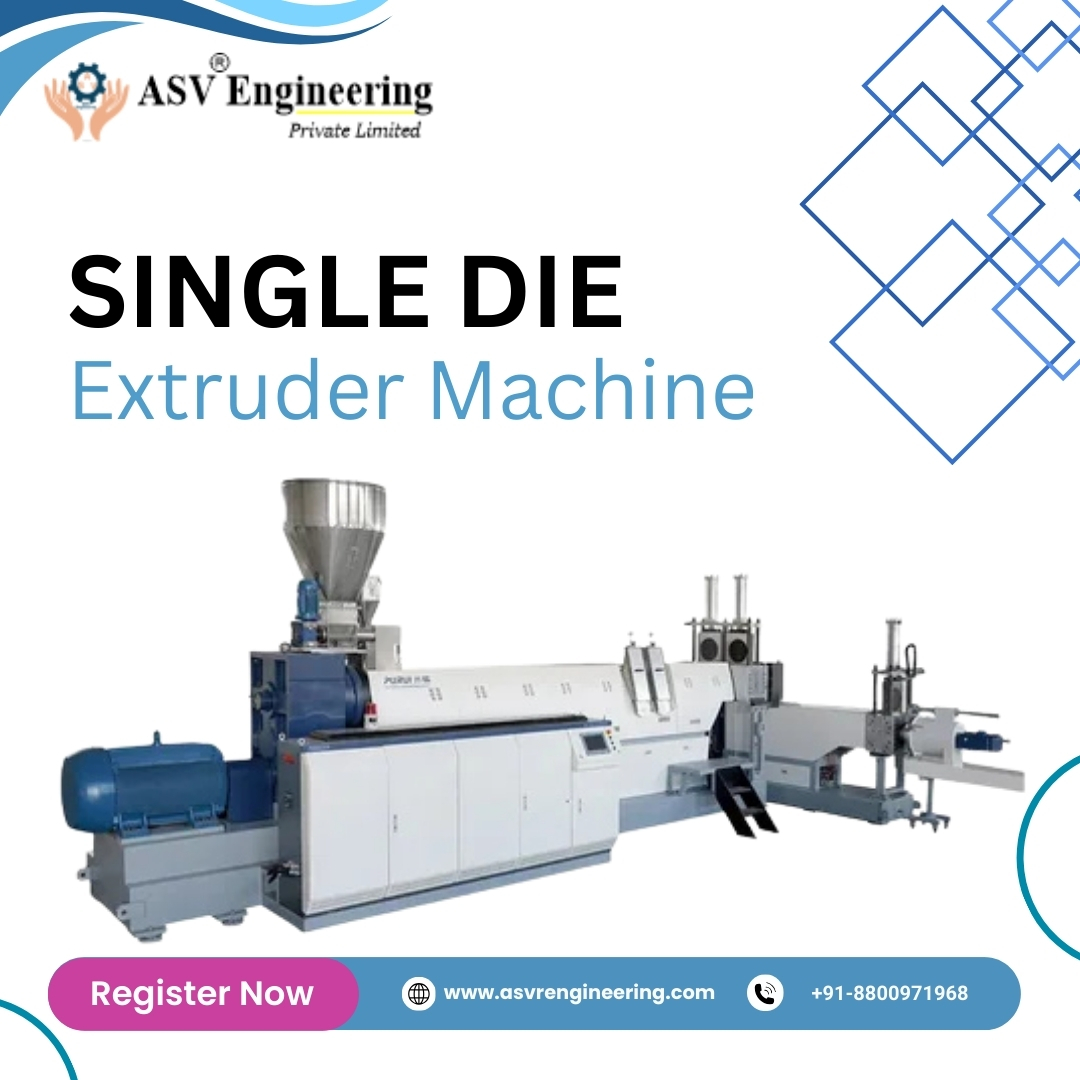

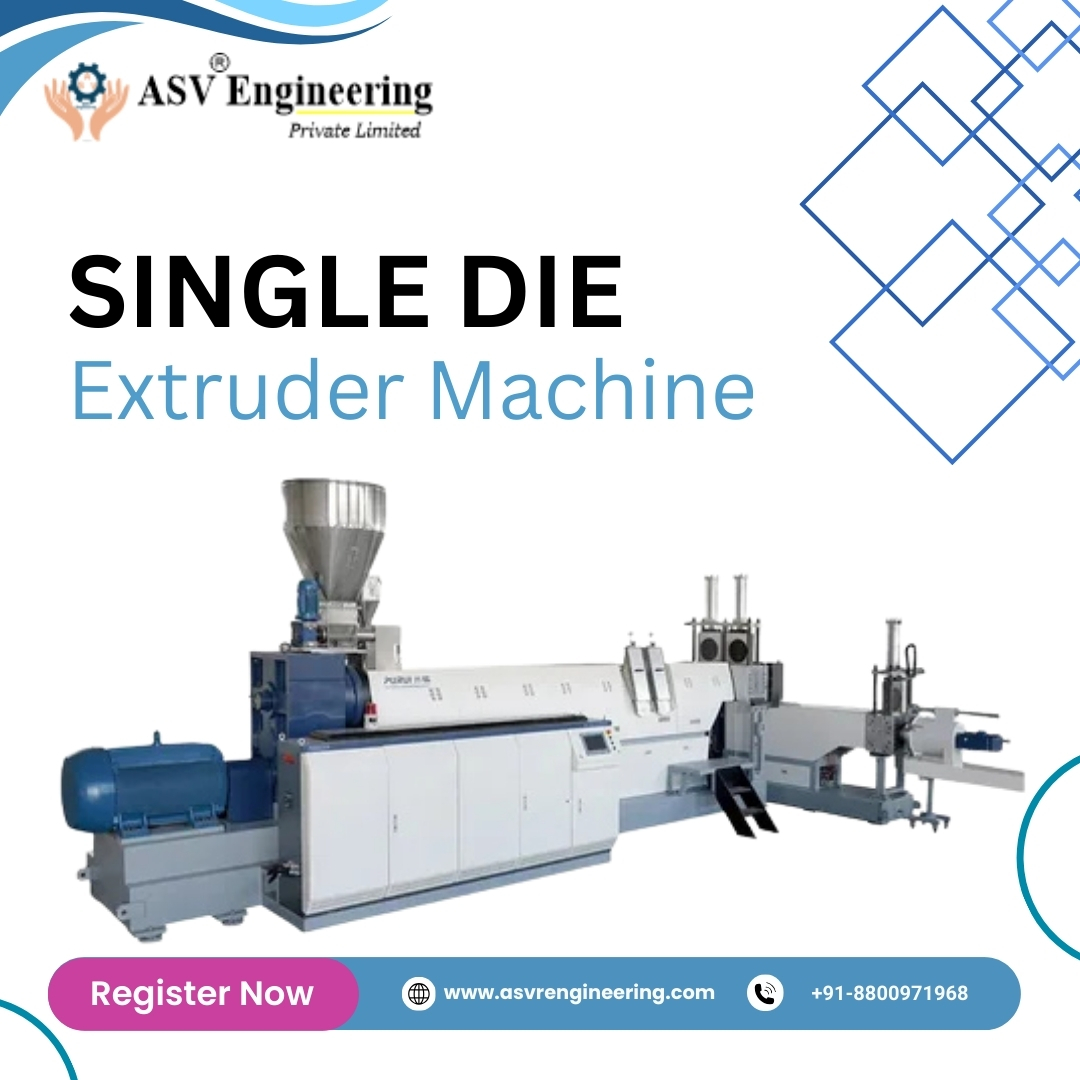

Reliable Puff Extruder Machine Distributors Supplying Advanced Extrusion Technology for Snack Manufacturing

Price: ₹440000

Introduction

The snack food industry has grown rapidly over the past decade, driven by changing lifestyles, increasing urbanization, and rising demand for ready-to-eat products. Among the wide range of snacks consumed across India and global markets, puffed snacks remain one of the most popular categories. Producing these products consistently, hygienically, and at scale requires reliable and advanced machinery. This is where puff extruder machines play a vital role.

As a trusted name in industrial food processing solutions, ASVR Engineering stands out as one of the reliable puff extruder machine distributors supplying advanced extrusion technology for snack manufacturing. With a strong focus on quality, durability, and performance, ASVR Engineering supports snack manufacturers in achieving higher productivity, better product consistency, and long-term operational efficiency.

Understanding Puff Extruder Machines

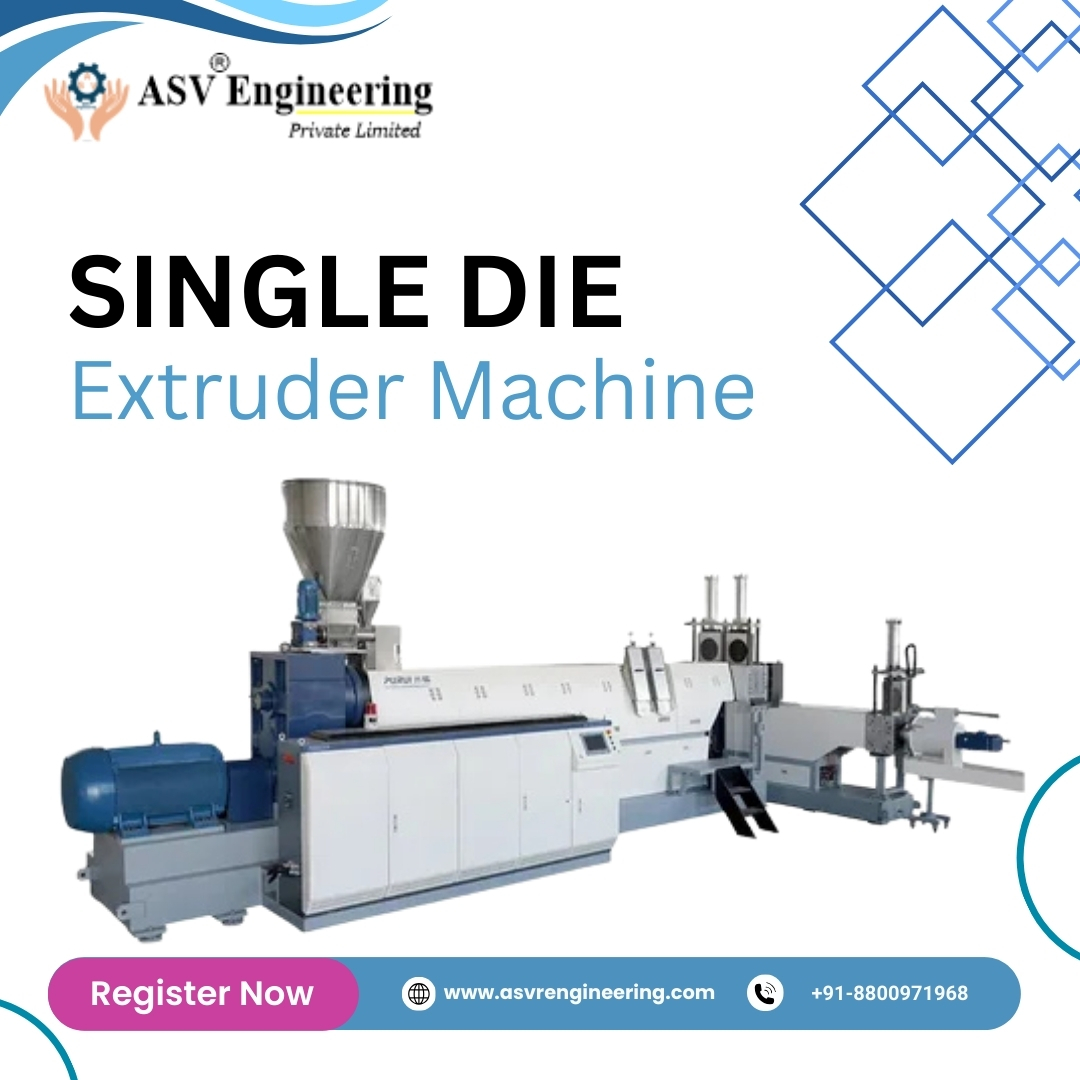

A puff extruder machine is a specialized food processing system designed to transform raw ingredients such as corn grits, rice flour, wheat flour, or mixed cereals into light, crispy, and expanded snack products. Through a controlled combination of heat, pressure, and mechanical shear, the extrusion process cooks and expands the raw material, resulting in the signature puffed texture loved by consumers.

Modern extrusion technology allows manufacturers to produce a wide variety of snacks, including corn puffs, rings, balls, curls, tubes, and other customized shapes. Flavoring and seasoning can be added after extrusion, making the final product appealing to different regional and international markets.

Why Advanced Extrusion Technology Matters

In today’s competitive snack manufacturing environment, basic machinery is no longer sufficient. Manufacturers need advanced extrusion technology that ensures:

-

Consistent product quality

-

High production capacity

-

Energy efficiency

-

Minimal raw material wastage

-

Easy operation and maintenance

ASVR Engineering supplies puff extruder machines designed with these critical factors in mind. Their solutions are engineered to deliver stable output, uniform expansion, and precise control over temperature and pressure. This ensures that every batch meets quality standards while maintaining cost efficiency.

Role of a Reliable Puff Extruder Machine Distributor

Choosing the right distributor is just as important as selecting the right machine. A reliable puff extruder machine distributor does more than sell equipment. They provide guidance, technical support, and long-term service assistance.

ASVR Engineering has earned trust in the industry by offering:

-

Expert consultation to select the right machine configuration

-

Transparent technical specifications

-

Installation and commissioning support

-

After-sales service and spare parts availability

-

Practical training for operators

This distributor-focused approach ensures that manufacturers, whether startups or established brands, can operate their snack production lines smoothly and confidently.

Applications in Snack Manufacturing

Puff extruder machines supplied by ASVR Engineering are suitable for a wide range of snack products, including:

-

Corn puffs and curls

-

Ring-shaped puff snacks

-

Multi-grain puff snacks

-

Pellet-based expanded snacks

-

Regional namkeen-style puff products

These machines are widely used by small-scale units, medium-sized snack producers, and large industrial food processing plants. With scalable capacity options, manufacturers can expand production as demand grows without compromising on quality.

Quality Engineering and Robust Construction

One of the key strengths of ASVR Engineering lies in its emphasis on robust machine design. Puff extruder machines are manufactured using high-grade raw materials and precision-engineered components. This ensures long service life, reduced breakdowns, and stable performance under continuous operation.

Critical parts such as screws, barrels, motors, and control panels are carefully selected to withstand high temperature and pressure conditions. The result is a machine that performs reliably even in demanding production environments.

Hygiene and Food Safety Compliance

Food safety is a top priority in snack manufacturing. Puff extruder machines supplied by ASVR Engineering are designed with hygiene in mind. Smooth surfaces, food-grade materials, and easy-to-clean structures help maintain cleanliness throughout the production process.

This focus on hygiene not only protects consumer health but also helps manufacturers comply with food safety standards and regulations, enhancing brand credibility in the market.

Energy Efficiency and Cost Control

Rising energy costs can significantly impact production expenses. Advanced puff extruder machines from ASVR Engineering are engineered to optimize energy consumption while delivering high output. Efficient motors, optimized heating systems, and precise process control help reduce power usage without compromising product quality.

By minimizing energy wastage and raw material loss, manufacturers can improve profit margins and achieve better return on investment over time.

Customization for Market Needs

Different markets demand different snack textures, shapes, and flavors. ASVR Engineering understands this diversity and offers customization options to meet specific production requirements. From screw design to die shapes and capacity configurations, machines can be tailored to match the manufacturer’s product portfolio.

This flexibility allows snack brands to innovate, introduce new products, and respond quickly to changing consumer preferences.

Support for New Entrepreneurs

The snack manufacturing industry attracts many first-time entrepreneurs due to its growth potential. ASVR Engineering actively supports new entrants by offering practical guidance on machine selection, production planning, and capacity estimation.

By working closely with customers, ASVR Engineering helps reduce startup risks and ensures that new manufacturers begin operations with confidence and clarity.

After-Sales Service and Long-Term Partnership

A machine’s true value is measured over years of operation. ASVR Engineering believes in building long-term partnerships rather than one-time transactions. Their after-sales support includes technical assistance, maintenance guidance, and timely supply of spare parts.

This commitment ensures minimal downtime, smooth operations, and peace of mind for manufacturers who rely on their equipment daily.

Why Choose ASVR Engineering

There are several reasons why ASVR Engineering is recognized as a reliable puff extruder machine distributor:

-

Proven experience in industrial food processing machinery

-

Focus on advanced extrusion technology

-

Transparent business practices

-

Strong customer support system

-

Competitive pricing with high-quality standards

Their dedication to performance, reliability, and customer satisfaction makes them a preferred choice in the snack manufacturing sector.

Conclusion

As demand for puffed snacks continues to rise, investing in the right extrusion technology becomes essential for long-term success. Reliable machinery not only ensures consistent product quality but also supports scalable growth and operational efficiency.

With its strong industry knowledge and commitment to excellence, ASVR Engineering continues to serve as a dependable partner for snack manufacturers across India. If you are looking for reliable puff extruder machine distributors supplying advanced extrusion technology for snack manufacturing, ASVR Engineering offers solutions you can trust.

Contact Details

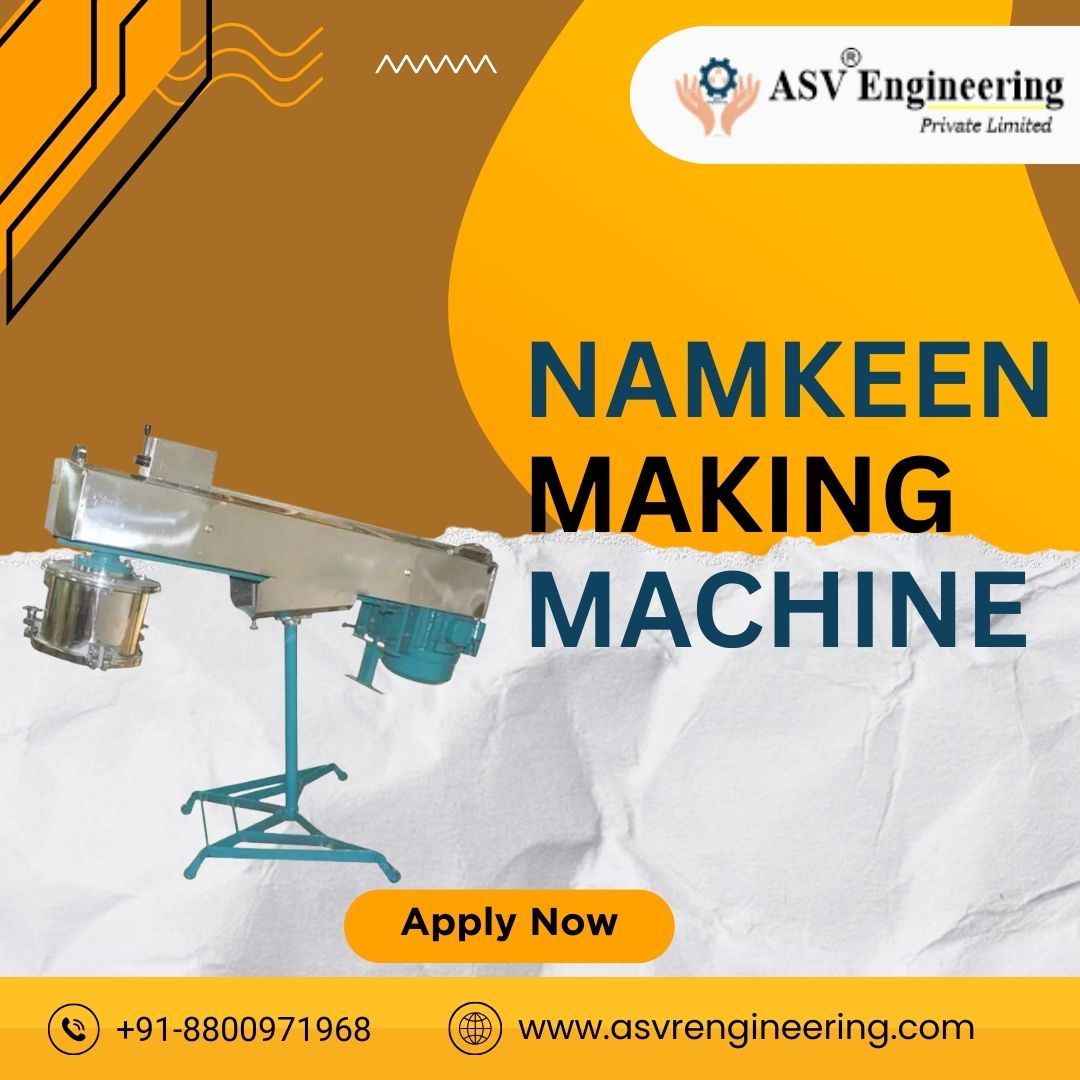

Company Name: ASVR Engineering

Website: https://www.asvrengineering.com

Contact Numbers: +91-8076004849, +91-8800971968

If you want, I can also localize this content for a specific city or state, or rewrite it for landing pages, brochures, or distributor listings.

Buy Now

Related Posts

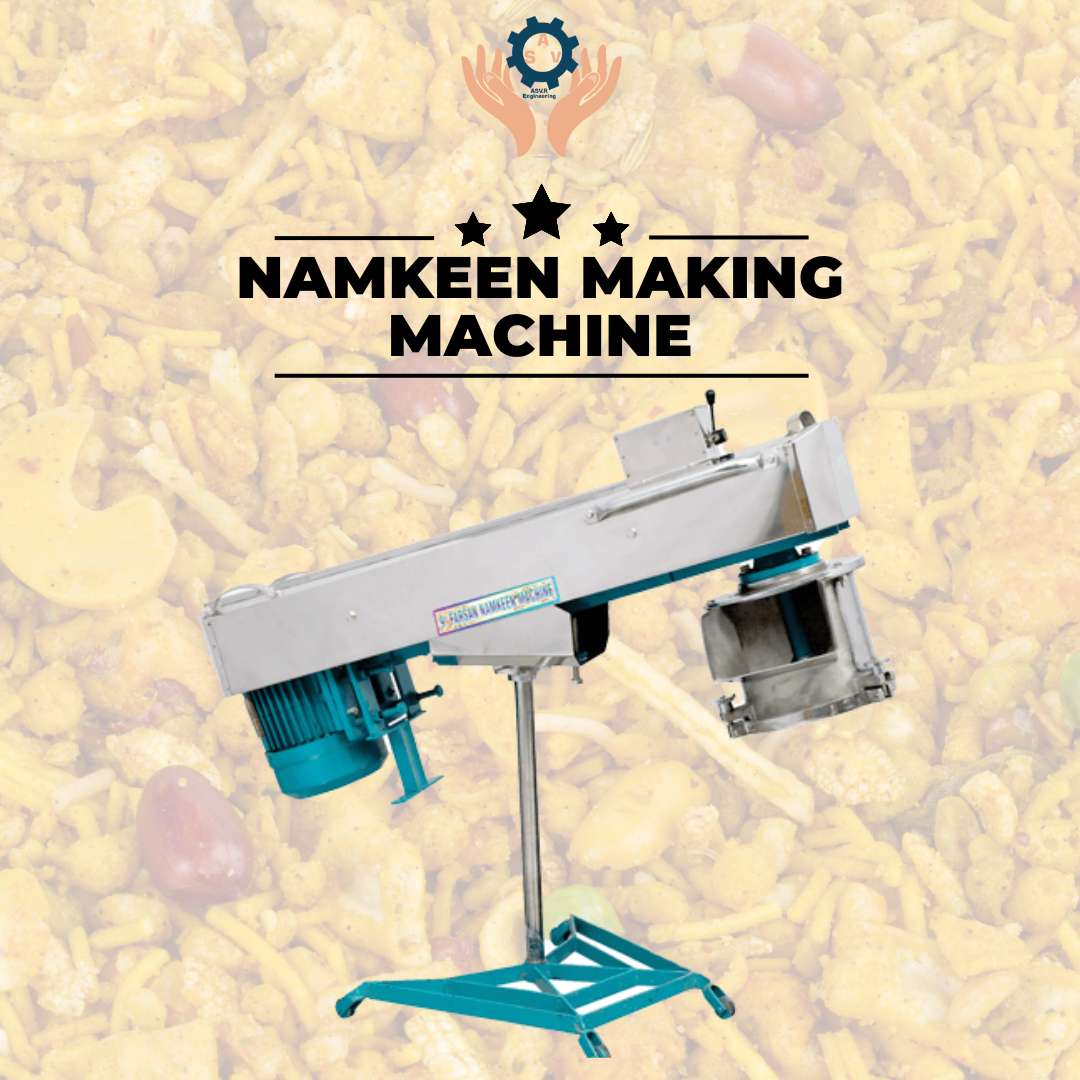

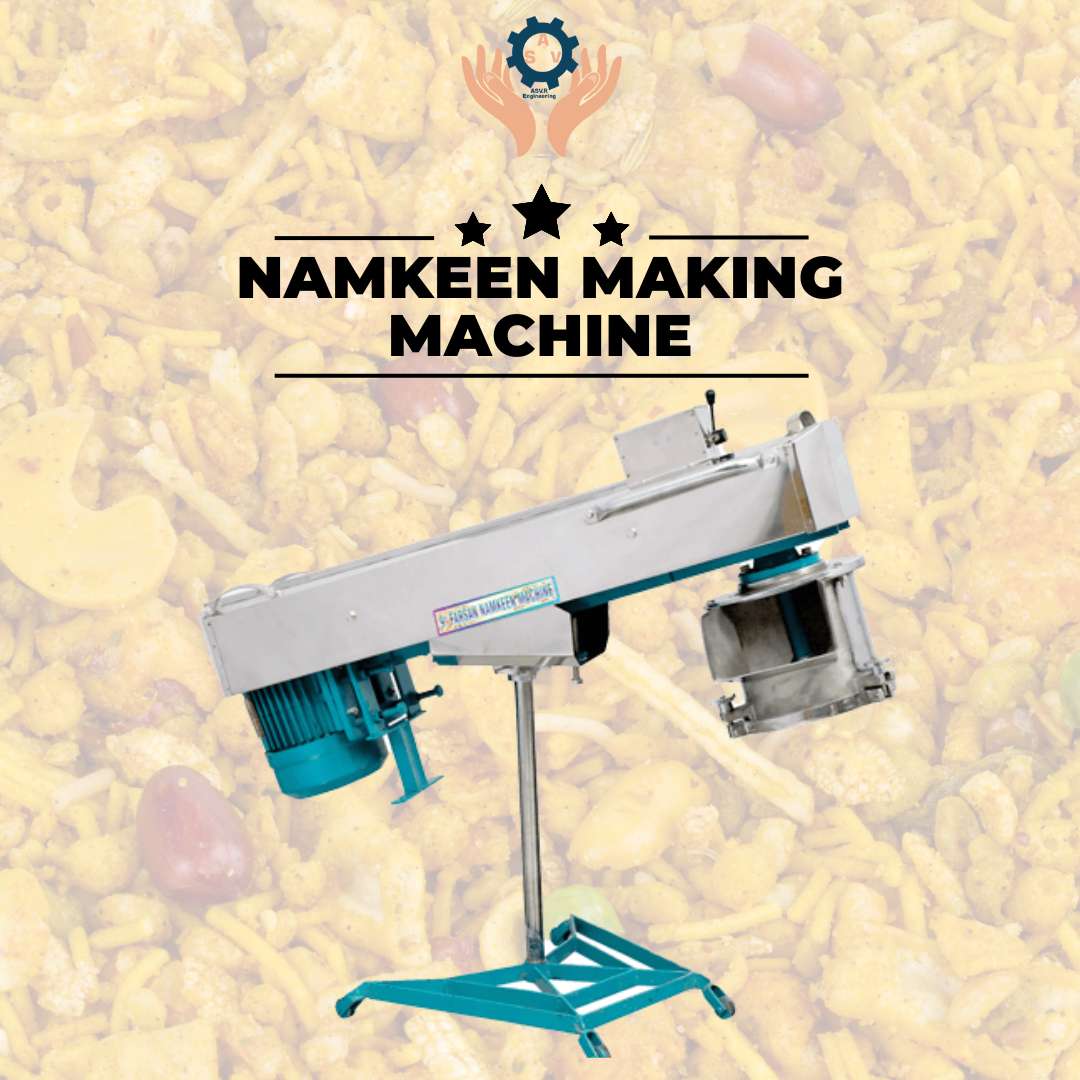

Trusted Automatic Namkeen Making Machine Importers Supplying Cost-Effective & Fully Automated Plants

(9).jpg)

(9).jpg)

(9).jpg)

(9).jpg)

(1).png)

(1).png)

(1).png)

(12).jpg)

(12).jpg)

(12).jpg)