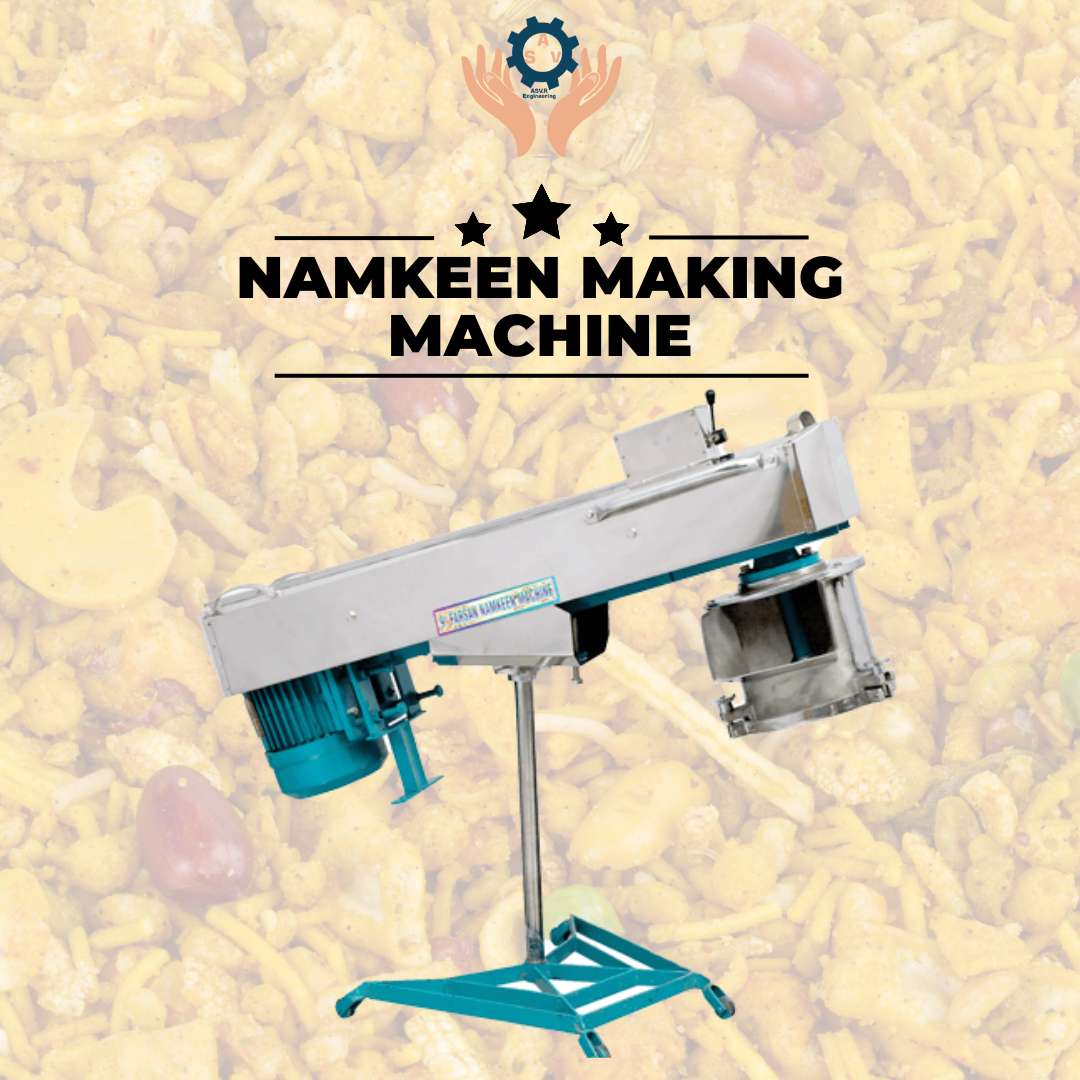

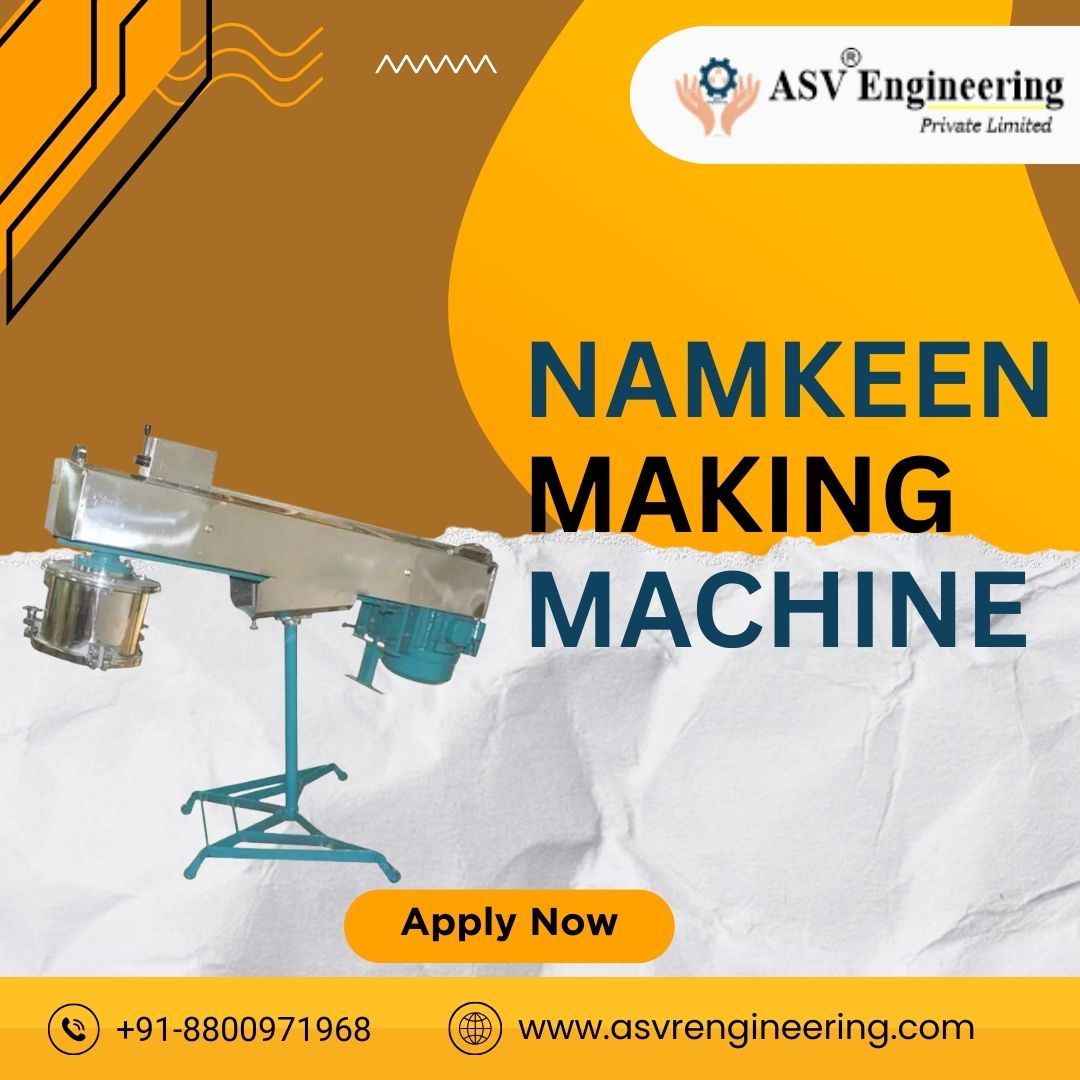

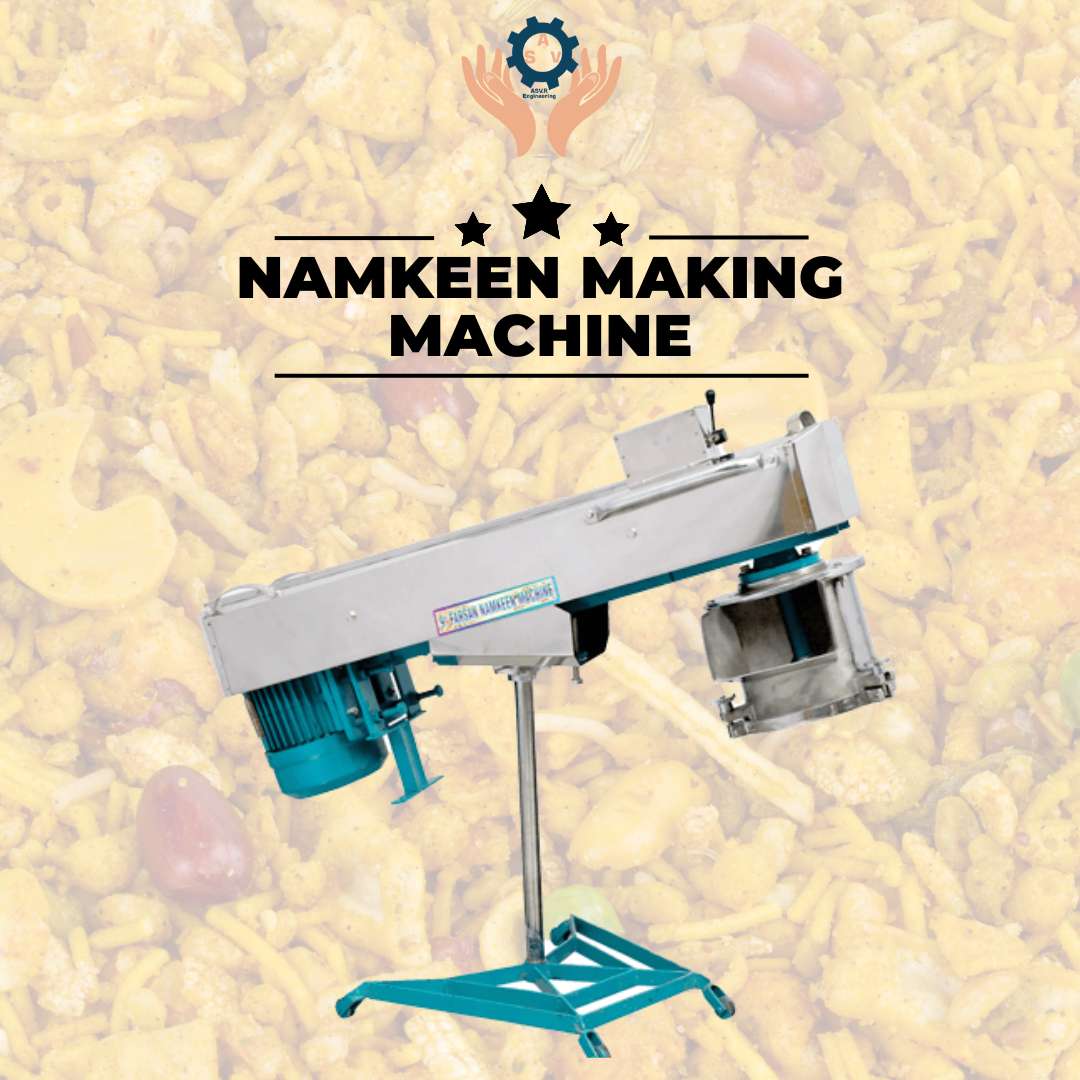

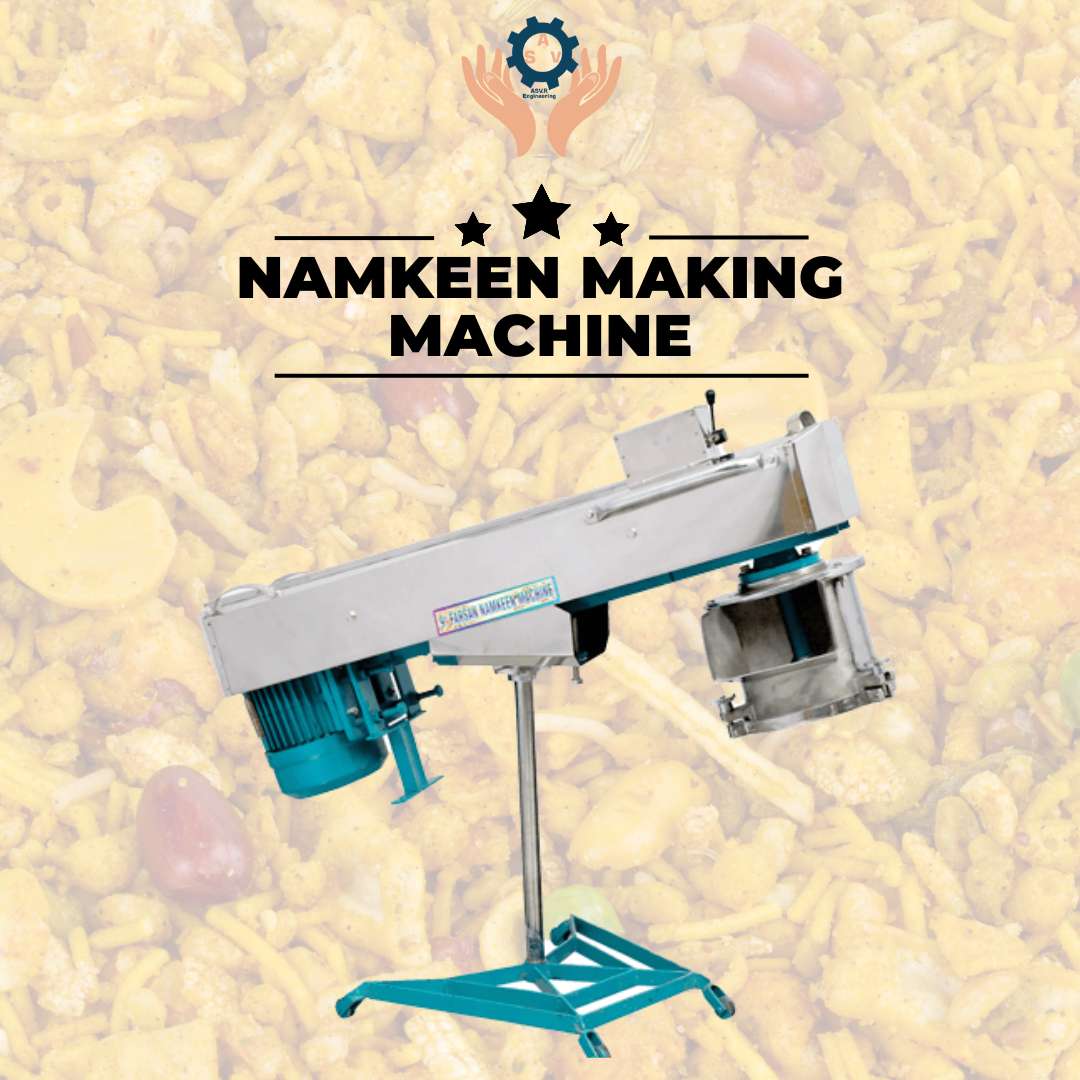

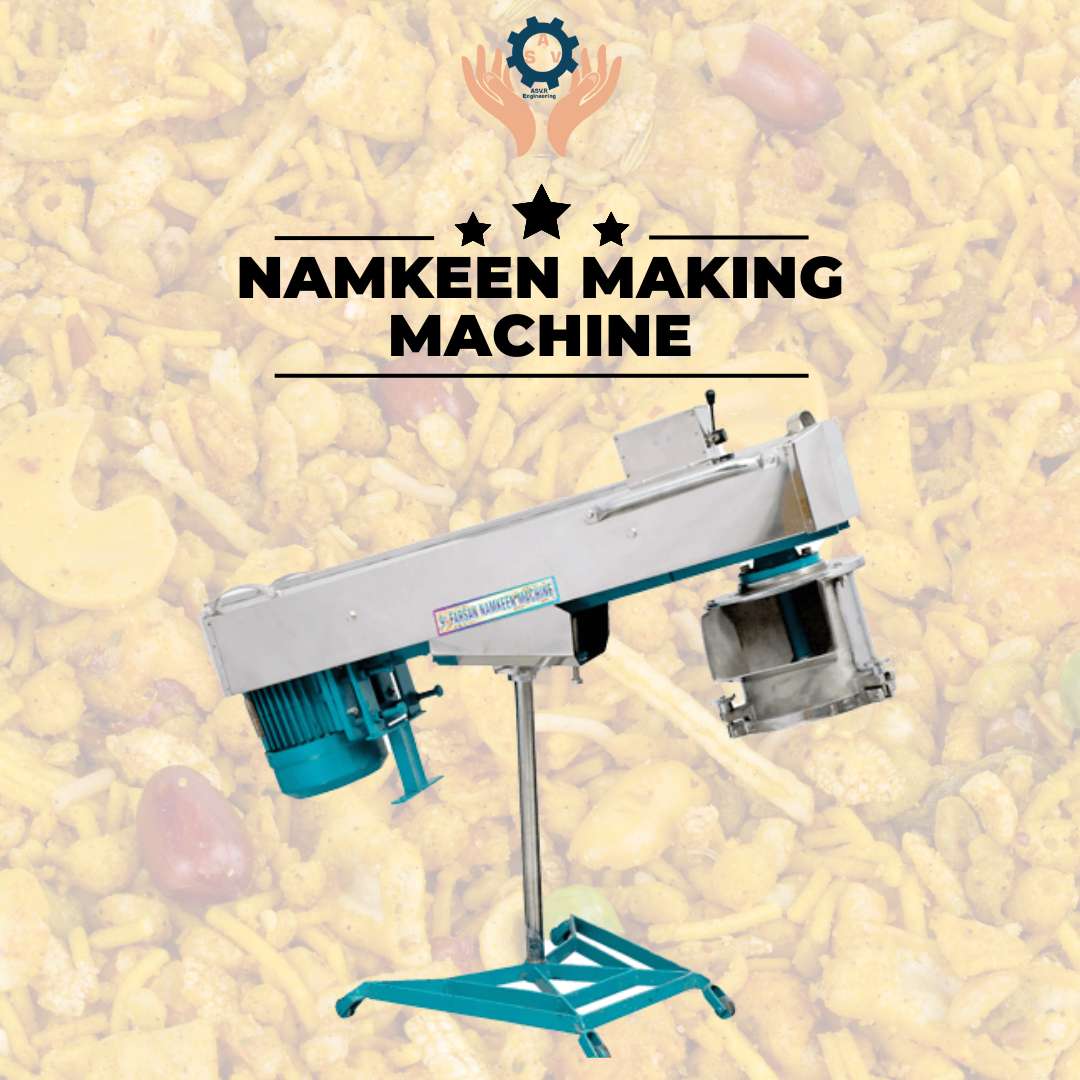

Trusted Automatic Namkeen Making Machine Exporters Offering High-Capacity & Energy-Efficient Plants

Price: ₹44500

In today’s competitive food processing industry, consistency, hygiene, speed, and cost efficiency decide the success of any namkeen manufacturing business. Traditional manual methods or semi-automatic setups are no longer sufficient to meet growing market demand, especially when customers expect uniform taste, texture, and quality in every pack. This is where trusted automatic namkeen making machine exporters play a crucial role by delivering high-capacity, energy-efficient, and fully automated namkeen production plants designed for modern snack manufacturers.

At ASVR Engineering, we understand the exact requirements of namkeen manufacturers in India and overseas markets. Our automatic namkeen making machines are engineered to deliver consistent output, reduce production costs, and maintain strict food safety standards. With years of experience in exporting advanced food processing machinery, we help businesses scale their operations confidently and profitably.

Growing Demand for Automatic Namkeen Making Machines

Namkeen is no longer limited to local sweet shops or regional markets. With the rise of organized retail, e-commerce grocery platforms, and global demand for Indian snacks, manufacturers must increase capacity without compromising quality. Automatic namkeen making machines allow producers to move from labor-intensive processes to streamlined production lines that ensure:

-

Uniform taste and texture

-

Higher daily output

-

Reduced dependency on skilled labor

-

Better hygiene and food safety compliance

-

Lower energy consumption per kilogram of production

High-capacity namkeen plants are especially beneficial for exporters and large-scale snack brands aiming to supply supermarkets, distributors, and international buyers.

What Makes Our Automatic Namkeen Making Plants Reliable?

As trusted exporters, our focus goes beyond just selling machines. We design complete solutions that align with your production goals, budget, and space availability. Each automatic namkeen making plant is built using premium-grade stainless steel and advanced automation technology to ensure long service life and low maintenance.

1. High-Capacity Production Design

Our machines are capable of handling large volumes of raw material, making them ideal for medium to large-scale namkeen manufacturers. Whether you produce sev, bhujia, gathiya, mixture, or customized snack varieties, the plant can be configured to match your product range.

2. Energy-Efficient Operation

Energy cost is one of the biggest concerns in continuous food processing. Our energy-efficient namkeen making machines are designed with optimized heating systems, efficient motors, and controlled oil circulation, reducing electricity and fuel consumption without affecting output quality.

3. Fully Automatic Workflow

From dough preparation to shaping, frying, seasoning, and cooling, the entire process is automated. This minimizes human intervention, reduces errors, and ensures consistent results in every batch.

Complete Namkeen Manufacturing Process Explained

Understanding the process helps manufacturers appreciate the value of automation. A typical automatic namkeen making plant includes the following stages:

Dough Mixing & Feeding:

Raw materials such as gram flour, spices, and additives are mixed uniformly in an automatic mixer. The prepared dough is then transferred to the forming section.

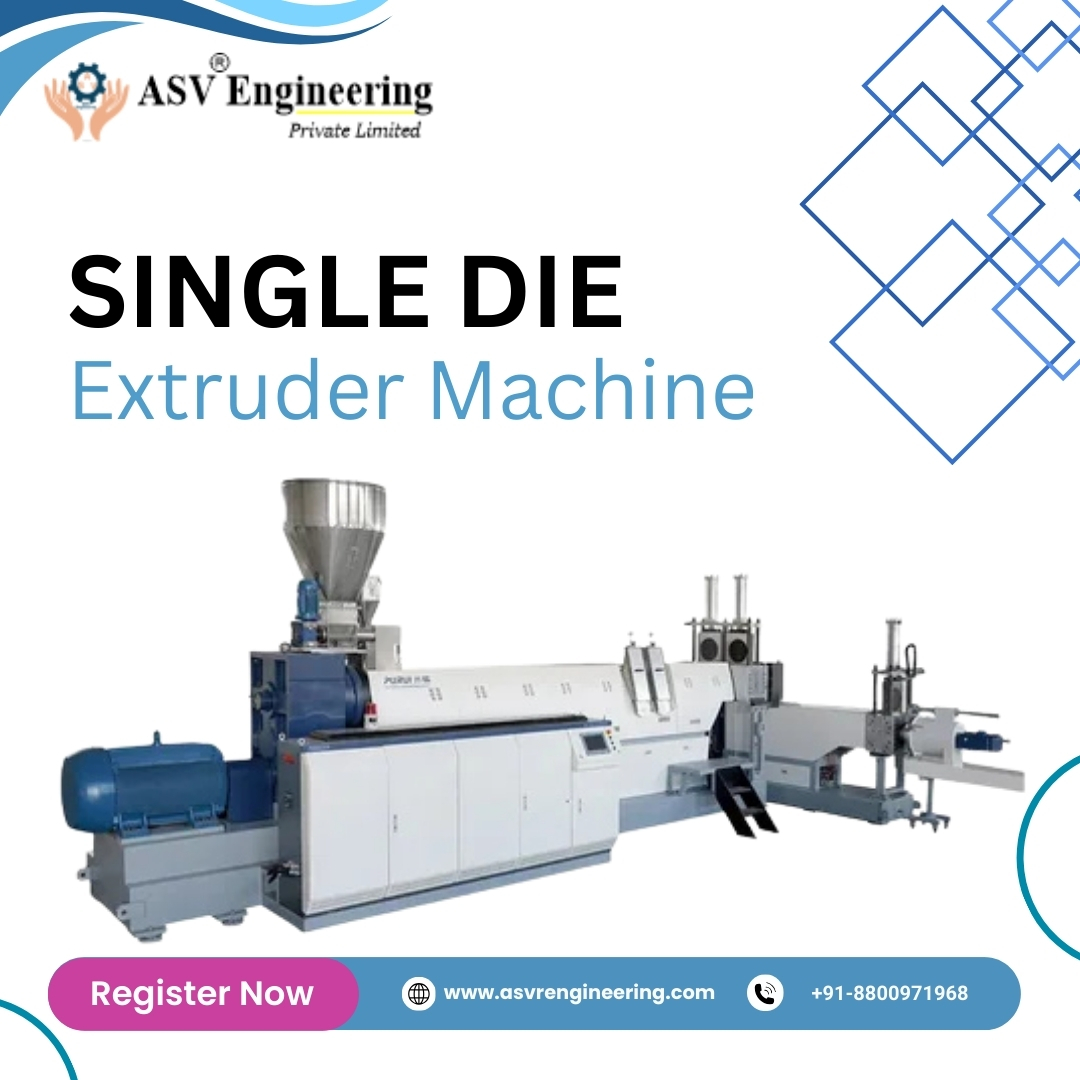

Shaping & Extrusion:

Different dies and molds are used to produce various namkeen shapes like sev, sticks, or flat snacks. The precision of the machine ensures uniform thickness and size.

Continuous Frying System:

The shaped namkeen passes through a continuous fryer with controlled temperature settings. This ensures even frying, better oil absorption control, and consistent crispness.

De-Oiling & Cooling:

Excess oil is removed using vibrating or centrifugal systems, followed by cooling conveyors to bring the product to room temperature before seasoning.

Seasoning & Packing Readiness:

Automatic seasoning systems evenly coat spices, making the namkeen flavorful and ready for packing or further processing.

Why Export-Quality Standards Matter

When choosing an automatic namkeen making machine exporter, quality standards are critical. Export-grade machines must meet international norms for safety, hygiene, and performance. Our machines are designed to comply with global food processing standards, making them suitable for domestic use as well as international exports.

Key export-focused features include:

-

Food-grade stainless steel construction

-

Robust electrical and control systems

-

Easy cleaning and maintenance design

-

Long operational life under continuous usage

These features ensure smooth customs clearance and acceptance in international markets.

Benefits for Namkeen Manufacturers & Exporters

Investing in a high-capacity automatic namkeen making plant offers long-term advantages:

-

Scalability: Easily increase production to meet seasonal or export demand

-

Consistency: Same taste and quality across all batches

-

Cost Reduction: Lower labor and energy costs

-

Brand Value: Uniform product quality strengthens brand reputation

-

Faster ROI: Higher output and reduced wastage lead to quicker returns

For businesses planning to expand globally, automation is no longer optional—it is essential.

Customization Options for Different Business Needs

Every namkeen business is unique. Small manufacturers may need compact plants, while large exporters require heavy-duty systems with continuous operation capability. As experienced exporters, we offer customization in:

-

Production capacity (kg/hour)

-

Type of namkeen products

-

Fuel options (electric, gas, diesel)

-

Automation level

-

Plant layout and space optimization

This ensures you get a solution that perfectly fits your production goals and budget.

After-Sales Support & Technical Assistance

A machine is only as good as the support behind it. We provide complete technical guidance, installation support, and operational training to ensure smooth commissioning. Our responsive after-sales service helps minimize downtime and keeps your production running efficiently.

Why Choose ASVR Engineering?

Choosing the right exporter directly impacts your business growth. With a strong focus on quality, performance, and customer satisfaction, ASVR Engineering has built a reputation for delivering reliable namkeen making machines to clients across India and abroad.

Key reasons to choose us:

-

Proven expertise in food processing machinery

-

Export-ready automatic namkeen plants

-

Competitive pricing with uncompromised quality

-

Customized solutions for diverse markets

-

Dedicated technical and after-sales support

Contact Us for Automatic Namkeen Making Machines

If you are planning to start or expand a namkeen manufacturing unit, now is the right time to invest in advanced automation. Our high-capacity and energy-efficient namkeen making plants are designed to help you grow faster, reduce costs, and meet market demand confidently.

📞 Contact Numbers: +91-8076004849, +91-8800971968

🌐 Website: https://www.asvrengineering.com

Buy Now

Related Posts

Trusted Automatic Namkeen Making Machine Importers Supplying Cost-Effective & Fully Automated Plants

(9).jpg)

(9).jpg)

(9).jpg)

(9).jpg)

(1).png)

(1).png)

(1).png)

(12).jpg)

(12).jpg)

(12).jpg)