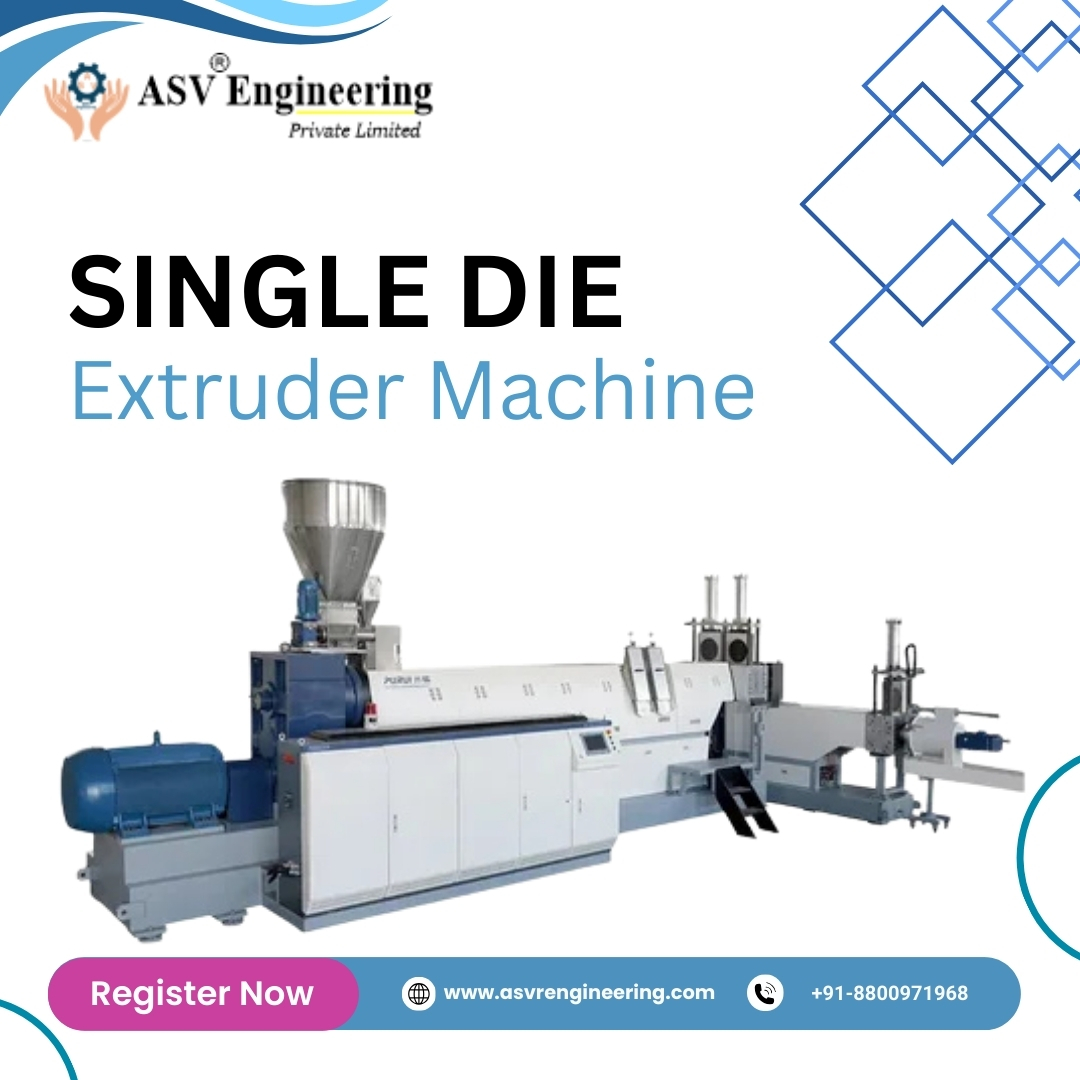

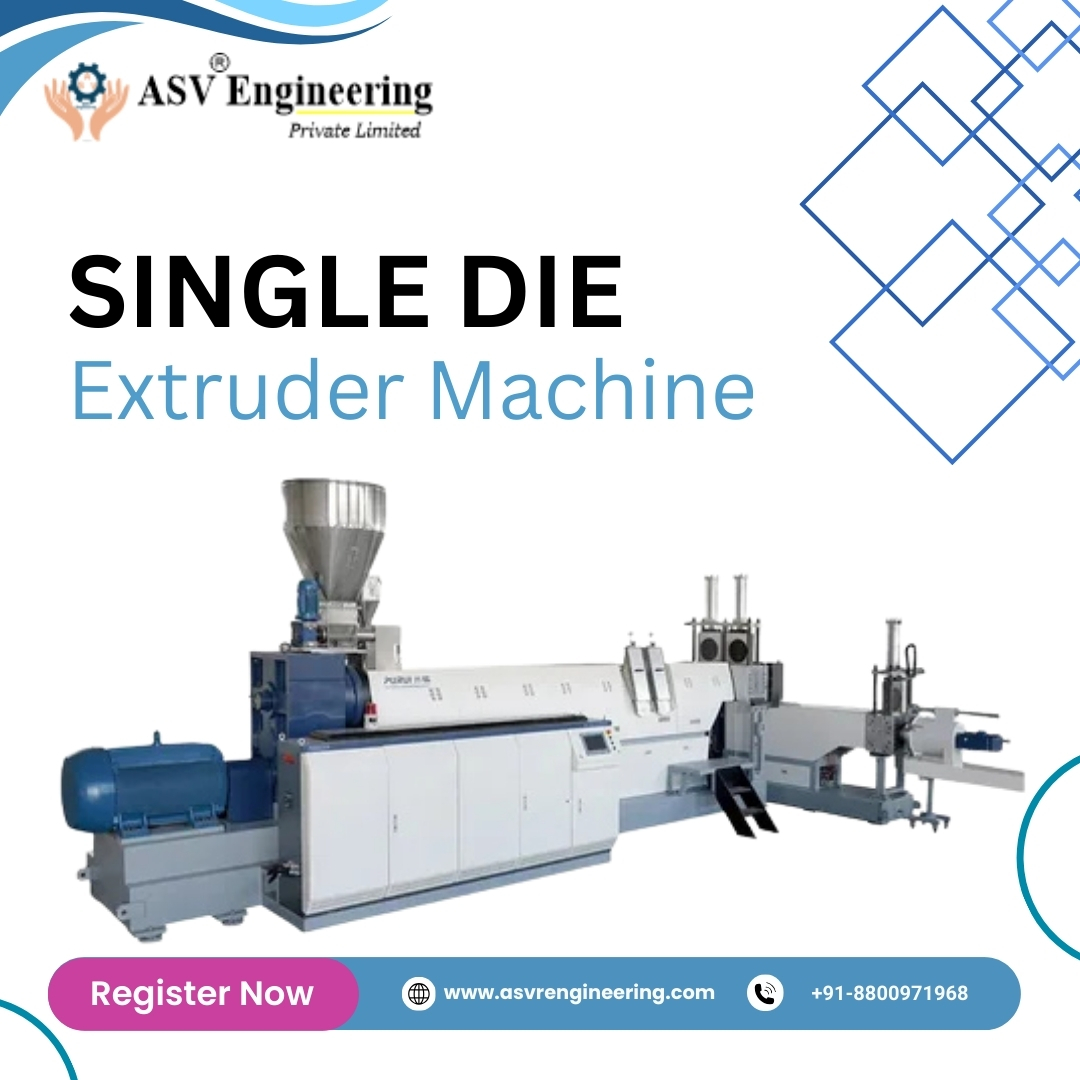

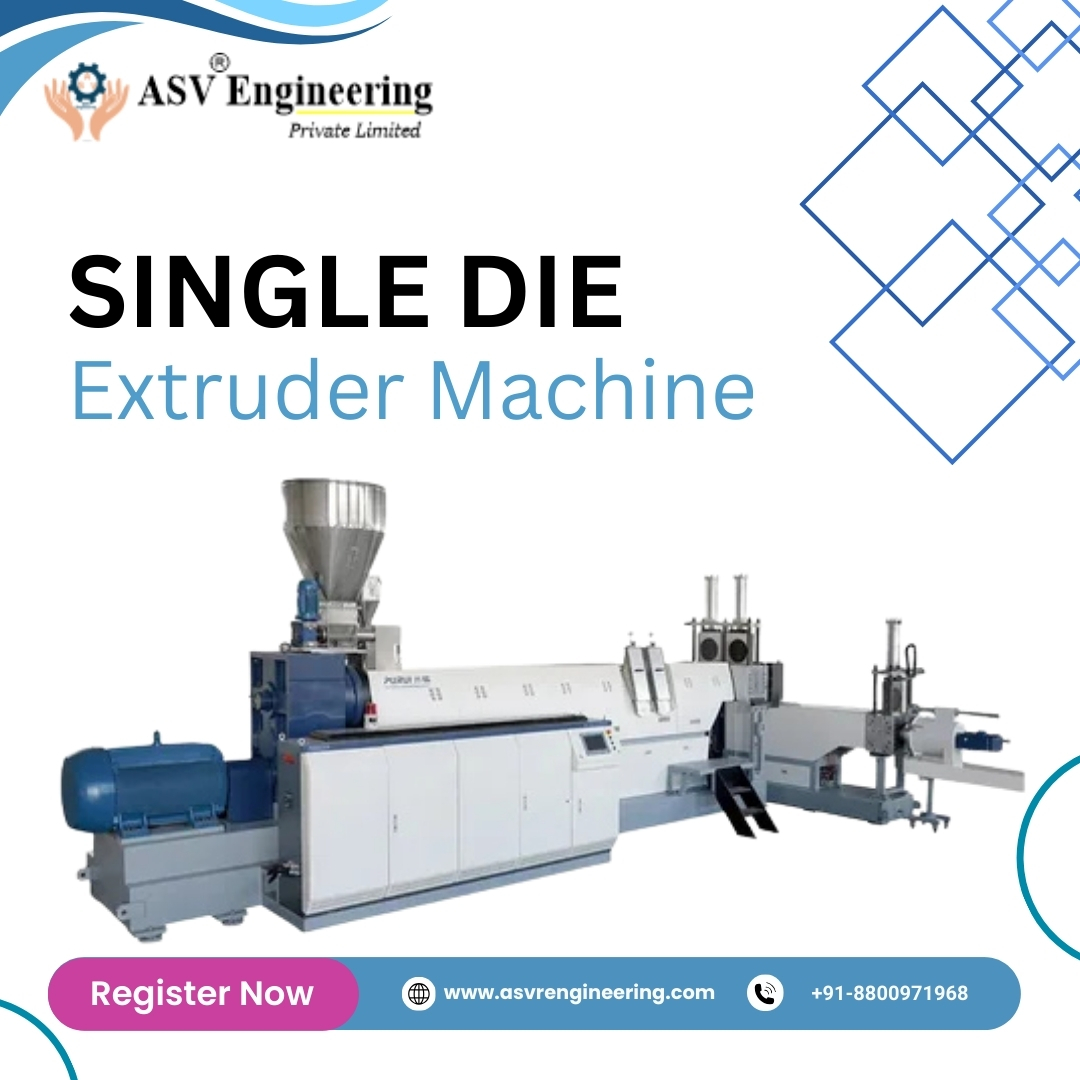

Leading Puff Extruder Machine Manufacturers for High-Output & Energy-Efficient Snack Production

Price: ₹449000

In today’s fast-growing snack food industry, manufacturers are constantly looking for reliable machinery that delivers consistent quality, higher production capacity, and lower operating costs. Puff extruder machines play a crucial role in producing popular ready-to-eat snacks such as corn puffs, kurkure-type snacks, cereal puffs, and other extruded food products. Choosing the right manufacturer is not just about buying a machine—it is about investing in long-term performance, efficiency, and business growth.

As one of the trusted names in the industry, ASVR Engineering stands at the forefront as a leading puff extruder machine manufacturer, delivering advanced solutions designed for high-output and energy-efficient snack production. With years of engineering expertise and a deep understanding of food processing requirements, ASVR Engineering offers machines that help snack manufacturers scale confidently while maintaining product quality.

Understanding Puff Extruder Machines and Their Importance

A puff extruder machine is a specialized food processing system that uses controlled heat, pressure, and mechanical shear to transform raw ingredients like corn grits, rice flour, wheat flour, or multigrain blends into light, crispy, and expanded snack products. The extrusion process not only shapes the product but also improves digestibility, texture, and shelf life.

In a competitive market where consumers demand consistent taste and hygiene, a well-designed puff extruder machine ensures:

-

Uniform puffing and expansion

-

Stable product shape and texture

-

Reduced raw material wastage

-

Continuous and uninterrupted production

This makes the choice of a reliable puff extruder machine manufacturer extremely important for both new entrepreneurs and established snack brands.

Why ASVR Engineering is a Preferred Puff Extruder Machine Manufacturer

ASVR Engineering has built a strong reputation by focusing on engineering precision, robust construction, and practical usability. Every puff extruder machine is designed to meet real-world production challenges faced by snack manufacturers in India and abroad.

1. High-Output Production Capability

The machines are engineered to deliver maximum output with minimum downtime. Whether you are running a small-scale unit or a large industrial snack plant, ASVR Engineering provides puff extruder machines capable of handling high volumes without compromising on product quality.

2. Energy-Efficient Design

Energy cost is a major concern in food processing. ASVR Engineering integrates energy-efficient motors, optimized screw design, and advanced heating control systems, ensuring lower power consumption per kilogram of finished product. This directly improves profitability and reduces long-term operational expenses.

3. Consistent Product Quality

Uniform expansion, even cooking, and smooth texture are critical for market acceptance. ASVR puff extruder machines are designed to maintain stable pressure and temperature, resulting in consistent puff size, crunch, and taste across every batch.

Advanced Engineering for Modern Snack Production

ASVR Engineering combines modern manufacturing technology with practical industry experience. Each puff extruder machine is fabricated using high-grade raw materials and precision-machined components to ensure durability and long service life.

Heavy-Duty Construction

The machine frame and body are made from robust materials that can withstand continuous industrial use. Food-contact parts are manufactured using food-grade stainless steel, ensuring hygiene and compliance with food safety standards.

Precision Extrusion System

The screw and barrel assembly is the heart of the puff extruder machine. ASVR Engineering designs this system to provide optimal mixing, cooking, and expansion, even when working with different raw material compositions.

User-Friendly Operation

Despite their advanced design, ASVR puff extruder machines are easy to operate. Simple control panels, clear indicators, and smooth feeding mechanisms help operators manage production efficiently with minimal training.

Wide Range of Applications

ASVR Engineering’s puff extruder machines are suitable for manufacturing a wide variety of snack products, including:

-

Corn puffs and curls

-

Rice-based extruded snacks

-

Wheat and multigrain snacks

-

Kurkure-type snacks

-

Flavored puff snacks

-

Breakfast cereal puffs

This versatility allows snack manufacturers to expand their product portfolio without investing in multiple machines.

Customization to Match Your Business Needs

Every snack manufacturing business has unique requirements based on capacity, raw material, product type, and available space. ASVR Engineering offers customized puff extruder machine solutions to match specific production goals.

Customization options may include:

-

Different production capacities

-

Single-screw or twin-screw extrusion systems

-

Customized dies and cutters

-

Integration with seasoning, drying, and packaging lines

This flexibility ensures that customers get a machine that fits perfectly into their production workflow.

Commitment to Quality and Reliability

Quality is not just a feature; it is a process at ASVR Engineering. Each puff extruder machine undergoes strict quality checks and trial runs before dispatch. This ensures that customers receive a machine that is ready for immediate production with minimal installation issues.

The focus on reliability helps reduce breakdowns, maintenance costs, and production losses—critical factors for maintaining consistent supply in the competitive snack food market.

After-Sales Support and Technical Assistance

A machine is only as good as the support behind it. ASVR Engineering is known for its responsive after-sales service and technical guidance. From installation support to operational training and maintenance assistance, the team ensures smooth functioning throughout the machine’s lifecycle.

This long-term support builds confidence among clients and makes ASVR Engineering a dependable partner rather than just a supplier.

Ideal Choice for Startups and Established Manufacturers

Whether you are:

-

A startup planning to enter the snack manufacturing business

-

An MSME looking to increase capacity

-

An established brand aiming to improve energy efficiency

ASVR Engineering offers puff extruder machines that deliver scalable growth, consistent quality, and strong return on investment.

Why Invest in a High-Quality Puff Extruder Machine?

Investing in a high-quality puff extruder machine from a trusted manufacturer like ASVR Engineering means:

-

Faster production cycles

-

Lower energy and maintenance costs

-

Consistent product quality

-

Higher customer satisfaction

-

Long-term operational stability

In a market where margins depend on efficiency and consistency, the right machine can make a significant difference.

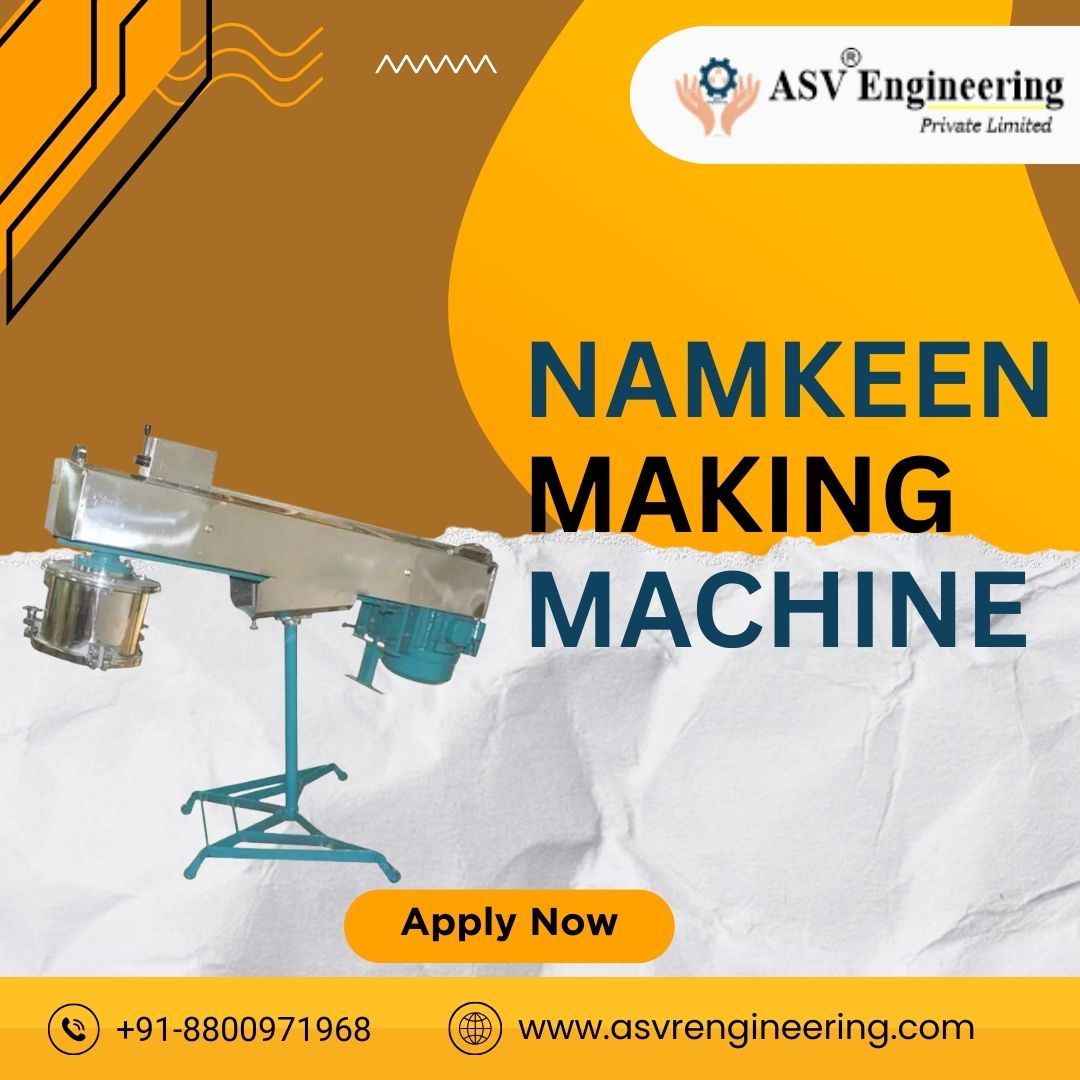

Contact ASVR Engineering

If you are searching for leading puff extruder machine manufacturers for high-output and energy-efficient snack production, ASVR Engineering is ready to support your business growth.

Contact Numbers:

📞 +91-8076004849

📞 +91-8800971968

Website:

🌐 https://www.asvrengineering.com

Connect today to discuss your requirements and take the next step toward building a successful snack manufacturing operation.

Buy Now

Related Posts

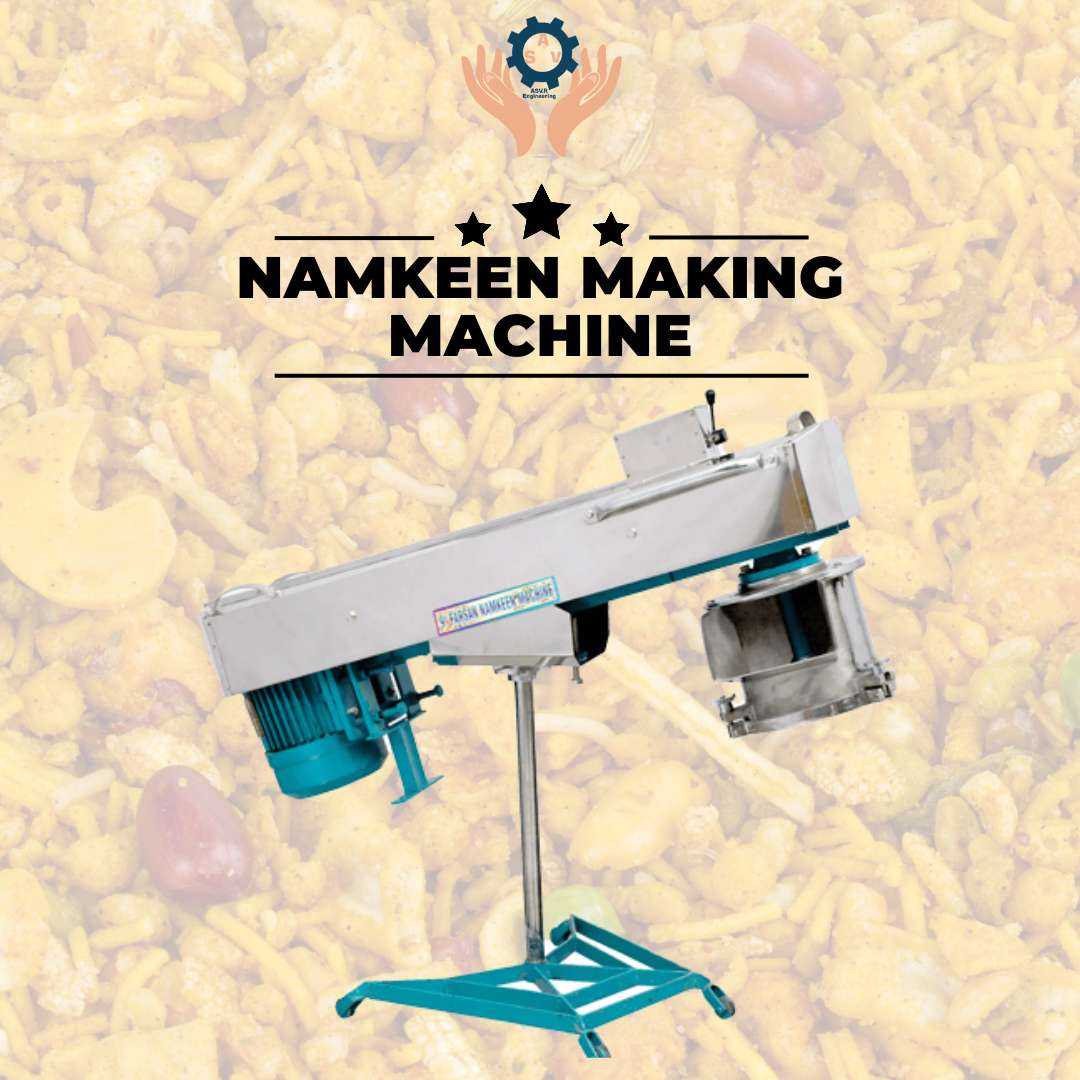

Trusted Automatic Namkeen Making Machine Importers Supplying Cost-Effective & Fully Automated Plants

(9).jpg)

(9).jpg)

(9).jpg)

(9).jpg)

(1).png)

(1).png)

(1).png)

(12).jpg)

(12).jpg)

(12).jpg)